Professional Documents

Culture Documents

04.1 User Manual PDA5 - 0

Uploaded by

KevinCRomeroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04.1 User Manual PDA5 - 0

Uploaded by

KevinCRomeroCopyright:

Available Formats

User manual for

Plant Design & Allocation 5.0

ABB Switzerland Ltd.

No. of sh.

Prep. SEASY/Z Per-Olov Andersson 2000-01-29

Appr. SEASY/Z Gunnar Arvestål User Manual 93

Resp. dept. SEASY/Z Plant Design & Allocation 5.0

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A i

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Contents

1. INTRODUCTION..........................................................................................................5

1.1 General ................................................................................................................................................................... 5

1.2 Workflow................................................................................................................................................................ 5

1.2.1 Workflow for PDA administrator ..................................................................................................................... 6

1.2.2 Workflow for PDA user.................................................................................................................................... 6

1.3 Help......................................................................................................................................................................... 8

2. MAIN FUNCTIONS ......................................................................................................8

2.1 Starting up for the first time................................................................................................................................. 8

2.2 New Project ............................................................................................................................................................ 9

2.3 Project Setup ........................................................................................................................................................ 10

2.3.1 Project details ................................................................................................................................................. 10

2.3.2 Supplier........................................................................................................................................................... 11

2.3.3 Document details ............................................................................................................................................ 11

2.4 Revisions............................................................................................................................................................... 12

2.4.1 New revision................................................................................................................................................... 12

2.4.2 Copy revision.................................................................................................................................................. 12

2.4.3 Support Web (not more supported in PDA BM 3.1) ...................................................................................... 13

2.5 General form functions ....................................................................................................................................... 13

2.5.1 View ............................................................................................................................................................... 13

2.5.2 Move and resize fields .................................................................................................................................... 15

2.5.3 Save Form....................................................................................................................................................... 15

2.5.4 Sort ................................................................................................................................................................. 15

2.5.5 Filter By/Excluding selection ......................................................................................................................... 16

2.5.6 Filter ............................................................................................................................................................... 16

2.5.7 Apply/Remove filter ....................................................................................................................................... 17

2.5.8 Saved Filters ................................................................................................................................................... 17

2.5.8.1 Import Filters ........................................................................................................................................... 18

2.5.9 Fill Down........................................................................................................................................................ 19

2.5.10 Series Fill Down ........................................................................................................................................... 19

2.5.11 Undo Fill Down ............................................................................................................................................ 20

2.5.12 Replace ......................................................................................................................................................... 20

No. of sh.

Prep. SEASY/Z Per-Olov Andersson 2000-01-29

Appr. SEASY/Z Gunnar Arvestål User Manual 93

Resp. dept. SEASY/Z Plant Design & Allocation 5.0

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A i

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.5.13 Expression Builder........................................................................................................................................ 20

2.5.14 Copy Paste .................................................................................................................................................... 22

2.5.15 Sub Forms..................................................................................................................................................... 22

2.5.15.1 How to build new subforms................................................................................................................... 23

2.5.16 Freeze Columns ............................................................................................................................................ 23

2.5.17 Find............................................................................................................................................................... 23

2.5.18 Select File(s) to Work With .......................................................................................................................... 24

2.5.19 Navigator (no more Supported in PDA 3.1) ................................................................................................. 24

2.5.20 Filtering Reports ........................................................................................................................................... 24

2.5.21 Compact database ......................................................................................................................................... 25

2.5.22 Default Values .............................................................................................................................................. 25

2.6 Import................................................................................................................................................................... 26

2.6.1 Supplier Data format....................................................................................................................................... 26

2.6.1.1 Importing data including I/O allocation................................................................................................... 26

2.6.2 Select Files to import ...................................................................................................................................... 26

2.6.3 Merging files................................................................................................................................................... 28

2.6.4 Preview data ................................................................................................................................................... 29

2.6.5 Mapping.......................................................................................................................................................... 30

2.6.5.1 Automatic mapping ................................................................................................................................. 31

2.6.5.2 Manual mapping ...................................................................................................................................... 31

2.6.6 Export data to file ........................................................................................................................................... 31

2.6.7 Add new fields in customer data..................................................................................................................... 32

2.6.8 Add new field in Database.............................................................................................................................. 32

2.6.9 Test Structure.................................................................................................................................................. 34

2.6.10 Error log........................................................................................................................................................ 34

2.6.11 Suggested procedure for mapping form use ................................................................................................. 35

2.6.11.1 Importing revised customer data............................................................................................................ 36

2.7 Validation ............................................................................................................................................................. 36

2.8 Compare ............................................................................................................................................................... 38

2.8.1 Merge revisions .............................................................................................................................................. 40

2.8.2 Compare I/O allocation................................................................................................................................... 41

2.9 Edit data ............................................................................................................................................................... 41

2.9.1 Copy I/O allocation......................................................................................................................................... 41

2.9.2 I/O allocation .................................................................................................................................................. 42

2.9.2.1 Controller Level....................................................................................................................................... 43

2.9.2.2 S100 Boards............................................................................................................................................. 43

2.9.2.3 Reports showing I/O allocation ............................................................................................................... 45

2.9.2.4 S800 Boards............................................................................................................................................. 46

2.9.2.5 Labels for S800 I/O ................................................................................................................................. 46

2.9.2.6 Not connected Boards.............................................................................................................................. 47

2.9.2.7 Signal Pool............................................................................................................................................... 48

2.9.2.8 Allocate Signals to Boards....................................................................................................................... 49

2.9.3 ADG (no more supported in PDA BMI 3.1)................................................................................................... 49

2.9.4 Board .............................................................................................................................................................. 50

2.9.4.1 Board Info................................................................................................................................................ 50

2.9.4.2 Import Board Types ................................................................................................................................. 50

2.9.4.3 Connection Unit....................................................................................................................................... 52

2.9.4.4 Import Connection Unit Types ................................................................................................................ 52

2.9.5 Generate Signals ............................................................................................................................................. 53

2.9.5.1 Signal Library .......................................................................................................................................... 53

2.9.5.2 Import Signal libraries from other projects.............................................................................................. 54

No. of sh.

