Professional Documents

Culture Documents

Siemens CU240E Replacement

Uploaded by

Văn Nghĩa NguyễnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Siemens CU240E Replacement

Uploaded by

Văn Nghĩa NguyễnCopyright:

Available Formats

Changeover SINAMICS CU240E to

CU240E-2 (as from Firmware V4.4)

SINAMICS G120

FAQ October 2012

Service & Support

Answers for industry.

Question

This entry is from the Siemens Industry Online Support. The general terms of use

(http://www.siemens.com/terms_of_use) apply.

Clicking the link below directly displays the download page of this document.

http://support.automation.siemens.com/WW/view/en/54997738

Caution

The functions and solutions described in this article confine themselves to the

realization of the automation task predominantly. Please take into account

furthermore that corresponding protective measures have to be taken up in the

context of Industrial Security when connecting your equipment to other parts of the

plant, the enterprise network or the Internet. Further information can be found

under the Content-ID 50203404.

http://support.automation.siemens.com/WW/view/en/50203404

Question

What do I have to observe, if I want to replace a CU240E of the SINAMICS G120

with a CU240E-2 (as from firmware V4.4)?

Answer

To respond to this question with the appropriate amount of detail, follow the

instructions listed in this document.

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Item ID: 54997738 2

Table of content

Table of content

1 Presentation of SINAMICS G120 CU240E-2...................................................5

1.1 Comparison between the CU240E and the CU240E-2 .......................6

1.2 Adaptations that must be made when making the changeover ...........7

2 Hardware dimensions ....................................................................................8

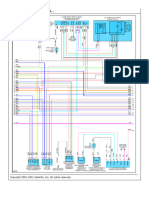

3 IO interface .....................................................................................................9

3.1 Terminal assignment .........................................................................9

3.2 Digital inputs....................................................................................10

3.2.1 Changed PNP / NPN logic ............................................................... 10

3.2.2 Changed BICO interconnection of the digital inputs..........................10

3.2.3 Simulation of the digital inputs (NEW) .............................................. 12

3.2.4 Monitoring the load / speed via a digital input (NEW)........................ 12

3.2.5 Fail-safe digital inputs (F-DI, NEW).................................................. 12

3.3 Digital outputs..................................................................................12

3.3.1 Modified parameter numbers ........................................................... 12

3.3.2 Hardware change DO1 .................................................................... 12

3.4 Analog inputs...................................................................................13

3.4.1 Modified factory setting.................................................................... 13

3.4.2 Changed ADU dead band (p761) ..................................................... 13

3.4.3 Simulation of the analog inputs (NEW)............................................. 13

4 Communication ............................................................................................14

4.1 GSD files.........................................................................................14

4.2 Dataset routing through a CPU ........................................................ 14

The following CPUs support dataset routing:.................................... 14

Presently, the following systems do not support dataset routing: ...... 15

4.3 Teleservice......................................................................................15

4.3.1 Teleservice via a CPU ..................................................................... 15

4.3.2 Teleservice directly to the fieldbus ................................................... 16

4.4 Slave-to-slave traffic (NEW)............................................................. 17

4.5 Direct HMI connection ..................................................................... 17

5 Local operator control via BOP-2 or IOP..................................................... 18

5.1 Manual operation with IOP or BOP-2 ............................................... 18

5.2 Status signals of the IOP or BOP-2 operator control panels.............. 18

6 Parameterization ..........................................................................................19

6.1 Changed reference quantities .......................................................... 19

6.2 Fixed setpoints that can be freely used (NEW)................................. 19

6.3 Parameterizing the command and setpoint sources (NEW).............. 19

6.4 Expanding the command / drive datasets......................................... 19

6.5 Speed-dependent controller adaptation (NEW) ................................ 19

6.6 Changed second ramp function ....................................................... 20

6.7 U/f characteristic (U/f with programmable characteristic) .................. 20

6.8 Operating hours counter (NEW)....................................................... 20

6.9 Changes to the braking chopper ...................................................... 20

6.10 BF-LED can be deactivated ............................................................. 20

6.11 Expansion of the motor holding brake function ................................. 21

6.12 Changes to the free function blocks (FFBs)...................................... 21

6.13 Changes to the phase failure monitoring .......................................... 21

6.14 Wobbulation generator has been eliminated .................................... 21

6.15 Positioning down ramp has been eliminated .................................... 21

7 Safety functions ...........................................................................................22

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Item ID: 54997738 3

Table of content

8 Drive fault messages....................................................................................23

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Item ID: 54997738 4

1 Presentation of SINAMICS G120 CU240E-2

1 Presentation of SINAMICS G120 CU240E-2

SINAMICS G120 CU240E-2 (as from firmware V4.4), as successor to the CU240E,

has the following new additional properties/features:

Communication (see chapter 3 for details)

USS / Modbus communication interface (CU240E-2 and CU240E-2-F)

PROFIBUS communication interface (CU240E-2 DP and CU240E-2 DP-F)

PROFINET communication interface (CU240E-2 PN and CU240E-2 PN-F)

Slave-to-slave communication for direct data exchange between drives

Safety functions (for details, refer to chapter 7)

The STO (Safe Torque Off) safety function is integrated in all versions as

standard.

The “-F” versions of the CU240E-2 have the following safety functions STO

(Safe Torque Off), SS1 (Safe Stop 1), SLS (Safely Limited Speed), SSM (Safe

Speed Monitoring) and SDI (Safe Direction). Speed feedback using an encoder

is not required for these safety functions.

Direct control of the safety functions via onboard F-DIs or via PROFIsafe

(PROFIBUS and PROFINET) from a fail-safe control system.

Fail-safe transfer of the F-DI status via PROFIsafe for the “-F” version. As a

consequence, the F-DIs of the drive can be used as distributed IOs of an fail-

safe control system.

