Professional Documents

Culture Documents

Conc Mini Project

Uploaded by

An FakeihahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conc Mini Project

Uploaded by

An FakeihahCopyright:

Available Formats

CHAPTER 4 : CONCLUSION

In conclusion, the calculation made for this mini project was based on references from many

resources. Most of the compositions were assumed for the calculation of mass balance. At the

stream 1(feed), the mass fraction of Acetic Acid was assumed lower than the mass fraction of

water since the solution is dilute. 100% solvent assumed to enter stream 2 since hexanol was a

pure solvent. Hexanol was selected as the solvent since it is immiscible towards water and

miscible towards acetic acid. Other than that, hexanol has higher boiling point and lower

volatility compared to acetic acid. Hence, at the end of separation, acetic acid exist as a vapour in

extraction stream while hexanol exist as a liquid in raffinate stream .This characteristic is very

important since it will result to the amount of acetic acid separated from the dilute acetic acid

solutions. In extraction column, 100kg/s of solvent was used as the basis calculation feed since

the percentage recovery of acetic acid depends on the mass flow rate of the solvent

(Hexanol).The maximum amount of water which is 99% flow out in raffinate stream as

undesired product. Thus, loss of solvent to waste water can be minimize as much as possible. In

distillation column, in which separation of acetic acid and hexanol take place, 85% recovery of

solvent at bottom stream recovered from the solvent feed. Therefore, low cost solvent required in

order to achieve high purity of acetic acid which is 99% in extraction. Azeotrope also not

forming at the end of separation process which is easily for the next separation to take place.

From all the above statements, we can conclude that the extractive distillation is the best method

for separation and purification of acetic acid compared to other method.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Breakeven Analysis: CPE604 - EH220Document11 pagesBreakeven Analysis: CPE604 - EH220An FakeihahNo ratings yet

- Ewc MethodologyDocument1 pageEwc MethodologyAn FakeihahNo ratings yet

- Perception Practise Nepotism (DATA)Document5 pagesPerception Practise Nepotism (DATA)An FakeihahNo ratings yet

- Reaction Engineering 1 (Che502) Assignment 2 JUNE 2020 Industrial Reactor Design (PO2, CO3, C6)Document17 pagesReaction Engineering 1 (Che502) Assignment 2 JUNE 2020 Industrial Reactor Design (PO2, CO3, C6)An FakeihahNo ratings yet

- Project CharterDocument1 pageProject CharterAn FakeihahNo ratings yet

- Newton's Law of ViscosityDocument8 pagesNewton's Law of ViscosityAn FakeihahNo ratings yet

- Lab 4 Group 1: Prepared By: Wan Nur Aisyah Binti Wan MD Puzlee (2018201144) An Umillah Binti Mohd Apandi (2018272896)Document3 pagesLab 4 Group 1: Prepared By: Wan Nur Aisyah Binti Wan MD Puzlee (2018201144) An Umillah Binti Mohd Apandi (2018272896)An FakeihahNo ratings yet

- CBE 658: Ultrasonic Process of Tempoyak Group 6Document11 pagesCBE 658: Ultrasonic Process of Tempoyak Group 6An FakeihahNo ratings yet

- University of Melbourne Department of Chemical and Biomolecular Engineering 411-102 Chemical Process Analysis Tutorial Sheet CDocument3 pagesUniversity of Melbourne Department of Chemical and Biomolecular Engineering 411-102 Chemical Process Analysis Tutorial Sheet CAn FakeihahNo ratings yet

- Trans FatDocument2 pagesTrans FatAn FakeihahNo ratings yet

- Trans Fats: Issues in Food PreservationDocument12 pagesTrans Fats: Issues in Food PreservationAn FakeihahNo ratings yet

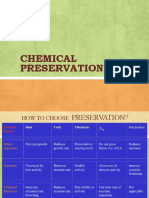

- 2 - 1 Chemical PreservationDocument18 pages2 - 1 Chemical PreservationAn FakeihahNo ratings yet

- CRYOPRESERVATIONDocument13 pagesCRYOPRESERVATIONAn FakeihahNo ratings yet

- Blue and Purple Simple Teamwork Keynote PresentationDocument19 pagesBlue and Purple Simple Teamwork Keynote PresentationAn FakeihahNo ratings yet

- Green and Pink Geometric Special Interest Keynote PresentationDocument15 pagesGreen and Pink Geometric Special Interest Keynote PresentationAn FakeihahNo ratings yet