Prep. SEASY/Z Per-Olov Andersson 2000-01-29

Appr. SEASY/Z Gunnar Arvestål User Manual 93

Resp. dept. SEASY/Z Plant Design & Allocation 5.0

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A ii

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.9.5.3 Abbreviation ............................................................................................................................................ 55

2.9.5.4 Process Objects........................................................................................................................................ 57

2.9.6 Signal.............................................................................................................................................................. 59

2.9.7 Soft Signals..................................................................................................................................................... 60

2.9.8 Loops .............................................................................................................................................................. 60

2.9.9 Solutions ......................................................................................................................................................... 61

2.9.9.1 Build and Export Scriptfiles .................................................................................................................... 62

2.10 Budget................................................................................................................................................................. 63

2.10.1 Signal budget ................................................................................................................................................ 64

2.10.2 Spare Calculation.......................................................................................................................................... 64

2.11 Export ................................................................................................................................................................. 65

2.11.1.1 Export Revision ..................................................................................................................................... 65

2.11.1.2 Export Table/Query ............................................................................................................................... 66

2.12 Control Builder M Interface............................................................................................................................. 68

2.12.1 Project defaults ............................................................................................................................................. 68

2.13 System Administration...................................................................................................................................... 69

2.13.1 Security......................................................................................................................................................... 69

2.13.2 General ......................................................................................................................................................... 69

2.13.3 Agree on the data format and contents with the Customer/subcontractor .................................................... 70

2.13.4 Create a new database................................................................................................................................... 70

2.13.5 Add new fields to the database. .................................................................................................................... 70

2.13.5.1 Import Object......................................................................................................................................... 71

2.13.6 Create new validation queries....................................................................................................................... 71

2.13.7 Create new forms.......................................................................................................................................... 72

2.13.7.1 Rebuild Form(s)..................................................................................................................................... 72

2.13.8 Create new reports ........................................................................................................................................ 73

2.13.9 Create new queries........................................................................................................................................ 74

2.13.10 Add new Forms, Reports and Queries into PDA ........................................................................................ 74

2.13.11 Fill in budget values for the agreed number of Signals .............................................................................. 75

2.13.12 Distribute project specific forms and reports to project members .............................................................. 75

2.13.13 File location ................................................................................................................................................ 75

2.13.14 Create Category .......................................................................................................................................... 76

2.13.15 Compact Database ...................................................................................................................................... 77

2.13.16 Data structure.............................................................................................................................................. 77

3. APPENDIX.................................................................................................................78

3.1 Supplier Data ....................................................................................................................................................... 78

3.1.1 Instrument schedule ........................................................................................................................................ 79

3.1.2 I/O schedule/ Signal........................................................................................................................................ 79

3.1.3 I/O allocation / Node, Bus, Station and Board................................................................................................ 79

3.1.4 Software specification / Loop ......................................................................................................................... 79

3.1.5 Definition of fields.......................................................................................................................................... 80

3.1.5.1 List of attributes....................................................................................................................................... 80

3.1.5.2 Data types ................................................................................................................................................ 80

3.1.6 Handling Revised Customer Data................................................................................................................... 80

3.2 Validation Queries............................................................................................................................................... 83

3.2.1.1 Boards...................................................................................................................................................... 83

3.2.1.2 Bus ........................................................................................................................................................... 84

No. of sh.

Prep. SEASY/Z Per-Olov Andersson 2000-01-29

Appr. SEASY/Z Gunnar Arvestål User Manual 93

Resp. dept. SEASY/Z Plant Design & Allocation 5.0

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A iii

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

3.2.1.3 Loops (MOD only) .................................................................................................................................. 84

3.2.1.4 Process Objects........................................................................................................................................ 86

3.2.1.5 Node......................................................................................................................................................... 86

3.2.1.6 Signals ..................................................................................................................................................... 87

3.2.1.7 Soft Signal ............................................................................................................................................... 89

3.2.1.8 Signal path ............................................................................................................................................... 89

3.2.1.9 Station...................................................................................................................................................... 89

4. GLOSSARY OF TERMS............................................................................................90

5. INDEX ........................................................................................................................91

No. of sh.

Prep. SEASY/Z Per-Olov Andersson 2000-01-29

Appr. SEASY/Z Gunnar Arvestål User Manual 93

Resp. dept. SEASY/Z Plant Design & Allocation 5.0

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A iv

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

1. Introduction

1.1 General

Plant Design & Allocation 3.1 can import customer data in Excel or Lotus

format, and map it to internal PDA names. PDA can also validate and

compare the different versions of data, coming from customer or created

during the engineering process.

The output from this tool is OCS data for AEW. In AEW the data is used

to build up the OCS structure in STB and to add parameters in PAR.

It is also possible to export/import data directly to/from FCB, using a .bax

file.

There is also an output to ADG/CAD to automatically build circuit

diagrams in AutoCAD.

For MOD users scriptfiles are built with parameters for Typical Solutions

in Engineering Station.

The flexible export can also be used to downstream Design & Production

processes.

