Professional Documents

Culture Documents

Hydraulics For Fluid Systems and Reactors: - Detailed System Thermal

Uploaded by

totoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulics For Fluid Systems and Reactors: - Detailed System Thermal

Uploaded by

totoCopyright:

Available Formats

RELAP/SCDAPSIM

MODELING • Control system components to build

CONCEPTS powerful control logic and

ADVANCED FLUID SYSTEMS ANALYSIS computations

o Control components can operate on

any time-advanced quantity

• Detailed system thermal including other control variables

hydraulics for fluid systems and o Basic functions available for control

reactors systems

o Multi-dimensional fluid transport § Constant (Yi = S)

o Heat conduction in structures § Addition or Subtraction (Yi = S(Ao +

A1V1 + A2V2 ….)

o Heat conduction, melting (including

§ Multiplication (Yi = S1V1V2)

molten pool natural circulation) in § Division (Yi = S/V1 or S1(V1/V2)

porous materials § Integer Exponentiation (Yi = SV1i)

o Control systems § Real Exponentiation (Yi = SV1r)

• System hydrodynamic solution § Variable Exponentiation (Yi = SV1v)

§ Table lookup

uses engineering transport § Integration

approach § Differentiation

o Two fluid, non-equibrium • Powerful user options

conservation equations – liquid, o Integrated uncertainty analysis

vapor/non-condensable gases o Hydrodynamic loads analysis

o Mass, energy, momentum o Integrated, interactive 3D GUI

o Thermodynamic state for fluids

§ H2O, D2O, Pb-Bi, Li-Pb, molten 1500

1400

salts, oil, non-condensable gases

1300

1200

1100

§ Other fluids easily added as

Temperature (K)

1000

900

needed

800

700

600

o Constitutive relationships for heat, 500

400

mass transfer developed through

300

950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500 1550 1600 1650 1700

Time (s)

international research programs

• System structures can be modeled

with multi-D models

o Slab, cylindrical, spherical structures

o Porous media – used to model 2D

structures, pebble beds

§ Convective heat removal (RELAP5

boundary condition)

§ Chemical reactions

§ Heat conduction

§ Melting with in. nat. circulation

SPECIALIZED REACTOR MODELS AND • BWR control components use 3D

CORRELATIONS models to predict temperature

(r,z), deformation, chemical

• Point and 3D reactor kinetics interactions and melting

• Shroud component include heat

• Fuel and severe accident models conduction, oxidation, and melt

and correlations relocation models

• SCDAP core components used to

define representative assemblies

• Fuel rod components use 2D

models to predict temperature

(r,z), deformation, chemical

interactions and melting

• Fuel rod simulator components

use special electrically-heater

models plus fuel rod model

• Control rod components use 2D

models to predict temperature • Material properties are contained

(r,z), deformation, chemical in an easily modifiable separate

interactions and melting materials library

You might also like

- Petrel Thermal Simulation WorkflowDocument36 pagesPetrel Thermal Simulation WorkflowMuhamad Afiq Rosnan100% (1)

- Vabr000774 en A4Document12 pagesVabr000774 en A4GRUPO MERCANTIL HECSANNo ratings yet

- Solenoid Valves 90barDocument31 pagesSolenoid Valves 90baralessandro silvaNo ratings yet

- A Review of Organic Rankine Cycles (ORC) For The Recovery of Low-Grade Waste HeatDocument7 pagesA Review of Organic Rankine Cycles (ORC) For The Recovery of Low-Grade Waste HeatErdinç KurşunNo ratings yet

- RTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWDocument1 pageRTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWMohamed MohamedNo ratings yet

- Chapter 9: Gas Power Cycles: MAE 3311 - 002 Thermodynamics IIDocument31 pagesChapter 9: Gas Power Cycles: MAE 3311 - 002 Thermodynamics IImamdudurNo ratings yet

- 1 s2.0 S0140700714002102 MainDocument12 pages1 s2.0 S0140700714002102 MainGustavo PiresNo ratings yet

- Underground 66 75 Modern Power Transformers Hitachi ABBDocument10 pagesUnderground 66 75 Modern Power Transformers Hitachi ABBjatin patelNo ratings yet

- MECH 432 Lab - Thermoelectric Cooler Laboratory GoalsDocument4 pagesMECH 432 Lab - Thermoelectric Cooler Laboratory GoalsDavid AlexanderNo ratings yet

- Slides 16935695789455034964f1d22a61d19Document11 pagesSlides 16935695789455034964f1d22a61d19Tilakraj BaghelNo ratings yet

