Professional Documents

Culture Documents

Manual LF210 LF 219

Uploaded by

ccordobestexanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual LF210 LF 219

Uploaded by

ccordobestexanoCopyright:

Available Formats

Microflush Half Gallon Toilets

Model LF-210

Air Operated

Installation/Service Manual

P/N 24154

452 East Hill Road Fax: 707.459.6617

Willits, CA 95490 USA E-mail: info@microphor.com

Phone: 707.459.5563 www.microphor.com 10/16/01

Toll Free: 1.800.358.8280 www.wabtec.com 24154.WPD

ROUGH-IN DIMENSIONS

Cut out at rear of toilet. Run 1/4" compressed airline through finished wall or floor within inside perimeter of

toilet. NOTE: Toilet is designed for flush installation to finished wall. Below are rough-in dimensions and may

vary ½" (plus or minus). These measurements are subject to change or modification. No responsibility is

assumed for use of superseded or voided installation information.

LF-210 Manual P/N 24154 2 April, 2003

THANK YOU! CAUTIONS

Thank you for purchasing a Microphor product. Water Pressure to the toilet must be regulated at

Please read this manual completely prior to an even pressure between 20 to 50 PSI.

installation of your Microflush® toilet. Microphor Air Pressure at the toilet must be regulated at 60-65

General Terms and Conditions Covering Sales PSI constant.

apply.

Do Not Use any "Loctite" brand adhesive on any

CUSTOMER SERVICE plastic components as fumes will

If you have any questions concerning your cause damage to plastic parts.

Microphor product, please contact us: Do Not Use products containing petroleum

8:AM-5:PM PST Monday-Friday distillates or formaldehyde on any

Tel: (800) 358-8280 or (707) 459-5563 rubber parts.

Fax: (707) 459-6617, 24 hour Use only Silicone lubricants.

E-mail: info@microphor.com Do Not Use Teflon tape on any air fittings as

Website: www.microphor.com clogging may occur.

System vacuum breaker is not intended to be

PATENTS

pressurized longer than a normal flushing cycle.

Microflush toilets are covered by one or more of

the following U.S. patents 5245710; 4918764;

1280554; 169471 and related foreign patents.

CHANGES IN DESIGN

Continuing a policy of research and development,

Microphor reserves the right of price, product or

design change without notice or obligation.

APPLICATIONS

Land: Read this manual.

Railroad: See additional Railroad Installation

Instructions & Specifications

How Microflush Toilets Operate

LF-210 Manual P/N 24154 3 April, 2003

AIR SYSTEM DESIGN AIR CONNECTION

Filter-regulators are Install a filter-regulator

available in a variety of assembly in airline. Place

sizes and types. Their the filter-regulator as close

purpose is to remove as possible to the first

water, oil and other toilet and in an accessible

foreign matter from the air location. The plastic

line and to maintain a airline (provided) from the

constant pressure of 60-65 air source connects to the toilet at the flush

PSI at the toilet. The activator. On models where the flush handle is

following steps must be mounted on the side of the toilet, the plastic air line

observed to assure moisture will be removed from enters the toilet through the back wall or up through

the airline: the floor under the back of the toilet. Install air

1. Drain air compressor receiver regularly. Most shut-off valve at toilet. Fitting on toilet is 1/4"

water tends to accumulate at this point. compression fitting. Do not over-tighten fittings on

2. Install drip legs with condensate drains at all toilet. Blow any debris from airline prior to

low points in air piping. connecting to toilet.

3. Whenever possible, grade all airlines back to air Regulate air pressure to 60-65 PSI constant at

receiver or drip leg assembly and drain the toilet for proper operation.

regularly.

4. The air supply to the toilet must be taken from Where an air main is required, such as a 1/2" copper

the top of the main or branch air line. line, the air line to the toilet should be connected to

the top of the main airline to prevent condensation

AIR COMPRESSOR reaching the toilet.

Be certain compressor crankcase has proper oil

levels. Locate the compressor in a clean, dry, well WATER CONNECTION

ventilated location. Size compressor according to Install water shut-off valve (angle

Air Compressor Spec, Form 273. stop) at 9" off center line and 3"

above floor (see Rough-In

INSTALLATION PROCEDURE Dimensions). Water supply line

should be 1/2" flexible line. Fitting

Read Installation

on toilet is ½" NPT slip joint nut

Procedures completely

(1/2" lavatory supply). Connect

regarding all

flexible water supply line to toilet

installation/start up points

first, then connect to angle stop.

prior to installation.