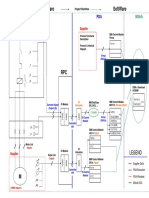

1.2 Workflow

The workflow below is only to be seen upon as a sample of how to use

the tool. There are a lot of different options depending of the scope of

delivery etc.

To make the use of the tool effective and to achieve a common way of

working each LABB is recommended to make their own workflow

describing how to use the tool.

There are two different workflows described.

The first workflow describes the administrative part and that is done by

the PDA administrator.

The second workflow describes a possible workflow for the engineer

using PDA.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 5

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

1.2.1 Workflow for PDA administrator

Below you will find a sample workflow for the administrator. All items

are optional and the items can be performed in almost any order.

Libraries User Interfaces etc.

Solutions for Forms

Build and maintain the solutions Build new forms and maintain

PDA. These solutions are used standard forms to suit the

generate scriptfiles for needs.

solutions in AS500ES

only).

Reports

Build newreportsand

Solutions in Signal the standardreportsto suit the

Build and maintain solutions project needs

PDA. The solutions are used

generate signals based on

Objects.

Validation

Select the validationqueries to use

in the project. Add project specific

Board queries.

Maintain the library of board

and Connection unit types and

needed add new board types for

project.

Project specific

Define the attributes needed for

different categories of data,

adding project specific attributes

the standard set of

1.2.2 Workflow for PDA user

Below you will find a sample workflow. Many of the items are optional

and are depending of scope of supply. Some of the items may be repeated

at different stages of the working process, e.g. validation will be

performed both after import and after doing the I/O allocation.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 6

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Setup Project & Incorporate Engineering Output

Data

New Project Generate Signals CBM Integration

Create a new database to store Generate signals based on Export IO Hardware, Signals,

the project data in. Process Objects and Library Groups and Process Objects to

objects. the 800xA Control Builder.

Exchange Format

Define the attribute names and I/O Allocation

data types for exchange of data. Allocate Signals to Boards.

Generate Circuits

Generate circuit diagram

Project Details Bulk Data handling (Consumer Circuits) showing the

Fill in general information for Add and edit Board data, Signal complete wiring signal and

the project, like e.g. document data and Process object data, power of an object (e.g. Motor,

headers. using the special designed bulk or Transmitter)

data functions in PDA.

Import

Import data in Excel, Lotus

Flexible Export

format or from HDRS I/O calculation Export data in flexible format

Check the quantity of I/O’s and e.g. to feed local tools.

Mapping compare them to the budget

Map customer attribute names to figures

internal PDA names.

ELCAD Consumer Circuits

Copy Revision Define Circuit Templates,

Use this function to create and Process Object and Signal

archive copies of data to always Parameters used to generate

have the original Customer data drwaings for ELCAD.

available to e.g. compare

revisions. (see: PDA BMI 3.1 User Manual

for details)

Validate

Validation of data. Reports can

Sofware Design for Control

be printed out, showing the

Builder M

detected errors from the

Define SW Libraries and

validation. It is also possible to

view the errors in List format Parameters for the Control

Modules to be created.

and directly correct them.

(see: PDA BMI 3.1 User Manual

Compare for details)

Compare different versions od

data to detect changes, e.g. detect

changes in customer data from

one revision to another.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 7

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

1.3 Help

To help you to use Plant Design & Allocation there is some help

functionality available. This document is a description of how to handle

the application and it is structured in the same way as the application is

structured. The best way to use this manual would be to have PDA

running on a PC as you read this manual. There are a lot of pictures in the

manual that you recognise if you run the application e.g. all forms are

available in the help file. This document is available as a Microsoft Word

document named PDAHELP.DOC. All documentation is available for

download on the support Web. The easiest way to get to the support web

is to use the hyperlink available in PDA, at the bottom of the main menu.

To view the online-help in PDA press the F1 key. This will take you to

the page that is relevant to the form in which the cursor is currently

placed. The online-help is based on the same text as this manual.

It is also possible to click the icon above to start the online-help in PDA.

Use Index or Contents to find the information that you are looking for.

Note!

The Help available from the Help menu is the normal Microsoft Access

Help, that also can be very useful.

2. Main functions

2.1 Starting up for the first time

On starting the PDA for the first time the first thing to do is to set-up the

file locations. Selecting the Project Detail TAB, at the top of the PDA

Menu form, displays a form with the button that is used for this

File Location

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 8

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

This form is used to define default locations. The default paths are e.g.

used when browsing for files to import etc.

Export To, Default path for Export, e.g. when exporting data in Excel

format

Import From, Default path for Import, starts at this location when

browsing for customer data

Project-data, Default paths for new projects

Systemfiles, Location of the application database (pda_3_1_2002.mdb)

Note: For other file types see: PDA BMI 3.1 User Manual

2.2 New Project

Use New Project button under Project Detail tab, to create a new project.

Select type of project. Two types of project templates are delivered with

PDA, MOD 300 and Master. There can also be locally built templates that

e.g. have been modified to suit a specific Business.

Browse to the path where you want to store the project and enter project

name in the File name field, (the extension “.mdb” will be filled in

automatically), then select Open.

By default the project will be stored as setup in file locations above (in

c:\pda\project, as delivered, but it is up to the user where to store it). If

more than one person wants to work with the same project, store it on a

network disk.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 9

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Use Select Project to select an existing project to work with. Either

double click on the database (.mdb) file or single click and then select

Open.

The selected project path and filename will then appear in the window

above the buttons.

2.3 Project Setup

This form is used to set up Document Header/Footer and suppliers.

2.3.1 Project details

Use this form to fill in data to be used in headers and footers of the reports

and forms.

