Professional Documents

Culture Documents

Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller Bearings

Uploaded by

sureshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller Bearings

Uploaded by

sureshCopyright:

Available Formats

MOUNTING DESIGN, FITTING PRACTICE, SETTING AND INSTALLATION

SPHERICAL AND CYLINDRICAL ROLLER BEARINGS

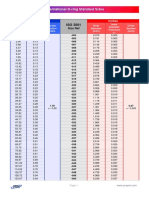

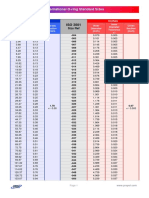

TABLE 41. RADIAL INTERNAL CLEARANCE LIMITS – SPHERICAL ROLLER BEARINGS – TAPERED BORE

TAPERED BORE

Suggested Axial Displacement of Inner Ring

Normal for RIC Reduction - Suggested

Bore C4 Reduction of RIC

CO Tapered Shaft(1) RIC After

(Nominal) Due to

Min. Max. Min. Max. Installation

Installation

C2 C3 C5 1:12 Taper(2) 1:30 Taper(2)

Over Incl. Min. Max. Min. Max. Min. Max. Min. Max. Max. Min. Max. Min. Min.

mm mm mm mm mm mm mm mm mm mm mm mm mm

mm mm

in. in. in. in. in. in. in. in. in. in. in. in. in.

24 30 0.02 0.03 0.04 0.055 0.075 0.095 0.015 0.02 0.30 0.23 - - 0.015

0.0008 0.0012 0.0016 0.0022 0.003 0.0037 0.0006 0.0008 0.0118 0.0091 - - 0.0006

30 40 0.025 0.035 0.05 0.065 0.085 0.105 0.02 0.025 0.38 0.30 - - 0.015

0.001 0.0014 0.002 0.0026 0.0033 0.0041 0.0008 0.001 0.0150 0.0118 - - 0.0006

40 50 0.03 0.045 0.06 0.08 0.1 0.13 0.025 0.03 0.46 0.38 - - 0.02

0.0012 0.0018 0.0024 0.0031 0.0039 0.0051 0.001 0.0012 0.0181 0.0150 - - 0.0008

50 65 0.04 0.055 0.075 0.095 0.12 0.16 0.03 0.038 0.56 0.46 - - 0.025

0.0016 0.0022 0.003 0.0037 0.0047 0.0063 0.0012 0.0015 0.0220 0.0181 - - 0.001

65 80 0.05 0.07 0.095 0.12 0.15 0.2 0.038 0.051 0.76 0.56 - - 0.025

0.002 0.0028 0.0037 0.0047 0.0059 0.0079 0.0015 0.002 0.0299 0.0220 - - 0.001

80 100 0.055 0.08 0.11 0.14 0.18 0.23 0.046 0.064 0.97 0.68 - - 0.036

0.0022 0.003 0.0043 0.0055 0.0071 0.0091 0.0018 0.0025 0.0382 0.0268 - - 0.0014

100 120 0.065 0.1 0.135 0.17 0.22 0.28 0.051 0.071 1.07 0.76 2.54 1.90 0.051

0.0026 0.0039 0.0053 0.0067 0.0087 0.011 0.002 0.0028 0.0421 0.0299 0.1000 0.0748 0.002

120 140 0.08 0.12 0.16 0.2 0.26 0.33 0.064 0.089 1.27 0.89 3.05 2.29 0.056

0.0031 0.0047 0.0063 0.0079 0.0102 0.013 0.0025 0.0035 0.0500 0.0350 0.1201 0.0902 0.0022

140 160 0.09 0.13 0.18 0.23 0.3 0.38 0.076 0.102 1.52 1.14 3.43 2.67 0.056

0.0035 0.0051 0.0071 0.0091 0.0118 0.015 0.003 0.004 0.0598 0.0449 0.1350 0.1051 0.0022

160 180 0.1 0.14 0.2 0.26 0.34 0.43 0.076 0.114 1.65 1.14 4.06 2.67 0.061

0.0039 0.0055 0.0079 0.0102 0.0134 0.0169 0.003 0.0045 0.0650 0.0449 0.1598 0.1051 0.0024

