Professional Documents

Culture Documents

Vacuum System Adjustments and Troubleshooting Notes

Uploaded by

Aleksandar MisicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vacuum System Adjustments and Troubleshooting Notes

Uploaded by

Aleksandar MisicCopyright:

Available Formats

Vacuum System Adjustments and Troubleshooting Notes

The Online Troubleshooting Procedure lists a large number of possible causes and corrective

actions for error code 600 13 24 – Low Vacuum. Following is a list of additional troubleshooting

tips:

Failed DCP: air in the fluid lines.

Corrective action: run the Dispense Test for all reagent probes and dispense ports 5 times to

prime the lines, and try DCP again.

Irregular vacuum pump performance / calibration – vacuum pump condensation wells and filters

are dirty.

Corrective action: Run “Vacuum Test” in Diagnostics Tools, and check the flow value on the

vacuum regulator gauge. If the flow is below 13.5 inHg, adjust it using the regulator knob.

Inspect the vacuum pump filters and clean them.

Water Trap:

1) Ball does not float correctly to protect the vacuum pump from moisture.

2) Vacuum flow is partially clogged.

3) Water trap seal is damaged.

Corrective action: clean the water trap and ensure that all connections are tight (no leaks).

Waste Reservoir Cap: loose or slight stress fracture in black cap, loose quick disconnects.

Corrective action: check the waste reservoir cap and quick disconnects for leaks and placement.

Defective waste sensor does not hold tight vacuum seal: ensure the clip holds sensor tight or the

sensor gasket material is worn.

Corrective action: clean the sensor, check the sensor gasket and ensure that the clip is sealing the

sensor to the reservoir.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dcs - Chlorine Dioxide Vs BleachDocument1 pageDcs - Chlorine Dioxide Vs BleachAleksandar MisicNo ratings yet

- UI Power Supply VoltagesDocument2 pagesUI Power Supply VoltagesAleksandar MisicNo ratings yet

- Tosoh Lubrfication Moving PartsDocument36 pagesTosoh Lubrfication Moving PartsAleksandar MisicNo ratings yet

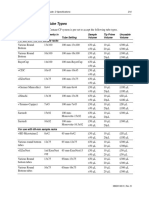

- Centaur CP Tube TypesDocument2 pagesCentaur CP Tube TypesAleksandar MisicNo ratings yet

- ADVIA Centaur XPT Volume Check GuideDocument7 pagesADVIA Centaur XPT Volume Check GuideAleksandar MisicNo ratings yet