CAUTION: Water supply connector is made of

nylon. Be careful not to cross

PRELIMINARY PROCEDURE threads.

Remove toilet from box carefully. Install toilet seat

and flush handle before mounting toilet to floor. Water pressure must be regulated at an even

Seat is not included with vitreous china models. Air pressure between 20 to 50 PSI at the toilet for it

connecting kit (P/N 93086), bolt caps and closet to operate properly.

screws are provided with all vitreous china models.

LF-210 Manual P/N 24154 4 April, 2003

DRAIN CONNECTION 6. Assemble the Air Connecting Kit (P/N 93086)

- See Rough-In Dimensions provided and connect to incoming air supply.

Bottom Discharge Models: Center on floor flange Do not connect to flush Activator.

12" (standard) from finished wall with wax ring 7. Turn OFF air shut-off cock at toilet.

(provided). If floor is uneven a second standard wax 8. Turn ON air supply at compressor.

ring may be added. If bottom ring of toilet hits 9. Turn ON air shut-off cock at toilet to blow out

flange, it should be ground down for added airlines for a few seconds. This procedure

clearance, as any contact will break seal on hopper. should remove any debris or contaminants from

the airline. Turn OFF air shut-off cock.

Rest toilet on its back on a padded surface (e.g. 10. Now connect airline to the top of the Flush

packing from shipping box). Center wax ring on Activator. Turn ON air shut-off cock. Check

toilet discharge flange. Turn toilet over, lifting up, total installation for air leaks using soapy water.

and center the horn of the wax ring into the toilet 11. Turn ON water. Check for water leaks.

floor flange. Compress the wax ring by applying 12. Flush toilet four times, waiting twenty seconds

weight to the toilet. between flushes to get water through toilet and

operating regularly. To flush properly, hold

REAR DISCHARGE MODELS: Discharge line down handle until flapper opens.

should be connections at hopper with a No-Hub 13. Water level in bowl should be at top edge of

Coupling (P/N 33324, provided). Do not glue or flapper opening.

connect fittings until fitting alignment has been 14. If the toilet does not operate correctly or have

checked. Toilet discharge line must have a rise the proper water level in bowl, refer to adjusting

(trap) (see ROUGH-IN DIMENSIONS) in order to Toilet or Troubleshooting sections of this

provided water trap seal when flapper is open. manual.

CAUTION: do not apply stress to align outlet to

waste line. This will result in eventual seal damage.

DOWNWARD DISCHARGE MODELS: Toilet

mounts to floor with 1/4" closet bolts. Install screws

with a 3/8" nut driver. Screw on bolt caps to

mounting screws.

INSTALLATION AND START UP

1. Position and mount

the Toilet to floor.

See Rough-In

Dimensions.

2. For units with

Remote Flush,

position and mount

Remote Flush

Assembly to wall with Vacuum Breaker at least

6" above the rim of the toilet bowl. The

maximum water line distance between the toilet

and the Remote Flush Assembly is 4'.

3. Position and mount the Flush Activator to wall.

The maximum distance between the Flush

Activator and the Remote Flush Assembly is

72".

4. Connect the incoming water supply to the 3/4"

I.D. Hose Barb on the Remote Flush Assembly.

5. Connect the water line from Remote Flush

Assembly to the toilet spud assembly.

LF-210 Manual P/N 24154 5 April, 2003

ROUTINE MAINTENANCE Pipe will protect flapper seal. If valve will not

Your Microflush toilet operate with water off, hold flush lever down and

USAGE LUBRICATE turn water on and off quickly to free valve action.

has an air-operated Light Every 5 years

Air/Water Sequence Medium Every 2-3 years When the passage becomes clear, turn on the water

Valve which requires Heavy Every year and press flush handle to start the flush cycle.

periodic lubrication

with a silicone based CLEANING BLEED-OFF PLUG

lubricant. ASSEMBLY

Standard Flush:

CLEANING Remove plug and clean with solvent; air blow dry.