180 200 0.11 0.16 0.22 0.29 0.37 0.47 0.089 0.127 1.90 1.40 4.45 3.05 0.071

0.0043 0.0063 0.0087 0.0114 0.0146 0.0185 0.0035 0.005 0.0748 0.0551 0.1752 0.1201 0.0028

200 225 0.12 0.18 0.25 0.32 0.41 0.52 0.102 0.14 2.03 1.52 4.83 3.56 0.076

0.0047 0.0071 0.0098 0.0126 0.0161 0.0205 0.004 0.0055 0.0799 0.0598 0.1902 0.1402 0.003

225 250 0.14 0.2 0.27 0.35 0.45 0.57 0.114 0.152 2.29 1.78 5.33 4.06 0.089

0.0055 0.0079 0.0106 0.0138 0.0177 0.0224 0.0045 0.006 0.0902 0.0701 0.2098 0.1598 0.0035

250 280 0.15 0.22 0.3 0.39 0.49 0.62 0.114 0.165 2.54 1.78 5.84 4.06 0.102

0.0059 0.0087 0.0118 0.0154 0.0193 0.0244 0.0045 0.0065 0.1000 0.0701 0.2299 0.1598 0.004

280 315 0.17 0.24 0.33 0.43 0.54 0.68 0.127 0.178 2.67 1.90 6.22 4.45 0.102

0.0067 0.0094 0.013 0.0169 0.0213 0.0268 0.005 0.007 0.1051 0.0748 0.2449 0.1752 0.004

315 355 0.19 0.27 0.36 0.47 0.59 0.74 0.14 0.19 2.79 2.03 6.60 4.83 0.114

0.0075 0.0106 0.0142 0.0185 0.0232 0.0291 0.0055 0.0075 0.1098 0.0799 0.2598 0.1902 0.0045

355 400 0.21 0.3 0.4 0.52 0.65 0.82 0.152 0.203 3.05 2.29 7.11 5.33 0.127

0.0083 0.0118 0.0157 0.0205 0.0256 0.0323 0.006 0.008 0.1201 0.0902 0.2799 0.2098 0.005

400 450 0.23 0.33 0.44 0.57 0.72 0.91 0.165 0.216 3.3 2.54 7.62 5.84 0.152

0.0091 0.013 0.0173 0.0224 0.0283 0.0358 0.0065 0.0085 0.1299 0.1000 0.3000 0.2299 0.006

Note: Axial displacement values apply to solid-steel shafts or hollow shafts with bore diameter less than half the shaft diameter. Continued on next page.

For shaft materials other than steel, or for thin-walled shafts, please consult your Timken engineer

(1)This displacement is valid for assembly of tapered bore bearings and is measured starting from a line-to-line fit of the bearing

bore to the tapered shaft.

(2)1:12 Taper used for 222, 223, 230, 231, 232, 233, 239 series. 1:30 Taper used for 240, 241, 242 series. For sleeve mounting, multiply

axial displacement values by 1.1 for 1:12 Taper or by 1.05 for 1:30 Taper. For questions on tapered shaft data, consult your

Timken engineer.

86 TIMKEN ENGINEERING MANUAL

You might also like

- Measurement Conversion Table PDFDocument1 pageMeasurement Conversion Table PDFLalit KashyapNo ratings yet

- Atomic Molecular Optical Physics by Hertel C Schulz, Volume 1Document710 pagesAtomic Molecular Optical Physics by Hertel C Schulz, Volume 1anon_user-p100% (3)

- Cost Estimating Manual for Pipelines and Marine Structures: New Printing 1999From EverandCost Estimating Manual for Pipelines and Marine Structures: New Printing 1999Rating: 5 out of 5 stars5/5 (2)

- Composites in Aerospace PresentationDocument19 pagesComposites in Aerospace PresentationJithin Devan PadincharayilNo ratings yet

- Patterns and Equations Accomodated Unit TestDocument9 pagesPatterns and Equations Accomodated Unit Testapi-242345831100% (1)

