Professional Documents

Culture Documents

Exhaust Blower v1 0

Uploaded by

RanchojiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exhaust Blower v1 0

Uploaded by

RanchojiCopyright:

Available Formats

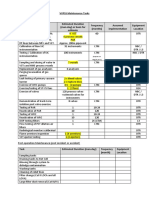

Tag Nº 24-VP-00-VK-001

Exhaust Filter Condensor

Revision Nº 1.0

Document Nº

EXHAUST FILTER CONDENSOR ITER Info

Category

Row CLASSIFICATION Rev.

1 Safety class SIC-2

2 Seismic class N/A

3 Vacuum class N/A

4 Tritium class N/A

5 ESPN class N2

6 Primary/Secondary barrier Secondary barrier

7 Quality class QC1

8 Design / Construction code PED

9 PURPOSE

The HMS relief gas is saturated with water vapour. A gas cooler / condenser is provided to cools the HMS relief gas in between 6 and 15°C & meets the humidity

requirement for the Detriation system .Reduction of the water content of the air also reduces the tritium content of the HMS relief gas.

10

11 GENERAL DATA

12 Service Exhaust Filter Cooler /Condensor

13 Quantity 2 ( 1 Working + 1 Standby)

14 Model No. VTA

15 Relative direction of fluid Crossflow

16 Unit Orientation Horizontal

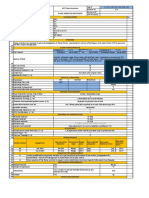

17 PROCESS DATA

Hot Side Cold Side

18 Parameter Unit

19 Inlet Outlet Inlet Outlet

20 Phase -- Vapor Vapor/Liq Vapor liquid Liquid Liquid

Fluid Name -- Air Water/Steam Air Condensed Chilled Water

Water

21

22 Total Flowrate Kg/Hr 646 646 VTA

23 Kg/Hr 607.2 38.76 607.2 38.76 VTA VTA

24 Operating Pressure bara 0.8 8

0

25 Temperature C 100 15 6 VTA

26 Density Kg/m3 0.7028 958.8 0.9356 998.8 1001 VTA

27 Viscosity cP 0.0211 0.282 0.0178 1.14 1.47 VTA

28 Specific heat KJ/Kg 0K 1.062 4.208 1.016 4.197 4.209 VTA

29 Thermal conductivity W/m0K 0.0308 0.681 0.0252 0.595 0.58 VTA

0

30 Dew Point C 39.5 -- 39.5 -- --

31 Molecular Weight Kg/mol 27.94 18 28.72 18 18

32 Critical Pressure bara 54.75 -- 41.71 -- --

33 latent Heat KJ/Kg 2410.2 -- 2410.2 -- --

34 Pressure Drop ( Allowable) kpa 1 100

35 Pressure Drop ( Calculated) kpa VTA VTA

36 Velocity m/s VTA VTA VTA VTA

37 Fouling Factor m20K/W 0.00018 0.00035

38 Heat Transfer coefficient ( Clean) W/m20K VTA

39 Heat Transfer coefficient ( Service) W/m20K VTA

40 Heat Exchanged kW 37

41 Heat Transfer Area m2 VTA

42 MECHANICAL REQUIREMENTS

43 No of plates -- VTA

44 Plate thickness mm VTA

45 No of passes -- VTA

46 Grouping ( Pass arrangement) -- VTA

47 Design Pressure barg 20

0

48 Design Temperature C 125

49 Test Pressure barg VTA

50 Dimensions ( L*W*H) mm VTA

51 Weight kg VTA

52 MATERIAL OF CONSTRUCTION

53 Plate -- SS316L

54 Lining -- SS316L

55 Gasket -- Graphite /VTA (to survive radiation conditions)

56 NOZZLE DETAILS

Nozzle number Designation Nozzle Size Connection Type Flange Class Remark

57

58 N1 Air Inlet VTA EN-1092 flange 150 #

59 N2 Air/condensate outlet VTA EN-1092 flange 150 #

60 N3 Chilled Water inlet VTA EN-1092 flange 150 #

61 N4 Chilled Water outlet VTA EN-1092 flange 150 #

62 NOTES

63 1) Vendor to highlight deviation if any, from the above specification along with technical reason for the same.

64 2) Vendor to submit the Calculation Sheet of the same.

65 3) Vendor to submit the catalogue along with offer.

66 4) Vendor to submit the Equipment installation manual & G.A. Drawings in hard copies 2 set.

67 REMARKS

68 VTA Vendor to advise

69 TBC To be confirmed (ITER)

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CBAM Guidance - non-EU InstallationsDocument266 pagesCBAM Guidance - non-EU InstallationsNAMPNo ratings yet

- Science8 - q1 - Mod7 - Heat and Temperature - v3Document24 pagesScience8 - q1 - Mod7 - Heat and Temperature - v3RUTH PIANG100% (5)

- Pressure Relief SystemDocument33 pagesPressure Relief SystemRanchojiNo ratings yet

- Chapter 15 Heat Exchanger NetworksDocument29 pagesChapter 15 Heat Exchanger NetworksRina Hapsarininggar0% (1)

- Mod 3-Process Engineering ObjectivesDocument141 pagesMod 3-Process Engineering ObjectiveslovjnxNo ratings yet