Use Micro-Clean Organic Spray Cleaner, P/N Positive Flush:

24542. Caustic drain openers or non-biodegradable Remove plug and clean with solvent; air blow dry;

cleaners should not be used if the toilet is connected remove and clean plug on Detent Valve.

to a septic tank or Microphor biological sewage

treatment system. Clean as follows: Note: Use 5/32" or 4mm Allen wrench to remove

1. While depressing the flush activator, turn OFF plugs.

the water. Allow the bowl cleaner to flow into

the lower chamber. Keep the flushing activator

depressed.

2. Insert bowl brush into lower chamber and agitate

mixture.

3. Remove the bowl brush and release the flush

activator.

4. Turn the water ON and flush twice to rinse

thoroughly.

WINTERIZING

(out-of-service winter storage)

Shut OFF water to toilet. Flush toilet three times or

until water no longer flows into the bowl. Unhook

water supply at angle stop. Empty water in line into

receptacle. Shut OFF air supply to the toilet. The

unit is now prepared for freezing temperatures.

OPEN petcocks on drip legs and air receiver drain

after shutting down air compressor and isolating

airlines.

CLEARING THE TOILET

If the toilet becomes plugged, shut off the water

supply, press the flush handle and hold. Flapper in Note: Bleed-off plugs on Air & Water Sequence

the bottom of the toilet will remain open until flush Valves and Detent Valves are different sizes that are

handle is released. Check to see if the restriction not interchangeable.

can be removed from lower portion of toilet with a

hooked wire, being careful not to damage the rubber

seal on the flapper or the mating surface on the

hopper. If obstruction can not be picked out with a

hook or tongs, use plunger by pushing in slowly and

pulling out quickly to pull object back into the

hopper. If necessary, turn air off and use a snake

inserted into a short plastic pipe placed in hopper.

LF-210 Manual P/N 24154 6 April, 2003

TROUBLESHOOTING

Your Microflush® toilet is designed to give you years of trouble-free operation. Please check the following

before beginning any service or repair:

Water supply: 1 Is the water turned on?

2 Is the water pressure between 20 and 50 psi at the toilet for pressure water system?

3 Is there 6 feet minimum of head for gravity systems?

Fluctuating or high water pressure can cause intermittent problems with the toilet operation.

Check the water pressure at different times of the day (i.e., early morning, noon, evening) to

determine if you have fluctuating or high water pressure. A pressure-reducing valve installed on

the incoming water line will assure you have even pressure. Make sure no check valve is

installed before the Air/Water Sequence Valve.

Air system: 1 Is the air turned on?

2 Is the air pressure set at a constant 60-65 psi at the toilet?

3 Do you have any air leaks or kinks in the air system?

4 Do you have water in the air system? This usually causes irregular timing.

Drain the compressor tank and check the filter regulator and drip leg(s) for water. To check for

water in Air/Water Seq. Valve, remove Bleed-Off Plug, put finger over screw opening and flush.

If water is present, it will squirt out. If water is detected, then the air cylinder and airlines must

also be drained.

Cycle time: 1 Is the flapper cycle time set correctly at 4-8 seconds?

2 Is the Bleed-Off Assembly plug blocked? (See page 6)

Trouble Possible Causes Correction

Flapper does not open. 1 No Air Supply to Microflush. 1 Supply compressed air at 60-65

Water does not flow. 2 Water has accumulated in psi at the toilet

Nothing happens. Air/Water Sequence Valve 2 See 'Check Air System" above.

Flapper opens and closes 4-8 1 No water supply to 1 Supply water at 20-50 psi at

seconds after handle is released, Microflush. toilet

but no water enters bowl. 2 Water turned off. 2 Open angle stop (shut-off valve).

Flapper opens when flushed, and 1 Excessively high water 1 Install water pressure regulating

closes immediately when activator pressure. valve, set at 20-50 psi.

is released. 2 Debris in check valve at base 2 Clean Air/Water Seq. Valve.

of Air/Water Sequence Valve.

Flapper opens and will not close. Bleed-Off Plug blocked. Remove, clean or replace, reinstall.

Water continues to run when Foreign object is under water Clean Air/Water Sequence Valve.

Microflush is not in use. valve in Air/Water Sequence Reference Service Kit P/N 95057.

Valve.

Water splashes when flushed. Water is too high in bowl. Reduce incoming water via angle

stop; Re-adjust cycle time.

Flush cycle is too long. Bleed-Off Plug blocked. Remove, clean or replace, reinstall.

