Professional Documents

Culture Documents

Spec DCMC

Uploaded by

Muhammad AqzelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spec DCMC

Uploaded by

Muhammad AqzelCopyright:

Available Formats

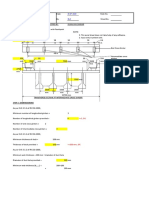

MCR-C MCR-B *9

MCR-A5C

Travel

X-axis travel (table front/back) mm 4,200 to 12,200 3,000 to 12,000 3,200 to 12,200

Y-axis travel (spindle horizontal) mm 3,200 to 4,200 2,700 to 4,200 2,600 to 4,100

Z-axis travel (ram vertical) mm 1,050 [1,250] 800 [1,000] 800

W-axis travel (crossrail vertical) mm 1,000, 1,200 700 to 1,300 800 to 1,200

Effective width between columns mm 2,650 to 3,650 2,050 to 3,550 2,150 to 3,650

Table to spindle nose (max) mm 1,650 to 1,850 1,350 to 1,850 1,450 to 1,850

*1 *1

[1,550 to 1,750] [1,250 to 1,750] [1,350 to 1,750] *1

Table

Working surface mm 2,000 × 4,000 to 1,500 × 2,800 to 1,500 × 3,000 to

3,000 × 12,000 3,000 × 11,800 3,000 × 12,000

Maximum load kg 22,000 to 66,000 12,000 to 72,600 12,000 to 66,000

T-slots 24H7 × 11, 13, 15 24H7 × 9 to 15 24H7 × 11, 13, 15

mm

[Width x No. (spacing)] (Center 200) (Center 200) (Center 140, 200)

Height from the floor mm 850 to 950 800 to 950 850 to 950

Feedrates

Rapid traverse m/min X: 30, Y: 32, Z: 20

X-Y: 24, Z: 15 (X: 30, Y: 32*2, Z: 20) *20

(X-Y: 24*2, Z: 15) *3 X: 15, Y: 20*10, Z: 15 (X: 20, Y: 32*2, Z: 20) *21

(X: 20, Y: 24*2, Z: 15) *4 (X: 30, Y: 30*2, Z: 20) *22

(X: 20, Y: 30*2, Z: 20) *23

Cutting feedrate mm/min 1 to 10,000 1 to 10,000 1 to 10,000

W-axis (crossrail vertical) mm/min 3,000 3,000 3,000

ATC

Tool shank MAS BT50 MAS BT50 MAS BT50

Pull stud MAS 2 MAS 2 MAS 2

Tool magazine capacity tools 50 32*11 50

[80, 100, 120, 180] [50, 72, 100, 120, 180] [80, 100, 120, 180]

Max tool diameter mm W/ adjacent tools: ø135 W/ adjacent tools: ø135 W/ adjacent tools: ø135

W/o adjacent tools: ø264 W/o adjacent tools: ø230 W/o adjacent tools: ø230

Max tool length mm 600 400 400

Max tool weight kg 25 25 25

Tool selection Fixed address Fixed address Fixed address

Spindle

Spindle speed min-1 4,000 [6,000] 4,000 [3,600, 6,000, 8,000, 10,000] 4,000 [6,000, 10,000]

Taper bore

7/24 Taper No. 50 7/24 Taper No. 50 7/24 Taper No. 50

Bearing diameter mm ø100 [ø85*5, ø130*6, ø100*7] ø100 [ø85*12] ø100[ø85*24]

Motors

Spindle drive kW 30/22 (30 min/cont) *8

45/37 (30 min/cont) 26/22 (30 min/cont) *8

[45/37 (30 min/cont) *13, 22 (cont) *5

[37 (cont)] *5 [26/22 (30 min/cont) *24, 30/22 (30 min/cont) *25]

26/22 (30 min/cont) *14]

