Professional Documents

Culture Documents

Tefugen Resources Designoptimization1

Uploaded by

Christiano ElondoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tefugen Resources Designoptimization1

Uploaded by

Christiano ElondoCopyright:

Available Formats

DESIGN OPTIMIZATION USING FEA FOR THERMAL POWER PLANT

Power Plant is an assembly of systems or subsystems to generate electricity. The power plant

equipments are subjected to fluctuating thermal and mechanical loading during its operations. To

ensure optimum performance with high reliability, it is mandatory to accommodate the varying load

parameters at the design stage. TEFUGEN offers FEA solutions in the following areas of Thermal

Power Plants apart from various other domains.

AIR-PreHeater Diaphragm Plate – Prediction of Thermal Deflection

The temperature gradient in the Air-PreHeater (APH)

causes thermal deflection of the diaphragm plates. This

deflection increases the clearance between the seals

(attached to the diaphragm plate) and the sector plate.

As a result of increased clearance, there is a heavy

leakage from air to gas side due to differential pressure.

FEA is used to predict the diaphragm deflection caused

by thermal gradient during its operation. Depending on

the predicted deflection, accurate APH seals setting is

done to minimize the APH leakage.

AIR-PreHeater Bearing Housing – Prediction of Stress &Deformation due to static loading

APH Bearing Housing is a major component which holds the

whole weight of the APH. Bearing Housing is subjected to both

axial and radial loads resulting from both weight of the APH & its

operation. If the housing deflection exceeds 0.03 mm in the

bearing outer race seating area, then it reduces the life of the

bearing depending up on the deflection magnitude.

FEA is used to determine whether the stresses and deflection

induced in the housing is within the limits prior to the designing

and manufacturing of the housing. Such type of FEA simulations

are extremely useful during renovation & modernization works

Resultant Deflection (mm) carried out at power plants.

Pressure Vessel – Prediction of stresses and deflection

Pressure vessel is a container designed to hold gases at a higher

pressure. Due to high operating pressure & temperature including

the fluctuation of the same inside the vessel, fatigue crack can be

initiated at the discontinuity where fatigue strength will be very

weak. These regions are typically the location of highest stress in

the component.

FEA is used for the evaluation of local failure & fatigue in the

pressure vessel. Stress Classifications Lines are also typically

located at the local structural discontinuity of vessel using FEA.

Von Mises Stress (MPA)

TEFUGEN TECHNOLOGIES PRIVATE LIMITED

G Floor, L-2, Electrical & Electronics Industrial Estate, Thuvakudy, Tiruchirapalli – 620 015. Tamilnadu, India.

+91 431 2500322 +91 431 2501134 tefugen@tefugen.com www.tefugen.com

You might also like

- Salient Design Features of 70 Mva 400 KV Generator Transformer Short Circuit Tested at Kema Abhilash Mishra and Richik Manas DasDocument13 pagesSalient Design Features of 70 Mva 400 KV Generator Transformer Short Circuit Tested at Kema Abhilash Mishra and Richik Manas DasRichik Manas DasNo ratings yet

- The Ifa Concept of EleniniDocument14 pagesThe Ifa Concept of Eleniniifakoya178% (9)

- Aeroflex Isolators Catalogue PDFDocument28 pagesAeroflex Isolators Catalogue PDFraju3685No ratings yet

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXNo ratings yet

- Nasa Doc For Stress ConcentrationDocument33 pagesNasa Doc For Stress ConcentrationTeresa PerryNo ratings yet

- Korfund Spring MountsDocument50 pagesKorfund Spring Mountsuamiranda3518No ratings yet

- Intro To Anti Vibration MountsDocument7 pagesIntro To Anti Vibration Mountsrmm99rmm99No ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Fatigue Stress Analysis PDFDocument4 pagesFatigue Stress Analysis PDFAR HassanNo ratings yet

- Installation, Operation and Maintenance of Airflex@ VC Grinding Mill ClutchesDocument28 pagesInstallation, Operation and Maintenance of Airflex@ VC Grinding Mill ClutchesCesar Casachagua DavilaNo ratings yet

- Generators and MotorsDocument19 pagesGenerators and MotorsrohitctppNo ratings yet

- Free Mechanical Aptitude Questions AnswersDocument12 pagesFree Mechanical Aptitude Questions Answerswhriyj177No ratings yet

- Protection of Alternator, Transformers, Bus Bar and Lines: Group 1Document61 pagesProtection of Alternator, Transformers, Bus Bar and Lines: Group 1KennethNo ratings yet

- 01 - Stress Analysis - BasicsDocument35 pages01 - Stress Analysis - BasicsJacey Jane100% (1)

- SAEJ987 V 001Document22 pagesSAEJ987 V 001hemnNo ratings yet

- Conflicted City: Hypergrowth, Urban Renewal and Urbanization in IstanbulDocument45 pagesConflicted City: Hypergrowth, Urban Renewal and Urbanization in IstanbulElif Simge FettahoğluNo ratings yet