Commissioning and optimization

Increased usability of the BOP-2 (Basic Operator Panel)

By using the IOP, faster local commissioning using the commissioning wizard,

simpler optimization of the parameterization and fault diagnostics using plain

text display.

User-friendly, graphic commissioning using the STARTER parameterizing

software, which is free-of-charge. Optimization of the parameterization using

the trace function. Connections established via the USB port or via fieldbus

(PROFIBUS and PROFINET).

Parameterization is optionally saved on an MMC / SD card so that the devices

can be quickly replaced when service is required.

Same standard parameter structure as for SINAMICS S110 and S120

One common firmware basis and standard parameterizing screen forms for all

SINAMICS drives. Therefore, it is simpler to get to know a member of the

SINAMICS family that has not been used up until now.

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 5

1 Presentation of SINAMICS G120 CU240E-2

1.1 Comparison between the CU240E and the CU240E-2

Some of the most important features/properties of the CU240E when compared to

the CU240E-2 family are listed below

CU240E CU240E-2 CU240E-2 DP CU240E-2 F CU240E-2 DP F

RS485 / USS / Profibus DP with RS485 / USS / Profibus DP with

Communication RS485 / USS

Modbus PROFIsafe Modbus PROFIsafe

STO

STO

SS1

SS1

No STO STO SLS

SLS

SDI

Safety SDI

SSM

6

6

Digital inputs (DI3 can be used as pulse input up to 32kHz)

Up to 1 Up to 3

0

Fail-safe digital inputs (from two standard DI) (each from two standard DI)

3 3

Digital outputs (relay) (1 x transistor / 2 x relay), each 30V DC max. 0,5A

2

(AI0: 0/4…20mA,

2

0/2 ...10V and +/-

( both 0/4…20mA, 0...10V and -10…+10V)

10V)

the AI can be used as additional digital inputs (DI11 and 12)

(AI1: 0…20mA

Analog inputs and 0…10V

2

(AO0 and 1: 2

0/4…20mA, AO0: (both 0…10V and 0/4…20mA)

Analog outputs 0 ...10V)

Terminals Spring-load. fixed Spring-loaded, can be inserted, improved accessibility

Motor temperature sensor PTC and KTY PTC, KTY and Thermoklick ( bimetallic switch)

RS485, not

Communication interface RS485, isolated Profibus DP, isol. RS485, isol. Profibus DP, isol.

isolated

Via parameter Via DIP switch Via DIP switch Via DIP switch Via DIP switch

Communication address p2011 or p2011 or p918 or p2011 or p918

Memory card No MMC or SD card

RS232 via PC-

converter USB (Micro USB cable)

Parameterizing interface connection kit

BOP or IOP (via

Local control BOP-2 or IOP

handheld)

Mechanical design Plastic housing Based on CU240S, rugged metal/plastic housing

Operation with PM340 (1AC

No Yes

230V)

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 6

1 Presentation of SINAMICS G120 CU240E-2

1.2 Adaptations that must be made when making the

changeover

As a result of the expanded functional scope of the CU240E-2 when compared to

the CU240E, the CU240E configuring must be adapted. These will now be

subsequently listed and explained in detail in the following chapters.

In addition, new functions will be listed in the individual chapters.

Hardware design (see chapter 2)

Changes to the height and depth of the CU

IO interface (see chapter 3)

Changes to the terminal assignment regarding NPN / PNP logic and reference

potential of the digital inputs

Changeover, DO1 to the transistor output

An external 24V power supply can be connected

Analog inputs; dead zone function has been modified

Communication (see chapter 4)

Existing programs to control a SINAMICS G120 with CU240E from a PLC, in

most cases, can still be used for the CU240E-2. For example, if parameters

are accessed via cyclic or non-cyclic communication, then the only change that

is required is as a result of the modified parameter numbers.

There are some restrictions regarding routing and teleservice functions.

Local operator control via IOP or BOP-2 (see chapter 5)

Changes to the manual/automatic changeover

The IOP or BOP-2 operator control elements can no longer be used as BICO

source.

Parameterization (see chapter 6)

It is not possible to directly migrate from CU240E projects to CU240E-2. The

drive must be re-commissioned.

Safety functions (see chapter 7)

Up until now, the CU240E had no integrated safety functions. If the safety

functions of the CU240E-2 are to be used, then these must be correspondingly

commissioned.

Drive fault messages/signals (see chapter 8)

The drive fault messages/signals of the CU240E-2 have changed when

compared to the CU240E. If these are to be displayed on an HMI for diagnostic

purposes, then the new fault messages must be integrated into the HMI.

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 7

2 Hardware dimensions

2 Hardware dimensions

Changed dimensions between the CU240E and CU240E-2

Width:

– No change

Height (195 mm for the CU240E):

– 200mm for the CU240E-2 DP and CU240E-2 DP F

– 215mm for the CU240E-2 / CU240E-2 F

– 255mm with shield connection plate (all CU240E-2)

Depth (31mm for the CU240E with/without BOP):

– 39mm without BOP-2 / IOP

– 50mmhe with BOP-2

– 60mm with IOP

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 8

3 IO interface

3 IO interface

3.1 Terminal assignment

The terminals of the CU240E will be compared with those of the CU240E-2 family.

Changes between the CU240E and CU240E-2 have been color coded.