- SR en 10025-04Document8 pagesSR en 10025-04pukla100% (2)

- SR en 10025-04Document8 pagesSR en 10025-04pukla100% (2)

- International Body Psychotherapy Journal Issue 2Document75 pagesInternational Body Psychotherapy Journal Issue 2Corina Tengher100% (2)

- O-Ring Standar Sizes PDFDocument14 pagesO-Ring Standar Sizes PDFJoseJSanchezNo ratings yet

- Iso 3601 PDFDocument14 pagesIso 3601 PDFSujalsathwara0% (1)

- DLL Bread and Pastry g7 8Document71 pagesDLL Bread and Pastry g7 8AvelynJamoraNo ratings yet

- Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingsDocument1 pageMounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingssureshNo ratings yet

- Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingsDocument1 pageMounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingssureshNo ratings yet

- Statin-Rev Canal 1150x250Document1,936 pagesStatin-Rev Canal 1150x250Thiago_R_ANo ratings yet

- Sheet Metal Thickness ChartDocument1 pageSheet Metal Thickness CharttylerstearnsNo ratings yet

- DisplacementDocument4 pagesDisplacementAndi HakimNo ratings yet

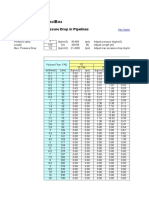

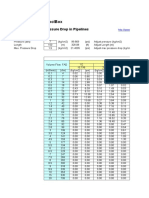

- Pressure DropDocument6 pagesPressure Dropdept.processnamoNo ratings yet

- CAESAR II 2019 Ver.11 Displacement ReportDocument66 pagesCAESAR II 2019 Ver.11 Displacement ReportAntonio Alonso Diaz ArriagaNo ratings yet

- Quality ChartDocument17 pagesQuality Chartlalankumar888rajNo ratings yet

- Folga Radial de RolamentoDocument1 pageFolga Radial de RolamentoDavid Lima de freitasNo ratings yet

- Up Down Up Up Down UpDocument41 pagesUp Down Up Up Down UpFaisal Rizki MujahidNo ratings yet

- Pressure DropDocument6 pagesPressure Dropeyas12hNo ratings yet

- The Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesDocument6 pagesThe Engineering Toolbox: Compressed Air - Pressure Drop in PipelinesSooraj S BabuNo ratings yet

- Engineering ToolBox Pressure Drop CalculatorDocument6 pagesEngineering ToolBox Pressure Drop CalculatorMinh TranNo ratings yet

- Engineering ToolBox Pressure Drop CalculatorDocument6 pagesEngineering ToolBox Pressure Drop CalculatorAnonymous 70lCzDJvNo ratings yet

- Engineering ToolBox Pressure Drop CalculatorDocument6 pagesEngineering ToolBox Pressure Drop Calculatorkrunal panchalNo ratings yet

- Dinamika Struktur 1Document14 pagesDinamika Struktur 1HOBI KuNo ratings yet

- Commercial Sieve Mesh DimensionsDocument9 pagesCommercial Sieve Mesh DimensionsMuhammad MuneebNo ratings yet

- Table 8Document1 pageTable 8mamnd tahaNo ratings yet

- Compressed Air Pressure Drop ChartDocument6 pagesCompressed Air Pressure Drop ChartWael WaelNo ratings yet

- Espectro de Diseño MADERADocument5 pagesEspectro de Diseño MADERAmatiasNo ratings yet

- HY-8 Culvert Analysis Report: Crossing Discharge DataDocument9 pagesHY-8 Culvert Analysis Report: Crossing Discharge DatajoselarNo ratings yet

- Solving First-Order Differential Equations NumericallyDocument10 pagesSolving First-Order Differential Equations NumericallyJemmyNo ratings yet

- Gid01 - DFS-PL-CPT37 Suite1Document221 pagesGid01 - DFS-PL-CPT37 Suite1morchedtounsiNo ratings yet

- Standard Normal TableDocument2 pagesStandard Normal TableJoseph TawfikNo ratings yet

- Makrolon 6487 Stress-Strain Data and CurveDocument3 pagesMakrolon 6487 Stress-Strain Data and Curvekrishnakant gargNo ratings yet

