Professional Documents

Culture Documents

Polyken 930: Product Data Sheet

Uploaded by

Edwin Bustamante CabreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyken 930: Product Data Sheet

Uploaded by

Edwin Bustamante CabreraCopyright:

Available Formats

PRODUCT DATA SHEET

POLYKEN® 930

Product properties of Polyken® 930

Product Information Typical values

Property Method 930-35 930-50 Units

Product description: The Polyken® 930 is a cold applied tape coating Tensile strength ASTM D 1000 15 25 pli

system designed for the corrosion protection of field joints, fittings and 2.6 4.4 N/mm

specialty piping.The unique adhesive retains conformability over a Elongation ASTM D1000 340 300 %

wide temperature range, yet exhibits an elevated level of shear Peel adhesion to ASTM D1000 15.6 18.7 pli

resistance, which is a key in-ground performance characteristic. primed steel 2.7 3.3 N/mm

Coupled with a very malleable polyethylene backing, this versatile tape Peel adhesion to EN12068 1.6 N/mm

primed steel

system can be applied by hand or with a wrapping machine.

Cathodic ASTM G 8 0.25 0.27 in radius

disbondment 6.4 6.9 mm

Features: Water vapor ASTM E 96B 0.07 0.07 perm

• Heavy duty adhesive. transmission

• Conformable to irregular shapes. Water vapor ASTM F 1249 0.04 0.04 g/100in.2/

• No release liner. transmission rate (100°F, 100% 24hr

RH) 0.6 0.6 g/m2/24 hr

• Worldwide reference lists.

Volume resistivity ASTM D257 2.5x1016 2.5x1016 Ω cm

• Complies with AWWA standard C-209, EN12068, DIN30672.

Dielectric ASTM D 1000 650 650 V/mil

• Compatible with generic plant coatings systems. breakdown 25.6 25.6 kV/mm

Dielectric strength ASTM D 149 21 28 kV

Benefits: Insulation ASTM E 257 1.4x107 2.0x107 MΩ

• Ensures a strong bond & impervious seal. resistivity

• Offers a solution for nearly every application. Impact resistance EN 12068* >8 J

• Makes installation fast and easy. Indentation EN 12068 * Class

• Established in-ground history. resistance B30

• Reliable, high performance corrosion protection. * For 930-35 tape installed with 66% overlap.

• Versatile.

Equation for Pipe Coating Requirements

Squares** of (width of coating in inches) x (area of pipe in square feet)*

Product selection guide coating required (width of coating in inches – overlap in inches) x 100

Max.operating temperature 85°C (185°F) * Area of pipe in ft² = (diameter in inches / 12) x 3.1416 x length in feet

Recommended primer 1027 or 1033A ** One Square = one hundred square feet = 9.29 square meters

Additional mechanical layer 955 or 954 Square meters of (width of coating in mm) x (area of pipe in square meter)*

Compatible line coatings PE, FBE, Cold Tape, CT, CTE coating required (width of coating in mm – overlap in mm)

Recommended pipe preparation SSA-ST2 (SSPC-SP3) or * Area of pipe in m² = (diameter in mm / 1000) x 3.1416 x length in meter

SSA-SA 2 (SSPC-SP6)

1 – 3 mil anchor profile Squares** (width of roll in inches) x (length of roll in feet)

per roll (12) (100)

(25 – 76 micron anchor profile)

Performance AWWA C209

EN 12068 class B30 Square meters (width of roll in mm) x (length of roll in m)

Per roll (304.8) (30.48)

DIN 30672 class B30

Rolls (squares of coating required)

Product construction Required (squares per roll)

930-35 930-50

Backing 6.5 mils (0.165 mm) 10 mils (0.254 mm) Rolls (square meters of coating required)

Adhesive 28.5 mils (0.724 mm) 40 mils (1.016 mm) Required (square meters per roll)

Backing color Black, White* Black*

* Other colors are available on request.