Flush cycle is too short. Bleed-Off Plug hole too large or Remove, replace, and check for air

related air lines leaking. line leaks.

If other problems are encountered, please contact the factory: Toll Free: 1-800-358-8280

LF-210 Manual P/N 24154 7 April, 2003

EXPLODED VIEWS

Integral Valve Layout

VITREOUS CHINA COLOR CHART

A B C

Round Elong.

Remote Installation

China Shell & Shell & Lid Bolt

Color Code Lid Lid Only Caps

Beige SC4 44333 44334 99064-15 44371

Black N-5 44337 44338 99064-7 44076

Blue B-5 44343 44344 99064-13 44373

Bone S4 44039 44012 99064-3 93974

Gray 651 44329 44330 99064-5 44377

Ivory SC1 44327 44328 99064-24 44370

Oak N/A N/A N/A 99071 N/A

Pink SR2 44331 44332 99064-21 44368

Red R-5 44345 44346 99064-9 44372

Rose R3 44335 44336 99064-17 44375

White -- 44023 44010 99064 93972

LF-210 Manual P/N 24154 8 April, 2003

PARTS CHART

PART Integral Remote Air Line Layouts

D Flush standard 95002 N/A

Activator positive 95054 95086

Pilot Valve standard 95562 N/A

positive 95083 95085

E Air/Water Sequence Valve 39501

Rebuilt 39501 Exchange 99899

F Vacuum Breaker 33559 33039

Vacuum Breaker Mntg Bracket 91897 20003

G Bleed-Off standard 94598

Plug Assy. remote 95100

H Valve Mounting Bracket 91897 20003

I Hopper Rear Discharge 90005-3

Downward Disch. 90004-3

Down Conv. Kit 90008

P-Trap 96029

Crank Assy 90042

Flapper Assy 90048

Screws (14 each) 00064

Top 90003

Bottom, Down 90002

Bottom, Rear 90009

Flange 45010

K Mounting Assy 90899-5

N Air Cylinder 94540

Q Spud Assy 96347 96004

R Water Supply Tube 96352 35053

S Water Connection 96387

Air Lines from Air/Water Seq. Valve

T Air Fittings 90E 30385

1/4" O.D. 180E 30365

Nut/Ferrell 30396

U Air Tubing green-35381, blue-35382, red-35383,

per foot yellow-35384, white-35385, black-35419

V Air Shut-Off Cock 30008

W Air Connecting Kit 93086

K Master Service Kit 93100

I Air/Water Seq. Valve Kit 95057

T

Air Cylinder Kit 94502

S

Flush Activator (Standard) Kit 95020

Flush Activator (Positive) Kit 95081

Flapper Kit 90066

Vacuum Breaker Kit 95037

LF-210 Manual P/N 24154 9 April, 2003

HOPPER REPLACEMENT

CAUTION: Read this Entire Procedure Before Beginning Work!

1. Remove toilet from floor. Place toilet upside down on a sheet of cardboard or other padded surface.

2. Remove nuts from J-bolts on either side of Hopper, lift hopper away from bowl.

3. Remove O-ring from between hopper and sealing adaptor. Check that O-ring is not damaged.

4. Re-assemble in reverse order. MAKE SURE J-BOLTS ARE TIGHT! Proper torque specification is 4-6

inch/lbs.

HOPPER COMPONENTS

Rear Discharge Hopper

J - Optional P-trap, P/N 96029

Downward Discharge Hopper

To Change Flapper Gasket:

1. Turn water and air off.

2. Reach behind flapper to grasp gasket tails.

3. Pull tails out of slots to remove old gasket.

4. Installation is the reverse of removal.

5. Tails must be pulled all the way through to insure smooth surface.

LF-210 Manual P/N 24154 10 April, 2003

AIR CYLINDER ADJUSTMENT INSTRUCTIONS

1. Remove hopper assembly.

2. Remove clevis pin retaining ring and

clevis pin.

3. Inspect the crank arm, clevis and clevis

pin for wear. Replace if required.

4. Hold the crank arm in the UP position

(flapper closed).

5. Fully extend the air cylinder and note the

position of the holes in the crank arm and

the clevis. The clevis hole should extend

half its diameter past the crank arm hole.

Adjust as necessary by turning clevis

clock-wise to loosen, counter clock-wise

to tighten. Make sure not to nick or

damage shaft.