If the project has multiple order numbers there are two options, either

leave the field blank and fill in order number in the cover sheet instead or

correct the field before printing out a report.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 10

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.3.2 Supplier

Fill in Suppliers from which data shall be imported.

Note!

The predefined supplier System that already exists should be left in place.

The description field for Supplier could e.g. be used to fill in which type

of data the supplier is supposed to supply. The purpose of filling in the

supplier is that mapping of customer names and internal names are stored

with the supplier. Next time data is imported from the same supplier the

default mapping is the mapping used previously, for the same supplier.

2.3.3 Document details

This form allows the user to change the titles, document number and

revision Id etc. for the reports.

Note!

It is only reports where Dockind is Report that are valid. The other reports

are for internal use ore use header data from another source. Locally built

reports will also be available in this form.

Field Name Description Label in footer

ObjectName Name of the report in PDA

Doc_Id Unique identification of a document Doc.No.

Approved Dept. and name of person that has approved document Appr.

DocKind Classification of document to it’s content and form of present. Doc.Kind

Title1 Title of document Title (row1)

Title2 Title of document Title (row2)

Prep Department of person who created doc. and date when created Prep.by

Based Number of source document when applicable Based On

Status Revision status Appr.

Designation1 Document designation 1 See 9ADA354 Doc.Des. (row1)

Designation2 Document designation 2 See 9ADA354 Doc.Des. (row2)

IDesignation 1 Item Designation 1 ItemDes. (row1)

IDesignation 2 Item Designation 2 ItemDes. (row2)

Rev Revision index Rev.Ind

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 11

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.4 Revisions

The PDA can work with multiple revisions of project data for each

project.

Make sure you select the correct project and revision before working with

the data. The revision can be selected from any tab in the main menu.

Current revision, the current revision, use drop down menu to select

another revision. Double-click in the field to be able to change the name

of the revision.

Created Date/Time, date and time when the revision was created and

also the username

Description, a description field to make it easier to distinguish between

the revisions

2.4.1 New revision

Select New Revision to create a new, empty, revision Index.

The default value for the Revision Note follows the ABB standard

starting with "-" and then A, B…. Etc. You can change the Revision Note

to anything you want to use by double clicking in the Current Revision

field. You can change to a different revision by selecting the drop down

menu in the Current Revision field.

You may wish to create new revisions when you import new customer

data or when you reach a freeze point in the project and you want to issue

data for downstream activities.

2.4.2 Copy revision

This function is used to make a copy of the selected revision. The purpose

of this is to separate the original requirements and the changes. It is up to

the user if changes are done directly to customer data or not.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 12

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

If the customer's revision is called A the new revision will as default be

called A/1 to make clear as to which revision it belongs. The new revision

will automatically become the current revision. By using the Select

File(s) to Work with form the copy can be limited to the selected files.

It is advisable that immediately after an import activity, have a copy of

the imported revision made and work continued on the copy. The original

imported revision can then be kept as an archive copy for comparison

purposes etc.

The “Copy I/O allocation” form will allow you to copy data from an old

revision to a new/empty revision. Alternatively data can be exported from

the old revision and then re-imported into the new revision.

2.4.3 Support Web (not more supported in PDA BM 3.1)

2.5 General form functions

To support flexible forms and powerful bulk data handling a set of

functions are available in PDA. The functions can be found using right

mouse button in the current form. Only the functions available for that

specific form are visible.

2.5.1 View

The view function enables building flexible views of the forms to work

efficiently. The views are built up per form so the views will differ from

form to form. Some views are delivered with PDA but it is also easy to

add project specific views and even personal views.

The views include both filters and layout of the forms. E.g. in the I/O

allocation form it could be useful to build a view showing not allocated

analogue input signals. This view could then include a filter showing only

not allocated analogue input signals. The view could then only show the

fields that are interesting in this specific project, sorted and ordered in an

efficient way for a specific operation.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 13

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Selecting a view e.g. “AI Signals not allocated” will show all unallocated

analogue input signals and the valid fields for that type of signals.

<Refresh List> is used in forms including subforms e.g. the I/O

allocation form, to refresh the available view depending on which form is

current. Click in the form where you want to apply a view, select

<Refresh List> to show the available view for the selected form.

<Clear Filters> will keep the selected layout of the form but remove the

filter if there are any. E.g. if Clear Filters is selected using view

“Unallocated AIS” all signals will be available but the layout will be the

same. To add the filter again simply select “Unallocated AIS” again.

<Modify Setting> is used to modify views or to build new views. The

following form will pop up.

Select the fields you want to see , the All/None buttons can be used to

speed up the selection. Select Update View to modify the view according

to the changes done. If the form is closed without selecting Update View

the screen will still be updated with the modification but the view will not

be updated. This could be useful for temporary changes.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 14

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Views can be imported from libraries or other projects by selecting import

on right mouse button in this form, click in the grey area of the form.

Delete view is used to delete views that are not to be used any more.

Create View is used to build up new view for different operations. The

proposed workflow for building a new view is as follow.

1 Build up the filters and sorting using the Filter by Selection or Filter

functions and the sort function, to show the valid records for the view.

2 Select <Modify View> to get into the above form. Select the columns

to be shown.

3 Select Create View and type in the name of the new view at the

bottom of the form and then close the form.

4 Modify the order of the fields and the size of the fields in the

displayed view. Then select <Modify Setting> and Update View to

save these settings to the view.

Step 1 and 4 are optional if all records are to be shown and the standard

length and order of the fields are to be used.

2.5.2 Move and resize fields

All fields can be moved around and resized or hidden to suite different

purposes. To move Field(s) Select the header of the Column(s) to move

and drag the fields with the left button of the mouse activated. To resize

columns left-click the right side of the column header and drag it to

correct size or double-click it to automatically size it to fit.