Feed drives kW X: 9.4 (14*15), Y: 7.3, Z: 4.6 × 2

X: 14.0, Y: 9.4, Z: 5.2 × 2 X: 9.4 (14*26), Y: 7.3, Z: 5.2 × 2

(X: 9.4 (14*16), Y: 9.4, Z: 4.6×2)*17

Crossrail traverse kW W: 4.6 (5.2*18) × 2 W: 4.6 (5.2*18) × 2 W: 4.6 × 2

Power Requirements

Electrical power supply kVA 60*8 60*8 60*8

Compressed air flow rate L/min (ANR) 650 (over 0.5 MPa) *8 650 (over 0.5 MPa) *8 650 (over 0.5 MPa) *8

Machine Size

Height mm 6,730, 6,980 6,250 to 6,850 5,820 to 6,300

Floor space (machine only) mm 7,810 × 10,730 to 6,950 × 8,200 to 6,180 × 8,430 to

8,835 × 27,930 8,700 × 27,400 7,780 × 27,930

Weight (machine only) kg 48,000 to 116,000 36,000 to 120,900 32,000 to 101,000

CNC OSP-P300MA OSP-P300MA OSP-P300MA

MCR-H MCR-AF MCV-A

Travel

X-axis travel (table front/back) mm 4,200, 5,200 2,600 2,000 to 5,200

Y-axis travel (spindle horizontal) mm 3,200, 3,700 1,500, 2,000 1,600, 2,000

Z-axis travel (ram vertical) mm 800 [1,000] 800 450 (Quill vertical)

W-axis travel (crossrail vertical) mm 1,000 − 1,000, 1,150

Effective width between columns mm 2,550, 3,050 2,600 1,650, 2,050

Table to spindle nose (max) mm 1,100 1,360 to 1,510

1,550

[1,000*29] [1,380 to 1,530] *36

Table

Working surface mm 2,000 × 4,000, 2,000 × 1,500, 1,200 × 1,800 to

2,500 × 5,000 2,000 × 2,000 1,500 × 5,000

Maximum load kg 22,000, 33,000 10,000 6,000 to 16,000

T-slots 24H7 × 11, 13 20H7 × 9, 11 20H7 × 9, 11

mm

[Width x No. (spacing)] (Center 200) (Center 200) (Center 140)

Height from the floor mm 920 850 700 to 750

Feedrates

Rapid traverse m/min X-Y: 30, Z: 15 X-Y: 20, Z: 10 X-Y: 20, Z: 10

Cutting feedrate mm/min X-Y: 1 to 30,000, Z: 1 to 15,000 1 to 10,000 1 to 10,000

W-axis (crossrail vertical) mm/min 5,000 − 420/500 (50/60Hz)*37

ATC

Tool shank MAS BT50 MAS BT50 [MAS BT50*29, MAS BT40*30, HSK-A63*31*32] MAS BT50

Pull stud MAS 2 MAS 2*33 MAS 2

Tool magazine capacity tools 50 24 24

*30*31*32 *30*31*32 *34 *34 *34

[80, 100, 120, 180] [32 , 48 , 50 , 72 , 100 ] [50, 72, 100]

Max tool diameter mm W/ adjacent tools: ø135 W/ adjacent tools: ø125*34 [ø135*35, ø90*30*31*32] W/ adjacent tools: ø128

W/o adjacent tools: ø230 W/o adjacent tools: ø230*34 [ø125*30*31*32] W/o adjacent tools: ø230

Max tool length mm 400 400 400

Max tool weight kg 25 25 *34 *30*31*32

[8 ] 20

Tool selection Fixed address Fixed address*34 [random memory*30*31*32] Fixed address

Spindle

Spindle speed min-1 8,000 8,000 [12,000, 15,000, 20,000, 25,000] 4,000 [6,000, 10,000]

Taper bore 7/24 Taper No. 50

7/24 Taper No. 50 7/24 Taper No. 50

[7/24 Taper No.50*29, 7/24 Taper No.40*30, HSK-A63*31*32]

Bearing diameter mm ø85 ø85 [ø100*29, ø70*30*31, ø60*32] ø100 [ø85*24]

Motors

Spindle drive kW 26/22 (30 min/cont)*8

22/18.5 (30 min/cont)