6. Re-install hopper.

LF-210 Manual P/N 24154 11 April, 2003

FLUSH ACTIVATORS

95054 - Commercial Flush Activator

95557 - Palm Button Conversion Kit

95002 - Residential Flush Activator

LF-210 Manual P/N 24154 12 April, 2003

POSITIVE FLUSH ACTIVATOR (Commercial) Remote, P/N 95087

The Detented Positive Flush Activator has been added (as an option) to our product line. It was developed in

order to overcome the necessity for the toilet user to hold the standard flush actuator in the deflected position for

a definite time (about 2 1/2 seconds) to insure full actuation of the toilet flush cycle. This option is

recommended for high use, public facilities.

It's principle of operation is as follows:

A) Under user control, a two way valve, requiring no more than 1/32" deflection for full flow, pilots a piston

drive detented mechanism.

B) The detent force is overcome after air pressure over the piston rises to 40 psi thus driving the standard flush

actuator to the full flush position.

C) The detent is reset after the entrapped air over the piston is bled to atmosphere. The bleed rate (and thus the

length of time the flush actuator is held in the flush mode) is controlled by the head bleed plug with a fixed

orifice size.

LF-210 Manual P/N 24154 13 April, 2003

AIR WATER SEQUENCE VALVE LUBRICATION

1. Disassemble valve from bottom to top by first unscrewing the Bottom Cap from the Main Body. Then, to

unthread the piston from the spool, insert a 3/16" hex into the hex opening at top of spool. Use an adjustable

end wrench on the oblong boss on bottom of piston to unscrew piston from spool and push spool up through

valve body to remove. Remove Top Cap and Water Seal. You will need a pair of needle nose pliers to

remove the Nut and Stem from the Bottom Cap.

2. Replace parts indicated in BOLD supplied with kit. Lubricate all O-Rings with lubricant provided. A light,

complete coating is all that is required as over lubrication will clog air passages.

3. Re-assemble valve from top to bottom as shown, with the exception of the Top Cap and Water Seal which go

on last. Make sure to align the yellow timing marks on Bottom Cap, Main Body and Water Body.

4. If desired, this valve may be returned to the factory for rebuilding and lubrication.

LF-210 Manual P/N 24154 14 April, 2003

AIR/WATER SEQUENCE VALVE OPERATION

LF-210 Manual P/N 24154 15 April, 2003

Insert Terms & Conditions.

LF-210 Manual P/N 24154 16 April, 2003

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- MICROPHOR Manual24563MicroflushGBHDocument14 pagesMICROPHOR Manual24563MicroflushGBHwarrimaint28094No ratings yet

- Installation - Check-List - Eng - Rev-10 For Cooling Tower Filtration UnitDocument10 pagesInstallation - Check-List - Eng - Rev-10 For Cooling Tower Filtration UnitMidha NeerNo ratings yet

- Installation Instructions: For Stacked Washers and DryersDocument24 pagesInstallation Instructions: For Stacked Washers and DryersMircea FrantNo ratings yet

- Winterization GuideDocument8 pagesWinterization GuidelpaslgirlNo ratings yet

- Nipple Tube DiffusersDocument11 pagesNipple Tube Diffusersiyappan i.p.sNo ratings yet

- Manual SandMediaFilterDocument21 pagesManual SandMediaFilterFAHAD HASSANNo ratings yet

- Autotrol Performa Valve With 400 Series Control Installation InstructionsDocument24 pagesAutotrol Performa Valve With 400 Series Control Installation InstructionsWattsNo ratings yet

- Durojet SW Jet Pumps 51451 EnglishDocument12 pagesDurojet SW Jet Pumps 51451 EnglishJhun Michael JaminalNo ratings yet

- Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterDocument3 pagesOperating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterhoseyliauNo ratings yet

- Autotrol Performa Prosoft PDFDocument24 pagesAutotrol Performa Prosoft PDFintermountainwaterNo ratings yet

- PureFlo 6, 12 & 18 Installation and OperationDocument19 pagesPureFlo 6, 12 & 18 Installation and OperationDesy HelnandaNo ratings yet