Note!

If a form do not seem to have been updated/refreshed then use the F9 key

(refresh). The Refresh command updates only data that already exists in

your datasheet or form. It doesn't reorder records, display new records, or

remove deleted records or records that no longer meet the specified

criteria. To perform those actions, requery the records by pressing

SHIFT+F9

2.5.3 Save Form

Use Save Form to save the form settings e.g. the location of a subform. It

can be found under Forms Setting... in right mouse button menu.

To save the settings to the view use the view <Modify Setting>.

2.5.4 Sort

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 15

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Sort Ascending. Sorts records based on the selected column(s) in

ascending order (0 to 9, A to Z), subsequent sorts replace previous sorts.

To undo a sort, choose Apply/Remove Filter.

Sort Descending. Sorts records based on the selected column(s) in

descending order (9 to 0, Z to A). If more than one column is selected the

sorting is done is done on all columns starting from the left column.

Subsequent sorts replace previous sorts. To undo a sort, choose

Apply/Remove Filter.

2.5.5 Filter By/Excluding selection

Filter By Selection, right-click on the value to be filtered by. A click on

e.g. SignalType DIS will show all signals of that type.

Filter Excluding selection, right-click on the value to be excluded in the

filter. A click on e.g. SignalType DIS will show signals of all types

except DIS e.g. DOS, AOS and AIS.

2.5.6 Filter

Filter function is used to build more complex filters than Filter by

selection. Right-click on the field that you want to build a filter on and

select Filter. Filter can be built on more than one field.

The first field shows the field to build the filter on, as default the field that

was selected when the filter was activated from will be used. The second

field shows to operator to be used with the criteria, the following fields

are available.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 16

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

The last field is used for the criteria. In the sample above all SigTags

starting with either H1 or H2 will be shown. If more than one expression

is defined for the same column it is an OR criteria between the

expressions as in the sample above.

By Criteria will activate the filter.

Use Show all filters to show all active filters on any field, including

filters belonging to the selected view. All filters built or activated from

here will be available from Filter Save function.

If more than one column is filtered there is an AND criteria between the

columns. If e.g. SigTag is filtered for DIS and Node for N1, only signals

that fulfil both criteria’s will be shown.

2.5.7 Apply/Remove filter

Use Apply/Remove filter to remove all active filters or to apply the last

used filter if there are no filter activated. If a filter is activated a text string

Filtered is shown to the right of the record selector in each form.

Note!

If two different subforms are filtered and then one of the filters is

removed, then the text filtered will be removed in both sub forms. This

can be very confusing since the subform is filtered but it is not indicated

that this is the case. This is a bug in Access. Click Apply/Remove filter

in the subform where it is missing, to see the text filtered again.

2.5.8 Saved Filters

The Saved Filters function makes it possible to save filters and to be able

to reuse them. It can be very time saving to build up a set of filters for

different frequent operations.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 17

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

As soon as the Filter function is used the above form is updated. If Filter

By/Excluding Selection is used this form will only be updated if the

Filter function is opened and criteria button is pressed. Also the sorting

functions can be included in the filters but also here it will only be

updated if the Filter function is opened and criteria is pressed.

Description, used to name filters that are to be reused

Add Filter, a double-click in this field will add the selected filter to the

current filter. The contents of the field is the filter in SQL format, built up

as described above

Replace Filter, a double-click in this field will replace the current filter

with the selected filter. The contents of the field is the filter in SQL

format.

Order By, sorting order. All filters are stored locally per user but it is

possible to import filters from other user by using Import From

described below.

The Saved Filters function can be used in combination with the View

function. If there is a filter included in the view e.g. for DI signals the

Saved Filters will be added to these filters.

2.5.8.1 Import Filters

The Filters can be imported from other projects or from specific Library

projects.

Select Import From right-button menu.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 18

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Use Browse to select the project to import from.

Overwrite Record determine if the imported objects shall overwrite the

existing objects in case they already exist. If a duplicate is detected during

import and Overwrite is not selected an error message will appear

informing you that the object not will be imported.

Select button will show all available objects of the correct type in the

selected database.

2.5.9 Fill Down

A function to fill down a value from current record to all records below.

Right-Click the value to be used and select Fill Down, all records below

the current record will be updated. Use this function in combination with

the filter and sorting functions to only update a limited number of records.

Use Undo Fill Down undo the last Fill Down.

If it is not possible to undo the operation a popup message will appear

before the Fill Down is performed to make it possible to cancel the action.

The function also works with combo boxes and check boxes.

2.5.10 Series Fill Down

A function to fill down a value from current record to all records below

and at the same time increase the value with 1. Right-Click the value to be

used and select Series Fill Down, all records below the current record

will be updated. If Series Fill Down is used on value such as X20:1 the

records below will get the values X20:2, X20:3 etc. Use this function in

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 19

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

combination with the filter and sorting functions to only update a limited

number of records. Use Undo Fill Down undo the last Fill Down.

If it is not possible to undo the operation a popup message will appear

before the Fill Down is performed to make it possible to cancel the action.

2.5.11 Undo Fill Down

Use Undo Fill Down to undo the last Fill Down or Series Fill Down

performed. If during the Fill down operation, the system detects that it is

not possible to undo the operation a popup message will appear before the

Fill Down is performed to make it possible to cancel the action.

2.5.12 Replace

The Replace function can be used to replace strings or part of strings in a

field.

In the sample above the string CLOSE is replaced with OPEN, since

Match Whole Field is not selected it will find strings where CLOSE is

only a part of the string e.g. OP_CLOSE will be changed to OP_OPEN.

