Professional Documents

Culture Documents

Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1

Uploaded by

mdmarufurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1

Uploaded by

mdmarufurCopyright:

Available Formats

MSc Sustainable Energy Systems

EUB_7_133

Renewable Energy Technologies 1

Photovoltaics

Department of Urban Engineering

2012/13

Alan Dunn 1 01/07/2021

Contents

1. Nomenclature....................................................................................................................4

2. Introduction.......................................................................................................................5

3. Basic principles..................................................................................................................5

3.1. Atomic structure of silicon........................................................................................5

3.2. Doping.......................................................................................................................6

3.3. Band Gap...................................................................................................................7

3.4. The PV Effect.............................................................................................................8

4. Four generations of photovoltaics.....................................................................................9

4.1. First Generation: Silicon based..................................................................................9

4.2. Second Generation: thin film................................................................................10

4.3. Third Generation: breaking the efficiency limit.......................................................10

4.3.1. Tandem cells...................................................................................................10

4.4. Summary.................................................................................................................10

5. Performance of photovoltaic modules............................................................................11

5.1. Configuration of PV modules..................................................................................11

5.2. Standard Test Conditions........................................................................................11

5.3. Strings and arrays....................................................................................................12

5.4. Temperature dependence......................................................................................12

5.5. Design conditions....................................................................................................13

5.6. Normal Operating Cell Temperature (NOCT)..........................................................13

5.7. Calculation of Power Output for Non-Standard Conditions....................................14

6. Shading, Soiling and Reflection Losses.............................................................................15

6.1. Shading...................................................................................................................15

6.2. Soiling......................................................................................................................16

6.3. Incident Angle Modifier (IAM).................................................................................16

6.3.1. Physical Model of IAM.....................................................................................16

6.3.2. ASHRAE Model................................................................................................17

6.3.3. Martin and Ruiz Model....................................................................................17

7. Model of a PV Cell...........................................................................................................18

7.1. The standard single-diode model............................................................................18

8. Module Temperature......................................................................................................20

9. Environmental Impact and Safety....................................................................................20

10. References..................................................................................................................21

11. Modelling Procedure..................................................................................................22

(a) Irradiance and Weather..............................................................................................22

(b) Incident Irradiance..................................................................................................22

Alan Dunn 2 01/07/2021

(c) Shading, Soiling, and Reflection Losses.......................................................................22

(d) Cell Temperature....................................................................................................22

(e) Module Output.......................................................................................................22

(f) DC and Mismatch Losses.............................................................................................22

(g) DC to DC Max Power Point Tracking...........................................................................22

(h) DC to AC Conversion...............................................................................................22

(i) AC Losses....................................................................................................................22

12. Solar cell single-diode model solution........................................................................23

12.1. Parameter extraction..............................................................................................23

12.2. Model solution........................................................................................................24

12.3. Example..................................................................................................................24

Alan Dunn 3 01/07/2021

1. Nomenclature

b eV Band gap

Greek

λ m Wavelength

Constants

c 299,792,458 m·s-1 Speed of light

h 6.63×10-34 J·s Planck’s Constant

e 1.602×10-19 C Elementary Charge

q 1.602×10-19 C Charge of the electron

k 1.381×10-23 J∙K-1 Boltzmann’s constant

Alan Dunn 4 01/07/2021

2. Introduction

Figure 1 Taxonomy of PV systems [ CITATION DGS08 \l 2057 ]

Photovoltaic modules may be integrated in a buildings structure [ CITATION CIB00 \l 2057 ]

but will not be specifically covered in this module.

3. Basic principles

Although there are an increasing number of materials being used to construct PV cells we

shall examine the principles using the most common, silicon, which is used in about 80% of

all installations.

3.1. Atomic structure of silicon

The atomic number of an element is determined by the number of

positively charged protons in its nucleus; in the case of silicon this is

14. The number of protons is matched by an equal number of

negatively charged electrons orbiting around the nucleus in electron

shells, as shown in Figure 2. Each shell can only hold a fixed number of

electrons: the first 2, the second 8, the third up to 18 etc. In fact each

shell is made up of a number of subshells as shown in Table 1.

Shell Subshell Subshell max Shell max Figure 2 Electron

name name electrons electrons configuration of silicon

K 1s 2 2

2s 2

L 8

2p 6

M 3s 2 18

3p 6

Alan Dunn 5 01/07/2021

3d 10

Table 1 Electron shells and subshells

Each shell corresponds to a particular energy level and there are no intermediate levels. If an

electron receives energy, by absorbing a photon, it can move up to the next shell. If it loses

energy by emitting a photon then it will drop back to a lower shell.

The outer shell, known as the valence shell, determines the element’s chemical properties –

how it combines with other atoms. If the valence shell is full, the element will be inert; if it is

not full, then it can combine with other atoms by sharing electrons.

The valence shell of pure silicon is not full and in its natural state will

share an electron from four adjacent silicon atoms forming a cubic

crystal lattice as shown in Figure 3. Above the valence band is the

conductance band which is empty at 0 oK, but if electrons in the valence

band absorb sufficient energy they can jump into the conductance band.

Figure 3 Structure of

In metals electrons move freely into the conductance band creating an monocrystalline silicon

electron cloud that can move through the solid transporting both

electrical charge and heat. Conversely, insulators have electrons locked in the valence shell

unable to move freely and therefore insulators do not conduct heat or electrical charge.

3.2. Doping

The ability of semiconductors to conduct charge, as you might expect, lies somewhere

between conductors and insulators. Natural semiconductors are to be found in Group IV of

the periodic table and include silicon and germanium. Others may be formed by binary

compounds of elements from adjoining groups. E.g. gallium arsenide (III-V), cadmium

telluride (II-VI).

The electrical properties of pure semiconductors may be modified by the process of doping.

Doping consists of introducing small quantities of another element into the crystalline

structure of the silicon. Doping silicon with group V elements such as phosphorus, which has

five electrons in its outer shell, introduces an extra valence electron in the lattice which can

become unbounded creating an electrically conductive n-type semiconductor.

Doping with a group III elements such as boron, which only has three electrons in the outer

shell, creates a broken bond in the lattice which is free to move and forms an electrically

conducting p-type semiconductor (Figure 4).

Alan Dunn 6 01/07/2021

Figure 4 Doping of silicon

If an n-type and p-type are placed together it will create a p-n junction. Electrons will diffuse

across the junction from the n-type material and fill the holes in the p-type material. As the

electrons migrate they will leave the phosphorus atoms in the n-type material with a positive

charge (+ve ion) and as they fill the holes the p-type material becomes negatively charged (-

ve ion). This build-up of charge creates a region depleted of charge carriers across which an

electric field opposes the flow of electrons and the flow will eventual stop.