- CHH2 Pid All AlDocument28 pagesCHH2 Pid All AlRanchojiNo ratings yet

- Designation of The Manufacturer: IO Decision On For Nuclear Pressure EquipmentDocument2 pagesDesignation of The Manufacturer: IO Decision On For Nuclear Pressure EquipmentRanchojiNo ratings yet

- PIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationDocument2 pagesPIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationRanchojiNo ratings yet

- Pic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºDocument2 pagesPic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºRanchojiNo ratings yet

- CHL Mass Sizes of VVPSS Equipments (Updated)Document3 pagesCHL Mass Sizes of VVPSS Equipments (Updated)RanchojiNo ratings yet

- VVPSS Maintenance Tasks: (Depends On Integrity Level)Document2 pagesVVPSS Maintenance Tasks: (Depends On Integrity Level)RanchojiNo ratings yet

- Pool Scrubber TankDocument37 pagesPool Scrubber TankRanchojiNo ratings yet

- Vacuum EngineeringDocument2 pagesVacuum EngineeringRanchojiNo ratings yet

- Pool Scrubber Tank OfferDocument10 pagesPool Scrubber Tank OfferRanchojiNo ratings yet

- Area Hazard Analysis: Example of Possible ApproachDocument11 pagesArea Hazard Analysis: Example of Possible ApproachRanchojiNo ratings yet

- Poo Scrubber TankDocument25 pagesPoo Scrubber TankRanchojiNo ratings yet

- Spark IgniterDocument1 pageSpark IgniterRanchojiNo ratings yet

- MHT-Unit 5Document12 pagesMHT-Unit 5Aariyan K. ArkoNo ratings yet

- L3-4 Heat Transfer 2023Document21 pagesL3-4 Heat Transfer 2023TurzaNo ratings yet

- General Chemistry Anomalous Expansion of WaterDocument15 pagesGeneral Chemistry Anomalous Expansion of WaterDietherNo ratings yet

- Btd-1. Fundamental Concepts & DefinitionsDocument18 pagesBtd-1. Fundamental Concepts & Definitionsmahammad kamaluddeenNo ratings yet

- CEI Graduate Diploma SyllabusDocument257 pagesCEI Graduate Diploma Syllabuse--cityandguilds100% (8)

- 082 CH 20Document3 pages082 CH 20Jagdip ShethNo ratings yet

- High Speed Aerodynamics NotesDocument243 pagesHigh Speed Aerodynamics NotesawarialocksNo ratings yet

- Piston V C and P C Combined Vapor Mixture PDFDocument10 pagesPiston V C and P C Combined Vapor Mixture PDFKONDRU SIVAKUMARNo ratings yet

- 1st Year Chemistry NotesDocument24 pages1st Year Chemistry NotesShasha Jain88% (8)

- Cemi - 321 - Lecture 4 - 2023Document15 pagesCemi - 321 - Lecture 4 - 2023Mare' TaljaardNo ratings yet

- Tacite UgDocument129 pagesTacite Ugarmando0212-1No ratings yet

- Birla Institute of Technology and Science, Pilani: Pilani Campus AUGS/ AGSR DivisionDocument3 pagesBirla Institute of Technology and Science, Pilani: Pilani Campus AUGS/ AGSR DivisionHIMANSHU JAINNo ratings yet

- Module Reviews (Year 1)Document20 pagesModule Reviews (Year 1)Le Chriffe ChipNo ratings yet

- Heat Class 7 Science Chapter 4Document9 pagesHeat Class 7 Science Chapter 4Gaurav SethiNo ratings yet

- Development of A Novel Vacuum Pyrolysis Reactor WithDocument17 pagesDevelopment of A Novel Vacuum Pyrolysis Reactor WithWASHINGTON LUIZ VOGLIOTTI JERICONo ratings yet

- June 2022 (v2) QP - Paper 2 CAIE Physics IGCSEDocument20 pagesJune 2022 (v2) QP - Paper 2 CAIE Physics IGCSEMonoNo ratings yet

- ShirtsDocument18 pagesShirtsAkash SinghNo ratings yet

- Thermodynamics Lecture #01: Engr. Yasir Yasin Department of Mechanical EngineeringDocument19 pagesThermodynamics Lecture #01: Engr. Yasir Yasin Department of Mechanical EngineeringyasiryasinNo ratings yet

- User Manual - 7square (Hotplate) Magnetic Stirrer ABS450Document19 pagesUser Manual - 7square (Hotplate) Magnetic Stirrer ABS450LocNo ratings yet

- Gaitonde ProgAeroSci 2015 (SWBLI Review)Document20 pagesGaitonde ProgAeroSci 2015 (SWBLI Review)Taro YamadaNo ratings yet

- Aqa 84022 W MS Jun13Document18 pagesAqa 84022 W MS Jun13BrianChanNo ratings yet

- 5 2018 10 17!09 00 37 PM PDFDocument7 pages5 2018 10 17!09 00 37 PM PDFMuhammad Irsan SaputraNo ratings yet

- Proposal For A Solar Fruit Dryer Design With OrganDocument5 pagesProposal For A Solar Fruit Dryer Design With OrganZaidi RasipNo ratings yet

- Nyberg 2000Document7 pagesNyberg 2000Frigidianus GriffinNo ratings yet

- ModellingDocument10 pagesModellingalmadhagiNo ratings yet

- ME Transfer Course DescriptionDocument16 pagesME Transfer Course Descriptionsolidworksmanics2023No ratings yet