It is also possible to look for spaces, or any other characters or strings,

within a text field and replace or remove them.

For example to remove spaces: click in correct field and open replace

function; make sure “Match Whole Field “ is not ticked; type a space into

the Find What; field do not type anything in the Replace With; field

then press Find Next - Replace. This is very useful for removing spaces

from fields where space might lead to problems.

2.5.13 Expression Builder

Expression Builder is used to update values in a field using Access

standard expressions. It is also possible to place the values in a calculated

field instead of updating an existing field.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 20

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Foe example the expressions can be used to e.g. combine fields or to

divide one field into two fields. To select a function double-click on the

functions and fields to be used in the expression, make sure to follow the

syntax that appears after selecting a function.

The last used expressions are available to select from the dropdown menu

in the field where the expressions are built up.

LEFT, returns a Variant (String) containing a specified number of

characters from the left side of a string.

RIGHT, returns a Variant (String) containing a specified number of

characters from the right side of a string.

MID, returns a Variant (String) containing a specified number of

characters from a string.

NULL, gives the field the value NULL

INSTR, Returns a Variant (Long) specifying the position of the first

occurrence of one string within another.

IIF, Returns the result one of two expressions, depending on the

evaluation of a conditional expression. The first expression is used if the

criteria is true.

VAL, Returns the numbers contained in a string as a numeric value of

appropriate type.

STR, Returns a Variant (String) representation of a number.

CHR, Returns a String containing the character associated with the

specified character code.

STRING, Returns a Variant (String) containing a repeating character

string of the length specified.

SPACE, Returns a Variant (String) consisting of the specified number of

spaces.

TRIM, LTRIM, RTRIM, Returns a Variant (String) containing a copy

of a specified string without leading spaces (LTrim), trailing spaces

(RTrim), or both leading and trailing spaces (Trim).

TIME, Returns a Variant (Date) indicating the current system time.

DATE, Returns a Variant (Date) containing the current system date.

UCASE, Returns a Variant (String) containing the specified string,

converted to uppercase.

LCASE, Returns a String that has been converted to lowercase.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 21

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

FORMAT, Returns a Variant (String) containing an expression formatted

according to instructions contained in a format expression.

For more detailed information regarding the functions use MS Access

help, which can be found in the Help menu.

Calculated fields, is a function that makes it possible to add a field in the

form where the value in the field is based on the expression built up in

Expression builder. Build an expression that gives the wanted result, in

the sample above the calculated field EN_H2 will be “1” if HI_LIM2 is

not Null.

Select Calculated Field and type in a suitable name for the field in

FieldName, press enter and the OK button.

Close the current form and select Rebuild Form from Template before

opening the form again, the new calculated field will then be available by

selecting in the wanted view.

Any existing calculated fields can be modified or deleted using

Expression builder. The form must be rebuilt after each change.

2.5.14 Copy Paste

The name PDA Copy/PDA Paste indicates that this is not a standard

copy paste function.

The PDA Copy function makes it possible to copy one or more signals,

Loops or Process Objects. The copy can be done within the same revision

or between revisions in the same project.

Use the record selector to select the signal(s) to copy, click the right-

mouse button and select Copy Signals. The selected signals will be

copied and the signal Name (SigTag) will have the same name as the

copied signal(s) with a “$” added in the beginning. Filter for signals like $

and give the copied signals a correct name.

Warning do not use [Ctrl] +[C] to copy signals, Loops or Process Objects

it will not work.

2.5.15 Sub Forms

The Sub Form function (that can be found under Design..) makes it

possible to view selectable subforms from the main forms. PDA will be

delivered with some subforms e.g. in Process Objects form and I/O

allocation form and then it is up to the administrator or user to build

subforms suitable for the local organisation.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 22

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

To activate existing subforms just select SubForms with a right-mouse

click in a form that contains subforms e.g. I/O allocation form and select

the subform(s) you want to see. When the subform first is opened another

record has to be selected in the mainform to show something in the

subform.

The subforms can be minimised and resized, the size and location will be

remembered if Save Form is used. Save Form can be found in right

mouse button menu under Forms Setting.. Close the form by deselecting

it in the Subform field select.

2.5.15.1 How to build new subforms

The first step is to build a suitable subform, which is a standard Access

form. The form must be built on a separate query, it will not work

correctly if the query is included in the form. A recommendation is to

name the form Subform:+ descriptive name to be able to identify the

subforms.

Select Sub Forms from the right-mouse button menu.

Select, select if the subform shall be visible or not.

Datasheet, select if the subform shall be shown in Datasheet view or

Form View, the recommendation is datasheet view.

Sub Form name, select the sub form to use, all forms are available

SubKey1, select the field to be used for the relation to the main form, all

fields for selected subform are shown

SubKey2, the second SubKey if more than one key is to be used

MainKey1, select the field to be used for the relation to the Sub form, all

fields for selected Main form are shown. The values must be the same as

in the subform to build up the relation, the field names do not have to be

the same.

MainKey2, the second MainKey if more than one key is to be used.

2.5.16 Freeze Columns

Use Freeze on the toolbar to freeze the selected columns on the left side

of the window to prevent them from scrolling off the screen.

2.5.17 Find

Use Find in the toolbar to search for a string, such as Signal tagname in a

datasheet or form.

Some of the above functions can be activated both from the right-mouse

button, the toolbar or the menu.

The recommendation is to use the right-mouse button menu where

available, to activate the functions. By using the right-mouse button menu

it is always clear in the current form, which menu options exist.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 23

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.5.18 Select File(s) to Work With

The Select File(s) to Work With makes it possible to filter which “Files”

to work with in the forms, as default all files are selected. If the project

has two different suppliers of data, this filter can be used to only work

with signals from one customer at the time during the I/O allocation.