Figure 5 Formation of electric field at p-n junction

3.3. Band Gap

The band gap, b is the difference in energy level between valence band and the conduction

band: electrons cannot exist in between these two levels. If an electron in the valence band

receives energy equal to, or greater than, the band gap it can jump into the conduction band

and mover through the crystalline structure. The energy of a photon depends upon its

wavelength – the shorter the wavelength the greater the energy.

The speed of light, c is the product of its frequency, f and wavelength, λ

c= λf 3-1

Alan Dunn 7 01/07/2021

The energy of a photon, E in Joules is

E=hf 3-2

Where h is Planck’s constant1.

Substituting for f from Equation 3 -1 to 3 -2 gives

hc

E= 3-3

λ

When dealing with photons it is usual to use units of electron volt (eV) rather than Joules.

Dividing by the elementary charge, e gives E in eV

hc

E= 3-4

λe

We can use Equation 3 -4 to find the and wavelength corresponding to a given band gap, b .

ch 1

λ= ∙ 3-5

e b

(Note: the wavelength is in metres.)

The band gap and corresponding wavelengths for various PV materials are shown in Figure 6.

Figure 6 Band gaps for various PV materials

Example

What is the cut-off wavelength corresponding to a band gap of 1.11 eV?

ch 1 299,792,458 × 6.63× 10−34 −9

λ= ∙ = × 10 =1,117 nm

e b 1,11 ×1.602 ×10−19

How do holes move?

In the first row below the hole (white)

1

is on the left with two electrons (blue)

The values of constants used in this derivation may be found

on theinright.

the The

Nomenclature

electron at B jumps

into the hole at A leaving a hole

behind. In row two the .electron at C

Alan Dunn 8

jumps into the new hole at B. 01/07/2021

3.4. The PV Effect

When electrons absorb a photon their electron bond is broken and they move from the

valence to the conduction band. The negatively charged electrons are pulled through the

electric al field into the n-region. The holes created in p-region remain in the valence band

and move in the opposite direction. If the PV is not connected to a load electrons will

accumulate at one terminal and holes at the other, creating the open circuit voltage.

If a load is connected, a current will flow with electrons leaving the cell, passing through the

load, and returning to the other terminal of the cell where they recombine with the waiting

holes.

Not all the electrons make it to the terminal. When they leave the depleted region and

diffuse through the n-region they may meet a boron atom with a missing electron (a hole)

and recombine. The electron will no longer generate a current and recombination reduces

the efficiency of the cell.

In Solar Resource we saw that solar radiation is distributed over a wide spectrum. Any

radiation at a wavelength having less energy than the band gap will not move electrons into

the conduction band and therefore will not generate electricity. In the example calculation

above radiation of a wavelength less than 1,117nm will not be converted to electricity.

Radiation of a shorter wavelength having energy greater than the band width will dislodge

electrons, but energy possessed by photons in excess to

the band with (1.11 eV for silicon) will simply heat the

cell.

This creates a theoretical maximum efficiency for

photovoltaics called the Shockley–Queisser limit. As

shown in Figure 7 the limit is 33.7% for a single p-n

junction with a band gap of 1.34 eV using an AM 1.5 solar

spectrum.

Figure 7 Shockley–Queisser limit

4. Four generations of photovoltaics

Although the boundaries are blurred, the industry speaks of four generations of photovoltaic

cell currently in use.

4.1. First Generation: Silicon based

The earliest, and still the most common, type of photovoltaic cell is made from silicon

semiconducting p-n junctions.

a. Monocrystalline Silicon

A large, pure crystal is grown, cut into thin wafers and doped. The process is expensive

but the technology is well established.

b. Polycrystalline

Alan Dunn 9 01/07/2021

Figure 8 Monocrystalline module Figure 9 Polycrystalline module

4.2. Second Generation: thin film

Second generation photovoltaics achieved a reduction in

cost through the development of thin film technologies.

Although less efficient than first generation they are cost

effective - if area is not restricted. These PVs may be grown

on flexible substrates which lead to interesting, aesthetically

pleasing applications. Three types:

a. Amorphous Silicon a-Si silicon is deposited on a

substrate copper, glass or plastic –cheaper – flexible,

lower efficiency.

b. Cadmium Telluride/Cadmium Sulfide (CdTe/CdS). Figure 10 Thin film technology

c. CIS and Copper Indium Gallium (di)Selenide (CIGS).

4.3. Third Generation: breaking the efficiency limit

Researchers are working in many different areas to overcome the Shockley–Queisser limit of

33% power efficiency for single band gap solar cells as discussed in Section 3.4. Most

attempts remain in the laboratory but two techniques are close to commercial use.

a. Nanocrystal dye sensitized

b. Concentrated 10 – 100 suns

4.3.1. Tandem cells

Common third-generation systems include multi-layer ("tandem") cells made of amorphous

silicon or gallium arsenide or even polymers. We have seen that a single junction cell can

only use a limited range of wavelengths – by stacking three junction made from different

materials with each turned to a different wavelength, more energy may be extracted.

Alan Dunn 10 01/07/2021

Figure 11 Tandem solar cell

4.4. Summary

Silicon Thin Film

Panel Type

Monocrystalline Polycrystalline Amorphous Silicon CIGS CdTe

Peak Power W/m2 160 140 120 100 50

Typical Efficiency/% 16 14 12 9.5 5

Area for 1 kWp 6.25 7.1 8.3 10 20

Table 2 Summary of PV performance data

5. Performance of photovoltaic modules

5.1. Configuration of PV modules

After manufacture cells are tested and matched in terms of current and voltage. Around 36 2

matched cells are then connected in series and encapsulated as shown in Figure 12. The

process of encapsulation means that the module efficiency is 1 – 2% less than the cell

efficiency

Figure 12 PV Module structure

5.2. Standard Test Conditions

Manufacturers publish data for PV modules measured under standard test conditions (STC)

as defined in [ CITATION IEC05 \l 2057 ] (Table 3)

2

A typical silicon cell has a voltage around 0.5 – 0.6 V and so 36 cells in series produces a

voltage of 18 – 21.6 V which is just right for charging 12 V lead acid batteries.

Alan Dunn 11 01/07/2021

Irradiance G 1000 W·m-2

Air Mass AM 1.5 -

Cell Temperature Tc 25 oC

Ambient air temperature Ta 20 oC

Wind speed v 1.0 m·s-1

Table 3 Standard Test Conditions (STC)

The test data provided by manufacturers is shown in Table 4. Manufacturers will provide at

plot of current versus voltage (an I-V curve) measured under STC.

