Professional Documents

Culture Documents

Cracks in Concrete

Uploaded by

Ahmed Daahir AdenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cracks in Concrete

Uploaded by

Ahmed Daahir AdenCopyright:

Available Formats

Cracks in concrete

The cracking phenomenon

When placed concrete typically contains more water than is required for hydration of the cement.

As the concrete hardens and starts to lose the excess water, shrinkage begins. If the concrete is

unrestrained, no cracks will develop. But it is virtually impossible to support a structure of any

appreciable size without some restraint.

The cracking phenomenon is complex and depends upon a number of things; rate and amount of

drying, drying shrinkage, tensile strength, tensile strain, creep, elasticity, degree of restraint, and

other factors.

While most types of cracking do not affect structural stability or durability, all cracks are unsightly

and in extreme cases cracking can reduce the use and serviceability of the structure. For this

reason, cracking should be kept to a minimum.

In the laboratory, drying shrinkage tests are the most easily and most frequently performed tests in

relation to shrinkage/cracking problems. However, there is sometimes too much emphasis on the

drying shrinkage of hardened concrete as the criterion of susceptibility to cracking.

Drying shrinkage alone is influenced by many factors - water/cement ratio; amount, fineness and

composition of cement; mineral composition, stiffness, shape, surface texture, and grading of the

aggregate; characteristics and amount of any admixture; size and shape of the concrete mass;

and conditions of humidity and temperature.

Preventative measures at the time of placing and curing remain the best means of minimizing

cracking.

Some Types and Causes

In most cases where cracks appear in concrete the crack can be identified and the cause of

cracking established. An extensive survey carried out revealed that concrete cracking can be

attributed to the following:

• construction and supervision problems - approx. 36%

• design defects approx. 27%

• ambient conditions (temperature, humidity, etc.) - approx. 21%

• quality of materials - approx 17%

In addition all cracks can be grouped into two broad categories:

• cracks occurring before and during hardening

• cracks occurring after hardening of concrete

Recognising Cracks

1. Shrinkage cracks avoid by cutting contraction joints along dotted lines

2. Shrinkage cracks caused by stress concentration at corners - prevent by placing expansion joint

along dotted line, or by using reinforcing steel

3. Settlement cracks caused by movement of sub-grade or footings

4. Cracks due to heaving under the slab through poor drainage of sub-grade

5. Expansion cracks prevent by placing expansion joints at dotted lines

6. Shrinkage cracks in feathered sections. Narrow feathered sections should be avoided

7. Plastic shrinkage cracks, due to quick loss of water to dry sub-grade or to the atmosphere

8. Shrinkage cracks at door or window corners avoid by use of reinforcing steel or (in solid concrete

walls) by careful placement of low-slump concrete

Inside Outside

Cracks before and during hardening

Plastic shrinkage cracks occur when wind velocity,

low relative humidity, high ambient temperature, or

a combination of all three, cause water to evaporate

from a concrete surface faster than it can be replaced

by bleeding to the surface. The rapid evaporation

which causes this cracking can be checked by

windbreaks, shading and surface treatments.

Vertical cracks may be caused by the settlement of

concrete around reinforcing bars. Such cracks occur

when the concrete near the surface takes a partial set

while the rest of the concrete is still able to settle. Typical three-branch plastic shrinkage

Cracking of this type can be identified by a pattern crack, caused by too rapid loss of water

which follows reinforcement. Thus cracks can often soon after concrete has been finished

be prevented by revibration of concrete. Slopping

cracks sometimes appear when coarse aggregate

particles near the surface form a skeleton in which

cement paste can settle and separate. Once again,

vibration and revibration will reduce or prevent

cracking.

Relatively small movements of formwork in the

early stages of hardening will cause cracks. Swelling

or bulging of timber, springing of nails, clumsy or

excessive use of vibrators are the common causes of When concrete settles over obstructions

form movement resulting in irregular cracks. Such as reinforcing bars, cracks may

appear along the surface above the

Wide cracks, sometimes extending through the slab, obstruction. Avoid this by using low-slump

occur when sub-grade subsides before concrete has concrete and vibrating well throughout the

developed strength. This may occur because the sub- depth of formwork

grade is not level and well compacted, or is muddy,

or is unstable for any other reason.