- De Pura DoraDocument53 pagesDe Pura DoraKenneth BlackNo ratings yet

- ClemcoDocument8 pagesClemcogeraldNo ratings yet

- Model OFTWH OneFlow Anti-Scale System Installation InstructionsDocument20 pagesModel OFTWH OneFlow Anti-Scale System Installation InstructionsWattsNo ratings yet

- Installation Tank AeratorDocument6 pagesInstallation Tank Aeratornawrim_sugaNo ratings yet

- Manual Alimentador Piab PDFDocument28 pagesManual Alimentador Piab PDFsol soto100% (1)

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- 1.air Washer ManualDocument3 pages1.air Washer ManualAmit Balot100% (1)

- Pantera Sand ManualDocument21 pagesPantera Sand Manualisme78No ratings yet

- And Dosage Pumps - Installation GuideDocument6 pagesAnd Dosage Pumps - Installation GuideJose R C FernandesNo ratings yet

- Leisuretime Sand Manual ONGADocument16 pagesLeisuretime Sand Manual ONGARicardo Cesar Bueno BertichevicNo ratings yet

- Model OF240-4 OneFlow Anti-Scale System Installation InstructionsDocument20 pagesModel OF240-4 OneFlow Anti-Scale System Installation InstructionsWattsNo ratings yet

- Model OF220-2 OneFlow Anti-Scale Systems Installation InstructionsDocument20 pagesModel OF220-2 OneFlow Anti-Scale Systems Installation InstructionsWattsNo ratings yet

- Tefen Pump (Pompa Untuk Lubrikasi)Document64 pagesTefen Pump (Pompa Untuk Lubrikasi)Aditya BayuNo ratings yet

- Manual Filtros Dynamic Series Rainbow Pentair InglesDocument2 pagesManual Filtros Dynamic Series Rainbow Pentair InglesIrvin Enrique Solano SalvadorNo ratings yet

- LFE Desicant Dryer ManualDocument12 pagesLFE Desicant Dryer ManualNaveen KumarNo ratings yet

- Nilfi SK E 130.2, E 140.2: User ManualDocument18 pagesNilfi SK E 130.2, E 140.2: User ManualDavid TynanNo ratings yet

- Anchor Inst1004-Wd2010Document13 pagesAnchor Inst1004-Wd2010Jorge QuinteroNo ratings yet

- Instructions Guide To InstallationDocument4 pagesInstructions Guide To InstallationIvan BriscoeNo ratings yet

- Bobbin Filters - Instructions and Operation ManualDocument37 pagesBobbin Filters - Instructions and Operation Manual8nqm4p3veNo ratings yet

- Pumps XP IOIDocument8 pagesPumps XP IOIdamiencwalkerNo ratings yet

- RB Manual For North America EnglishDocument21 pagesRB Manual For North America EnglishEduardo FeitosaNo ratings yet

- Slimline PDFDocument40 pagesSlimline PDFmmmitchNo ratings yet

- Manual de Filtro AutolimpianteDocument29 pagesManual de Filtro AutolimpianteMegan PierceNo ratings yet

- Navigator UsuarioDocument24 pagesNavigator UsuarioLuis DomingoNo ratings yet

- Installation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpDocument14 pagesInstallation and Start-Up Information PV Series: Variable Displacement Axial Piston PumpAPURV GOYALNo ratings yet

- Millipore Reservoir ManualDocument13 pagesMillipore Reservoir ManualLucian BuhalteanuNo ratings yet

- Cartridge Filter Standard System Owner'S ManualDocument4 pagesCartridge Filter Standard System Owner'S Manualjp nayakNo ratings yet

- Dwf-200as Service ManualDocument41 pagesDwf-200as Service ManualKarim Fernandez CampusanoNo ratings yet

- Size Drawing Number Name Date CTC PF Name Date 5/27/2009 RevDocument3 pagesSize Drawing Number Name Date CTC PF Name Date 5/27/2009 RevJelena Kalc100% (1)

- A R INewDocument28 pagesA R INewBhavesh TandelNo ratings yet

- Model OF210-1 OneFlow Anti-Scale Systems Installation InstructionsDocument20 pagesModel OF210-1 OneFlow Anti-Scale Systems Installation InstructionsWattsNo ratings yet

- Sand Filter - Owner's Manual: Installation, Operation & PartsDocument6 pagesSand Filter - Owner's Manual: Installation, Operation & Partscao anhNo ratings yet