V oc 22.1 V Open Circuit Voltage

∆ V oc -(80±10) mV·K-1 Temperature coefficient of V oc

I sc 5.0 A Short Circuit Current

∆ I sc (0.065±0.015) %·K-1 Temperature coefficient of I sc

NOCT 47±2 o

C Normal Operating Cell Temperature

Pmax 85 W Peak Power

Table 4 Typical PV performance data

The short-circuit current, I SC occurs when the module terminals are shorted and there is no

load resistance.

The open circuit voltage, V OC occurs when the

terminals are disconnect from the load and no

current flows.

Peak power, Pmax occurs at a point along the I-V

curve when the product of current and voltage is

a maximum.

An online[ CITATION Pho13 \l 2057 ] database

offers performance data for more than 48,000

PV modules – useful for comparisons.

Figure 13 I-V curve

5.3. Strings and arrays

For most applications multiple PV modules are required and we have the option of either

connecting them in series or in parallel, or a combination of both.

If they are connected in series they form what is known as a string. Each module will share

the same current but the voltage across the string will be the sum of the voltages across

each module. If they are connected in parallel the total current will be the sum of the

module currents and the voltage will be the same as a module.

Alan Dunn 12 01/07/2021

It is important that modules in a string are of the same type and ideally have their I_V curves

matched.

5.4. Temperature dependence

The short circuit current and the open circuit voltage are both dependent on the cell

temperature, making the power output also temperature dependent.

The published temperature coefficients (Table 4) indicate the degree of dependence which is

also shown in Figure 14. Notice that the short circuit current is the least affected, reducing

slightly with an increase in cell temperature. For practical purposes this dependence is often

neglected. Open circuit voltage is more strongly affected, increasing with an increase in

temperature.

Figure 14 shows that the current is

proportional to the solar irradiance, whereas

the voltage is only slightly affected.

Figure 14 Temperature and irradiance dependence of a PV

5.5. Design conditions

Variations in environmental operating conditions will affect the performance of the PV

module and should be taken into account when specifying the voltage/current ratings of the

DC system components. Currents and voltages may often exceed those quoted by the

manufacture for standard test conditions.

Maximum Voltage

This occurs when the modules are open

circuit and depends upon the cell

temperature. The sensitivity to

temperature change, the temperature

coefficient of V oc , is part of the

standard test and provided by

manufactures.

For example, for a typical a

monocrystalline cell, V oc = 0.6 V and ΔV oc = -2.1 mV·K-1. So, a 36 cell module operating at

0oC would have an open circuit voltage of:

V oc =n × ( V oc + ΔV oc × ΔT c )=¿

This compares with a V oc of 21.6 V under standard test conditions – an increase of nearly

9%.

Alan Dunn 13 01/07/2021

In fact, for design a multiplication factor of 1.15 is normally used corresponding to an

operating condition of -15oC.

Maximum Current

The maximum current produced by a cell

occurs under short circuit conditions and is

affected slightly by temperature, but more

significantly by the irradiance. Even in the UK

the irradiance can exceed the STC of 1000

W·m-2 if the sun is high in the sky, the sun is

not obstructed, and there is significant diffuse

radiation from surrounding cloud.

A design multiplication factor of 1.25 is

normally used for I sc .

The above factors do not include the initial high output during the first few weeks of

operation, nor does it include allowances for fouling (10-15%).

The above factors are for monocrystalline cells, other types of cell have different

characteristics. Peak values for V oc and I sc should be determined for individual

cases.

5.6. Normal Operating Cell Temperature (NOCT)

Manufacturers publish the NOCT which is the temperature of the PV cell when operating

under the following standard conditions.

Irradiance 0.8 kW·m-2

Spectral distribution AM 1.5

Ambient temperature 20oC

Wind speed > 1 m·s-1

It is assumed that there is a linear relationship between cell temperature, T a an ambient

temperature, T a and irradiation, G give by:

T c =T a+ ( NOCT−20

0.8 )G

This equation may be used to predict the cell temperature when operating under non-

standard conditions. This is a very simplified approach and subject of predicting cell

temperature is discussed further in Section 8.

5.7. Calculation of Power Output for Non-Standard Conditions

Using hourly values of irradiance and ambient temperature for a typical day in each month,

the performance of a PV module may be determined. At each hour the output of the PV is

recalculated accounting for the deviation between STC and the actual air temperature and

irradiance. This is best demonstrated by way of an example

Alan Dunn 14 01/07/2021

Example

Determine the actual power delivered by the module below at an hour when the global

irradiance is 700 W·m-2 and the ambient temperature is 34 oC.

Module Data

Number of cells 34

Cell size 125mm x125 mm

I sc 3 A

∆ I sc negligible

V oc 20.4

∆ V oc -2.3 mV·K-1

Pmax 45.9 W

NOCT 43oC

Solution

Short-circuit current

Ignoring the temperature coefficient for I sc which is small:

G

I sc , act =I sc, STC ×

G STC

Where G = actual irradiance, kW·m-2

0.7

I sc , act =3.0× =2.10 A

1.0

Solar cell temperature

Calculate the cell temperature under actual operating conditions:

T c −T a= ( NOCT0.8−20 ) G T =34+( 43−20

c

0.8 )

×0.7=54.12

Open-circuit voltage

Adjusting for the temperature dependence of V oc

∆ V oc=−2.3× n ×∆ T ¿−2.3 ×34 × (54.12−25 ) /1000=−2.28 V

V oc =20.4−2.28=18.1V

Peak Power

Calculate the module Fill Factor under Standard Test Conditions:

Pmax 45.9

FF= = =0.75

I sc V oc 3.0 × 20.4

Assuming that the Fill Factor is independent of ambient temperature, T a and irradiance, G ,

the power output under the actual operating conditions is:

Alan Dunn 15 01/07/2021

Pmax =2.1 ×18.1× 0.75=28.5W

Efficiency

Cell efficiency is given by:

Pmax

η=

Ac G

So, under standard test condition the efficiency is:

45.9

η= =0.086

( 34 × 0.125 ×0.125 ) ×1000

Under the actual operating conditions:

28.5

η= =0.077

( 34 × 0.125 ×0.125 ) ×700

So the efficiency reduces from 8.6% to 7.7%

6. Shading, Soiling and Reflection Losses

The calculated incident radiation on the plane of the array (POA) may be further reduced by

shading, soiling by dirt and increased reflection loss with non-normal angles of incidence.

6.1. Shading

When deciding on the location and orientation of PV arrays careful consideration must be

given to shading from distant and nearby objects[ CITATION DGS08 \l 2057 ]. Analysis

requires the use of software such as EcoTect of IES<VE>3 to model potential obstructions

throughout the year.

A shadow not only reduces the area of module in direct sunshine but turns shaded cells into

resistors.

