Professional Documents

Culture Documents

1

1

Uploaded by

ernarendersaini0 ratings0% found this document useful (0 votes)

8 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 page1

1

Uploaded by

ernarendersainiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

PROJECT NO.: CSL-H114-08

3.0 TESTING METHOD

Cross-Hole Sonic Logging generally applies to drilled shafts and requires that at least three tubes

be installed in a drilled shaft prior to pouring the conerete, and that stress pulses are sent from one

tube to the other at 50mm vertical intervals. The arrival time of the pulse at the receiver tube

indicates the quality and integrity of the concrete between the tubes.

For conducting the sonic logging test mild steel tubes as described earlier were installed throughout

the length of the shaft by tying them to the reinforcement cage. They were filled with water and the

top and bottom of the tubes was sealed before concreting. This was to take into account the

differential temperature during conereting and curing,

The test can be conducted after minimum 3 to 7 days of concreting. For this a transmitter is lowered

in one of those tubes and a receiver - in another. Both transmitter and receiver are connected by

cables to the Cross Hole Analyzer (CHA), which records the arrival time and the energy attenuation

as the probes are simultaneously raised to the top. As long as the arrival time and the energy

attenuation are roughly constant, one may deduce that the concrete quality is also uniform and the

pile is therefore acceptable.

The CHA determines the quality of concrete between pairs of tubes pre-installed in r. c. bored piles.

A transmitter lowered down one tube sends a high frequency signal that is sensed some time later

by a receiver in another tube. As the sensors are being pulled, the CHA records, at regular depth

intervals, the time that the signal takes to travel from the transmitter to the receiver (arrival time), as

well as the signal energy. These two quantities are indicative of concrete quality between the pair of

tubes at a particular depth. The entire shaft length is scanned in this fashion by repeating the test

across diagonals & adjacent perimeters.

The CHA is easy to use and data interpretation is straightforward. Defects in the pile are easy to

recognize. They appear as weak signals in the signal plot, as missing signals in the traditional pot,

as delayed arrivals in the arrival time plot, and as signals with low energy.

4.0 INTERPRETATION OF RESULTS

By sending ultrasonic pulse through conerete from one probe to another (probes located in parallel

tubes), the CSL procedure inspects the drilled shaft structural integrity, and extent and location of

defects, if any. At the receiver probe, pulse arrival time and signal strength are affected by the

concrete. For equidistant tubes, uniform concrete yields consistent first arrival times (FAT) with

reasonable pulse wave speed and signal strengths. Non-uniformities such as contamination, soft

concrete, and honeycombing, voids, or inclusions exhibit delayed arrival times (FAT) with reduced

signal strength.

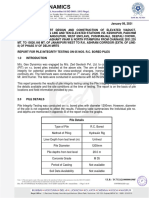

Typically the following classification explains interpretation of defects in the shaft. Here, the rating

of the shaft integrity considers the increases in “first arrival time” (FAT) and the energy reduction

relative to the arrival time or energy in a nearby zone of good concrete.

i FAT Increase relative | Energy reduction relative

Pile Classification to good concrete te-good conerete

Satisfactory / Good 0-10% <6 db

Minor Defect 11-20% <9 db

Poor/Flaw 21 to 30% <9 to 12 db

Poor/Defect 331% > 12 db

ro mrsasace ULR - 7C752120000006186F

You might also like

- 5Document1 page5ernarendersainiNo ratings yet

- 5Document1 page5ernarendersainiNo ratings yet

- 2Document1 page2ernarendersainiNo ratings yet

- Project No.: PIT-H147-10: Pile: P96-1Document1 pageProject No.: PIT-H147-10: Pile: P96-1ernarendersainiNo ratings yet

- 3Document1 page3ernarendersainiNo ratings yet

- PIT H118 15 P354LwerDocument1 pagePIT H118 15 P354LwerernarendersainiNo ratings yet

- PIT H114 15 P354LdfghDocument1 pagePIT H114 15 P354LdfghernarendersainiNo ratings yet

- DISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TestDocument1 pageDISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TesternarendersainiNo ratings yet

- Project No.: PIT-H147-10: Impact Toe Response Toe Response DefectDocument1 pageProject No.: PIT-H147-10: Impact Toe Response Toe Response DefecternarendersainiNo ratings yet

- PIT H114 15 P354LsdfghDocument1 pagePIT H114 15 P354LsdfghernarendersainiNo ratings yet

- Technical Specifications (NCRTC) DM/CN/COR-OF/108Document1 pageTechnical Specifications (NCRTC) DM/CN/COR-OF/108ernarendersainiNo ratings yet

- Project No.: PIT-H147-10: ULR - TC752120000006415FDocument1 pageProject No.: PIT-H147-10: ULR - TC752120000006415FernarendersainiNo ratings yet

- RDSO Vendor ListDocument7 pagesRDSO Vendor Listernarendersaini62% (13)

- 3622 Sand Stone For Slab & TilesDocument7 pages3622 Sand Stone For Slab & TilesernarendersainiNo ratings yet

- 4 Balanced CantileverDocument28 pages4 Balanced Cantileverernarendersaini100% (1)

- Manufactures of Lime Based Blocks PDFDocument9 pagesManufactures of Lime Based Blocks PDFernarendersainiNo ratings yet

- Book 1Document16 pagesBook 1ernarendersainiNo ratings yet

- 653 Linoleum Sheets & TilesDocument8 pages653 Linoleum Sheets & TilesernarendersainiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)