- Naval Aviation News - Dec 1950Document36 pagesNaval Aviation News - Dec 1950CAP History Library100% (1)

- PTR 01-Introduction ENU PDFDocument29 pagesPTR 01-Introduction ENU PDFAhmed HasanNo ratings yet

- System Learning Plan Preparation: Krislizz International AcademyDocument11 pagesSystem Learning Plan Preparation: Krislizz International AcademyQhutie Little CatNo ratings yet

- Protection Guide of SSEE Power Transformer PDFDocument177 pagesProtection Guide of SSEE Power Transformer PDFIvanNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Selection Guide For Transformer-Primary Fuses in Mediumand High-Voltage Utility and Industrial SubstationDocument124 pagesSelection Guide For Transformer-Primary Fuses in Mediumand High-Voltage Utility and Industrial SubstationNicol Belén EscobarNo ratings yet

- CT O & M ManualDocument14 pagesCT O & M ManualRAJNIKANT saini50% (2)

- Safe Aviation: Tungsten Carbide Coatings On Jet Engine ComponentsDocument4 pagesSafe Aviation: Tungsten Carbide Coatings On Jet Engine ComponentsDeviprasad MNo ratings yet

- Siemens Offshore Transformer - OTMDocument2 pagesSiemens Offshore Transformer - OTMtoni gonzalezNo ratings yet

- Stearns Industrial Solenoid Catalog 02 2023Document12 pagesStearns Industrial Solenoid Catalog 02 2023mruizNo ratings yet

- Expansion JointDocument10 pagesExpansion JointMohammed BaquarNo ratings yet

- Air As Bearing SystemDocument4 pagesAir As Bearing System李宗耀No ratings yet

- Fuse OlogyDocument9 pagesFuse OlogyMario Sestanj PericNo ratings yet

- Til 1937-R1Document12 pagesTil 1937-R1BouazzaNo ratings yet

- Promat Wall SystemDocument12 pagesPromat Wall SystemBaljit SinghNo ratings yet

- 3EE Surge ArrestersDocument32 pages3EE Surge ArrestersGerman RuitaNo ratings yet

- PROMATECT® H Double Layer Steel Stud PartitionsDocument14 pagesPROMATECT® H Double Layer Steel Stud PartitionsjeffNo ratings yet

- PTH Internal Partition PDFDocument17 pagesPTH Internal Partition PDFMartin KwanNo ratings yet

- RP Maint GuideDocument10 pagesRP Maint GuideRaja Sekaran SajjaNo ratings yet

- Jsir 78 (7) 458-465Document8 pagesJsir 78 (7) 458-465Vilas AndhaleNo ratings yet

- Pub004 003 00 - 0111Document12 pagesPub004 003 00 - 0111Arman MominNo ratings yet

- Design Modification For Fillet Stresses in Steam Turbine BladeDocument4 pagesDesign Modification For Fillet Stresses in Steam Turbine BladechandruNo ratings yet

- Forces On Turbine BladesDocument2 pagesForces On Turbine BladesSwatantra KumarNo ratings yet

- Pfisterer Surge Arresters 11kV 33kV MV HV Medium High Voltage ArrestersDocument4 pagesPfisterer Surge Arresters 11kV 33kV MV HV Medium High Voltage Arrestersricosa00No ratings yet

- 3ee, Ef Seimens Surge ArrestersDocument32 pages3ee, Ef Seimens Surge ArrestersKenneth ParkerNo ratings yet

- Problems and Solutions With Expansion Joints in Gas Turbine Applications PDFDocument17 pagesProblems and Solutions With Expansion Joints in Gas Turbine Applications PDFJorge Bismarck Jimenez BarruosNo ratings yet

- Cooper Power 24067Document8 pagesCooper Power 24067govindarulNo ratings yet

- 1HSM 9543 16-01en Insulation Withstand and Clearances With EXLIM and PEXLIM Surge Arresters - Ed1 2011-12Document8 pages1HSM 9543 16-01en Insulation Withstand and Clearances With EXLIM and PEXLIM Surge Arresters - Ed1 2011-12alpcruzNo ratings yet

- Eaton 15kV Current Limiting FusesDocument78 pagesEaton 15kV Current Limiting FusespwmvsiNo ratings yet

- FS Catalog Current Limiting Power Fuses-151Document28 pagesFS Catalog Current Limiting Power Fuses-151heri fauziNo ratings yet

- Asc LB Ds 3040Document2 pagesAsc LB Ds 3040Francisco MartinezNo ratings yet

- Study of Transformer Explosion Prevention With Bushing Turret ProtectionDocument11 pagesStudy of Transformer Explosion Prevention With Bushing Turret ProtectionSuvendu Sekhar SabatNo ratings yet