Slight bulging or shifting of forms may

Cause cracking. Usually the concrete

Surface will be slightly distorted if form

has moved

Uneven sub-grade, or rupture of any covering over

Subgrade may allow concrete to shift while setting.

Deep cracks usually result.

Cracks after hardening

This category covers the performance of concrete whose shape can no longer be altered without

damage It includes cracks caused by drying shrinkage, as well as those which result from the

temperature movements which take place in all materials exposed to the elements. Unless the

structure concerned permits movements of its members without development of excessive

stresses, extensive cracking often may occur. Crazing cracks after hardening can result from

excessive floating which tends to draw water and cement to the surface, which then comprises

weak concrete subject to high shrinkage stresses. More often, they result from poor curing. Other

cracks which occur after hardening can be caused by lack of adequate reinforcement at corners,

insufficient depth of concrete over bends in reinforcement, nesting of reinforcing steel in concrete,

lack of expansion and contraction joints.

Slots and joints

Shrinkage cracks cannot always be prevented,

but they can be controlled by making planes of

weaknesses to establish the direction of

cracking when contraction occurs. This is done

by cutting slots one third the thickness of the

slabs, and is done as soon as the concrete is

hard enough to resist damage by the saw.

Cracking, if it occurs, will then occur neatly

beneath the line of the slot. (If the cutting is

left much later than the point of time

mentioned, surface cracks may suddenly Construction joints cut one-third the dept of

appear, veering off in the line of sawing.) The slab permit free contraction and help

establish direction of any cracking

The contraction should be cut at logical points

of stress in paths, at ½ to 2 metre intervals

(lightweight paths can be scored with a double

edger); in driveways or large floors, at 5 to 7

metre intervals. Where the floor is divided into

bays by columns, the joints may be placed

from column to column for better appearance

(see illustration). However, they should not be

more than 7 metres apart unless slabs contain

substantial steel reinforcement. Expansion

joints, or isolation joints, usually consist of

pre-moulded tar material 10mm thick, as deep

as the slab, and as long as the slab. They

should be placed where paths of driveways A standard method of positioning

meet, and where slabs meet a column base, contraction and expansion joints in a floor

wall, or any other mass which will resist divided into bays by columns

expansion in that direction (see illustration).

Summary

The majority of cracks occur within 2-3 days after concrete has been placed. These are preventive

measures which will minimise cracking in that period:

• see that sub-grade is well-compacted

• check that form work is firm

• ensure that sub-grade and form work are moist before pouring

• do not add water to ready-mixed concrete in placing

• compact low-slump mixes well

• cut sufficient contraction joints to allow for shrinkage

• provide expansion joints where necessary

• start curing as soon as possible

• maintain proper curing for an adequate period.

By the use of the procedures in this publication and by exercising proper care you will obtain the

best performance from your READYMIX concrete. READYMIX concrete, READYMIX

laboratories have trained technical staff who are available

to answer any technical enquiries you may have and assist in designing concrete mixes

and conduct trial mixes specifically for your needs.

You might also like

- Cracks in Building mmbc8Document35 pagesCracks in Building mmbc8Anjali ShahNo ratings yet

- Defects in Concrete Monday, 18 November 2019: Title: DateDocument49 pagesDefects in Concrete Monday, 18 November 2019: Title: DateKrishnan SubraNo ratings yet

- Enggao AllDocument8 pagesEnggao AllAngeLo Ryan AmparoNo ratings yet

- Iraq University College: What Type of Crack Happens in The BeamDocument9 pagesIraq University College: What Type of Crack Happens in The Beamعبدالهادي كاظم معله الخفاجيNo ratings yet