6.2. Soiling

Soiling (or fouling) is the build-up of dirt on the glazed face of the collector. Increased

collector tilt improves the self-cleaning properties of a module (providing it rains) and there

is research into surface treatments to enhance the self-cleaning properties.

In some climate zones snow may cover PV modules for extended periods, even when

significant solar radiation is available.

6.3. Incident Angle Modifier (IAM)

3

LSBU students can download Ecotect for free and buy a student licence for IES<VE> for £50

per annum.

Alan Dunn 16 01/07/2021

When solar radiation strikes a glass surface some is reflected and some passes through the

glass and is refracted and absorbed as it passes through the glass. The value of reflection,

refraction and absorption are all functions of wavelength and polarisation.

Some PV modules have grooved surfaces that will …

Module performance data is based on a zero angle of incidence (i.e. radiation normal to the

POA). Unless the PV array is mounted on a 2-axis tracker, the angle of incidence will vary

throughout the day as the sun moves through the sky. As the angle of incidence increases,

the radiation reaching the PV will decrease because of increased reflection from the glass

cover. A correction is normally only made to the beam radiation, but there is also an effect

on the diffuse radiation. An Incident Angle Modifier for beam radiation, IAM B may be

defined as:

τ (θ )

IAM B = 6-6

τ (0 )

Where τ ( 0 ) is the transmittance at normal incidence ( θ=0) and τ ( θ ) is the transmittance at

an angle of incidence of θ .

6.3.1. Physical Model of IAM

PV cover may be modelled as a simple air-glass interface using laws by Snell and Bouguer as

described Chapter 5 [ CITATION Duf91 \l 2057 ] and [CITATION DeS05 \l 2057 ].

Snell’s law defines:

n2 v 1 sin θ1

= =

n1 v 2 sin θ2

1-0.5*(A+B)

The refractive index of air, n1 =1.0003, which can be taken as 1. The angle of refraction, θ2

is therefore

−1

θ2=sin ( n2 sinθ 1 ) 6-7

A typical refractive index for glass is 1.526

The transmission coefficient for a single surface of glass is given by:

2 2

− ( KL/ cos θ2)

τ ( θ ) =e

[ (

1−

1 sin ( θ2−θ 1 ) tan ( θ2 −θ1 )

+

2 sin 2 ( θ2 +θ 1) tan 2 ( θ 2+θ 1 ) )] 6-8

Where typical values might be

K 4 m-1 Glazing extinction coefficient

L 0.002 m Glazing thickness

Alan Dunn 17 01/07/2021

The exponential term in Equation 6 -8 is Bouguer’s Law4 that predicts the absorption of

radiation in a partially transparent medium. The term in square brackets comes from

Fresnel’s Law for reflection. (See Spreadsheet Tab: IAM2)

6.3.2. ASHRAE Model

A simple approach was developed by [ CITATION Sou66 \l 2057 ] and adopted by ASHRAE.

IAM B =1−b 0 ( 1/cos θ−1 ) 6-9

Where

θ = incidence angle on the plane of the array.

b 0 is normally taken as 0.1 for a thermal collector, but PVSYST recommends 0.05 for PVs.

Figure 15 ASHRAE Incident Angle Modifier

Notice that there is a discontinuity at θ=90o and some authors recommend that the

expression should not be used for θ>80 o. This not a serious problem as at such low angles

little electricity is being produced.

6.3.3. Martin and Ruiz Model

Another popular model of IAM is described in a series of papers [ CITATION Mar01 \l 2057 ],

[CITATION Mar02 \t \l 2057 ] and [CITATION Mar05 \t \l 2057 ]

It should be noted that the incident angle modifier is affected by the degree of soiling.

7. Model of a PV Cell

In section 5.5 we calculated the new maximum power and efficiency of a PV operating under

non-standard conditions. This is often sufficient for our modelling needs, however there are

times when we would like to generate the complete I-V curve under non-standard

conditions. Such a model is required for the software in a maximum power point tracker.

A variety of models are available based on equivalent circuits[ CITATION Cas02 \l 2057 ],

[ CITATION Gra11 \l 2057 ] and the simplest is present below.

4

Also known as the Beer–Lambert–Bouguer law, or various combinations thereof.

Alan Dunn 18 01/07/2021

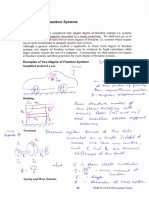

7.1. The standard single-diode model

The performance of a PV cell may be simulated using the Shockley's simple "one diode"

model based on the equivalent circuit in Figure 16 below.[CITATION San13 \l 2057 ]

The power source generates a current I ph

proportional to irradiance. At a low

voltage the parallel diode will pass very

little current, but as the voltage rises

current through the diode will increase,

decreasing the current delivered by the

cell.

The series resistor R s is of the order of a

few milliohms and represents the voltage

drop as the charge carriers migrate

through the resistive semiconductor and

the electrical contacts.

The shunt resistor R sh models shunts at the emitter layer or cell border. Recombination

losses may be modelled by the addition of a second diode, but are not considered here.

Figure 16 PV Equivalent Circuit

Using Kirchhoff’s current law

I =I ph−I d−I sh 7-10

I A Load current supplied by the cell/module

I ph A Light-generated current in cell

Id A Diode current, represents the voltage-

dependent current lost to recombination

I d is modeled using the Shockley equation for an ideal diode:

V + I ∙ Rs

[ (

I d=I 0 exp

nVT )−1

] 7-11

WhereV + I ∙ Rs is the voltage across the diode, n is the diode ideality factor (dimensionless

and usually between 1 and 2 for a single junction cell), I 0 is the saturation current, and V T is

the thermal voltage given by:

Alan Dunn 19 01/07/2021

k Tc

VT=

q

From Kirchhoff’s voltage law the voltage drop around the left-hand loop must equal zero. So

V + I R s + I sh Rsh

Rearranging

V + I Rs

I sh = 7-12

R sh

Substituting equations 7 -11 and 7 -12 into equation 7 -10 gives the complete governing

equation for the single diode model

V + I ∙ Rs V + I ∙ Rs

[

I =I ph−I 0 exp

( nVT ) ]

−1 −

R sh

7-13

And the power, P is given by

P=IV

Where

V V Voltage at the terminals of the module

q 1.602×10-19 C Charge of the electron

k 1.381×10-23 J∙K-1 Boltzmann’s constant

n - Diode quality factor, normally between 1 and 2

N cs - Number of cells in series.

Tc K Effective temperature of the cells

To use the equation five parameters must be known, all of which may be a function of cell

temperature:

I ph A Light-generated current in cell

I0 A Inverse saturation current

Rs Ω Series resistance

R sh Ω Shunt resistance

a Curve fitting parameter

Model parameters can be estimated from manufacturers’ data measured a standard test

conditions.[ CITATION Duf91 \l 2057 ][ CITATION Sch07 \l 2057 ].