- Tensile Stress, Thread Root & Thread Stripping AreasDocument1 pageTensile Stress, Thread Root & Thread Stripping AreastedNo ratings yet

- Reporte Simu 2 FinDocument4 pagesReporte Simu 2 Finmariela nava riveraNo ratings yet

- Informe 4 (Datos)Document5 pagesInforme 4 (Datos)Zaira Camila CriolloNo ratings yet

- Mesh (Scale) : Mesh Series Have Been EstablishedDocument4 pagesMesh (Scale) : Mesh Series Have Been EstablishedKewell LimNo ratings yet

- A12 10400 EtDocument68 pagesA12 10400 EtAntonio Alonso Diaz ArriagaNo ratings yet

- IEEE 10 Generator 39 Bus System: General OutlineDocument7 pagesIEEE 10 Generator 39 Bus System: General Outlineadau100% (1)

- Matrix KU F (Beta!!)Document7 pagesMatrix KU F (Beta!!)Chelo RomanNo ratings yet

- Ejercicio Estructuras IIDocument17 pagesEjercicio Estructuras IIValentina ObesoNo ratings yet

- Process Capability Index - CPK: Potato Chip Salter % Salt 1.00 0.98 1.02 1.01 0.005Document33 pagesProcess Capability Index - CPK: Potato Chip Salter % Salt 1.00 0.98 1.02 1.01 0.005Abdulaziz AlzahraniNo ratings yet

- Typical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Document2 pagesTypical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Mohammad TaherNo ratings yet

- Standard Specifications For Metal Casting TolerancesDocument1 pageStandard Specifications For Metal Casting TolerancesJohn ChanNo ratings yet

- Isolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F PDocument7 pagesIsolated Footing: Fy DF 15 415 130 FOT Pu Mux Muy BC DC Req. A (KN) (KN-M) (KN-M) (MM) (MM) (FT) (FT) (M) (M) F Prockey shresthaNo ratings yet

- ISOLATED FOOTING DETAILSDocument7 pagesISOLATED FOOTING DETAILSSakar ShresthaNo ratings yet

- Phenolic Tolerances and Cross ReferenceDocument3 pagesPhenolic Tolerances and Cross ReferencecaelamparoNo ratings yet

- Consum Cherestea Decembrie 2014 Tabel de Calcul Paleti Din Lemn PTR Tabla Palet Din LemnDocument8 pagesConsum Cherestea Decembrie 2014 Tabel de Calcul Paleti Din Lemn PTR Tabla Palet Din LemnGheorghita FanelNo ratings yet

- Revisi ValidDocument12 pagesRevisi ValidirfanNo ratings yet

- Comprission Ratio 8 Coprission Ratio 10Document5 pagesComprission Ratio 8 Coprission Ratio 10zjpixrejNo ratings yet

- GSD PointSplineLoftFromExcelDocument1 pageGSD PointSplineLoftFromExcelVinoth KumarNo ratings yet

- Bessel Table: Ngu N: K60 - ĐTVT ĐH Bách Khoa Hà N IDocument1 pageBessel Table: Ngu N: K60 - ĐTVT ĐH Bách Khoa Hà N ILộc LýNo ratings yet

- International O-Ring Standar Sizes PDFDocument14 pagesInternational O-Ring Standar Sizes PDFJoseJSanchezNo ratings yet

- MN Karola DobrzeeeDocument94 pagesMN Karola DobrzeeePiKiVNo ratings yet

- Cedula CPQuinocay Final19.08.2019Document24 pagesCedula CPQuinocay Final19.08.2019EnriqueReyesNo ratings yet

- SamplingDocument4 pagesSamplingMahmoud KhalifaNo ratings yet

- Direccion X-X: Z U S 0.600 2.000 Irregular? No Ia Ip 0 Aislamiento? Zus/R G Zusg/R T TDocument19 pagesDireccion X-X: Z U S 0.600 2.000 Irregular? No Ia Ip 0 Aislamiento? Zus/R G Zusg/R T TGIANCARLO CHUMBES TRUJILLONo ratings yet