- Rrs Cracks in Concrete & Their PreventionDocument22 pagesRrs Cracks in Concrete & Their PreventionJaswant SharmaNo ratings yet

- Causes of Cracks in Portland Cement Concrete PavementDocument6 pagesCauses of Cracks in Portland Cement Concrete PavementJahara GarciaNo ratings yet

- Types of Defects in RCC During and After ConstructionDocument10 pagesTypes of Defects in RCC During and After Constructionanon_831233388No ratings yet

- Draft Recommendation For Damage ClassificationDocument8 pagesDraft Recommendation For Damage ClassificationThanongsak ImjaiNo ratings yet

- l3 - Defects in ConcreteDocument33 pagesl3 - Defects in ConcreteWajira Sanjaya PereraNo ratings yet

- Unit - Iii Distress Measurement & ControlDocument23 pagesUnit - Iii Distress Measurement & ControlramNo ratings yet

- Curling of Concrete Slabs On GradeDocument6 pagesCurling of Concrete Slabs On GradeBennet Kuriakose100% (1)

- CIP 6 Joints in Concrete Slaabs On Grade PDFDocument2 pagesCIP 6 Joints in Concrete Slaabs On Grade PDFAli ParvezNo ratings yet

- Joints in Concrete SlabsDocument2 pagesJoints in Concrete SlabsmutyokaNo ratings yet

- Thermal Expansion and Contraction of ConcreteDocument6 pagesThermal Expansion and Contraction of Concretexjsddjwef100% (1)

- Errors in The Construction Site and How To Avoid ThemDocument6 pagesErrors in The Construction Site and How To Avoid ThemAriana CabellonNo ratings yet

- Construction Defects in ConcreteDocument13 pagesConstruction Defects in ConcreteManish KumarNo ratings yet

- Cracks: Types of Cracks Repairing TechniquesDocument13 pagesCracks: Types of Cracks Repairing TechniquesAli Zain Ul AbadeenNo ratings yet

- Self Healing Concrete PDFDocument26 pagesSelf Healing Concrete PDFthirumal100% (2)

- CrackingDocument2 pagesCrackingdeinaNo ratings yet

- Summary On Causes of Cracks and RecommendationDocument2 pagesSummary On Causes of Cracks and RecommendationBonzibit Zibit0% (1)

- 2.2 Concrete FailureDocument64 pages2.2 Concrete Failuremuhammad harrisNo ratings yet

- Time Dependent Deformation 1Document8 pagesTime Dependent Deformation 1Neil Myco Duterte SarsalejoNo ratings yet

- CIP 4 - How to Prevent Concrete CrackingDocument2 pagesCIP 4 - How to Prevent Concrete CrackingKhaleelNo ratings yet

- Finishing & Curing of Concrete: MethodsDocument28 pagesFinishing & Curing of Concrete: MethodsNishith SinghNo ratings yet

- Concrete Characteristics and BehaviorDocument3 pagesConcrete Characteristics and BehaviorJaymark ParbaNo ratings yet

- Dam Concrete Problems Detection DeteriorationDocument2 pagesDam Concrete Problems Detection DeteriorationManish WaniNo ratings yet

- CIP 6 - Controlling Concrete Cracks with JointsDocument2 pagesCIP 6 - Controlling Concrete Cracks with JointsBalaji_Rajaman_2280No ratings yet

- Civil Equaltion PDFDocument2 pagesCivil Equaltion PDFBalaji_Rajaman_2280No ratings yet

- Types of Joints in Concrete Construction PDFDocument5 pagesTypes of Joints in Concrete Construction PDFEarl AradoNo ratings yet

- Concrete Slab On Grade (Ground)Document24 pagesConcrete Slab On Grade (Ground)arman_zaman100% (6)

- Construction Joints:: Expansion JointDocument5 pagesConstruction Joints:: Expansion JointSathya MurthyNo ratings yet

- Types of cracks in concrete and their causesDocument2 pagesTypes of cracks in concrete and their causesdhan singhNo ratings yet