- Engineering of Superalloys: Jane BlackfordDocument20 pagesEngineering of Superalloys: Jane BlackfordCaio Fazzioli TavaresNo ratings yet

- Module 03: Setting Up Physics: ANSYS Fluent Getting Started - Part 1Document15 pagesModule 03: Setting Up Physics: ANSYS Fluent Getting Started - Part 1ReytingNo ratings yet

- Hydrogen As Energy StorageDocument23 pagesHydrogen As Energy StorageNadia Iskandar100% (1)

- Ebullated Bed Reactor Modeling For Residue Conversion PDFDocument9 pagesEbullated Bed Reactor Modeling For Residue Conversion PDFMohmmed Abdullah Sanam100% (1)

- Dowtherm T PdsDocument2 pagesDowtherm T PdsÖmer LaçinNo ratings yet

- Extracting of Silicon Carbide Schottky Diode Model Parameters Using Lateral Optimization Method Including The Parallel ConductanceDocument5 pagesExtracting of Silicon Carbide Schottky Diode Model Parameters Using Lateral Optimization Method Including The Parallel ConductanceKrishna KumarNo ratings yet

- Specification Sheet: Alloy 400/400AR: (UNS N04400) / W.Nr. 2.4360 and 2.4361Document2 pagesSpecification Sheet: Alloy 400/400AR: (UNS N04400) / W.Nr. 2.4360 and 2.4361iqbal haiderNo ratings yet

- Process Heat TransferDocument16 pagesProcess Heat TransferDanish ShakeelNo ratings yet

- Forward Osmosis Energy Use: Comparisons To RO, MSF, MEDDocument25 pagesForward Osmosis Energy Use: Comparisons To RO, MSF, MEDHayehoyehuNo ratings yet

- Mec681:Materials For Engineering Applications: Review of Material Science and EngineeringDocument92 pagesMec681:Materials For Engineering Applications: Review of Material Science and Engineeringمحمد فائزNo ratings yet

- Mechanical Actuators: Dr. Bruce K. Gale Fundamentals of MicromachiningDocument8 pagesMechanical Actuators: Dr. Bruce K. Gale Fundamentals of MicromachiningChidananda BasavannaNo ratings yet

- 1 s2.0 S111001681200004X MainDocument8 pages1 s2.0 S111001681200004X MainSaiful IslamNo ratings yet

- Binder 1Document7 pagesBinder 1izudin.dNo ratings yet

- Heat Transfer Analysis of Automotive Radiator by Using Nano FluidsDocument20 pagesHeat Transfer Analysis of Automotive Radiator by Using Nano FluidssivaenotesNo ratings yet

- Kalina Cycle - Wikipedia, The Free EncyclopediaDocument3 pagesKalina Cycle - Wikipedia, The Free Encyclopediawilliam4132No ratings yet

- Thermal Energy StorageDocument10 pagesThermal Energy Storagesurendra ratreNo ratings yet

- Applied Energy: SciencedirectDocument26 pagesApplied Energy: SciencedirectLéo SilvaNo ratings yet

- Welding and FabricationDocument54 pagesWelding and FabricationSungJun Park100% (1)

- Plrcapbv1a102 KVDocument8 pagesPlrcapbv1a102 KVamruta21No ratings yet

- Der 331 PDFDocument5 pagesDer 331 PDFTamer BidakNo ratings yet

- Peper AguirreDocument11 pagesPeper AguirreJosé Miguel MartínezNo ratings yet

- Applied Energy: Su Guo, Deyou Liu, Xingying Chen, Yinghao Chu, Chang Xu, Qunming Liu, Ling ZhouDocument15 pagesApplied Energy: Su Guo, Deyou Liu, Xingying Chen, Yinghao Chu, Chang Xu, Qunming Liu, Ling ZhouHafiz Ghulam NabiNo ratings yet

- Rheem PROE50 T2 RH95Document2 pagesRheem PROE50 T2 RH95Lovan SoNo ratings yet

- Epoxy 128Document5 pagesEpoxy 128Hesham MostafaNo ratings yet

- Synopsis PPT 1Document41 pagesSynopsis PPT 1api-423757765No ratings yet

- Data Sheet HFE-7000 Prod SpecDocument6 pagesData Sheet HFE-7000 Prod Specsshaffer_9No ratings yet

- Technical Brochure: High Pressure Multi-Stage PumpsDocument32 pagesTechnical Brochure: High Pressure Multi-Stage PumpsNicolás González GuerreroNo ratings yet