26/22 (30 min/cont) [37/26 (10 min/cont) *29, 26/18.5 (10 min/cont) *30,

[22/15 (30 min/cont)*5, 22 (cont)*42]

30/22 (10 min/cont)*31, 15/11 (30 min/cont) *32]

Feed drives kW X: 12*27*28 (18*27*43) X: 3.5 (4.2*38, 4.6*39)

X-Y: 5.2, Z: 3.6 × 2

*27

Y: 6 , Z: 4.6 × 2 Y: 4.2, Z: 4.2

Crossrail traverse kW W: 5.2 × 2 − 3.7 (AC) [3.6*40]

Power Requirements

Electrical power supply kVA 80*8 55*8 40*8 45*8

Compressed air flow rate L/min (ANR) 950 (over 0.5 MPa) *8 700 (over 0.5 MPa) *8 500 (over 0.5 MPa) *8

Machine Size

Height mm 6,450 4,670 [4,450*29] 4,375 to 4,585*41

Floor space (machine only) mm 7,825 × 10,730, 5,560 × 4,200, 4,935 × 6,000 to

8,425 × 12,830 5,560 × 5,230 5,335 × 12,920

Weight (machine only) kg 64,000, 75,000 24,500, 26,000 19,500 to 30,500

CNC OSP-P300MA OSP-P300MA OSP-P300MA

[ ]: Optional *1. Asterisk *1 marked square brackets indicate with 250-mm extension head. *2. Deceleration near both ends of Y-axis travel

*3. ( ): 30 × 50, 30 × 65, 35 × 50, 35 × 65 machine nominal sizes *4. ( ): 30 × 80, 30 × 100, 35 × 80, 35 × 100, 35 × 120 machine nominal sizes *5. 6,000 min-1 specs

*6. 4,000 min-1, high output specs *7. 6,000 min-1, high output specs *8. Standard specs *9. Elevating crossrail *10. Deceleration near both ends of Y-axis travel with 30

and 35 size machines *11. With 32-tool ATC there are limitations to ATC range with 25 and larger size machines *12. 6,000, 8,000, 10,000 min-1 specs

*13. 3,600 min-1 specs *14. 8,000, 10,000 min-1 specs *15. 30 × 120 size machine *16. 35 × 120 size machine *17. ( ): 35 size machine *18. 35 size machine

*20. ( ): 30 × 50, 30 × 65 size machines *21. ( ): 30 × 80, 30 × 100 size machines *22. ( ): 35 × 50, 35 × 65 size machines

*23. ( ): 35 × 80, 35 × 100, 35 × 120 size machines *24. 6,000, 10,000 min-1 specs *25. 10,000 min-1 aluminum machining specs

*26. 25 × 50, 25 × 65, 30, 35 size machines *27. Linear motor *28. 25 × 40 size machine *29. 12,000 min-1 specs *30. 15,000 min-1 specs *31. 20,000 min-1 specs

*32. 25,000 min-1 specs *33. No pull stud with HSK specs *34. 8,000, 12,000 min-1 specs *35. 8,000 or 12,000 min-1 specs and 50-tool magazine capacity

*36. [ ]: 10,000 min-1 specs *37. Auto-positioning crossrail; 400 mm/min for 16, 340 mm/min for 20 size machines *38. 20 × 40 size machine *39. 20 × 50 size machine

*40. Auto-positioning crossrail *41. Standard pendant (fixed) and no thru-spindle *42. 10,000 min-1 specs *43. 30 × 50 size machine

You might also like

- Catalogue of HOTONMC-1Document13 pagesCatalogue of HOTONMC-1Chitko KoNo ratings yet

- PCI MeteorTS900V ENDocument2 pagesPCI MeteorTS900V ENHX WEINo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- EGM - CNC Precision Hybrid ID & OD GrinderDocument6 pagesEGM - CNC Precision Hybrid ID & OD GrinderGatyo GatevNo ratings yet

- Millac V Series Full Specs Formatted Rev. 2014 08 12bDocument1 pageMillac V Series Full Specs Formatted Rev. 2014 08 12bGunGunSetiawanNo ratings yet