Ordering information

Polyken® 930 Tape Coatings are available in roll form.

Example 930-35 BLK 2X50 ft 4.1cm

930 Product type Standard Ordering options

35 Total tape thickness in 35 mils (0.89 mm)

mils 50 mils (1.27 mm)

BLK Tape backing color Black (BLK), White (WHI),Yellow

(YEL), Purple (PUR)

2 Tape width in inches 1” (25 mm), 2” (50 mm),

4” (101 mm), 6” (152 mm)

50 Tape roll length in feet 50 ft (15 m)

4.1 Tape inner core diameter 4.1 cm (1.6”)

For other ordering options please contact your Seal For Life representative.

PDS-POLYKEN-930- V4-MAY19-AARPS-0543 Page 1 / 2

PRODUCT DATA SHEET POLYKEN® 930

Application instruction: Job preparation Step 4 Spirally or circumferentially apply the 930 with a

Tools, equipment Temperature gauge, DFT/WFT gauge, Primer 1% to 2% neckdown. A minimum of two layers of

and auxiliaries application equipment/agitator, Tape application the 930 shall be applied.

equipment, Coating “hot box” Step 5 If a single 930 layer is required, then a

Additional coating 931 or 939 filler material, and 905, 954, or 955 mechanical protection outerwrap layer (905, 954,

materials mechanical protection layers 955) shall be applied over the single layer of

High humidity Polyken® 930 can be applied in a humid 930.

atmosphere. The substrate should be free from Step 6 Perform holiday detection per NACE SP0274

condensing water which can be reached by

keeping the temperature at least 5°F (3°C) Handling and commissioning

above dew point. Exposure to loads Objects coated with Polyken® 930 should not be

Work area and The substrate surface should be dry, clean and exposed to loads e.g. from supports- or lifting

substrate protected against negative weather influences. equipment.

Product conditions The Polyken® 930 shall be stored and/or Backfill Backfill is possible immediately after completion

transported in a dry, ventilated location. Storage of the coating application. Consult application

temperature shall be a minimum of 60°F (16°C) guidelines for specific instructions. Backfill

and a maximum of 120°F (49°C). The minimum should be clean and not contain any foreign

primer and roll body temperature for application items that can cause damage to the coating

will be 60°F (16°C). system.

Application instruction: Surface preparation Information

General The area to be coated has to be clean, dry, and Documentation Extensive information is available on our web-

free from oil, grease and dust. All contamination site. Application instructions and other

including mill-scale has to be removed. documentation can be obtained by contacting

Degreasing Degrease surfaces with Toluene or Heptane and our offices, from our local distributor or by

e.g. a lint-free cloth. sending an email to info@sealforlife.com

Preventing Prior to and during the application, the Certified staff Application of the described coating system shall

condensation of temperature of the substrate(s) must be at least be carried out by certified personnel.

water 5°F (3°C) above the dew point.

Substrate Temperature of the substrate should preferably

temperature be between 68°F and 104°F (20°C / 40°C).

Preheating may be required.

Application instruction: Brief version

Step 1 Clean substrate to SSA-ST2, SSPC-SP3 (power

wire brush) or SSA-SA 2, SSPC-SP6

(commercial blast). Surface (anchor) profile

depth shall be no less than 1.0 mils (25 micron)

and no greater than 3 mils (76 micron).

Step 2 Uniform primer application achieving 2 to 3 mil

WFT. Primer should be “dry to touch” before

application of inner layer.

