Professional Documents

Culture Documents

NCR RAK-B.10049-20

Uploaded by

Victor NairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NCR RAK-B.10049-20

Uploaded by

Victor NairCopyright:

Available Formats

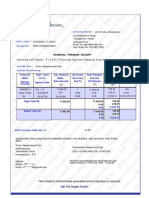

AIR LIQUIDE MIDDLE EAST MANUFACTURING

RMC FZC

RAK-FRM-30-13-23

Rev.: 4

NON-CONFORMITY REPORT Date: 02/01/2020

Page: 2 of 2

●INTERNAL

Filled by QMS Specialist or Supplier Quality Representative (for Supplier NCR)

ROOT CAUSE-If applicable

The failure to identify the correct location for the supports and also failure to identify instruction of not welding any item on the control panel .

CLOSE EFFECTIVENE

CORRECTIVE ACTIONS (If required) LEADER DEADLINE PROGRESS %

OUT DATE SS CHECK

In future to avoid these issues in future criticality

of the equipments should be passed on to the

contractor ,prior to start of the project ,also

contractor needs to ask the client prior to any hot

PM

works any special care required to be

taken.Critical equipment areas needs to be

identified in a project and permits to taken for the

any hot works near the same to be taken

CORRECTIVE ACTION APPROVAL:

Client Approval Name (If required) Comment:

Regulatory Authority Approval Name (If required) Comment:

Design Authority Approval Name (If required) Comment:

Filled by QMS Specialist or Supplier Quality Representative

NONCONFORMITY CORRECTIVE ACTIONS CLOSING

Validated Name: Victor Nair Position: Compliance Engineer Date: 24/11/2020

Comments : Cable tray supports that were tack welded to the Control Panel Has been grinded & removed,to avoid these mistakes in futures special hot work permit to

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Project Schedule For Replacement of Battery Bank and DC UPSDocument1 pageProject Schedule For Replacement of Battery Bank and DC UPSVictor NairNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Form No. 102B - Solenoid ValveDocument1 pageForm No. 102B - Solenoid ValveVictor NairNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Form No. 102A - Shutdown Valve 38Document2 pagesForm No. 102A - Shutdown Valve 38Victor NairNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Finvasia Equity DP IndividualDocument20 pagesFinvasia Equity DP IndividualVictor NairNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Form No. 102 - Control ValveDocument2 pagesForm No. 102 - Control ValveVictor Nair100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Form No. 101 - Field InstrumentDocument2 pagesForm No. 101 - Field InstrumentVictor NairNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Received With Thanks ' 17,876.72 Through Payment Gateway Over The Internet FromDocument1 pageReceived With Thanks ' 17,876.72 Through Payment Gateway Over The Internet FromVictor NairNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Flexicon Technical SubmittalDocument139 pagesFlexicon Technical SubmittalVictor NairNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Project Completion Plan Project TitleDocument28 pagesProject Completion Plan Project TitleVictor Nair100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Al Yaseah Oil & Gas: Health, Safety and EnviornmentalDocument1 pageAl Yaseah Oil & Gas: Health, Safety and EnviornmentalVictor NairNo ratings yet

- PROJECT:Design & Construction of 2 Nos. Vertical Silos in ESNAD (LOT 1) and Provision of Electronic Water and Electrical Meters in ESNAD (LOT 2)Document1 pagePROJECT:Design & Construction of 2 Nos. Vertical Silos in ESNAD (LOT 1) and Provision of Electronic Water and Electrical Meters in ESNAD (LOT 2)Victor NairNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Aftec Technical SubmittalDocument185 pagesAftec Technical SubmittalVictor NairNo ratings yet

- MS-02-484 Released (002) (44 Nos)Document12 pagesMS-02-484 Released (002) (44 Nos)Victor NairNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lessons Learned: Project Name: Project Number: Project Manager: Project SponsorDocument1 pageLessons Learned: Project Name: Project Number: Project Manager: Project SponsorVictor NairNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- E Commerce BBADocument137 pagesE Commerce BBAMd. Touhidul IslamNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Sales Manager Executive ResumeDocument4 pagesSales Manager Executive ResumeAnirban SamantaNo ratings yet