- Horizontal Boring MillsDocument2 pagesHorizontal Boring MillsRaluca UrseNo ratings yet

- Drilling Machine TR40Document1 pageDrilling Machine TR40عمر عمرNo ratings yet

- PSC I Girder Design by IRC Code (Old)Document109 pagesPSC I Girder Design by IRC Code (Old)Structural SpreadsheetsNo ratings yet

- Liebherr Measuring Instruments WGT 280 1200Document8 pagesLiebherr Measuring Instruments WGT 280 1200CAT MINING SHOVELNo ratings yet

- CNC Hyundai HS 4000 IDocument58 pagesCNC Hyundai HS 4000 IJohn Harold BenavidesNo ratings yet

- Shot Blasting Machines: AirblastDocument16 pagesShot Blasting Machines: AirblastBoanerges BritoNo ratings yet

- PCI Meteor3000 ENDocument2 pagesPCI Meteor3000 ENHX WEINo ratings yet

- Emco e 300Document1 pageEmco e 300robalitojgpNo ratings yet

- Hyundai f400500600 MachiningcenterDocument42 pagesHyundai f400500600 MachiningcenterOmarAlirioSuarezCañareteNo ratings yet

- Radial Drill Catalog-110620Document14 pagesRadial Drill Catalog-110620Anto SiminNo ratings yet

- TPX6113DDocument1 pageTPX6113Dluki prasetyoNo ratings yet

- 1sp V 2sp V Series Full Specs 2015 04 30 PDFDocument1 page1sp V 2sp V Series Full Specs 2015 04 30 PDFAlexandru ZdbNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Discotom100 10 Tech EnglishDocument2 pagesDiscotom100 10 Tech EnglishKathia Bernal RamirezNo ratings yet

- 10 Product Spillage Solution Impact BedDocument36 pages10 Product Spillage Solution Impact BedvishnusankarNo ratings yet

- Catalogue Máy Nhôm JihDocument28 pagesCatalogue Máy Nhôm JihhongphuongcrNo ratings yet

- Sakai SW300 Series Shop ManualDocument114 pagesSakai SW300 Series Shop ManualLU YO100% (4)

- MAIN BEAM 1200 X 600: Double WebDocument2 pagesMAIN BEAM 1200 X 600: Double WebsalmanNo ratings yet

- IPH750 Hydraulic Piling Hammer and Rig Technical SpecsDocument4 pagesIPH750 Hydraulic Piling Hammer and Rig Technical SpecsAdam LimNo ratings yet

- ByStar Fiber Datasheet Eng Original 14278Document2 pagesByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhNo ratings yet

- UntitledDocument12 pagesUntitledAngel Rodriguez PizarroNo ratings yet

- TSM1000D CNC Double Rollers Spinning and Turning MachineDocument3 pagesTSM1000D CNC Double Rollers Spinning and Turning MachineMahendra AdityaNo ratings yet

- Maximize throughput and efficiency with dsb innocrush impact crushersDocument1 pageMaximize throughput and efficiency with dsb innocrush impact crushersАнтон ЛазаровNo ratings yet

- Wimmer Luna ENDocument2 pagesWimmer Luna ENHorea CordunianuNo ratings yet

- Cu 325Document4 pagesCu 325Pedja BekicNo ratings yet

- CNC Lathes for Bar, Rod and Section MillsDocument2 pagesCNC Lathes for Bar, Rod and Section Millsjeorgepoletto50% (2)

- Scheda 6Document2 pagesScheda 6Amr RizkNo ratings yet

- NT-Boom SpecsDocument8 pagesNT-Boom SpecsSello PhailaNo ratings yet

- EDM Machine Specifications ComparisonDocument7 pagesEDM Machine Specifications ComparisonFadhilsei OthmanNo ratings yet

- Gambar Mesin Utm GT7001-LCUDocument3 pagesGambar Mesin Utm GT7001-LCUAgung SetiawanNo ratings yet

- Ds Romi D in Aq Final BXDocument12 pagesDs Romi D in Aq Final BXjubileuNo ratings yet