Step 3 If required, apply weld seam filler material

* For further detailed information, please view the corresponding Application

Guideline *

PDS-POLYKEN-930-V4-MAY19-AARPS-0543 Page 2 / 2

You might also like

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetAgustina De Winne100% (1)

- PDS Polyken 980 955 V3 Jan19 Aarps 0285Document2 pagesPDS Polyken 980 955 V3 Jan19 Aarps 0285Irawan FajarNo ratings yet

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazNo ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- Ficha Tecnica Cinta de Juntas 930 35 50 PDFDocument3 pagesFicha Tecnica Cinta de Juntas 930 35 50 PDFfernando100% (1)

- PDS Polyken Ygiii Oct13 V2 Aarps 0591Document2 pagesPDS Polyken Ygiii Oct13 V2 Aarps 0591Senthilkumar NarayananNo ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- TDS FlexiClad 70Document2 pagesTDS FlexiClad 70DuongNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- Nitoproof 600: Constructive SolutionsDocument22 pagesNitoproof 600: Constructive SolutionsMazen AlRefaaiNo ratings yet

- Polyken 4000 PrimerlessDocument2 pagesPolyken 4000 PrimerlessKyaw Kyaw AungNo ratings yet

- PolykenYG IIIDocument2 pagesPolykenYG IIISenthilkumar NarayananNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- Sikawrap® Hex-230 C: Product Data SheetDocument4 pagesSikawrap® Hex-230 C: Product Data SheetArindam SarkarNo ratings yet

- DS 40 Full SubmittalDocument50 pagesDS 40 Full Submittalahmed100% (1)

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- CCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0Document4 pagesCCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0amanraza.canNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- Tikidan TDS - Selfdan Ipe Plus, R3Document3 pagesTikidan TDS - Selfdan Ipe Plus, R3sandeepNo ratings yet

- Delta Protekt KL120Document1 pageDelta Protekt KL120GavinNo ratings yet

- Polycarbonate Data SheetDocument1 pagePolycarbonate Data SheetJoseph Cloyd Lamberte100% (1)

- Pds Covalence Htlp80 v3 Dec16 Aarps 0199Document2 pagesPds Covalence Htlp80 v3 Dec16 Aarps 0199Benaknaik S GajannavarNo ratings yet

- Polyken 932 TapeDocument2 pagesPolyken 932 TapeKyaw Kyaw AungNo ratings yet

- Adding A New Dimension To Impact Resistant Glazing and CladdingDocument1 pageAdding A New Dimension To Impact Resistant Glazing and CladdingOmer TahaNo ratings yet

- Poly FlameDocument2 pagesPoly Flamemk779900mkNo ratings yet

- Torch SealDocument2 pagesTorch Sealmk779900mkNo ratings yet

- 62 017 Dowsil 890 SL Si Joint SealantDocument4 pages62 017 Dowsil 890 SL Si Joint SealantScott HendersonNo ratings yet

- 3M Cold Shrink Pre-Stretched Tubes Silicone RubberDocument4 pages3M Cold Shrink Pre-Stretched Tubes Silicone RubberJovelino SimãoNo ratings yet

- PREMCOTE 101 corrosion protection tape for pipelinesDocument1 pagePREMCOTE 101 corrosion protection tape for pipelinesHuythuong NguyenNo ratings yet

- CANUSA Wrapid TapeDocument2 pagesCANUSA Wrapid TapeHalimNo ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- Innovations in Fluid Sealing PTFE Gasket SheetDocument1 pageInnovations in Fluid Sealing PTFE Gasket SheetArunNo ratings yet

- Self-Adhesive Waterproofing MembranesDocument2 pagesSelf-Adhesive Waterproofing Membraneskhiem44No ratings yet

- Flexible Duct Insulated & Non InsulatedDocument4 pagesFlexible Duct Insulated & Non Insulatedali faragallahNo ratings yet

- 3m - Scotch - 2228 Rubber Mastic TapeDocument3 pages3m - Scotch - 2228 Rubber Mastic TapeLuis NovaisNo ratings yet

- Pds Tial m80Document2 pagesPds Tial m80Yan FerizalNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- PREPRUFE 300R Plus & 160R Plus Membranes Data Sheet (US Version)Document2 pagesPREPRUFE 300R Plus & 160R Plus Membranes Data Sheet (US Version)Joyce Agustine Glory LNo ratings yet