- HD 247 Alarm Valve Model-HDocument16 pagesHD 247 Alarm Valve Model-HAjjuParmarNo ratings yet

- Ssicap Om ManualDocument19 pagesSsicap Om Manualsianuli_936086174No ratings yet

- Manual Hippo Vacuum SystemDocument3 pagesManual Hippo Vacuum SystemFerry Triyana AnirunNo ratings yet

- Chemgaurd Bladder Tank Design and System Installation PDFDocument7 pagesChemgaurd Bladder Tank Design and System Installation PDFVignesh WaranNo ratings yet

- Upload 00129242 1526010566661Document20 pagesUpload 00129242 1526010566661A-selam IbraNo ratings yet

- Erie 541-008 Manual2Document16 pagesErie 541-008 Manual2John KoNo ratings yet

- Model OF110-1 OneFlow Anti-Scale System Installation InstructionsDocument20 pagesModel OF110-1 OneFlow Anti-Scale System Installation InstructionsWattsNo ratings yet

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaNo ratings yet

- Integrity Testing of Hydrophilic Membrane Filters: Figure 1 - Wetting & Integrity Test SetupDocument4 pagesIntegrity Testing of Hydrophilic Membrane Filters: Figure 1 - Wetting & Integrity Test SetupVijay Kumar NandagiriNo ratings yet

- MiniVac OIM ManualDocument10 pagesMiniVac OIM ManualGiorgiana RosuNo ratings yet

- Element Filter: WarningDocument4 pagesElement Filter: WarningShouzab AbbasNo ratings yet

- Propotional Injector Bomba de Dosificación Proporcional Pompe À Dosage ProportionnelDocument30 pagesPropotional Injector Bomba de Dosificación Proporcional Pompe À Dosage ProportionnelimamedinaNo ratings yet

- DU1055XTVS8Document40 pagesDU1055XTVS8mrcmhNo ratings yet

- 08 PDFDocument6 pages08 PDFSelenia ReyesNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Arduino Mega2560 R3 PinMapping v05Document3 pagesArduino Mega2560 R3 PinMapping v05ccordobestexanoNo ratings yet

- 1999 Broderson IC 80 3FDocument2 pages1999 Broderson IC 80 3Fccordobestexano0% (1)

- 1981 Winter Demo Coach Chassis Fuse/Terminal Panel: BrownDocument3 pages1981 Winter Demo Coach Chassis Fuse/Terminal Panel: BrownccordobestexanoNo ratings yet

- Service Manual: Induction Slide-In RangeDocument97 pagesService Manual: Induction Slide-In Rangeccordobestexano100% (1)

- Technical Specification: 40' X 8' X 9'6" ISO 1AAA TYPE Steel Dry Cargo ContainerDocument16 pagesTechnical Specification: 40' X 8' X 9'6" ISO 1AAA TYPE Steel Dry Cargo ContainerccordobestexanoNo ratings yet

- Account Summary: Combined Spending For All Cards On The AccountDocument31 pagesAccount Summary: Combined Spending For All Cards On The AccountccordobestexanoNo ratings yet

- Yamaha MusicCast HTTP Simplified API For ControlSystemsDocument10 pagesYamaha MusicCast HTTP Simplified API For ControlSystemsccordobestexanoNo ratings yet

- Installing Tile in Pools and Fountains: Technical White PaperDocument6 pagesInstalling Tile in Pools and Fountains: Technical White PaperccordobestexanoNo ratings yet

- Yamaha MusicCast HTTP Simplified API For ControlSystemsDocument10 pagesYamaha MusicCast HTTP Simplified API For ControlSystemsccordobestexanoNo ratings yet

- Protocol RS-232: in ST Ru Ction ManualDocument10 pagesProtocol RS-232: in ST Ru Ction ManualccordobestexanoNo ratings yet

- 8V92 Water Pump Replacement DirectionsDocument2 pages8V92 Water Pump Replacement DirectionsccordobestexanoNo ratings yet

- SSP267 The 6.0 L W12 Engine in The Audi A8 - Part 1Document64 pagesSSP267 The 6.0 L W12 Engine in The Audi A8 - Part 1ccordobestexano100% (1)

- Germ PlasmDocument9 pagesGerm PlasmKeenisha KannanNo ratings yet

- Department of Human Services: Course Information Course DescriptionDocument9 pagesDepartment of Human Services: Course Information Course DescriptionS ElburnNo ratings yet