2.5.19 Navigator (no more Supported in PDA 3.1)

2.5.20 Filtering Reports

It is possible to filter all the available reports. The function makes it

possible to add a user defined filter on any of the reports. Select Filter in

the right mouse menu in the print preview form.

Description, is used to give the filter a name. Use the record selector at

the bottom of the form to switch between the existing filter for the report.

The filters are saved per report.

FieldName, the name of the field to filter on. This is the name in the

query and it can differ from the name in the report.

Operator, the operator to be used for the criteria.

Criteria, the criteria.

Clear/Apply Filter, is used to switch between with and without filter.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 24

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Use above filter, activates the selected filter. Examine the result in the

report before printing it.

2.5.21 Compact database

To maintain the performance the databases should be compacted on a

regular basis.

This menu item can be found beside

the starting icon for PDA 3.1. This function is open for all users and it

will repair and compact the application database.

2.5.22 Default Values

This function enable you to define temporary default values to be used

when updating the data. Double-click in the field where you want to use

the default value.

The default values can be either text that is directly typed in or

expressions that pick up values from the other fields in the form. To use

Expressions select Build Expressions from the right mouse menu in the

above form.

To use the default values just select the default value to use and then

double-click in the field where to paste it. The default values are stored

per field per form and can be reused when ever you want.

Signal, shows all available signals. Can be useful when using signal

names in Process objects or Loops. If

Pro.Obj, shows all available Processobjects. Can be useful when using

Process object names in Signals or Loops. If [Process].[Name] is used in

the Build Expressions it will pick up the value from this field.

Node and Filter, is used to show only a limited number of Signals and

Process Objects. If [Signal].[SigTag] is used in the Build Expressions it

will pick up the value from this field.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 25

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Default Value can be used in combination with Fill Down and Series

Fill Down and will then take the values from the selected default value.

2.6 Import

2.6.1 Supplier Data format

The PDA requires that import data is of a specified format (see appendix

1) to pass the PDA internal validation checks and ensure that the data

relationships within the PDA are correct.

It is important that the rules given in appendix 1 are followed.

• If supplier is providing I/O schedules only then signals only would be

imported.

• If supplier is providing Loop data, Loops and Signals must be

imported with cross-reference in signals to Loops. The field

LoopName in Signals shall include the Loop that the signal belongs to.

• Make sure that the customers data field names do not include illegal

characters i.e. “spaces”, “/” and “.”. Also during the import do not use

these characters if you create new fields.

2.6.1.1 Importing data including I/O allocation

To import data including I/O allocation follow this procedure:

First import the Board data that should include a unique identity of the

board. The unique identity of the board have to be built up by using one

or more of the following fields, Node (Controller), Bus (LAN), Station

(if S800 I/O) and Designation. If all fields are filled in then the OCS

structure will be built up completely but if e.g. only board Designation is

used the signals still will be allocated to the boards but the Node, Bus and

Station will have to be added in PDA.

During import select Aut.Gen. Structure in the mapping form to

automatically build up the Node, Bus, Station structure.

The next step is to import the Signal data. Signal data must include the

same unique identification as for the Board, using one or more of the

fields, Node (Controller), Bus (LAN), Station (if S800 I/O) and

Designation. Channel have also to be included.

2.6.2 Select Files to import

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 26

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Before you start importing data, make sure you have selected the correct

project and revision.

ImportObject is used to define which type of data you are about to

import e.g. Signal data or Board data etc.

Supplier defines the supplier for current category, the PDA will then

identify which mapping for customer names to internal names to use,

providing this category/supplier combination has been used previously. If

this combination of category/supplier has not been used before, then you

will create the mapping in one of the next stages.

Use Browse to select the FileName to import. Select the file you wish to

import and press the Import button. The Following formats are possible to

import, Excel (*.xls),and Lotus (*.wk?). If you want to import other

formats please import the files to Excel first and save them in Excel 5.0

format.

It is possible to have more than one supplier per category and also more

than one file per supplier. The combination of Category +Supplier

+Filename must be unique. In most of the forms in PDA it is possible to

choose to work with all files or only one file at the time. This makes it

possible to e.g. do I/O allocation only on signals from one file. As default

all files are included.

Note!

SigTag have to be unique within the whole revision, not only within a

file.

The Description field can be used to describe the imported files.

Once you have selected ImportObject, Supplier and FileName the

Select will be marked up. If you proceed past this point, but then return to

it later, you will have to manually tick select”. You can now proceed to

the next stage by selecting the Next button.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 27

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Once a file has been successfully imported or signals have been created

in PDA, the Imported field will identify this by showing a tick.

To delete all data in PDA coming from a file that has been imported,

select the file to delete using the record selector for the file and then press

the delete button.

To delete a whole revision, use the form record selector and then press the

delete button. Deleting like this will remove all data for the file selected

from the current revision of the project. You may wish to do this if you

have made a mistake in the import and want to re-import the data.

View Mapping will bring up the following form.

In this form it is possible to view the default mapping. It is also possible

to delete mapping that has been done by mistake. Use record selector to

select the rows to delete and press the Delete key.

HDRS Import is used to directly import data from HOLCIM HDRS

Database.

2.6.3 Merging files

Merge files is used to merge two files into one

file. The function can be used if some signals have been created as if

supplied by system and these signals should have belonged to a specific

supplier.