- Crack Control - ECS PDFDocument8 pagesCrack Control - ECS PDFTaraknath PalNo ratings yet

- Presented By:-Gautam SwalaDocument30 pagesPresented By:-Gautam SwalaChandrabhan Singh YadavNo ratings yet

- How To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Document10 pagesHow To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Cimpureanu FlorinNo ratings yet

- Cracking Joint No RestrictionDocument2 pagesCracking Joint No RestrictionThanh Khiet UngNo ratings yet

- Minimizing Reflective Cracking in Cement-Stabilized Pavement BasesDocument10 pagesMinimizing Reflective Cracking in Cement-Stabilized Pavement BasesSreten ObrenovicNo ratings yet

- Cracking Concrete SurfacesDocument2 pagesCracking Concrete SurfacesCivilEngClubNo ratings yet

- Case Study - Lester Lazo (MSCE-SE)Document7 pagesCase Study - Lester Lazo (MSCE-SE)Lester LazoNo ratings yet

- CAUSES AND PREVENTION OF CRACKS IN BUILDINGSDocument35 pagesCAUSES AND PREVENTION OF CRACKS IN BUILDINGSharNo ratings yet

- Report On Cracks in BuildingsDocument16 pagesReport On Cracks in BuildingsJatin George86% (7)

- Method ConstructionDocument5 pagesMethod ConstructionNurzulaikha SalimNo ratings yet

- Slab Surface Prevention RepairDocument16 pagesSlab Surface Prevention Repairambryx2001No ratings yet

- Early Cracking of Concrete PavementDocument25 pagesEarly Cracking of Concrete PavementRajesh KhadkaNo ratings yet

- Concrete JointsDocument15 pagesConcrete JointsJay Ann EmanNo ratings yet

- Alligator CrackingDocument4 pagesAlligator Crackingmit patelNo ratings yet

- CIP 3 - Crazing Concrete SurfacesDocument2 pagesCIP 3 - Crazing Concrete SurfacesHyunkyoun JinNo ratings yet

- Types of CracksDocument3 pagesTypes of CracksShativel ViswanathanNo ratings yet

- CIP03-Crazing Concrete SurfacesDocument2 pagesCIP03-Crazing Concrete Surfaces7774R105No ratings yet

- Cracking of Concrete DetailsDocument8 pagesCracking of Concrete DetailsMirosha NavaratnaNo ratings yet

- Concrete Joint Types at KIST Building & Civil DeptDocument5 pagesConcrete Joint Types at KIST Building & Civil DeptDenzel OwuorNo ratings yet

- Non Structural Crack: Concrete Technology 2Document29 pagesNon Structural Crack: Concrete Technology 2محمد عليNo ratings yet

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcFrom EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcRating: 5 out of 5 stars5/5 (1)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

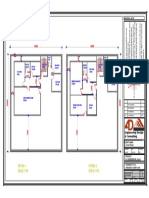

- D C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Document1 pageD C B A D C B A: Ground Floor Plan SCALE 1:100 1 3 Architectural Floor Plan SCALE 1:100Ahmed Daahir AdenNo ratings yet

- Concrete batch procedureDocument13 pagesConcrete batch procedureAhmed Daahir AdenNo ratings yet

- Tribhuvan University Institute of Engineering Himalaya College of EngineeringDocument124 pagesTribhuvan University Institute of Engineering Himalaya College of EngineeringMukoma100% (2)

- ACI Method of Mix DesignDocument11 pagesACI Method of Mix DesignCivilax.comNo ratings yet

- Math105 solnChap12PracticeExam Sp2010 PDFDocument16 pagesMath105 solnChap12PracticeExam Sp2010 PDFHector BanquezNo ratings yet

- TVET Somalia Construction Engineer VacancyDocument2 pagesTVET Somalia Construction Engineer VacancyAhmed Daahir AdenNo ratings yet