- TB 03Document29 pagesTB 03Nashwa SaadNo ratings yet

- Quiz - Quiz 2 Partnership Dissolution and Liquidation AnswersDocument15 pagesQuiz - Quiz 2 Partnership Dissolution and Liquidation AnswersKent Zirkai CidroNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Systematic Methods of Community Action in Understanding Community Background Information For LearnersDocument2 pagesSystematic Methods of Community Action in Understanding Community Background Information For Learnersapollo100% (3)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Iso 4379 1993Document9 pagesIso 4379 1993gökhan tanrıseverNo ratings yet

- Strategy EvaluationDocument6 pagesStrategy EvaluationJan Gelera100% (1)

- Lecture 9 Part 2 Performance EvaluationDocument3 pagesLecture 9 Part 2 Performance EvaluationAryaman JunejaNo ratings yet

- Maize, Wheat, Soya Beans, Sugar Beans, Cowpeas, Sorghum, Groundnuts and VegetablesDocument2 pagesMaize, Wheat, Soya Beans, Sugar Beans, Cowpeas, Sorghum, Groundnuts and Vegetablescretu gabiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Eastwell Sells East Telecom To KT-SumitomoDocument1 pageEastwell Sells East Telecom To KT-SumitomoTelecomMediaNo ratings yet

- Upgr Op2020Document30 pagesUpgr Op2020JackNo ratings yet

- CRS WFCS 594092 ADocument4 pagesCRS WFCS 594092 ADiego Rosa de OliveiraNo ratings yet

- Finance Module 4 Financial PlanningDocument7 pagesFinance Module 4 Financial PlanningKJ JonesNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Company Law ProjectDocument17 pagesCompany Law ProjectIshita UpraleNo ratings yet

- Print Reciept RequestDocument1 pagePrint Reciept RequestMuhd AbdullahiNo ratings yet

- Bank Reconciliation Solution - Uhuru Sacco LTD V1Document9 pagesBank Reconciliation Solution - Uhuru Sacco LTD V1Daniel Dayan SabilaNo ratings yet

- Crown Cork and Seal inDocument22 pagesCrown Cork and Seal inMuhammad Wahyu PriyambudiNo ratings yet

- Cemco Holdings, Inc., G.R. No. 171815Document17 pagesCemco Holdings, Inc., G.R. No. 171815JaylordPataotaoNo ratings yet

- Payguides - MA000012 - 1 July 2023Document21 pagesPayguides - MA000012 - 1 July 2023mahmoudadel6363No ratings yet

- Christopher John Iwaki - MSDocument1 pageChristopher John Iwaki - MSMadison ArtitaNo ratings yet

- AIPM - Part D - Certified Practising Senior Project ManagerDocument29 pagesAIPM - Part D - Certified Practising Senior Project ManagerMauricio Rodriguez PeñaNo ratings yet

- Common Practices in Business OrganizationsDocument33 pagesCommon Practices in Business OrganizationsDump Gandara100% (1)

- Oscb Banking Assistant Previous Paper With Solutions PDFDocument62 pagesOscb Banking Assistant Previous Paper With Solutions PDFRupeshNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Organizational ObligationDocument2 pagesOrganizational ObligationEfsha KhanNo ratings yet

- Forecasting For Financial Planning: "If You Are Going To Forecast, Forecast Often."Document26 pagesForecasting For Financial Planning: "If You Are Going To Forecast, Forecast Often."Trần Huyền MyNo ratings yet

- CE1401 EstimationandQuantitySurveyingDocument28 pagesCE1401 EstimationandQuantitySurveyingTarak A Positive100% (5)

- M/S Best Sellers Retail (I) P.Ltdvs M/S Aditya Birla Nuvo Ltd.&Ors (2012) 6 SCC 792Document20 pagesM/S Best Sellers Retail (I) P.Ltdvs M/S Aditya Birla Nuvo Ltd.&Ors (2012) 6 SCC 792sai kiran gudisevaNo ratings yet

- Design Structure Matrix Methods and Applications - The MIT PressDocument2 pagesDesign Structure Matrix Methods and Applications - The MIT PressVamsi Reddy50% (2)

- 3 A Brief Survey of Cloud ComputingDocument7 pages3 A Brief Survey of Cloud ComputingKartikaNo ratings yet

- 02 Chapter1Document17 pages02 Chapter1Ragner LOTHBROKENo ratings yet