- Pugh ChartDocument1 pagePugh Chartapi-92134725No ratings yet

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- Module 5 Lesson 5.1 - For ResearchDocument16 pagesModule 5 Lesson 5.1 - For ResearchJohn Clieford AdarayanNo ratings yet

- Introduction To Device ManagementDocument72 pagesIntroduction To Device ManagementMOHAMMED SHEHBAAZNo ratings yet

- Format of Actual BatchDocument16 pagesFormat of Actual Batchaljhon dela cruzNo ratings yet

- tgs2600 Product Information Rev02 PDFDocument2 pagestgs2600 Product Information Rev02 PDFAbhishek SinghNo ratings yet

- Route TrainingDocument14 pagesRoute Trainingjohn100% (1)

- HFAss 6Document1 pageHFAss 6Taieb Ben ThabetNo ratings yet

- Richard Whish - InterviewDocument17 pagesRichard Whish - Interviewbaba bofaNo ratings yet

- Workshop Practical Attendance SheetDocument2 pagesWorkshop Practical Attendance SheetSachidhanandam MNo ratings yet

- Glazing Risk AssessmentDocument6 pagesGlazing Risk AssessmentKaren OlivierNo ratings yet

- 20years Cultural Heritage Vol2 enDocument252 pages20years Cultural Heritage Vol2 enInisNo ratings yet

- Draft Use or Cite: Chapter 16 Nonlinear Response History Analysis 16.1 General Requirements 16.1.1 ScopeDocument14 pagesDraft Use or Cite: Chapter 16 Nonlinear Response History Analysis 16.1 General Requirements 16.1.1 ScopesharethefilesNo ratings yet

- Improving Orientation With Yoked PrismDocument2 pagesImproving Orientation With Yoked PrismAlexsandro HelenoNo ratings yet

- Basa Pilipinas: Supplementary Outlines For Multigrade Classes (Grades 1 & 2) IlokanoDocument130 pagesBasa Pilipinas: Supplementary Outlines For Multigrade Classes (Grades 1 & 2) IlokanoMarinica NagollosNo ratings yet

- Payaman KamiDocument35 pagesPayaman Kamifaye tamayoNo ratings yet

- 4.0 Air Separators 4.1Document31 pages4.0 Air Separators 4.1Dilnesa Ejigu100% (1)

- HW 3Document10 pagesHW 3Hande ÖzerNo ratings yet

- Barometric Pressure Sensor AB 60 / AB 100 S31100 / S31200Document3 pagesBarometric Pressure Sensor AB 60 / AB 100 S31100 / S31200IsmaelanayaNo ratings yet

- ITS US Special Edition 2017-18 - Volume 14 Issue 10Document15 pagesITS US Special Edition 2017-18 - Volume 14 Issue 10Leo Club of University of MoratuwaNo ratings yet

- Language and The Pursuit of Hap - Chalmers BrothersDocument1,184 pagesLanguage and The Pursuit of Hap - Chalmers BrothersGeorge Adrian Oprea100% (2)

- Asphaltene Eng2020Document4 pagesAsphaltene Eng2020Elprince MidoNo ratings yet

- Literature & MedicineDocument14 pagesLiterature & MedicineJoyce LeungNo ratings yet

- Assignment / Tugasan HBEF3703 Introduction To Guidance and Counselling / May 2021 SemesterDocument8 pagesAssignment / Tugasan HBEF3703 Introduction To Guidance and Counselling / May 2021 SemesterTHURGANo ratings yet

- Moxa Eds 2005 El Series Datasheet v1.3 PDFDocument3 pagesMoxa Eds 2005 El Series Datasheet v1.3 PDFPatrick RNo ratings yet

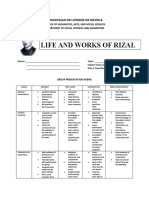

- Rubrics - Reporting - RizalDocument2 pagesRubrics - Reporting - RizaljakeNo ratings yet

- A Level Biology A Core Practical 10 - Ecology InvestigationDocument6 pagesA Level Biology A Core Practical 10 - Ecology InvestigationAlfred SangNo ratings yet

- MAE 320 Syllabus PDFDocument4 pagesMAE 320 Syllabus PDFRobert V. AbrasaldoNo ratings yet