To determine five parameters we need to know the current and voltage at five measured

points. However, manufacturers normally only publish three: open circuit, short circuit and

maximum power point.

PVSyst is a sophisticated tool for modelling the performance of solar systems. It uses the

single diode model and the manual[ CITATION PVs13 \l 2057 ] explains how the equations

are solved.

8. Module Temperature

Alan Dunn 20 01/07/2021

At the design stage it is necessary to predict the module temperature under installed

conditions as it strongly affects the output of the module.

We have seen that a PV module does not convert all the incident radiation into electricity.

The radiation that is not converted will heat the module, increasing its temperature until the

long-wave radiative and convective heat losses are equal to the radiant heat input. At this

point the module will reach an equilibrium temperature.

Factors that determine the module temperature include incident solar radiation, air

temperature, wind speed and direction, mean radiant temperature of the surroundings, the

geometry of the module installation, and the construction of the module itself.

It should be noted that the module rarely reaches an equilibrium temperature as the climate

variables are constantly changing and change is not instantaneous because of the thermal

capacity of the module. Other real-world complexities which are rarely considered:

- There will be a difference between cell temperatures on the same module.

Differences of up to 2 K between centre and corner cells have been reported.

[ CITATION Fai08 \l 2057 ]

- Different modules in a array may be at different temperatures owing to the

mounting geometry.

Faiman published a module temperature model that has been widely adopted.[CITATION

Fai08 \l 2057 ] The model uses a modified form of the Hottel-Whillier-Bliss equation used to

analyse flat-plate solar collectors.

G

T c =T a+ 8-14

U +U '1 v

'

0

Values of U '0 and U '1 are found by fitting data. Faiman found the values to be fairly constant

for the seven collector types he studied and proposed the following values:

U '0 =24.9± 1.0 W ∙m −2 K−1

U '1=7.0 ± 0.55 W ∙m −2 K−1

Example

What will be the temperature of a PV module when the irradiance is 700

W·m-2, the ambient temperature is 26oc and the wind speed is 4 m·s-1?

G 700

T c =T a+ =26+ =39.2o C

' '

U +U 1 v

0

24.9+7 × 4

9. Environmental Impact and Safety

A common misconception is that more energy is expended in the manufacture and

installation of PVs than the energy generated in their lifetime. This may have been true with

early PVs, but modern efficient production technologies have dramatically improved the

energy payback time (EPT).

A Japanese team found the EPT of thin film CdS/CdTe PV modules to be 1.7–1.1 years and

the life-cycle CO2 emissions were estimated at 14–9 g-C/kWh, which was less than that of

electricity generated by utility companies.[ CITATION Kaz01 \l 2057 ]

Alan Dunn 21 01/07/2021

A European study found silicon PV systems to have energy pay-back times of 1.5-2 years for

South-European locations and 2.7-3.5 years for Middle-European locations. Thin film

technologies were found to have energy pay-back times in the range of 1-1.5 years for

Southern Europe.[CITATION Als06 \l 2057 ]

10. References

Alsema, E. A., & de Wild-Scholten, M. J. (2006). Environmental impacts of PV electricity

generation - a critical comparison of energy supply options. 21st European

Photovoltaic Solar Energy Conference,. Dresden.

Castañer, L., & Silvestre, S. (2002). Modelling photovoltaic systems using PSpice. Chichester:

Wiley.

CIBSE. (2000). TM 25 Understanding building integrated photovoltaics. London: Chartered

Institution of Building Services Engineers.

De Soto, W., Klein, S. A., & Beckman, W. A. (2006). Improvement in the validation of a model

for photovoltaic array performance. Solar Energy 80, 78-88.

DGS. (2008). Site surveys and shading analysis. In DGS, Planning and installing photovoltaic

systems (pp. 129-150). London: Earthscan.

Duffie, J. A., & Beckman, W. A. (1991). Solar Engineering of Thermal Processes (2nd ed.). New

York: Wiley.

Faiman, D. (2008). Assessing the outdoor operating temperature of photovoltaic modules.

Progress in Photovoltaics: Research and Application, 16(4), 307-315.

Gray, J. L. (2011). The Physics of the Solar Cell. In S. Hegedus, & A. Luque, Handbook of

Photovoltaic Science and Engineering. John Wiley.

IEC. (2005). 61215 Crystalline silicon terrestrial photovoltaic (PV) modules – Design

qualification and type approval. Geneva: International Electrotechnical Commission,.

Kazuhiko, K. (2001, March). A life-cycle analysis on thin-film CdS/CdTe PV modules. Solar

Energy Materials and Solar Cells, 67(1-4), 279–287.

Martin, N., & Ruiz, J. M. (2001). Calculation of the PV modules angular losses under field

conditions by means of an analytical model. Solar Energy Materials & Solar Cells 70,

25-38.

Martin, N., & Ruiz, J. M. (2002). A New Model for PV Modules Angular Losses Under Field

Conditions. International Journal of Solar Energy , 22(1) 19-31.

Martin, N., & Ruiz, J. M. (2005). Annual Angular Reflection Losses in PV Modules. Progress in

Photovoltaics: Research and Applications, 13 75-84.

Photon. (2013, September 30). Solar Module Database. Retrieved 9 30, 2013, from

Photon.info: http://www.photon.info/photon_site_db_solarmodule_en.photon

PVsyst. (2013, 9 30). PV Module - model description. Retrieved 9 30, 2013, from PVsyst 6

Help: http://files.pvsyst.com/help/index.html

Sandia National Laboratories. (2013). Retrieved 5 30, 2013, from PV Performance Modeling

Collaborative: http://pvpmc.org/

Sandia National Laboratories. (2013). Single Diode Equivalent Circuit Models. Retrieved 5 28,

2013, from PV Performance Modelling Collaborative: http://pvpmc.org/modeling-

steps/module-iv-curve/diode-equivalent-circuit-models/

Schumacher, J., Eicke, U., Pietruschka, D., & Catani, A. (2007). Exact Analytical Calculation of

the One-diode Model Parameters from PV Module Data Sheet Information. 22nd

European Photovoltaic Solar Energy Conference. Milan.

Souka, A. F., & Safwat, H. H. (1966). Determination of the optimum orientations for the

double-exposure, flat-plate collector and its reflectors. Solar Energy, 10, 170-174.

Alan Dunn 22 01/07/2021

Click on RefWorks to access a supplementary online bibliography.