CU240E CU240E-2

Term ina Term ina

Function l De signation l Des ignation Note re garding CU240E-2

1 +10V 1 +10V Out

Pow er supply AI

2 0V 2 GND

3 AI0+ 3 AI0+ Can also be used as additional digital input

Analog input AI0

4 AI0- 4 AI0- (DI11)

Digital input 0 5 DI0 5 DI0 For the CU240E-2 F and E-2 DP F, both DI

can be reparameterized to become an F-DI0

Digital input 1 6 DI1 6 DI1

Digital input 2 7 DI2 7 DI2 For the CU240E-2 F and E-2 DP F, both DI

can be reparameterized to become an F-DI1

Digital input 3 8 DI3 8 DI3

Pow er supply DIs 9 U24V 9 +24V Out

10 AI1+ 10 AI1+ Can also be used as additional digital input

Analog input AI1

11 AI1- 11 AI1- (DI12)

12 AO0+ 12 AO0+

Analog output AO0

13 AO0- 13 GND

14 PTC+ 14 T1 Motor PTC, KTY 84 and Thermoclick (bimetal)

Thermal sensor

15 PTC- 15 T2 Motor sensors can be connected here

For the CU240E-2 and E-2 DP, both DI can

Digital input 4

16 DI4 16 DI4 be reparameterized to become an F-DI0

For the CU240E-2 F and E-2 DP F, both DI

Digital input 5

can be reparameterized to become an F-DI2

17 DI5 17 DI5

18 DO0 NC 18 DO0 NC

Relay output DO0 19 DO0 NO 19 DO0 NO

20 DO0 COM 20 DO0 COM

21 DO1 NO 21 DO1+

Relay/digital output DO1 Change over from relay to transistor output

22 DO1 COM 22 DO1-

23 DO2 NC 23 DO2 NC

Relay output DO2 24 DO2 NO 24 DO2 NO

25 DO2 COM 25 DO2 COM

26 AO1+ 26 AO1+

Analog output AO1

27 AO1- 27 GND

Reference potential for

+24V 28 U0V 28 GND

Pin 1 0V

29 RS485 -A Pin 2 RS485P RS485 interface for CU240E-2 and CU240E-

RS485 interf ace

30 RS485 -B Pin 3 RS485N 2 F via separate connector

Pin 4 Shield

External 24V supply of

31 +24V IN

the CU, instead of supply

via PM 32 GND IN

Reference potential for For NPN logic, connect both terminals w ith

DI1, 3 and 5 34 DI COM2 terminal 28

Reference potential for For PNP logic, connect both terminals w ith

DI0, 2 and 6 69 DI COM1 terminal 9

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 9

3 IO interface

3.2 Digital inputs

3.2.1 Changed PNP / NPN logic

The PNP / NPN logic changeover of the digital inputs is, for the CU240E-2, no

longer realized by parameterization (CU240E: p725) and the wiring; it is only

defined using the input wiring.

For an internal power supply

– For PNP logic: Connect terminals 34 and 69 with terminal 28.

– For NPN logic: Connect terminals 34 and 69 with terminal 9.

For an external power supply

– For PNP logic: Connect terminals 34 and 69 with the system ground.

– For NPN logic: Connect terminals 34 and 69 with the system 24V.

NOTE For more information refer to the List Manual (chapter 2, function diagram 2220)

http://support.automation.siemens.com/WW/view/en/49946755

3.2.2 Changed BICO interconnection of the digital inputs

Previously, the digital inputs for BICO interconnection had to be enabled using the

value 99; this is now no longer required. The interconnection can now be made

directly without having to use p701..p706 (no longer available in CU240E-2). In

addition, inverted signals of the digital inputs are now available.

Figure 3-1: CU240E, enabling of BICO interconnection of the DIs

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 10

3 IO interface

Figure 3-2: CU240E-2, direct BICO interconnection of the DIs

Figure 3-3: CU240E-2, direct BICO interconnection of DI0 (terminal 5)

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 11

3 IO interface

3.2.3 Simulation of the digital inputs (NEW)

Now, the digital inputs can be simulated for test purposes using the STARTER

parameterizing software.

Figure 3-4

3.2.4 Monitoring the load / speed via a digital input (NEW)

Using this function, load failure can be monitored as well as a speed deviation.

NOTE For details, refer to the operating instructions (chapters 7.9.5 and 7.9.6)

http://support.automation.siemens.com/WW/view/en/50815575

3.2.5 Fail-safe digital inputs (F-DI, NEW)

For the safety functions of the CU240E-2, two digital inputs can now be re-

parameterized to become one F-DI (fail-safe, two-channel input). The number of

F-DIs varies depending on the CU (see chapter 3.1).

CU240E-2 has just one F-DI

CU240E-2-F has up to 3 F-DIs

Using PROFIsafe, for the CU240E-2 DP-F, the status of the F-DIs can be

transferred to the F-CPU in a safety-relevant fashion so that these are available as

distributed F-IOs.

3.3 Digital outputs

3.3.1 Modified parameter numbers

The parameter numbers of the DOs are shifted in the expert list by one position, for

example DO0:

CU240E p731

CU240E-2 p730

3.3.2 Hardware change DO1

DO1 (terminal 21 / 22) was changed from being a relay output (CU240E) to a

transistor output (CU240E-2).

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 12

3 IO interface

3.4 Analog inputs

3.4.1 Modified factory setting

The factory setting was changed from 0-10V (CU240E) to +/-10V (CU240E-2).

3.4.2 Changed ADU dead band (p761)

This parameter is no longer shown in the graphic display, but is still in the expert

list.

Figure 3-5: CU240E

The following setting should be made in order to implement a wire break

monitoring function in the CU240E:

– p756 1 (for 2-10V) or 3 (for 4-20mA) and

– p761 0

If, using this function in the CU240E, the analog values around 0V are

suppressed, then this function can only be implemented by using FFBs (free

function blocks). We are presently working on an integrated solution.

3.4.3 Simulation of the analog inputs (NEW)

Now, the analog inputs can be simulated for test purposes using the STARTER

parameterizing software.