Select the file to merge from and select Merge Files. The merged file will

as default inherit the File Name and description from the target file

selected to merge into.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 28

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.6.4 Preview data

In the listbox Spreadsheet type different versions of Excel or Lotus can

be selected for the file to be imported

First line includes fieldnames is selected as default, deselect it if the

fieldnames are not included in the file.

Range is to be used if only a part of the file shall be imported. In the

bottom of the form you can scroll through the contents of the file to

determine the format.

If Back is chosen nothing is imported and you will go back to the

previous screen. Select Next to go to next step of the import procedure

where the mapping is defined.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 29

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.6.5 Mapping

In the upper part of this form you can see the customer data with the

customer attribute names. The lower part of the form is used to perform

the mapping of customer names to PDA internal names.

By using the filter function it is possible to import only a part of the data.

Only the visible data will be imported.

It is possible to modify the customer data during import into PDA.

Examples of possible operations:

• Split one column into two or more columns.

• Concatenate two or more fields into one field.

• Update values using the Expression Builder or doing it manually. E.g.

if Loops and Signal data is mixed the same file the file can be

imported twice, first to import the Signal columns and then to import

the Loop values. This can also be useful if customer I/O allocation is

provided as a signal list only.

Mapping is used so that the customer can use different field names to

those in the PDA, thus the PDA Queries, Forms, and Reports can remain

consistent for different projects, customers, and suppliers. Also, because

the mapping is stored, data validation reports (see later) can be printed

using customer names or internal names.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 30

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

The mapping is stored for each category/supplier combination. After the

initial mapping has been done all subsequent imports using the same

category/supplier combination will automatically display the previously

used mapping. If on a subsequent import you decide not to import a

previously imported field then the mapping for this field will remain as

per the previous import. Also if you mistakenly map a customer field, that

you do not want to import, use View Mapping button to delete a mapping.

2.6.5.1 Automatic mapping

If the customer field corresponds to the field name used by PDA, the

mapping will be done automatically. Be careful to check that the customer

fields are used for the same purpose as the internal fields. The purpose of

the fields inside PDA is described in the description field. The fields do

not have to be in any specific order. The automatic mapping can be

changed manually.

2.6.5.2 Manual mapping

Customer field names that do not have any corresponding field names in

PDA have to be mapped manually using the Internal Name combo box.

There are a number of free fields that could be used to import attributes

that do not have a pre-defined function within the PDA. Fields that are

not mapped will not be imported into PDA.

The next time an import is done from the same supplier the mapping will

be automatically filled in and no further mapping is required, as long as

no changes have been made to the format.

Data type and length will be checked during import. If Write Error Log

is not selected and data of wrong data type or length is detected during the

import the user has three options, skip field, skip row or interrupt the

import. If Write Error Log is selected the errors will appear in the

error log.

2.6.6 Export data to file

It is possible to manipulate customer data at this stage of the

import. By using the Filter/Update function on the upper form fields can be

concatenated, truncated etc. Use the Export Data button to save the changed file

in the chosen file format before importing it. The purpose of saving the customer

data as this stage could be to make it possible to store the changes done before

importing the data. So if you have to go back you can import from this saved

file, containing the changes, rather than import from the original file and re-do

all the changes.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 31

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

Select format for the file e.g. Excel format. Select location for the file by

using the Browse button.

2.6.7 Add new fields in customer data

Use the Customer Name New Field

button to create a new field in customer data during import. The purpose

of creating a new field could be to add a field concatenating values from

two or more fields into a new field.

Give the new field a suitable name.

2.6.8 Add new field in Database

Use the Internal Name Table Setup button

to create a new field in the project database during import. The added fields will

store the imported data in the project database.

To be able to see the data in the different forms select Rebuild Form

from Template before opening the forms.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 32

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

This form will enable you to add Name and Type size and Description for

the new field.

By pressing the Advanced button the options below becomes available.

Here it is possible to define default values, validation rules etc. It is also

possible to add a combobox to give selectable values in the forms.

The Add field/s form shows all fields that you are about to add. Double-

click on a field to check/modify it, before selecting Create/Modify to add

the fields.

Using the Include Field button in will bring up all new fields from the

Excelfile that you are about to import. The fields as default gets the same

name as in customer file and the datatype is Text 255 as default. Modify

the fields by double-click in the form above and changing the values in

the Create/Modify.. form. Delete the item you not want to create. Select

Create/Modify to add all remaining fields.

Include Field.., will include all fields in the Excel file

(that not already exist in PDA) you are about to import and add the fields

in the Add field(s) form above. As default the fields will be set to Text

255 but can modified by double-clicking the field to modify.

This could e.g. be very useful when importing a new category of data.

Document number Lang. Rev. ind. Sheet

ABB Automation and Drives 3BSE020288D0005 en A 33

TEMPLATE: D2H_NORM.DOT; FILENAME: USER MANUAL PDA5_0.DOC; PRINTDATE: 3/7/2007 6:16:00 PM; SAVEDATE: 3/7/2007 6:15:00 PM

2.6.9 Test Structure

Test Structure button is used to perform a test of the

data structure. Run the check to define problems with the structure before

trying to import the data.

In sample above duplicate SigTag names have been identified. It is

possible to correct the error directly in this form and then run the Test

Structure again. It is also possible to use the Filter/Update function in

this form to support the correction of the errors. See in chapter Filtering

and Update functions on how to use the PDA Filter/Update function. It

is not possible to delete rows in this form, use the filtering function

described earlier in this chapter to prevent their import.

If something goes wrong during import, just click the Back button.

Nothing has been imported so far, so there is no problem to change the

settings up to now.

When everything is set up correctly just click the Import button. At this

point the data is imported into the project database.

2.6.10 Error log

Write Error Log creates an error log for the errors