- End Sealing Kit for RMU and GIS BushingsDocument1 pageEnd Sealing Kit for RMU and GIS BushingsvikrantNo ratings yet

- Roxul Comfortboard 80: Insulated SheathingDocument1 pageRoxul Comfortboard 80: Insulated SheathingMark RauNo ratings yet

- FR Gboard Tds21Document1 pageFR Gboard Tds21rangarajan1989100% (1)

- Nitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneDocument4 pagesNitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneKunal MandalaywalaNo ratings yet

- Waterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetDocument3 pagesWaterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetCC Cost AdvisoryNo ratings yet

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Document2 pagesPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- AQUAPANEL Cement Board Outdoor Datasheet 0817Document3 pagesAQUAPANEL Cement Board Outdoor Datasheet 0817xander1982No ratings yet

- IMPERSEAL 7000XL waterproofing membraneDocument2 pagesIMPERSEAL 7000XL waterproofing membraneJeff GajeNo ratings yet

- 13894ssDocument2 pages13894ssPartagon PowNo ratings yet

- Raychem Shrink SleevesDocument12 pagesRaychem Shrink SleevesislamakthamNo ratings yet

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterNo ratings yet

- Vetotop DOC TECHNICAL MAP en 3589Document2 pagesVetotop DOC TECHNICAL MAP en 3589Demac SaudNo ratings yet

- Covalence HTLP80: Product Data SheetDocument3 pagesCovalence HTLP80: Product Data SheetJuan Carlos Contreras CherresNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

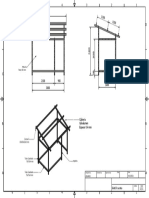

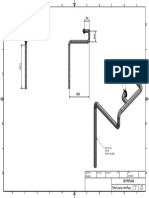

- 2.0 Escalera Dec PrimarioDocument1 page2.0 Escalera Dec PrimarioEdwin Bustamante CabreraNo ratings yet

- Flange 8" RF Slep On Class # 150 Astm A 304 Flange 8" RF Slep On Class # 150 Astm A 106 GRBDocument1 pageFlange 8" RF Slep On Class # 150 Astm A 304 Flange 8" RF Slep On Class # 150 Astm A 106 GRBEdwin Bustamante CabreraNo ratings yet

- Caceta Tanque HidroneumaticoDocument1 pageCaceta Tanque HidroneumaticoEdwin Bustamante CabreraNo ratings yet

- Stainless steel door frame assemblyDocument1 pageStainless steel door frame assemblyEdwin Bustamante CabreraNo ratings yet

- Usuario 4/8/2021: Designed by Checked by Approved by Date DateDocument1 pageUsuario 4/8/2021: Designed by Checked by Approved by Date DateEdwin Bustamante CabreraNo ratings yet

- Gradas ControlDocument1 pageGradas ControlEdwin Bustamante CabreraNo ratings yet

- Usuario 4/8/2021: Designed by Checked by Approved by Date DateDocument1 pageUsuario 4/8/2021: Designed by Checked by Approved by Date DateEdwin Bustamante CabreraNo ratings yet

- Com PuertaDocument1 pageCom PuertaEdwin Bustamante CabreraNo ratings yet

- Caceta Tanque HidroneumaticoDocument1 pageCaceta Tanque HidroneumaticoEdwin Bustamante CabreraNo ratings yet

- TOTAL 361.83 KG: Flange 6" RF Class # 150 Astm A 304 Flange 6" RF Class # 150 Astm A 106 GRBDocument1 pageTOTAL 361.83 KG: Flange 6" RF Class # 150 Astm A 304 Flange 6" RF Class # 150 Astm A 106 GRBEdwin Bustamante CabreraNo ratings yet