Figure 3-6

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 13

4 Communication

4 Communication

Existing programs to control a SINAMICS G120 with CU240E from a PLC, in most

cases can still be used for the CU240E-2. For example, if parameters are accessed

via cyclic or non-cyclic communication, then the only change that is required is as a

result of the modified parameter numbers.

4.1 GSD files

The new GSD files are available for the CU240E-2 family.

NOTE These can be downloaded under the following:

http://support.automation.siemens.com/WW/view/en/23450835

4.2 Dataset routing through a CPU

For routing beyond network limits (e.g. Industrial Ethernet to PROFIBUS) a network

device is needed, which must support routing functionality.

In addition - just as before - “DriveES Basic” is required.

Dataset routing, which is needed for the communication between ES (engineering

system) and SINAMICS G120 (new generation, “-2”), is supported by following

SIMATIC CPUs:

The following CPUs support dataset routing:

ET200S

– IM151-8 PN/DP CPU in conjunction with the DP master module

SIMATIC S7-300

– CPU313C-2 DP from version V3.3

– CPU314C-2 DP from version V3.3

– CPU314C-2 PN/DP from version V3.3

– CPU315-2 DP from version V3.0

– CPU315-2 PN/DP from version V3.1

– CPU317-2 DP from version V3.3

– CPU317-2 PN/DP from version V3.1

– CPU319-3 PN/DP from version V2.7

SIMATIC S7-400 CPUs from version V5.1

WinAC RTX from version 2010, update 1 with CP5603,

CP5613 or CP5623

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 14

4 Communication

Presently, the following systems do not support dataset routing:

SIMATIC S7-1200

WinAC MP

SIMOTION For SINUMERIK 840D sl: Data set routing is only

possible via the X150 PROFINET interface

4.3 Teleservice

4.3.1 Teleservice via a CPU

A CPU is needed, which supports dataset routing (see chapter 4.2). It means the

communication between TS Adapter and CPU is S7 communication, and the

communication between CPU and G120 is standard dataset communication.

Dataset routing into a PROFIBUS network is supported

Figure 4-1

NOTE The TS Adapter and the G120 must be connected via different interfaces of the

CPU.

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 15

4 Communication

Dataset routing into a PROFINET network is not supported

Figure 4-2

4.3.2 Teleservice directly to the fieldbus

With this configuration, the Teleservice Adapter is directly connected to the

fieldbus. In this case not the CPU, but the TS Adapter must support dataset

routing. Presently there is no TS Adapter available supporting dataset routing!

Figure 4-3

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 16

4 Communication

4.4 Slave-to-slave traffic (NEW)

With "Slave-slave communication" - also known as "Data Exchange Broadcast" -

fast data exchange is possible between the drives (slaves) without the master

being directly involved; for instance, to enter the actual value of one drive as

setpoint for the other drive.

NOTE Detailed information is provided in the operating instructions (chapter 6.1.4.4)

http://support.automation.siemens.com/WW/view/en/50815575

4.5 Direct HMI connection

A direct connection between an HMI and a CU240E-2 to read out and change drive

parameters without an intermediate CPU is not supported.

NOTE Drive parameters can be read from the CPU and then transfer them to the HMI.

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 17

5 Local operator control via BOP-2 or IOP

5 Local operator control via BOP-2 or IOP

For the CU240E-2, the BOP used by the CU240E has been replaced by the BOP-2

its successor.

BOP BOP-2

The IOP is also available for user-friendly commissioning supported by wizards.

IOP

5.1 Manual operation with IOP or BOP-2

For the CU240E, manual operation has been realized by changing over the

command datasets.

In the CU240E-2, switchover to manual operation is realized using the manual

button of the IOP/BOP-2. When activating manual operation, the control authority is

taken over by the IOP/BOP-2, the parameterized/active command and setpoint

sources are therefore decoupled.

Manual operation via the IOP/BOP-2 can be inhibited using parameter p806.

This inhibit can be permanent, but can also be selected using a digital input or

a fieldbus signal.

Manual operation via the IOP/BOP-2 permanently active:

This function is not possible. After line supply on, manual operation must be

reactivated at the IOP/BOP-2.

5.2 Status signals of the IOP or BOP-2 operator control

panels

The IOP/BOP-2 operator control panels can no longer be used as BICO sources as

for the CU240E (r19).

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 18

6 Parameterization

6 Parameterization

It is not possible to directly migrate from CU240E projects to CU240E-2 as a result

of the modified parameter structure. The drive must be recommissioned using

BOP-2, IOP or STARTER.

6.1 Changed reference quantities

The reference quantities (p2000..2004) apply in the CU240E-2 as standard for all

datasets. In addition, the reference quantities have been expanded by the

reference temperature (p2006).

In the CU240E-2, the speed setpoint and actual value no longer refer to Hz but to

rpm; this means that it is no longer necessary to convert the required speed into a

frequency.

6.2 Fixed setpoints that can be freely used (NEW)

Fixed setpoints that can be freely used can be defined in p2900 / p2901

(+/-100.00%) and p2930 (+/-100000.00 Nm). In addition, fixed setpoints that are

already defined are available in r2902 [0..14].

6.3 Parameterizing the command and setpoint sources

(NEW)

In the drive, the corresponding macros can be selected via p15 (e.g. during the

quick commissioning), via which the interfaces (command source, setpoint source,

IO interconnection) can be adapted to the corresponding application far faster than

before. However, depending on the STARTER version it is only possible to access

p15 online.

NOTE Details, refer to the operating instructions (chapters 3.4.5)

http://support.automation.siemens.com/WW/view/en/50815575

6.4 Expanding the command / drive datasets

There are now up to 4 command datasets (CDS) and up to 4 drive datasets (DDS)

available in the CU240E-2. Contrary to the CU240E, these must now first be

enabled using parameter p170 (CDS) or p180 (DDS).