- Sheet Metal Thickness GaugesDocument1 pageSheet Metal Thickness Gaugesting.draganNo ratings yet

- Tatt Agrotek BDocument17 pagesTatt Agrotek BJun AdityaNo ratings yet

- Influence Factors For Vertical Pressure Caused by A Point Load On Circular AreaDocument2 pagesInfluence Factors For Vertical Pressure Caused by A Point Load On Circular AreaAkhtar BahramNo ratings yet

- ACalfunanco T3Document32 pagesACalfunanco T3AngelaNo ratings yet

- Le Parkour → Limpa cú: Analysis of Acceleration Using Mass and Time DataDocument6 pagesLe Parkour → Limpa cú: Analysis of Acceleration Using Mass and Time DataRaquel AzevedoNo ratings yet

- Tabla Lee-KeslerDocument16 pagesTabla Lee-Keslerghella MendozaNo ratings yet

- Suggested Backlash When Assembled Metric EnglishDocument1 pageSuggested Backlash When Assembled Metric EnglishKeith FlandersNo ratings yet

- BS970 1955Document2 pagesBS970 1955sureshNo ratings yet

- Quality E335Document1 pageQuality E335Sivanaga DantuluriNo ratings yet

- BS970 1955Document2 pagesBS970 1955sureshNo ratings yet

- BSPT Thread ChartDocument1 pageBSPT Thread ChartAli FikarNo ratings yet

- Quality E335Document1 pageQuality E335Sivanaga DantuluriNo ratings yet

- BSPT Thread ChartDocument1 pageBSPT Thread ChartAli FikarNo ratings yet

- Chanda Paints: Bitumen 158 BLACKDocument1 pageChanda Paints: Bitumen 158 BLACKsureshNo ratings yet

- Chanda Paints: Bitumen 158 BLACKDocument1 pageChanda Paints: Bitumen 158 BLACKsureshNo ratings yet

- Safety Data Sheet: TECTYL 506 RAL 5008Document6 pagesSafety Data Sheet: TECTYL 506 RAL 5008sureshNo ratings yet

- Chanda Paints: Bitumen 158 BLACKDocument1 pageChanda Paints: Bitumen 158 BLACKsureshNo ratings yet

- Safety Data Sheet: TECTYL 506 RAL 5008Document6 pagesSafety Data Sheet: TECTYL 506 RAL 5008sureshNo ratings yet

- Is 2269.2006-Hex Soc Hd. Cap ScrewDocument20 pagesIs 2269.2006-Hex Soc Hd. Cap ScrewdombipinNo ratings yet

- MSDS - Fuchs Anticorit BW 366 - 6dec06 (FES)Document7 pagesMSDS - Fuchs Anticorit BW 366 - 6dec06 (FES)sureshNo ratings yet

- Final Tender Document Karatsu Nov - 12 - 1Document21 pagesFinal Tender Document Karatsu Nov - 12 - 1sureshNo ratings yet

- Me Machine Shop Guide v2Document18 pagesMe Machine Shop Guide v2Ibrahim SameirNo ratings yet

- FT / FTR SERIES, Floor-Type Horizontal Boring MillsDocument16 pagesFT / FTR SERIES, Floor-Type Horizontal Boring MillssureshNo ratings yet

- MSDS - Fuchs Anticorit BW 366 - 6dec06 (FES)Document7 pagesMSDS - Fuchs Anticorit BW 366 - 6dec06 (FES)sureshNo ratings yet

- Final Tender Document Karatsu Nov - 12 - 1Document21 pagesFinal Tender Document Karatsu Nov - 12 - 1sureshNo ratings yet

- Final Tender Document Karatsu Nov - 12 - 1Document21 pagesFinal Tender Document Karatsu Nov - 12 - 1sureshNo ratings yet

- Lagermeister XXL GBDocument2 pagesLagermeister XXL GBsureshNo ratings yet

- Lagermeister XXL GBDocument2 pagesLagermeister XXL GBsureshNo ratings yet

- FT / FTR SERIES, Floor-Type Horizontal Boring MillsDocument16 pagesFT / FTR SERIES, Floor-Type Horizontal Boring MillssureshNo ratings yet