- Flange 8" RF Slep On Class # 150 Astm A 304 Flange 8" RF Slep On Class # 150 Astm A 106 GRBDocument1 pageFlange 8" RF Slep On Class # 150 Astm A 304 Flange 8" RF Slep On Class # 150 Astm A 106 GRBEdwin Bustamante CabreraNo ratings yet

- Com PuertaDocument1 pageCom PuertaEdwin Bustamante CabreraNo ratings yet

- TOTAL 361.83 KG: Flange 6" RF Class # 150 Astm A 304 Flange 6" RF Class # 150 Astm A 106 GRBDocument1 pageTOTAL 361.83 KG: Flange 6" RF Class # 150 Astm A 304 Flange 6" RF Class # 150 Astm A 106 GRBEdwin Bustamante CabreraNo ratings yet

- Caceta Tanque HidroneumaticoDocument1 pageCaceta Tanque HidroneumaticoEdwin Bustamante CabreraNo ratings yet

- Caceta Tanque HidroneumaticoDocument1 pageCaceta Tanque HidroneumaticoEdwin Bustamante CabreraNo ratings yet

- Com PuertaDocument1 pageCom PuertaEdwin Bustamante CabreraNo ratings yet

- Flange 8" RF Slep On Class # 150 Astm A 304 Flange 8" RF Slep On Class # 150 Astm A 106 GRBDocument1 pageFlange 8" RF Slep On Class # 150 Astm A 304 Flange 8" RF Slep On Class # 150 Astm A 106 GRBEdwin Bustamante CabreraNo ratings yet

- Gradas ControlDocument1 pageGradas ControlEdwin Bustamante CabreraNo ratings yet

- Montaje Soplantes.1Document1 pageMontaje Soplantes.1Edwin Bustamante CabreraNo ratings yet

- Caceta Tanque HidroneumaticoDocument1 pageCaceta Tanque HidroneumaticoEdwin Bustamante CabreraNo ratings yet

- Montaje Soplantes.3Document1 pageMontaje Soplantes.3Edwin Bustamante CabreraNo ratings yet

- Drill. Drive. Done. Everywhere.: Screw Anchor HUS-HR/CR (SS 316)Document18 pagesDrill. Drive. Done. Everywhere.: Screw Anchor HUS-HR/CR (SS 316)Edwin Bustamante CabreraNo ratings yet

- Sketch Campamento MINEVOL - PILAHUIN ModelDocument1 pageSketch Campamento MINEVOL - PILAHUIN ModelEdwin Bustamante CabreraNo ratings yet

- Desing-CTI 08/01/2019: Designed by Checked by Approved by Date DateDocument1 pageDesing-CTI 08/01/2019: Designed by Checked by Approved by Date DateEdwin Bustamante CabreraNo ratings yet

- Lavadora - Vista OrtogonalDocument1 pageLavadora - Vista OrtogonalEdwin Bustamante CabreraNo ratings yet

- Desing-CTI 19/07/2018: Designed by Checked by Approved by Date DateDocument1 pageDesing-CTI 19/07/2018: Designed by Checked by Approved by Date DateEdwin Bustamante CabreraNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Calentador PDFDocument1 pageCalentador PDFEdwin Bustamante CabreraNo ratings yet

- Structural system for pallet racksDocument1 pageStructural system for pallet racksEdwin Bustamante CabreraNo ratings yet

- JSW Casting EquipDocument23 pagesJSW Casting EquipArnab GhoshNo ratings yet

- PSSLDocument8 pagesPSSLlokelooksNo ratings yet

- Drilling Fluids ExercisesDocument17 pagesDrilling Fluids ExercisesJohn Kevin De CastroNo ratings yet

- Jared Ledgard - The Preparatory Manual of Explosives - Radical, Extreme, Experimental Explosives Chemistry Vol.1-Jared Ledgard (2010)Document349 pagesJared Ledgard - The Preparatory Manual of Explosives - Radical, Extreme, Experimental Explosives Chemistry Vol.1-Jared Ledgard (2010)Santiago U. NarváezNo ratings yet