- Ac StandingDocument2 pagesAc Standingdharma kreasiNo ratings yet

- Mobicat MC 110 Z Evo Mobicat MC 110 R Evo: Contractor LineDocument2 pagesMobicat MC 110 Z Evo Mobicat MC 110 R Evo: Contractor Linetecnicomineria14060100% (1)

- 4PB Pilecap DesignDocument2 pages4PB Pilecap DesignJONAS NGNo ratings yet

- TEST-E Series Universal Testing MachinesDocument3 pagesTEST-E Series Universal Testing MachinesCirclesOnSandNo ratings yet

- Textile Calculation Formulas in ErodetextileindsDocument4 pagesTextile Calculation Formulas in ErodetextileindsVikram JunejaNo ratings yet

- Perhitungan Perkuatan FRP Balok PrategangDocument15 pagesPerhitungan Perkuatan FRP Balok PrategangAditya Bayu NugrahaNo ratings yet

- Catálogo BOST 2017 - BajaDocument13 pagesCatálogo BOST 2017 - BajaDavid S. Valenzuela PortilloNo ratings yet

- TPX6111B/2 Series Horizontal Milling and Boring MachineDocument1 pageTPX6111B/2 Series Horizontal Milling and Boring MachineYeissonNo ratings yet

- 2 Ceeb 97 BDocument4 pages2 Ceeb 97 BМитко МитковNo ratings yet

- Thomson Precision Linear Actuators Sep06Document8 pagesThomson Precision Linear Actuators Sep06mattiaNo ratings yet

- Mobirex MR 130 Z Evo 2: Contractor LineDocument2 pagesMobirex MR 130 Z Evo 2: Contractor LineMaxNo ratings yet

- CABEÇOTES - HTT - Stanki - Glubokogo - SverleniyaDocument12 pagesCABEÇOTES - HTT - Stanki - Glubokogo - Sverleniyacarolina lopesNo ratings yet

- Toshiba BSF-160L Horizontal Boring Machine SpecsDocument6 pagesToshiba BSF-160L Horizontal Boring Machine Specsjaka rahman darmawanNo ratings yet

- Tube Bundle ExtractorsDocument1 pageTube Bundle ExtractorsNadeemNo ratings yet

- TCF 160 / TCF 200 / TCF 224 / TCF 250 TCF 275 / TCF 300: Heavy Centre LathesDocument8 pagesTCF 160 / TCF 200 / TCF 224 / TCF 250 TCF 275 / TCF 300: Heavy Centre LathesRajiv GandhiNo ratings yet

- BBS Pile CapDocument1 pageBBS Pile CapSamanvay ChandnaoNo ratings yet

- C5240HP Technical Data Ver.1.1Document8 pagesC5240HP Technical Data Ver.1.1顏健軒No ratings yet

- Freza VerticalaDocument3 pagesFreza VerticalachetansergiurazvanNo ratings yet

- Split Cassette Carrier R410a Ficha TecnicaDocument1 pageSplit Cassette Carrier R410a Ficha TecnicaCarlos ManriquezNo ratings yet

- WasteTech 200Document1 pageWasteTech 200Miloš JovanovićNo ratings yet

- Retaining Wall-1Document6 pagesRetaining Wall-1Rajendra BadjatyaNo ratings yet

- Granifrigor Prospekt Brochure enDocument6 pagesGranifrigor Prospekt Brochure enLê Tất TiếnNo ratings yet

- Iodine Summaryupdate 2016Document26 pagesIodine Summaryupdate 2016FrankNo ratings yet

- PTC Document Status: (Updated 11 November 2015)Document5 pagesPTC Document Status: (Updated 11 November 2015)AndersonGabriel23No ratings yet

- Heliflex Hose CatalogueDocument119 pagesHeliflex Hose CatalogueAugustine DharmarajNo ratings yet