- Hydrogen Fuel Cells in Aviation IndustryDocument17 pagesHydrogen Fuel Cells in Aviation IndustrySonu GopanNo ratings yet

- WELLCAT Data Sheet 3 4Document2 pagesWELLCAT Data Sheet 3 4Andres SilveyraNo ratings yet

- Paper 9.5 - H DingDocument22 pagesPaper 9.5 - H Dingmarg1972No ratings yet

- 1 s2.0 S0009250921000853 MainDocument13 pages1 s2.0 S0009250921000853 MainGanjar GilaNo ratings yet

- Heat Transfer To Supercritical Pressure Carbon Dioxide Flowing Upward Through Tubes and A Narrow Annulus PassageDocument8 pagesHeat Transfer To Supercritical Pressure Carbon Dioxide Flowing Upward Through Tubes and A Narrow Annulus PassageJean AbelaNo ratings yet

- Diagramas de Entropia para Misturas de Amônia-Água Aplicações A Sistemas de Refrigeração Por AbsorçãoDocument13 pagesDiagramas de Entropia para Misturas de Amônia-Água Aplicações A Sistemas de Refrigeração Por AbsorçãoAlessandro G. MattosNo ratings yet

- 3 Geophysical MethodsDocument45 pages3 Geophysical MethodsFernando TerezonNo ratings yet

- The Relative Performance of Spur Gears Manufactured From Steel and PEEKDocument9 pagesThe Relative Performance of Spur Gears Manufactured From Steel and PEEKMohan MurthyNo ratings yet

- Alloy 330 Spec SheetDocument2 pagesAlloy 330 Spec SheetArman MominNo ratings yet

- Carrier - HAP Flyer Aug10Document2 pagesCarrier - HAP Flyer Aug10Alvaajid SaleemNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Modelling Heat Transfer Efficiency in Forced Convection Reflow OvensDocument6 pagesModelling Heat Transfer Efficiency in Forced Convection Reflow OvensAndersonNo ratings yet

- Self Lu RankenDocument42 pagesSelf Lu RankenIvanNo ratings yet

- Howard PresentationDocument15 pagesHoward PresentationAmir RostamiNo ratings yet

- Cat 4607 enDocument20 pagesCat 4607 enluisNo ratings yet

- Typical Uses:: Design Analysis TrainingDocument2 pagesTypical Uses:: Design Analysis TrainingSrashmiNo ratings yet

- Technical Data Sheet Linen PhenolicDocument1 pageTechnical Data Sheet Linen PhenolicKissa DolautaNo ratings yet

- Sundyne LMV BMP 311 Centrifugal Pump Data SheetDocument2 pagesSundyne LMV BMP 311 Centrifugal Pump Data Sheetmasoud67aNo ratings yet

- Barracuda Solution VRDocument2 pagesBarracuda Solution VRPayal MinochaNo ratings yet

- Brochure ERKDocument19 pagesBrochure ERKAri BinukoNo ratings yet

- Anaesth Pain Intensive Care 2016 20 Supp 91 96Document6 pagesAnaesth Pain Intensive Care 2016 20 Supp 91 96totoNo ratings yet

- LM Guide Separate Type (Radial) Model GSRDocument8 pagesLM Guide Separate Type (Radial) Model GSRtotoNo ratings yet

- Vaccinations Given With The FIADocument2 pagesVaccinations Given With The FIAtotoNo ratings yet

- Emily M.S. Houh University of Cincinnati College of LawDocument6 pagesEmily M.S. Houh University of Cincinnati College of LawtotoNo ratings yet

- TMHM 6 478Document4 pagesTMHM 6 478totoNo ratings yet

- GRAPE Activation GuideDocument7 pagesGRAPE Activation GuidetotoNo ratings yet

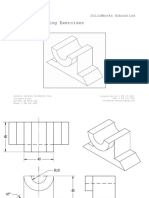

- Detailed Drawing Exercises: Solidworks EducationDocument51 pagesDetailed Drawing Exercises: Solidworks EducationtotoNo ratings yet

- GRAPE User's GuideDocument114 pagesGRAPE User's GuidetotoNo ratings yet

- Tutorial To Run CalculationsDocument14 pagesTutorial To Run CalculationstotoNo ratings yet