6.5 Speed-dependent controller adaptation (NEW)

The Tn and Kp components of the controller can now be adapted as a function of

the speed in the CU240E-2.

NOTE Refer to the parameter manual (function diagram 6050)

http://support.automation.siemens.com/WW/view/en/49946755

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 19

6 Parameterization

6.6 Changed second ramp function

It is no longer possible to use the JOG ramp-function generator to implement a

second ramp function.

NOTE However, when using the dataset changeover (DDS), up to 4 different

parameterizable ramp functions are now available. The dataset changeover can

be implemented in operation via digital inputs or via the fieldbus (for details, refer

to the operating instructions, chapter 7.11).

http://support.automation.siemens.com/WW/view/en/50815575

6.7 U/f characteristic (U/f with programmable

characteristic)

Contrary to the CU240E (3 voltage points and 3 frequency points along a

characteristic), the CU240E-2 has 4 voltage/frequency points, which means that

the characteristic can be more finely parameterized.

NOTE If the additional points are not required, then set points 3 and 4 to the same

value.

6.8 Operating hours counter (NEW)

The actual operating hours can be read out of p650 and a maintenance interval

can be activated in p651. Alarm A1590 is activated after the time in p651 has

expired.

6.9 Changes to the braking chopper

For the CU240E-2, the braking chopper is automatically activated when using a

PM240. The braking chopper must be externally protected against overload.

Connect the thermal sensor of the braking resistor to a DI of the drive and

parameterize this input with the function "[29] External fault".

In addition, the VDCmax controller must be deactivated

(for vector control: p1240 = 0, for U/f: p1280 = 0).

6.10 BF-LED can be deactivated

If a fieldbus is not used, then the BF-LED (bus failure LED) can be deactivated

using parameter p2030 = 0.

NOTE For more detailed information see

http://support.automation.siemens.com/WW/view/en/35230900

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 20

6 Parameterization

6.11 Expansion of the motor holding brake function

The parameterization of the motor holding brake has been expanded. Various

modes are now available, where the brake, as before, can be opened or closed

from the process, but now also permanently or as a function of an external signal.

NOTE For details refer to the operating instructions or the STARTER screen form

http://support.automation.siemens.com/WW/view/en/50815575

NOTE The CU240E-2 does not support the SBC (Safe Brake Control) safety function.

6.12 Changes to the free function blocks (FFBs)

The scope and functions of the free function blocks have been significantly

expanded over the CU240E. As a consequence, it was necessary to shift the

parameter numbers. Presently, the FFBs can only be interconnected via the expert

list.

NOTE For details refer to the list of manual (chapter 2.12)

http://support.automation.siemens.com/WW/view/en/49946755

6.13 Changes to the phase failure monitoring

For the CU240E-2, the phase failure monitoring (CU240E, p291) is always active

and cannot be deactivated.

6.14 Wobbulation generator has been eliminated

The wobbulation generator available in the CU240E is no longer available in the

CU240E-2.

6.15 Positioning down ramp has been eliminated

The positioning down ramp available in the CU240E (parameters p2480..p2488) is

no longer available in the CU240E-2.

NOTE Alternative the implementation using a rapid traverse / crawl switchover based

on FFBs or using a SINAMICS S110 with EPOS (basic positioner) is possible.

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 21

7 Safety functions

7 Safety functions

Contrary to the CU240E, the CU240E-2 has integrated safety functions. The

following table provides an overview of the available safety functions and how they

are controlled.

Drive family SINAMICS G120

Control Unit CU240E-2 CU240E-2 DP CU240E-2 F CU240E-2 DP-F

Firmware basis as from V4.4

Standards:

EN 954-1 Cat. 3

IEC 61508 SIL 2

ISO 13849-1 Pld

Functions:

STO Yes Yes Yes Yes

SS1 No No Yes Yes

SSM No No No Yes

SDI No No Yes Yes

SLS No No Yes Yes

Number of SLS

0 0 1 4

limit values

SBC No No No No

Controlling the safety functions:

F-DI Yes Yes Yes Yes

Number of F-DI up to 1 up to 1 up to 3 up to 3

PROFIsafe No Yes No Yes

F-DI and

Yes

PROFIsafe No Yes No

(only STO via F-DI)

together

F-DI status via

PROFIsafe No No No Yes

(telegram 900):

NOTE Speed sensing using an encoder is not required for the safety functions.

STO is permissible for all applications, where Emergency Stop functionality

is required.

SS1, SLS, SSM and SDI are not permissible for loads that drive the motor –

and loads that are permanently in the generator mode.

The F-DIs are formed by combining 2 standard DIs by making the

appropriate parameter assignment.

NOTE More detailed information on the safety functions is provided in the Safety

Integrated Function Manual; Entry-ID: 50736819

or under following link: https://www.automation.siemens.com/mcms/safety-

integrated/en/machine-safety/drive-technology/safety-

functions/Pages/Default.aspx

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 22

8 Drive fault messages

8 Drive fault messages

The drive fault messages/signals of the CU240E-2 have changed when compared

to the CU240E.