Background Reading: http://pveducation.org/

11. Modelling Procedure

The PV Performance Modelling Collaborative[CITATION Sca13 \l 2057 ] proposes a series of

steps for modelling a PV system. This is an excellent website for PV modelling – very practical

and with a wide selection of algorithms.

(a) Irradiance and Weather

Definition of irradiance and weather data for the performance model

(b) Incident Irradiance

Transposition of irradiance into direct and diffuse components

Translation of irradiance to the Plane-of-Array (POA)

(c) Shading, Soiling, and Reflection Losses

Evaluation of the loss of irradiance due to shading, soiling, and reflection losses

(d) Cell Temperature

Calculation of cell temperature from irradiance, ambient air temperature and wind speed

(e) Module Output

Calculation of the I-V curve for the specific irradiance and temperature conditions

(f)DC and Mismatch Losses

All series strings of modules must operate at the same current and all parallel string must

operate at the same voltage. If all modules are not operating identically some module will

not be operating at the maximum power point (MPP). Reasons why modules may not be

operating identically include:

Inherent performance difference

Heterogeneous irradiation

Differential wiring losses

(g) DC to DC Max Power Point Tracking

Adjusting the DC voltage to maximize output power from the array

(h) DC to AC Conversion

Most modern inverters operate with a conversion efficiency of 95%, but this does vary with

DC voltage, AC output power and sometimes temperature.

(i) AC Losses

Alan Dunn 23 01/07/2021

For domestic applications these losses will be negligible, but for larger systems where power

must be transferred a significant distance or raised in voltage through a transformer before

being connected to the grid, the losses must be accounted for.

Alan Dunn 24 01/07/2021

12.Solar cell single-diode model solution

In Section 7 a single diode model was developed that may be used to generate I-V curves

and predict the power produced by a cell or PV module.

V + I ∙ Rs V + I ∙ Rs

I =I ph−I 0 exp[ ( a )

−1 − ]

R sh

12-15

In order to use the equation five parameters must be quantified:

I ph A Photo current

Io A Diode reverse saturation current

Rs Ω Series resistance

R sh Ω Shunt resistance

a Modified ideality factor

12.1. Parameter extraction

These five parameters are determined using information provided under test conditions and

available from manufacturers’ literature following the method of [CITATION DeS05 \l 2057 ]

First known condition: short circuit

At short circuit conditions the load resistance is zero and the diode current is very small: so

the light current is equal to the short circuit current, I =I sc, and the voltage is zero, V =0.

Substituting into Equation 12 -15 gives:

I sc =I ph−I 0 exp [ ( I a∙ R )−1]− IR R

sc s sc

sh

s

12-16

Second known condition: open circuit

At the open circuit condition the current is zero I =0 and V =Voc , so Equation 12 -15

becomes

[

0=I ph−I 0 exp ( Va )−1]− VR

oc oc

sh

12-17

Third known condition: maximum power

At maximum power I =I mp and V =V mp which when substituted into Equation 12 -15 gives:

[

I mp=I ph−I o exp (V mp + I mp ∙ R s

a ) V +I R

]

−1 − mp mp s

R sh

12-18

Fourth known condition: derivative at maximum power is zero

d ( IV ) dI

dV |

mp

=I mp −V mp

dV | =0mp

12-19

Where

Alan Dunn 25 01/07/2021

−I o V +I mp Rs

1

mp

a

e −

dI a R sh

dV | = 1+ I R e

mp o s

V mp +I mp Rs

a

R

+ s

12-20

a R sh

Fifth known condition: derivative of the current at I sc

−I o I Rs

1

sc

a

e −

dI a Rsh 1

dV |I= I sc

=

1+

I o Rs

e

I sc R s

a

+

Rs

=

Rsh

a R sh

12.2. Model solution

The final equation is implicit, there is no analytical solution and it must be solved using

numerical methods.

12.3. Example

A PV module with 36 cells in series and an area of 0.427 m 2 has the following measured

characteristics at reference conditions:

I sc 2.9 A

V oc 20 V

I mp 2.67 A

V mp 16.5 V

μ I ,sc 1.325x10-3 A∙K-1

μV , oc -0.0775 V∙ K-1

Alan Dunn 26 01/07/2021

You might also like

- Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1Document26 pagesPhotovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1mdmarufurNo ratings yet

- UNESCO-NIGERIA TECHNICAL VOCATIONAL EDUCATIONDocument56 pagesUNESCO-NIGERIA TECHNICAL VOCATIONAL EDUCATIONDaniel Ayodeji Olawusi95% (20)

- (Undergraduate Lecture Notes in Physics) Wolfgang Demtröder - Electrodynamics and Optics (2019, Springer International Publishing)Document458 pages(Undergraduate Lecture Notes in Physics) Wolfgang Demtröder - Electrodynamics and Optics (2019, Springer International Publishing)Anum ZulfiqarNo ratings yet

- W 4 BookDocument55 pagesW 4 BookAdri De Udok100% (1)

- MIT Physics 8.02: Electricity & Magnetism: Course NotesDocument539 pagesMIT Physics 8.02: Electricity & Magnetism: Course NotesAnh Lương QuỳnhNo ratings yet

- Introduction To Quantum Electromagnetic CircuitsDocument59 pagesIntroduction To Quantum Electromagnetic CircuitsJohn BirdNo ratings yet

- Energy Storage Technology Review Kyle Bradbury 2010Document34 pagesEnergy Storage Technology Review Kyle Bradbury 2010nguyenphong201No ratings yet

- Computational ElectrochemistryDocument220 pagesComputational ElectrochemistryAnna Carolina MachadoNo ratings yet

- Electricity and MagnetismDocument74 pagesElectricity and MagnetismfaborodeharyomideNo ratings yet

- SMESDocument15 pagesSMESsimone.gallaretoNo ratings yet

- Lectures Week1 enDocument17 pagesLectures Week1 enDavid OliveiraNo ratings yet

- 6 732-pt2Document198 pages6 732-pt2Lalatendu BiswalNo ratings yet

- Molecular Electronics: Universit' A Degli Studi Di CataniaDocument32 pagesMolecular Electronics: Universit' A Degli Studi Di CataniaSatish Kumar KollaNo ratings yet

- Sanet - ST 3110349914Document218 pagesSanet - ST 3110349914aiko miNo ratings yet

- Schaum's Outline of Basic Electricity, Second EditionFrom EverandSchaum's Outline of Basic Electricity, Second EditionRating: 5 out of 5 stars5/5 (14)

- SSP TextDocument168 pagesSSP Textjagadeeshkumar116No ratings yet

- Semiconductor Physics and Laser Technology NotesDocument175 pagesSemiconductor Physics and Laser Technology NotesRandomNo ratings yet