- J.B. Institute M.Tech CAD/CAM Nano TechnologyDocument3 pagesJ.B. Institute M.Tech CAD/CAM Nano TechnologyGopinath GangadhariNo ratings yet

- Chapter-2 - Matter-and-EnergyDocument26 pagesChapter-2 - Matter-and-EnergyJam BermejoNo ratings yet

- Catalogo Consumibles Cromatografia de Gases y Espectrometria de Gases Parte3 PDFDocument218 pagesCatalogo Consumibles Cromatografia de Gases y Espectrometria de Gases Parte3 PDFTaranom SpNo ratings yet

- Operating Characteristics: Inlet Volumetric Rate of FlowDocument19 pagesOperating Characteristics: Inlet Volumetric Rate of FlowSandi AslanNo ratings yet

- Shigley Solve Cap. 5 &6Document63 pagesShigley Solve Cap. 5 &6Johnny SanchezNo ratings yet

- Fosroc Cebex 100 0811Document2 pagesFosroc Cebex 100 0811kannankrivNo ratings yet

- Discovery of IonsDocument10 pagesDiscovery of Ionsekadarma55No ratings yet

- Distillation ColumnDocument18 pagesDistillation ColumnChristy John NinanNo ratings yet

- Drinking Water StandardsDocument2 pagesDrinking Water StandardsCharan ReddyNo ratings yet

- Water Potential Ap Bio 2012-2013Document18 pagesWater Potential Ap Bio 2012-2013Keshav RaoNo ratings yet

- PM304 ch1Document6 pagesPM304 ch1何英奇No ratings yet

- ChiralVision Product ListDocument23 pagesChiralVision Product Listnilesh_rukeNo ratings yet

- Super Lube Multi-Purpose Synthetic Oil With Syncolon (PTFE) PDFDocument1 pageSuper Lube Multi-Purpose Synthetic Oil With Syncolon (PTFE) PDFKapo PuresNo ratings yet

- Food Tests Lab ReportDocument4 pagesFood Tests Lab ReportHirko BelayNo ratings yet

- Nptel Assignments & Solutions: Chapter 1: Introduction and Fundamental ConceptsDocument7 pagesNptel Assignments & Solutions: Chapter 1: Introduction and Fundamental ConceptsPanneer SelvamNo ratings yet

- PH and BuffersDocument24 pagesPH and BuffersJoshua LewisNo ratings yet

- GRP 7 Re Crystallization of Pure AcetanilideDocument3 pagesGRP 7 Re Crystallization of Pure AcetanilideKevin ReyesNo ratings yet

- DAE SSPS 2004 PresentationDocument32 pagesDAE SSPS 2004 PresentationRavi Kumar ChNo ratings yet

- MEM 661 - Applied Welding Engineering Individual Assignment Instruction and Guidelines CASE STUDY (Document10 pagesMEM 661 - Applied Welding Engineering Individual Assignment Instruction and Guidelines CASE STUDY (Shaikhan NadzemiNo ratings yet

- Pepsi Mix Max Mox ExperimentDocument2 pagesPepsi Mix Max Mox Experimentanon_192325873No ratings yet

- Test Report Needle Oil PerformanceDocument4 pagesTest Report Needle Oil Performancedimaster_jarkoNo ratings yet

- RESIN - TRANSFER - MOLDING - FINAL - REPORT With RefDocument37 pagesRESIN - TRANSFER - MOLDING - FINAL - REPORT With RefI DKNo ratings yet

- Physical Science Reviewer with 494 Multiple-Choice ItemsDocument118 pagesPhysical Science Reviewer with 494 Multiple-Choice ItemsKaren DellatanNo ratings yet

- Science Chapter 3Document93 pagesScience Chapter 3a.omera2010No ratings yet

- Microscopy REMOTE Quiz QuestionsDocument2 pagesMicroscopy REMOTE Quiz QuestionsadamNo ratings yet