- Technical Considerations Specification LV SwitchboardsDocument17 pagesTechnical Considerations Specification LV SwitchboardsZul FadzlyNo ratings yet

- Design Build of A Formula Sae Vehicle (Chassis, Shell and inDocument6 pagesDesign Build of A Formula Sae Vehicle (Chassis, Shell and inarslanNo ratings yet

- Franklin - Why ESP Motors FailDocument4 pagesFranklin - Why ESP Motors FailAutumn NunezNo ratings yet

- Bellow Design 1Document5 pagesBellow Design 1zingalala100% (2)

- Broken PGE - Standard Values For AICDocument3 pagesBroken PGE - Standard Values For AICBrandon ChoateNo ratings yet

- Winding and InsulationDocument6 pagesWinding and InsulationRatilal M JadavNo ratings yet

- Tozen Flex - RubberDocument4 pagesTozen Flex - Rubberkingathur26681No ratings yet

- Expansion Joints For Power GenerationDocument12 pagesExpansion Joints For Power GenerationNguyễn Hoàng PhúcNo ratings yet

- Selection Guide: For Transformer-Primary Fuses in Medium-And High-Voltage Utility and Industrial SubstationsDocument124 pagesSelection Guide: For Transformer-Primary Fuses in Medium-And High-Voltage Utility and Industrial SubstationsSe SamnangNo ratings yet

- Especificacion Transformadores CampamentoDocument8 pagesEspecificacion Transformadores CampamentofreddyNo ratings yet

- 04 - FEWA-EL-INSU-TS-0121, Rev 1, 2016Document3 pages04 - FEWA-EL-INSU-TS-0121, Rev 1, 2016MuraryspottyNo ratings yet

- TOX TB 1018 enDocument4 pagesTOX TB 1018 enAmmar YasserNo ratings yet

- 7PG15 - TR: Answers For EnergyDocument4 pages7PG15 - TR: Answers For Energyahmedmaged88No ratings yet

- Duobias Section1 Description of OperationDocument21 pagesDuobias Section1 Description of Operationkader arbiaNo ratings yet

- DevasenaDocument65 pagesDevasenaSriram ramsNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Design and CFD Analysis of Horizontal Axis Wind Turbine (HAWT)Document1 pageDesign and CFD Analysis of Horizontal Axis Wind Turbine (HAWT)Christiano ElondoNo ratings yet

- Tefugen - Resources - Sloshing - Effect of Internal Baffles Using Cfd1Document1 pageTefugen - Resources - Sloshing - Effect of Internal Baffles Using Cfd1Christiano ElondoNo ratings yet

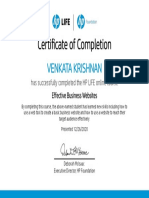

- Venkata Krishnan: Career Objective InternshipDocument1 pageVenkata Krishnan: Career Objective InternshipChristiano ElondoNo ratings yet

- Tefugen Resources Heat Exchanger1Document1 pageTefugen Resources Heat Exchanger1Christiano ElondoNo ratings yet

- CFD Analysis of Vortex Tube Refrigeration (Ranque-Hilsch Refrigerator)Document1 pageCFD Analysis of Vortex Tube Refrigeration (Ranque-Hilsch Refrigerator)Christiano ElondoNo ratings yet

- Tefugen Resources GD Test MKTG One Page Write Up1Document1 pageTefugen Resources GD Test MKTG One Page Write Up1Christiano ElondoNo ratings yet

- Tefugen Resources Heat Exchanger1Document1 pageTefugen Resources Heat Exchanger1Christiano ElondoNo ratings yet

- External Aerodynamic Analysis of Bus: ObjectiveDocument1 pageExternal Aerodynamic Analysis of Bus: ObjectiveChristiano ElondoNo ratings yet

- Tefugen Resources Heat Exchanger1Document1 pageTefugen Resources Heat Exchanger1Christiano ElondoNo ratings yet

- CFD Optimization Techniques in Power Boiler: ObjectiveDocument1 pageCFD Optimization Techniques in Power Boiler: ObjectiveChristiano ElondoNo ratings yet

- Rotordynamic Analysis of A Centrifugal Fan: ObjectiveDocument1 pageRotordynamic Analysis of A Centrifugal Fan: ObjectiveChristiano ElondoNo ratings yet

- External Aerodynamic CFD Analysis - Drag On A Truck: ObjectiveDocument1 pageExternal Aerodynamic CFD Analysis - Drag On A Truck: ObjectiveChristiano ElondoNo ratings yet

- External Aerodynamic Analysis of A Racing Car: ObjectiveDocument1 pageExternal Aerodynamic Analysis of A Racing Car: ObjectiveChristiano ElondoNo ratings yet