- Floating Photovoltaic Systems on Dams: A Preliminary StudyDocument41 pagesFloating Photovoltaic Systems on Dams: A Preliminary StudybluesbankyNo ratings yet

- Eth 14436Document125 pagesEth 14436mandipjungNo ratings yet

- Kamberaj2022 Book ElectromagnetismDocument400 pagesKamberaj2022 Book Electromagnetismernes argeNo ratings yet

- Characterization TechniquesDocument84 pagesCharacterization TechniquesRajendra HalorNo ratings yet

- Worked Examples From Introductory Physics Vol. V: Electric Currents and Magnetic FieldsDocument27 pagesWorked Examples From Introductory Physics Vol. V: Electric Currents and Magnetic FieldsAryn PhillipsNo ratings yet

- Lecture NotesDocument165 pagesLecture NotesCamiloUlloaNo ratings yet

- Solar Power PlantDocument22 pagesSolar Power PlantAbrhaNo ratings yet

- Solar Power PlantDocument22 pagesSolar Power PlantAbrhaNo ratings yet

- Quantum DevicesDocument132 pagesQuantum DevicesAritra LahiriNo ratings yet

- Geometrical BioelectrodynamicsDocument38 pagesGeometrical BioelectrodynamicsEstácio NetoNo ratings yet

- Field Theory HandoutsDocument217 pagesField Theory HandoutsDer Untiringe KäferNo ratings yet

- Electromagnetic Field TheoryDocument262 pagesElectromagnetic Field TheoryDuygu Nazan Gençoğlan100% (2)

- Field Theory PDFDocument217 pagesField Theory PDFCristian LópezNo ratings yet

- Solid State Theory NotesDocument164 pagesSolid State Theory NotesBasharat AhmadNo ratings yet

- Electro Erf EffectsDocument246 pagesElectro Erf Effectsaeroseb1No ratings yet

- Modern Aspects of Electrochemistry No. 34 - B. E. ConwayDocument296 pagesModern Aspects of Electrochemistry No. 34 - B. E. ConwaycyberdjoxNo ratings yet

- The Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionFrom EverandThe Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionNo ratings yet

- StaelinDocument443 pagesStaelinWilliam Marques100% (2)

- S3 KTU-Solid State Devices Module 1Document15 pagesS3 KTU-Solid State Devices Module 1nadheera ayisha67% (3)

- Large Scale Solar Power System DesignDocument90 pagesLarge Scale Solar Power System Design김동욱No ratings yet

- PH 409: Introduction To Condensed Matter PhysicsDocument168 pagesPH 409: Introduction To Condensed Matter Physics李亞竹No ratings yet

- Solid StateDocument167 pagesSolid StateramanrajputgNo ratings yet

- PoS 2014Document103 pagesPoS 2014Ladla Prince MNo ratings yet

- Hall EffektDocument15 pagesHall EffektputeluNo ratings yet

- Optical and Electronic Properties of Atomically Thin Layered Materials: First Principles CalculationsDocument162 pagesOptical and Electronic Properties of Atomically Thin Layered Materials: First Principles CalculationsMehmet YurtseverNo ratings yet

- Week 19 A2 Questions Name .. /40 1.: (Total 6 Marks)Document4 pagesWeek 19 A2 Questions Name .. /40 1.: (Total 6 Marks)Solace HusseinNo ratings yet

- Physical Handout NotesDocument121 pagesPhysical Handout NotesJimmy MachariaNo ratings yet

- Fundamentals of Electromagnetics (Full Book)Document228 pagesFundamentals of Electromagnetics (Full Book)Cooper Dawson100% (2)

- Undergraduate Research Report - Bimodal Tesla CoilDocument21 pagesUndergraduate Research Report - Bimodal Tesla CoilyogeshNo ratings yet

- Syllabi 2Document118 pagesSyllabi 2Nick ManshandenNo ratings yet

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- The Finite Element Method for Electromagnetic ModelingFrom EverandThe Finite Element Method for Electromagnetic ModelingGérard MeunierNo ratings yet

- Environmental Electrochemistry: Fundamentals and Applications in Pollution Sensors and AbatementFrom EverandEnvironmental Electrochemistry: Fundamentals and Applications in Pollution Sensors and AbatementNo ratings yet

- The Magnetic Universe: Geophysical and Astrophysical Dynamo TheoryFrom EverandThe Magnetic Universe: Geophysical and Astrophysical Dynamo TheoryNo ratings yet

- Electroanalysis: Theory and Applications in Aqueous and Non-Aqueous Media and in Automated Chemical ControlFrom EverandElectroanalysis: Theory and Applications in Aqueous and Non-Aqueous Media and in Automated Chemical ControlNo ratings yet

- Advanced Synthesis of Gold and Zirconia Nanoparticles and their CharacterizationFrom EverandAdvanced Synthesis of Gold and Zirconia Nanoparticles and their CharacterizationNo ratings yet

- Solar Resource Lecture Notes Rev2Document68 pagesSolar Resource Lecture Notes Rev2mdmarufurNo ratings yet

- Addendum To PV Notes: 1 Fill Factor, FFDocument6 pagesAddendum To PV Notes: 1 Fill Factor, FFmdmarufurNo ratings yet

- Problems: Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1Document6 pagesProblems: Photovoltaics: EUB - 7 - 133 Renewable Energy Technologies 1mdmarufur100% (1)

- Solutions: The Solar ResourceDocument14 pagesSolutions: The Solar ResourcemdmarufurNo ratings yet

- MSc Sustainable Energy Systems: The Solar ResourceDocument57 pagesMSc Sustainable Energy Systems: The Solar ResourcemdmarufurNo ratings yet

- Lectures 20 21 2017Document8 pagesLectures 20 21 2017mdmarufurNo ratings yet

- First Law of Thermodynamic CalculationsDocument3 pagesFirst Law of Thermodynamic CalculationsmdmarufurNo ratings yet

- Photovoltaic ExercisesDocument2 pagesPhotovoltaic ExercisesmdmarufurNo ratings yet

- Problems: The Solar ResourceDocument3 pagesProblems: The Solar ResourcemdmarufurNo ratings yet

- The Air Standard Diesel Cycle: (Ideal Cycle For Some Low Speed CI Engines)Document32 pagesThe Air Standard Diesel Cycle: (Ideal Cycle For Some Low Speed CI Engines)mdmarufurNo ratings yet

- Problems SupplementDocument3 pagesProblems SupplementmdmarufurNo ratings yet

- Control Engineering Exercise Questions and Answers - Control Y3 2011-12Document1 pageControl Engineering Exercise Questions and Answers - Control Y3 2011-12mdmarufurNo ratings yet