- Lagermeister XXL GBDocument2 pagesLagermeister XXL GBsureshNo ratings yet

- Chanda Paints: Bitumen 158 BLACKDocument1 pageChanda Paints: Bitumen 158 BLACKsureshNo ratings yet

- 3rd MODIFIED OXFORD-OREGON DEBATEDocument5 pages3rd MODIFIED OXFORD-OREGON DEBATEDoc AemiliusNo ratings yet

- CurriculumDocument3 pagesCurriculumJon SalvatierraNo ratings yet

- International Journal of English Language and Literature StudiesDocument9 pagesInternational Journal of English Language and Literature StudiesZara NurNo ratings yet

- JUST Safety Audit ReportDocument3 pagesJUST Safety Audit ReportMohammad LiftawiNo ratings yet

- About These Lesson Plans and ResourcesDocument8 pagesAbout These Lesson Plans and ResourcesAhmer TariqNo ratings yet

- Virtualization Enterprise Assignment 2Document2 pagesVirtualization Enterprise Assignment 2Rao Hammad ArshadNo ratings yet

- CV Mohsin GulzarDocument2 pagesCV Mohsin GulzarYousaf AsgharNo ratings yet

- Quiz Chapter 4 Questions and AnswersDocument10 pagesQuiz Chapter 4 Questions and AnswersHữu100% (2)

- Assignment MSL CaseDocument8 pagesAssignment MSL CasejenniferNo ratings yet

- AP Statistics - Chapter 8 Notes: Estimating With Confidence 8.1 - Confidence Interval BasicsDocument2 pagesAP Statistics - Chapter 8 Notes: Estimating With Confidence 8.1 - Confidence Interval BasicsRhivia LoratNo ratings yet

- Itala D'Ottavianno - Translations Between LogicsDocument6 pagesItala D'Ottavianno - Translations Between LogicsKherian GracherNo ratings yet

- Environmental Justice Case StudyDocument3 pagesEnvironmental Justice Case StudyIrish Pauline L. EreñoNo ratings yet

- The Making of A Modern Filipino HouseDocument16 pagesThe Making of A Modern Filipino HouseIvy Joy CamposNo ratings yet

- Bai Tap CNTTDocument198 pagesBai Tap CNTTthanhthao124No ratings yet

- U Wu Dkczu Fodkl: Low Carbon Development in China and IndiaDocument406 pagesU Wu Dkczu Fodkl: Low Carbon Development in China and IndiamaveryqNo ratings yet

- Employee perceptions of training programsDocument4 pagesEmployee perceptions of training programsReetika BhatiaNo ratings yet

- Indo Gulf Pest Control - Rodent Control Solutions & ThunderBolt TrapDocument17 pagesIndo Gulf Pest Control - Rodent Control Solutions & ThunderBolt Trapudyotta keshariNo ratings yet

- 4PH0 1P Que 20140515Document28 pages4PH0 1P Que 20140515ramexistsNo ratings yet

- Hyd 3Document1 pageHyd 3Jocelyn CabarlesNo ratings yet

- Detection of Incipient Faults in DistributionDocument9 pagesDetection of Incipient Faults in DistributionSahiba MirzaNo ratings yet

- Babasaheb Bhimrao Ambedkar University: (A Central University) Vidya Vihar, Rae Bareli Road, Lucknow-226025Document2 pagesBabasaheb Bhimrao Ambedkar University: (A Central University) Vidya Vihar, Rae Bareli Road, Lucknow-226025shrey YadavNo ratings yet

- CST 2410 Intro to Computer SecurityDocument3 pagesCST 2410 Intro to Computer SecurityMichael ZeroNo ratings yet

- Assignement 11.57 Residual PlotDocument11 pagesAssignement 11.57 Residual PlotMridul GuptaNo ratings yet

- 1 ZXMSG 5200 (V2 (1) .0.2) Technical ManualDocument69 pages1 ZXMSG 5200 (V2 (1) .0.2) Technical ManualNatan Getahun100% (2)