NOTE If the fault texts are to be displayed on an HMI for diagnostic purposes, then the

corresponding fault texts can be downloaded under the following Link:

http://support.automation.siemens.com/WW/view/en/47520881

Changeover SINAMICS CU240E to CU240E-2

Version 1.3, Article ID: 54997738 23

You might also like

- Feed Manual Version 2 3Document40 pagesFeed Manual Version 2 3amelchorNo ratings yet

- WB2500 User ManualDocument84 pagesWB2500 User Manualaurel_c12-1No ratings yet

- Omron DRM21 - W380E107Document293 pagesOmron DRM21 - W380E107sergiofer3239No ratings yet

- 0604JA01EN12 190925 FixDocument1,208 pages0604JA01EN12 190925 Fixjack danialsNo ratings yet

- GFK 1034b Series 90-30 Genius Bus Controller User ManualDocument93 pagesGFK 1034b Series 90-30 Genius Bus Controller User ManualoakalleyNo ratings yet

- G120 Lista de Parametros CU230-2Document668 pagesG120 Lista de Parametros CU230-2Ricky MclaughlinNo ratings yet

- W336 E1 10+CS CJ Series+OperManualDocument829 pagesW336 E1 10+CS CJ Series+OperManualKhoa Nguyen DangNo ratings yet

- Gek 113306CDocument77 pagesGek 113306Cananizisikim100% (1)

- BKSR 3202 R 3210 R 3220Document158 pagesBKSR 3202 R 3210 R 3220Flaviano SaccàNo ratings yet

- Sitrans F M Magflo & Sitrans F C Massflo: Profibus PA Profile 2 Add-On Module For USM II Transmitters FDK:085U0232Document32 pagesSitrans F M Magflo & Sitrans F C Massflo: Profibus PA Profile 2 Add-On Module For USM II Transmitters FDK:085U0232Rodrigo19792016No ratings yet

- Manual Profinet 3HAC031975-001 RevC enDocument72 pagesManual Profinet 3HAC031975-001 RevC enHerminio GómezNo ratings yet

- Service & Support: Migration of MICROMASTER MM440 To SINAMICS G120 (Firmware V4.6)Document43 pagesService & Support: Migration of MICROMASTER MM440 To SINAMICS G120 (Firmware V4.6)Anthony CadilloNo ratings yet

- 2023324-055 A ENG SA CardioSoftDocument118 pages2023324-055 A ENG SA CardioSoftAbdelhakszn SznNo ratings yet

- The H41q and H51q System Families: Programmable SystemsDocument37 pagesThe H41q and H51q System Families: Programmable SystemsObinna Benedict ObiojiNo ratings yet

- LH11 0112 EngDocument782 pagesLH11 0112 Engjarmo401290No ratings yet

- Migration g120 g120-2 enDocument240 pagesMigration g120 g120-2 enAyman Elotaify100% (1)

- W345 E1 5 CJ1 AnalogDocument406 pagesW345 E1 5 CJ1 Analogวรพงษ์ กอชัชวาลNo ratings yet

- PowerFlex Remote I-O Adapter 20 COMM-RDocument122 pagesPowerFlex Remote I-O Adapter 20 COMM-RMario Duarte100% (1)

- 20comm Um004 - en PDocument122 pages20comm Um004 - en PlclsiNo ratings yet

- 3170 MBS User Manual PDFDocument55 pages3170 MBS User Manual PDFnelson contrerasNo ratings yet

- ManualOperacion CompoBusUnits PDFDocument401 pagesManualOperacion CompoBusUnits PDFSergio Eu CaNo ratings yet

- W266 E1 09+CompoBus S+OperManualDocument423 pagesW266 E1 09+CompoBus S+OperManualMiguel_9862No ratings yet

- 900 TC8Document410 pages900 TC8joseNo ratings yet

- 66102EDocument197 pages66102E03sri03No ratings yet

- Technical Communication Omnipcx Enterprise: Date: 13 October 2009Document98 pagesTechnical Communication Omnipcx Enterprise: Date: 13 October 2009locuras34No ratings yet

- TG-0059 - 17 TM4 SUMO HD Ops and Maint GuideDocument62 pagesTG-0059 - 17 TM4 SUMO HD Ops and Maint GuidejalilemadiNo ratings yet

- Fairbanks Fb100Document44 pagesFairbanks Fb100edefrtgNo ratings yet

- Profisafe Su G120CDocument30 pagesProfisafe Su G120CRice CiprianiNo ratings yet

- Modem How To Make OneDocument150 pagesModem How To Make OneAira KrizelleNo ratings yet

- Field Communication Unit: Reference ManualDocument74 pagesField Communication Unit: Reference ManualRobertt StoneNo ratings yet

- peratorls: Downloaded From Manuals Search EngineDocument82 pagesperatorls: Downloaded From Manuals Search EngineLuis Segundo Chuello ChirinosNo ratings yet

- PSM 500Document124 pagesPSM 500clima ahoraNo ratings yet

- Release Notes: DOC-3004-01 Document Revision 07.02.04.02 - B59e9 October 10, 2017Document264 pagesRelease Notes: DOC-3004-01 Document Revision 07.02.04.02 - B59e9 October 10, 2017An AnNo ratings yet

- 9100 BTS Product Description Ed32relDocument67 pages9100 BTS Product Description Ed32relEng Sherif MahmoudNo ratings yet

- 802CIBN0102en PDFDocument142 pages802CIBN0102en PDFTrường Văn NguyễnNo ratings yet

- 20comm Um009 - en PDocument108 pages20comm Um009 - en Pjohnwu_2009No ratings yet

- Manual Modem Datum Psm500Document121 pagesManual Modem Datum Psm500Pablo BarbozaNo ratings yet

- CU240E-2 - Ed2013 PDFDocument820 pagesCU240E-2 - Ed2013 PDFSergio AlbarracinNo ratings yet

- eDXC RTB v4 MDocument115 pageseDXC RTB v4 Mamhtet100% (1)

- W465-E1-05 CS-CJ Ethernet IP Operation ManualDocument464 pagesW465-E1-05 CS-CJ Ethernet IP Operation ManualsisifoefiraNo ratings yet

- Genius IO High Speed Counter User's Manual, GFK-0415EDocument145 pagesGenius IO High Speed Counter User's Manual, GFK-0415EEduardo DiazNo ratings yet