- Biomass and Bioenergy: Z.N. Akhlisah, R. Yunus, Z.Z. Abidin, B.Y. Lim, D. KaniaDocument20 pagesBiomass and Bioenergy: Z.N. Akhlisah, R. Yunus, Z.Z. Abidin, B.Y. Lim, D. KaniaPutri sinagaNo ratings yet

- AAB 075323 EPDM Waterproofing Membrane (For RC Roof Build-Up Inc. Insulation)Document3 pagesAAB 075323 EPDM Waterproofing Membrane (For RC Roof Build-Up Inc. Insulation)tewodrosNo ratings yet

- Material ManagementDocument106 pagesMaterial ManagementRomi AfriansyahNo ratings yet

- Assignment in English Plus Core 11 Full CircleDocument76 pagesAssignment in English Plus Core 11 Full CircleRitu Maan68% (38)

- Nursing TheoriesDocument9 pagesNursing TheoriesMichelleneChenTadleNo ratings yet

- Financing of New EnterpriseDocument8 pagesFinancing of New EnterpriseSunil BhamuNo ratings yet

- To Begin: MantraDocument9 pagesTo Begin: MantraashissahooNo ratings yet

- Labcelldivision ErikagutierrezDocument10 pagesLabcelldivision Erikagutierrezapi-336047220No ratings yet

- Separation and Purification TechnologyDocument10 pagesSeparation and Purification TechnologyPedro Henrique MagachoNo ratings yet

- Solar Collectors Final WordDocument14 pagesSolar Collectors Final WordVaibhav Vithoba NaikNo ratings yet

- A Drop of Blood: Casting Time Range Components Duration Casting Time Range Components DurationDocument6 pagesA Drop of Blood: Casting Time Range Components Duration Casting Time Range Components DurationCristobal RencoretNo ratings yet

- Changing Landscape and Ecotourism Development in A Large Dam SiteDocument16 pagesChanging Landscape and Ecotourism Development in A Large Dam Siteವಿನಯ್ ಎಮ್. ಆರ್No ratings yet

- Effect of Water Immersion On Mechanical Properties of Polyurethane ...Document8 pagesEffect of Water Immersion On Mechanical Properties of Polyurethane ...konshoeNo ratings yet

- Drawing and Reading Structural FormulasDocument12 pagesDrawing and Reading Structural FormulasVy Nguyen100% (1)

- Monthly Fire Extinguisher Inspection ChecklistDocument2 pagesMonthly Fire Extinguisher Inspection ChecklistisaacbombayNo ratings yet

- Design of Temporary Floating Road for Construction SiteDocument6 pagesDesign of Temporary Floating Road for Construction SiteAnonymous hRWwL7pZnCNo ratings yet

- AstigmatismDocument1 pageAstigmatismAmmellya PutriNo ratings yet

- HymssheetDocument4 pagesHymssheettoby_wardmanNo ratings yet

- Resume Curt JerromeDocument5 pagesResume Curt JerromeAashish MuraliNo ratings yet

- Platelets & Blood Clotting: The Hemostasis ProcessDocument34 pagesPlatelets & Blood Clotting: The Hemostasis ProcesssamayaNo ratings yet

- Understanding and Quantifying Mountain TourismDocument84 pagesUnderstanding and Quantifying Mountain TourismfloridNo ratings yet

- GREEN AIR CONDITIONER Mechanical Presentation TopicsDocument9 pagesGREEN AIR CONDITIONER Mechanical Presentation TopicsCerin91No ratings yet

- TCB E-F 015cukDocument2 pagesTCB E-F 015cukTempcoNo ratings yet

- HSB Julian Reyes 4ab 1Document3 pagesHSB Julian Reyes 4ab 1Kéññy RèqüēñåNo ratings yet

- Science: Pure Substances Vs MixturesDocument33 pagesScience: Pure Substances Vs MixturesElle Ma Rie100% (1)

- Fundamental aim training routines and benchmarksDocument8 pagesFundamental aim training routines and benchmarksAchilles SeventySevenNo ratings yet

- Entry-Exit Arrangement With Service RoadDocument1 pageEntry-Exit Arrangement With Service RoadRamBhuvan SonkarNo ratings yet