- Lectures 14 19 2017Document22 pagesLectures 14 19 2017mdmarufurNo ratings yet

- Block Diagram Representation of Control SystemsDocument71 pagesBlock Diagram Representation of Control SystemsmdmarufurNo ratings yet

- Week 1 Exercise Questions and Answers - Control Y3 2011-12Document7 pagesWeek 1 Exercise Questions and Answers - Control Y3 2011-12mdmarufurNo ratings yet

- Introduction To Vapour Compression Refrigeration - Example AnswersDocument1 pageIntroduction To Vapour Compression Refrigeration - Example AnswersmdmarufurNo ratings yet

- Fluid Mechanics d203Document302 pagesFluid Mechanics d203Vignesh SundaramNo ratings yet

- Stress concentration around small circular holeDocument1 pageStress concentration around small circular holemdmarufurNo ratings yet

- Worked ExamplesFatigueDocument2 pagesWorked ExamplesFatiguemdmarufurNo ratings yet

- Week 1 Exercise Questions and Answers - Control Y3 2011-122Document6 pagesWeek 1 Exercise Questions and Answers - Control Y3 2011-122mdmarufurNo ratings yet

- Introduction To Vapour Compression RefrigerationDocument9 pagesIntroduction To Vapour Compression RefrigerationmdmarufurNo ratings yet

- Wear Mechanisms 11 BBDocument17 pagesWear Mechanisms 11 BBmdmarufurNo ratings yet

- Refrigeration Systems 2Document29 pagesRefrigeration Systems 2mdmarufurNo ratings yet

- Materials Course Work Font PageDocument1 pageMaterials Course Work Font PagemdmarufurNo ratings yet

- General Approach To Solve Stress ProblemDocument2 pagesGeneral Approach To Solve Stress ProblemmdmarufurNo ratings yet

- Fatigue OhpsDocument2 pagesFatigue OhpsmdmarufurNo ratings yet

- EmmnetworktutDocument2 pagesEmmnetworktutmdmarufurNo ratings yet

- Thermal Strain and Stresses in Compound BarsDocument5 pagesThermal Strain and Stresses in Compound BarsmdmarufurNo ratings yet

- Hierarchical Afaan Oromoo News Text ClassificationDocument11 pagesHierarchical Afaan Oromoo News Text ClassificationendaleNo ratings yet

- Adafruit Color SensorDocument25 pagesAdafruit Color Sensorarijit_ghosh_18No ratings yet

- MS Excel Word Powerpoint MCQsDocument64 pagesMS Excel Word Powerpoint MCQsNASAR IQBALNo ratings yet

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- Architecture After Modernism - Diane GhirardoDocument10 pagesArchitecture After Modernism - Diane GhirardoCebo DharuNo ratings yet

- A APJ Abdul Kalam Technological University First Semester M. Tech. Degree Examination December 2016 Ernakulum II ClusterDocument2 pagesA APJ Abdul Kalam Technological University First Semester M. Tech. Degree Examination December 2016 Ernakulum II ClusterAshwin JoseNo ratings yet

- Wave Optics - I: Created by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreDocument16 pagesWave Optics - I: Created by C. Mani, Principal, K V No.1, AFS, Jalahalli West, BangaloreNitesh Gupta100% (1)

- Water Booster Pump Calculations - Plumbing Engineering - Eng-TipsDocument3 pagesWater Booster Pump Calculations - Plumbing Engineering - Eng-TipsNeal JohnsonNo ratings yet

- Raoult's law and colligative propertiesDocument27 pagesRaoult's law and colligative propertiesGøbindNo ratings yet

- Organic Vapour List PDFDocument1 pageOrganic Vapour List PDFDrGurkirpal Singh MarwahNo ratings yet

- Giáo Trình LPTD 2Document40 pagesGiáo Trình LPTD 2Hưng Trịnh TrọngNo ratings yet

- GC 1999 03 Minas BrethilDocument5 pagesGC 1999 03 Minas BrethilErszebethNo ratings yet

- Course 4Document3 pagesCourse 4Ibrahim SalahudinNo ratings yet

- The Mini-Guide To Sacred Codes and SwitchwordsDocument99 pagesThe Mini-Guide To Sacred Codes and SwitchwordsJason Alex100% (9)

- H2 Physic 2010 A Level SolutionsDocument32 pagesH2 Physic 2010 A Level Solutionsonnoez50% (4)

- Cambridge English Business Vantage Sample Paper 1 Listening v2Document5 pagesCambridge English Business Vantage Sample Paper 1 Listening v2salma23478No ratings yet

- Rguhs Dissertation PharmacyDocument6 pagesRguhs Dissertation PharmacyWhatAreTheBestPaperWritingServicesSingapore100% (1)

- Compass 5000.1.12 157605HDocument360 pagesCompass 5000.1.12 157605HApurbajyoti Bora100% (2)

- Ebola Research ProposalDocument10 pagesEbola Research ProposalChege AmbroseNo ratings yet

- Samsung (UH5003-SEA) BN68-06750E-01ENG-0812Document2 pagesSamsung (UH5003-SEA) BN68-06750E-01ENG-0812asohas77No ratings yet

- DOCS-#165539-v8-Technical Manual FOB4 TS Section 5 - MaintenanceDocument108 pagesDOCS-#165539-v8-Technical Manual FOB4 TS Section 5 - MaintenanceBME AOHNo ratings yet

- Trailers Parts - Rocket Trailers - Suspension & FastenersDocument24 pagesTrailers Parts - Rocket Trailers - Suspension & FastenersRocket TrailersNo ratings yet

- Cowell - The Wizards of Once PDFDocument315 pagesCowell - The Wizards of Once PDFtatoes n lases100% (1)

- Al-Jahiz (781-869) : ZoologyDocument25 pagesAl-Jahiz (781-869) : ZoologyJA QuibzNo ratings yet

- Parleremo Pzfra1Document218 pagesParleremo Pzfra1Lucia FerentNo ratings yet

- Creatinine JaffeDocument2 pagesCreatinine JaffeOsinachi WilsonNo ratings yet

- Kafka Netdb 06 2011 PDFDocument15 pagesKafka Netdb 06 2011 PDFaarishgNo ratings yet

- Key Differences Between Natural Sciences and Social SciencesDocument6 pagesKey Differences Between Natural Sciences and Social SciencesAshenPerera60% (5)

- LEEA-030.2c2 Certificate of Thorough Examination (Multiple Items) (Overseas) (Dev)Document1 pageLEEA-030.2c2 Certificate of Thorough Examination (Multiple Items) (Overseas) (Dev)GaniyuNo ratings yet

- Cambridge IGCSE: Combined Science 0653/41Document24 pagesCambridge IGCSE: Combined Science 0653/41jesslynaureliaNo ratings yet