- Fanuc PC FaptDocument198 pagesFanuc PC FaptVincenzo Paternò50% (2)

- CPX FB33Document160 pagesCPX FB33Igor GonçalvesNo ratings yet

- Sinusoidal Commutation With HALL UGDocument34 pagesSinusoidal Commutation With HALL UGVISHNUNo ratings yet

- User Manual: Allen-BradleyDocument152 pagesUser Manual: Allen-BradleykennykufileNo ratings yet

- Apostila CLP Omrom BRDocument671 pagesApostila CLP Omrom BRreinaldopf2011No ratings yet

- 1769 DSI Modbus Comm ModuleDocument204 pages1769 DSI Modbus Comm ModuleThanh BaronNo ratings yet

- Omron CJ - ETN21Document285 pagesOmron CJ - ETN21manmathancellamNo ratings yet

- Tacite: User's GuideDocument128 pagesTacite: User's GuideIra Carolina Bello Patiño100% (1)

- Ig 022 0 en Ewon - Cosy131Document32 pagesIg 022 0 en Ewon - Cosy131handoko pocaNo ratings yet

- Operation Manual: Mimaki Engineering Co., LTDDocument176 pagesOperation Manual: Mimaki Engineering Co., LTDPablo SoberanisNo ratings yet

- Sysmac cs1wscb41v1Document781 pagesSysmac cs1wscb41v1AkhilNo ratings yet

- V062 E1 03 NT31 NT31C Setup ManualDocument299 pagesV062 E1 03 NT31 NT31C Setup ManualAlexander PenadoNo ratings yet

- 13Document59 pages13Hải Nguyễn KhắcNo ratings yet

- 802 Commissioning ManualDocument173 pages802 Commissioning ManualAbhijeet BhagavatulaNo ratings yet

- Deploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideFrom EverandDeploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideRating: 5 out of 5 stars5/5 (2)

- CAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitFrom EverandCAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitNo ratings yet

- Advanced PIC Microcontroller Projects in C: From USB to RTOS with the PIC 18F SeriesFrom EverandAdvanced PIC Microcontroller Projects in C: From USB to RTOS with the PIC 18F SeriesRating: 5 out of 5 stars5/5 (1)

- Triple Play: Building the converged network for IP, VoIP and IPTVFrom EverandTriple Play: Building the converged network for IP, VoIP and IPTVNo ratings yet

- Feed Forward LQR Controller Design for Electro Hydraulic ActuatorDocument17 pagesFeed Forward LQR Controller Design for Electro Hydraulic ActuatorVăn Nghĩa NguyễnNo ratings yet

- Industrial AutomationDocument10 pagesIndustrial AutomationVăn Nghĩa NguyễnNo ratings yet

- 2Tue4B Controlo18 Submission 2Document7 pages2Tue4B Controlo18 Submission 2Văn Nghĩa NguyễnNo ratings yet

- A Systematized Approach To Obtain Dependable Controller Specifications For Hybrid PlantsDocument20 pagesA Systematized Approach To Obtain Dependable Controller Specifications For Hybrid PlantsVăn Nghĩa NguyễnNo ratings yet

- Electro-Hydraulic Servo System'sDocument9 pagesElectro-Hydraulic Servo System'smirza kasimNo ratings yet

- Ying Xin, Yao Yao, Ming Liu and Wenyu ZhangDocument9 pagesYing Xin, Yao Yao, Ming Liu and Wenyu ZhangVăn Nghĩa NguyễnNo ratings yet

- Shaymaa Mahmood MahdiDocument11 pagesShaymaa Mahmood MahdiVăn Nghĩa NguyễnNo ratings yet

- Output Feedback Control of Electro-Hydraulic Asymmetric Cylinder System With Disturbances RejectionDocument21 pagesOutput Feedback Control of Electro-Hydraulic Asymmetric Cylinder System With Disturbances RejectionVăn Nghĩa NguyễnNo ratings yet

- Designing Two-Position Controllers for Pole PlacementDocument28 pagesDesigning Two-Position Controllers for Pole PlacementKhethanNo ratings yet

- 2013 - Kim Et Al. - Disturbance-Observer-Based Position Tracking Controller in The Presence of Biased Sinusoidal Disturbance For ElectroDocument9 pages2013 - Kim Et Al. - Disturbance-Observer-Based Position Tracking Controller in The Presence of Biased Sinusoidal Disturbance For ElectroVăn Nghĩa NguyễnNo ratings yet

- Thuật Toán Điều Khiển1Document23 pagesThuật Toán Điều Khiển1Văn Nghĩa NguyễnNo ratings yet

- Designing Two-Position Controllers for Pole PlacementDocument28 pagesDesigning Two-Position Controllers for Pole PlacementKhethanNo ratings yet

- Thuật Toán Điều Khiển1Document23 pagesThuật Toán Điều Khiển1Văn Nghĩa NguyễnNo ratings yet

- Electrohydraulics Basic Level: Textbook TP 601Document275 pagesElectrohydraulics Basic Level: Textbook TP 601Ali AbasiNo ratings yet

- A Novel Servovalve Pilot Stage Actuated by A PiezoDocument24 pagesA Novel Servovalve Pilot Stage Actuated by A PiezoVăn Nghĩa NguyễnNo ratings yet

- Health Assessment For Hydraulic Servo System Using Manifold Learning Based On EMDDocument12 pagesHealth Assessment For Hydraulic Servo System Using Manifold Learning Based On EMDVăn Nghĩa NguyễnNo ratings yet