- GRAPE Activation GuideDocument7 pagesGRAPE Activation GuidetotoNo ratings yet

- Relap5/Mod3.3 Code Manual Summaries and Reviews of Independent Code Assessment ReportsDocument152 pagesRelap5/Mod3.3 Code Manual Summaries and Reviews of Independent Code Assessment ReportstotoNo ratings yet

- ISS Input Deck Manual 021213Document285 pagesISS Input Deck Manual 021213totoNo ratings yet

- Imece2002-320 22Document6 pagesImece2002-320 22totoNo ratings yet

- Fdocuments - in Design Gantry Crane CalculationsDocument6 pagesFdocuments - in Design Gantry Crane CalculationstotoNo ratings yet

- Dry Compressing Vacuum PumpsDocument62 pagesDry Compressing Vacuum PumpsAnonymous zwSP5gvNo ratings yet

- Studies On Drying Kinetics of Solids in A Rotary DryerDocument6 pagesStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNo ratings yet

- Contemporary Strategic ManagementDocument2 pagesContemporary Strategic ManagementZee Dee100% (1)

- Lacey Robertson Resume 3-6-20Document1 pageLacey Robertson Resume 3-6-20api-410771996No ratings yet

- Ateneo de Manila University: Submitted byDocument5 pagesAteneo de Manila University: Submitted byCuster CoNo ratings yet

- Simon Ardhi Yudanto UpdateDocument3 pagesSimon Ardhi Yudanto UpdateojksunarmanNo ratings yet

- Grade 8 Science - Second GradingDocument5 pagesGrade 8 Science - Second GradingMykelCañete0% (1)

- Iguard® LM SeriesDocument82 pagesIguard® LM SeriesImran ShahidNo ratings yet

- The Rise of Australian NovelDocument412 pagesThe Rise of Australian NovelSampath Kumar GummadiNo ratings yet

- Worst of Autocall Certificate With Memory EffectDocument1 pageWorst of Autocall Certificate With Memory Effectapi-25889552No ratings yet

- Safety Data Sheet SDS For CB-G PG Precision Grout and CB-G MG Multipurpose Grout Documentation ASSET DOC APPROVAL 0536Document4 pagesSafety Data Sheet SDS For CB-G PG Precision Grout and CB-G MG Multipurpose Grout Documentation ASSET DOC APPROVAL 0536BanyuNo ratings yet

- 444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16Document1 page444323735-Chem-Matters-Workbook-2E-Teacher-s-Edn-pdf 16-16whatisNo ratings yet

- Pioneer 1019ah-K Repair ManualDocument162 pagesPioneer 1019ah-K Repair ManualjekNo ratings yet

- 3D Printing & Embedded ElectronicsDocument7 pages3D Printing & Embedded ElectronicsSantiago PatitucciNo ratings yet

- (Sat) - 072023Document7 pages(Sat) - 072023DhananjayPatelNo ratings yet

- BiografijaDocument36 pagesBiografijaStjepan ŠkalicNo ratings yet

- Theorising Mobility Justice-Mimi ShellerDocument18 pagesTheorising Mobility Justice-Mimi Shellerjllorca1288No ratings yet

- BBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)Document2 pagesBBL PR Centralizer Rig Crew Handout (R1.1 2-20-19)NinaNo ratings yet

- Vitamins - CyanocobalaminDocument12 pagesVitamins - CyanocobalaminK PrashasthaNo ratings yet

- State Space ModelsDocument19 pagesState Space Modelswat2013rahulNo ratings yet

- CBC Heo (Wheel Loader) NC IIDocument58 pagesCBC Heo (Wheel Loader) NC IIJohn JamesNo ratings yet

- PDFDocument27 pagesPDFER Saurabh KatariyaNo ratings yet

- Enlightened ExperimentationDocument8 pagesEnlightened ExperimentationRaeed HassanNo ratings yet

- CHARACTER FORMATION 1 PrelimDocument15 pagesCHARACTER FORMATION 1 PrelimAiza Minalabag100% (1)

- Maths Formulas For IGCSEDocument2 pagesMaths Formulas For IGCSEHikma100% (1)

- D25KS Sanvick PDFDocument4 pagesD25KS Sanvick PDFJiménez Manuel100% (1)

- Toolbox TalkDocument14 pagesToolbox Talkcall_mustafas2361No ratings yet

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocument30 pagesThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanNo ratings yet

- Federalist Papers 10 51 ExcerptsDocument2 pagesFederalist Papers 10 51 Excerptsapi-292351355No ratings yet

- Data MiningDocument28 pagesData MiningGURUPADA PATINo ratings yet