- 09 Chapter4-2Document7 pages09 Chapter4-2Ahmed Daahir AdenNo ratings yet

- EC2 Detailing of Slabs, Beams, Columns and FootingsDocument50 pagesEC2 Detailing of Slabs, Beams, Columns and FootingsArtjom SamsonovNo ratings yet

- TVET Somalia Construction Engineer VacancyDocument2 pagesTVET Somalia Construction Engineer VacancyAhmed Daahir AdenNo ratings yet

- Concrete Construction Article PDF Strategic Planning For ContractorsDocument4 pagesConcrete Construction Article PDF Strategic Planning For ContractorsMohammed NizamNo ratings yet

- Plumbing Design for Surabaya ApartmentDocument12 pagesPlumbing Design for Surabaya ApartmentAhmed Daahir AdenNo ratings yet

- Strategic Planning Practices of Contractor Firms in Turkey: Pinar Irlayici Cakmak, Elcin TasDocument7 pagesStrategic Planning Practices of Contractor Firms in Turkey: Pinar Irlayici Cakmak, Elcin TasAhmed Daahir AdenNo ratings yet

- A B C D: Rooftop/Terrace SCALE 1:100Document1 pageA B C D: Rooftop/Terrace SCALE 1:100Ahmed Daahir AdenNo ratings yet

- Finding The Equation of A Tangent LineDocument3 pagesFinding The Equation of A Tangent LineTony DomanicoNo ratings yet

- 01Document125 pages01Ahmed Daahir AdenNo ratings yet

- Strategic Planning Practices of Contractor Firms in Turkey: Pinar Irlayici Cakmak, Elcin TasDocument7 pagesStrategic Planning Practices of Contractor Firms in Turkey: Pinar Irlayici Cakmak, Elcin TasAhmed Daahir AdenNo ratings yet

- Finding The Equation of A Tangent LineDocument3 pagesFinding The Equation of A Tangent LineTony DomanicoNo ratings yet

- Summaryof Projects Progress ReportDocument8 pagesSummaryof Projects Progress ReportAhmed Daahir AdenNo ratings yet

- Construction Kickoff Meeting AgendaDocument2 pagesConstruction Kickoff Meeting AgendaAhmed Daahir AdenNo ratings yet

- BCM 1806.1 A1 - Design of Basement and Site Retaining Walls 05-13-09Document5 pagesBCM 1806.1 A1 - Design of Basement and Site Retaining Walls 05-13-09Ahmed Daahir AdenNo ratings yet

- Lecture 3 Bending and Shear in Beams PHG A8 2oct16Document30 pagesLecture 3 Bending and Shear in Beams PHG A8 2oct16HarithSilvaNo ratings yet

- Concrete BasementsDocument184 pagesConcrete BasementsAnonymous N74ok75100% (1)

- Hanson Uk Cracked ConcreteDocument1 pageHanson Uk Cracked ConcreteAhmed Daahir AdenNo ratings yet

- Concrete - Designing Concrete Basement Walls PDFDocument7 pagesConcrete - Designing Concrete Basement Walls PDFindrajit sodhaNo ratings yet

- WS CalculationDocument29 pagesWS CalculationMac ShaikNo ratings yet

- O'Boyle - Business Proposal For JPO Real Estate, LLC - 2010 - StaigerDocument30 pagesO'Boyle - Business Proposal For JPO Real Estate, LLC - 2010 - StaigerRyan WijayaNo ratings yet

- Water CalculationDocument38 pagesWater CalculationNghia100% (2)

- Complete RCC Design Very ImportantDocument41 pagesComplete RCC Design Very ImportantAmal PremachandranNo ratings yet

- Ismacil Salad-S01 PDFDocument1 pageIsmacil Salad-S01 PDFAhmed Daahir AdenNo ratings yet

- Interna Medicine RheumatologyDocument15 pagesInterna Medicine RheumatologyHidayah13No ratings yet

- Shimano Brakes ManualDocument36 pagesShimano Brakes ManualKon Arva100% (1)