- Text 4Document1 pageText 4Văn Nghĩa NguyễnNo ratings yet

- Blank DocumentDocument1 pageBlank DocumentVăn Nghĩa NguyễnNo ratings yet

- Simotics GP SD XP DP Catalogue D 81 1 en 2018 PDFDocument576 pagesSimotics GP SD XP DP Catalogue D 81 1 en 2018 PDFAnonymous wbDrYVBcNo ratings yet

- Biến Tần Simen ManualDocument328 pagesBiến Tần Simen ManualVăn Nghĩa NguyễnNo ratings yet

- Siemenscatalogtonghop Lowvoltagemotor 180804112721Document181 pagesSiemenscatalogtonghop Lowvoltagemotor 180804112721Văn Nghĩa NguyễnNo ratings yet

- Blank DocumentDocument1 pageBlank DocumentVăn Nghĩa NguyễnNo ratings yet

- Implementation of Selective Harmonics Elimination For Single Phase Inverter Using Arduino and Simulink MATLAB ModelDocument8 pagesImplementation of Selective Harmonics Elimination For Single Phase Inverter Using Arduino and Simulink MATLAB Modelالذوادي بن الذيبNo ratings yet

- PV Is Entering The AI Era: Special Edition Developed in Partnership With HuaweiDocument44 pagesPV Is Entering The AI Era: Special Edition Developed in Partnership With Huaweimarcoant2287No ratings yet

- Everything You Need to Know About Rekeying Schlage LocksDocument19 pagesEverything You Need to Know About Rekeying Schlage LocksPKMNo ratings yet

- Project DirectionDocument1 pageProject DirectionAnh NguyễnNo ratings yet

- ADE LAB ManualDocument75 pagesADE LAB ManualNITHIN NNo ratings yet

- Thinking ArchitecturallyDocument68 pagesThinking ArchitecturallyJose RojasNo ratings yet

- 3 - SQUARE D Model 6 Motor Control Center Profibus DPDocument4 pages3 - SQUARE D Model 6 Motor Control Center Profibus DPSalvatierra Rojas MoisesNo ratings yet

- Quad Cortex PDFDocument122 pagesQuad Cortex PDFChiara VichiNo ratings yet

- Most Often Needed: Radio DiagramsDocument241 pagesMost Often Needed: Radio DiagramsMARCELO F. MENEGASSONo ratings yet

- Engine Controls Hybrid System Circuit D2Document1 pageEngine Controls Hybrid System Circuit D2FranciscoNo ratings yet

- The Project: Book by Robert Grossblatt (ISBN 0830631712) - in My Opinion, This Second Book Is Better BecauseDocument12 pagesThe Project: Book by Robert Grossblatt (ISBN 0830631712) - in My Opinion, This Second Book Is Better Becauseبنیاد پرست100% (1)

- Simulation of SOI PIN Diode for Space Radiation DetectionDocument12 pagesSimulation of SOI PIN Diode for Space Radiation Detectionzuraixoz7967No ratings yet

- Project Synopsis on Software Quality AssuranceDocument11 pagesProject Synopsis on Software Quality AssuranceYajnaseni Neelabh0% (1)

- Koden Promotes Intelligent Foundation Work.: WWW - Koden-Electronics - Co.jpDocument2 pagesKoden Promotes Intelligent Foundation Work.: WWW - Koden-Electronics - Co.jpdennis rio perdana100% (1)

- Service Bulletin: PurposeDocument3 pagesService Bulletin: PurposejussmeeeNo ratings yet

- Airline Reservation System Project Report 1Document32 pagesAirline Reservation System Project Report 1Midhun PaynoorNo ratings yet

- List of PartsDocument7 pagesList of Partsmohammad etemad moghadamNo ratings yet

- BRKARC 2001 Cisco ASR1000 Series Routers System Solution Architectures 2013 Orlando 2 Hours PDFDocument115 pagesBRKARC 2001 Cisco ASR1000 Series Routers System Solution Architectures 2013 Orlando 2 Hours PDFSaptarshi BhattacharjeeNo ratings yet

- Naveen Kumar GDocument2 pagesNaveen Kumar GRajeshkumar PothupalepuNo ratings yet

- WWW Codeguru ComDocument5 pagesWWW Codeguru ComSaurab MehraNo ratings yet

- VTOL MQP 2020 SignedDocument116 pagesVTOL MQP 2020 SignedtfNo ratings yet

- Letter of Motivation Information SystemsDocument1 pageLetter of Motivation Information SystemsMd Raihanul Islam100% (5)

- Week 3 L4 (Design Thinking)Document16 pagesWeek 3 L4 (Design Thinking)buy inviteeNo ratings yet

- Fundamentals of Electrostatic Discharge: Part Six - ESD StandardsDocument16 pagesFundamentals of Electrostatic Discharge: Part Six - ESD StandardssandrasuaNo ratings yet

- The F5 SSL Orchestrator and Palo Alto Networks Next-Gen Firewall SolutionDocument39 pagesThe F5 SSL Orchestrator and Palo Alto Networks Next-Gen Firewall Solutionalways_redNo ratings yet

- HEPI CS How To Kill Your Undercarriage-1Document3 pagesHEPI CS How To Kill Your Undercarriage-1Lord Nafaryus100% (1)

- 8000io CutsheetDocument2 pages8000io CutsheetPadmo PadmundonoNo ratings yet

- LR3 (Eu)Document4 pagesLR3 (Eu)Đăng Điệp NguyễnNo ratings yet

- TE Supplier Portal - Certification Upload Stand Alone Application Training - MAR2020Document6 pagesTE Supplier Portal - Certification Upload Stand Alone Application Training - MAR2020Karthick MNo ratings yet

- Piano Suzuki GP-3 Manual 3521451Document100 pagesPiano Suzuki GP-3 Manual 3521451Andreea PanaitNo ratings yet