- CFD Analysis of Supersonic Flow Through CD Nozzle: ObjectiveDocument1 pageCFD Analysis of Supersonic Flow Through CD Nozzle: ObjectiveChristiano ElondoNo ratings yet

- Session 01 - Theory of CAEDocument17 pagesSession 01 - Theory of CAEChristiano ElondoNo ratings yet

- CFD Analysis of Gear Pump: Objective ChallengesDocument1 pageCFD Analysis of Gear Pump: Objective ChallengesChristiano ElondoNo ratings yet

- Microsoft AI Classroom SeriesDocument1 pageMicrosoft AI Classroom SeriesChristiano ElondoNo ratings yet

- CFD Analysis of Radiative Heat Transfer in Boiler First PassDocument1 pageCFD Analysis of Radiative Heat Transfer in Boiler First PassChristiano ElondoNo ratings yet

- (Lightweight/Hybrid Material For Automotive Application) : Innovative IdeasDocument1 page(Lightweight/Hybrid Material For Automotive Application) : Innovative IdeasChristiano ElondoNo ratings yet

- HP WebsiteDocument1 pageHP WebsiteChristiano ElondoNo ratings yet

- Failure Modes of RCC Beams Strengthened With NSM FRP TechniquesDocument9 pagesFailure Modes of RCC Beams Strengthened With NSM FRP TechniquesfelixNo ratings yet

- Form 1 Chapter 1 Introduction To ScienceDocument74 pagesForm 1 Chapter 1 Introduction To ScienceGooi Kee Win91% (43)

- UVM Run-Time Phasing GuideDocument55 pagesUVM Run-Time Phasing GuideVictor David SanchezNo ratings yet

- A Design of The Searcher Circuit: Sensing Channel Type: ProjectedDocument2 pagesA Design of The Searcher Circuit: Sensing Channel Type: ProjectedHu GyNo ratings yet

- Psyd CourseworkDocument5 pagesPsyd Courseworkguj0zukyven2100% (2)

- Grim Character ConceptDocument1 pageGrim Character ConceptJhansenNo ratings yet

- Theory Summarized R1 To R5Document10 pagesTheory Summarized R1 To R5ALINDOGAN, KimleeNo ratings yet

- Review For The Final ExamDocument12 pagesReview For The Final Examsteven mateNo ratings yet

- 3.assessment Tool TemplateDocument8 pages3.assessment Tool TemplateAnna Clarissa VillaverNo ratings yet

- Ga Verb Dictionary TemplatedDocument179 pagesGa Verb Dictionary TemplatedKIMANINo ratings yet

- Microptic CatalogDocument8 pagesMicroptic CatalogMhd DamNo ratings yet

- Kiyora Catlog SeiresDocument6 pagesKiyora Catlog SeiresMd SazadNo ratings yet

- OHS Learner Guide - V1Document30 pagesOHS Learner Guide - V1Education 2.0No ratings yet

- CHEM1701-lab3-202341 - 202341.12623-CHEM-1701-08 - PRE-HEALTH CHEMISTRY IDocument1 pageCHEM1701-lab3-202341 - 202341.12623-CHEM-1701-08 - PRE-HEALTH CHEMISTRY IMartha ChalmenageNo ratings yet

- Paper Tiodora 2014Document16 pagesPaper Tiodora 2014Dr. Tiodora Hadumaon SiagianNo ratings yet

- NDT Global Appoints New President - World PipelinesDocument2 pagesNDT Global Appoints New President - World PipelinesNutthakarn WisatsiriNo ratings yet

- S Siva Kishore Project - BADocument5 pagesS Siva Kishore Project - BAosuri sudheer kumarNo ratings yet

- Nearly Complete Spray Cap List .Document8 pagesNearly Complete Spray Cap List .Жиганов Володимир Андрійович 1АКІТ 18-БNo ratings yet

- 2 VCA ETT 2017 Training v2 0 - EnglishDocument129 pages2 VCA ETT 2017 Training v2 0 - EnglishMassimo FumarolaNo ratings yet

- Revision - The 1 Term Test Grade 12: A.Exercises I. PronunciationDocument16 pagesRevision - The 1 Term Test Grade 12: A.Exercises I. PronunciationBách LêNo ratings yet

- Overtaking Assistant System (OAS) With Fuzzy Logic Method Using Camera SensorDocument7 pagesOvertaking Assistant System (OAS) With Fuzzy Logic Method Using Camera SensorJustamNo ratings yet

- English 7 ASDocument16 pagesEnglish 7 ASAh RingNo ratings yet

- Decimal Million & Fraction MillionDocument21 pagesDecimal Million & Fraction MillionSuganthi SupaiahNo ratings yet

- Uplift ModelingDocument4 pagesUplift ModelingMatthew ChengNo ratings yet

- SAT Essay FormatDocument5 pagesSAT Essay FormatPrabh SimarNo ratings yet