- UT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)Document3 pagesUT Dallas Syllabus For Ee3311.002.07f Taught by Gil Lee (Gslee)UT Dallas Provost's Technology GroupNo ratings yet

- Euro4 vehicle diesel engines 199 - 397 kW (270 - 540 hpDocument6 pagesEuro4 vehicle diesel engines 199 - 397 kW (270 - 540 hpBranislava Savic63% (16)

- SIM5320 - EVB Kit - User Guide - V1.01 PDFDocument24 pagesSIM5320 - EVB Kit - User Guide - V1.01 PDFmarkissmuzzoNo ratings yet

- Hastrof Si Cantril. 1954. The Saw A Game. A Case StudyDocument6 pagesHastrof Si Cantril. 1954. The Saw A Game. A Case Studylandreea21No ratings yet

- MVJUSTINIANI - BAFACR16 - INTERIM ASSESSMENT 1 - 3T - AY2022 23 With Answer KeysDocument4 pagesMVJUSTINIANI - BAFACR16 - INTERIM ASSESSMENT 1 - 3T - AY2022 23 With Answer KeysDe Gala ShailynNo ratings yet

- Rakpoxy 150 HB PrimerDocument1 pageRakpoxy 150 HB Primernate anantathatNo ratings yet

- Types of LogoDocument3 pagesTypes of Logomark anthony ordonioNo ratings yet

- Grade 10Document39 pagesGrade 10amareNo ratings yet

- 153C Final Exam Study Guide-2Document6 pages153C Final Exam Study Guide-2Soji AdimulaNo ratings yet

- Compare and Contrast High School and College EssayDocument6 pagesCompare and Contrast High School and College Essayafibkyielxfbab100% (1)

- Write 10 Lines On My Favourite Subject EnglishDocument1 pageWrite 10 Lines On My Favourite Subject EnglishIrene ThebestNo ratings yet

- Osora Nzeribe ResumeDocument5 pagesOsora Nzeribe ResumeHARSHANo ratings yet

- Tugas B InggrisDocument6 pagesTugas B Inggrisiqbal baleNo ratings yet

- D257272 1200 FDD 002 R1 PDFDocument420 pagesD257272 1200 FDD 002 R1 PDFTap Toan100% (1)

- Lab ReportDocument5 pagesLab ReportHugsNo ratings yet

- Exam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023Document285 pagesExam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023maniNo ratings yet

- Tutorial 3Document2 pagesTutorial 3prasoon jhaNo ratings yet

- Little Book of Effective WritingDocument44 pagesLittle Book of Effective Writingshalashvili100% (1)

- WA Beretta M92FS Parts ListDocument2 pagesWA Beretta M92FS Parts ListDenis Deki NehezNo ratings yet

- The Invisible Hero Final TNDocument8 pagesThe Invisible Hero Final TNKatherine ShenNo ratings yet

- Where On Earth Can Go Next?: AppleDocument100 pagesWhere On Earth Can Go Next?: Applepetrushevski_designeNo ratings yet

- Agricultural Sciences P1 Nov 2015 Memo EngDocument9 pagesAgricultural Sciences P1 Nov 2015 Memo EngAbubakr IsmailNo ratings yet

- COT EnglishDocument4 pagesCOT EnglishTypie ZapNo ratings yet

- Manju Philip CVDocument2 pagesManju Philip CVManju PhilipNo ratings yet

- Motivations for Leaving Public Accounting FirmsDocument33 pagesMotivations for Leaving Public Accounting Firmsran0786No ratings yet

- Believer - Imagine Dragons - CIFRA CLUBDocument9 pagesBeliever - Imagine Dragons - CIFRA CLUBSilvio Augusto Comercial 01No ratings yet

- Turbine 1st Stage Nozzle - DPTDocument15 pagesTurbine 1st Stage Nozzle - DPTAnonymous gWKgdUBNo ratings yet

- Addition and Subtraction of PolynomialsDocument8 pagesAddition and Subtraction of PolynomialsPearl AdamosNo ratings yet