Professional Documents

Culture Documents

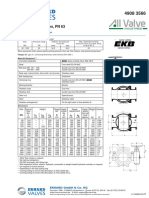

Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable Water

Uploaded by

hoseyliauOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable Water

Uploaded by

hoseyliauCopyright:

Available Formats

Operating and Maintenance Instructions for

Air Valve for Waste Water and Potable Water

Order No. 986

1. Intended use

The Hawle air valve Order No. 986 is used for aerating and deaerating of pressure lines for a pressure range of

0 - 16 bar. Medium: domestic sewage (industrial sewage, waste water with a high content of acid or alkali only on

consultation), potable water.

Please note that valves must be maintained at least 1 x per year according to DVGW W 392, and even more frequently in case of waste water pressure lines with a high degree of contamination or a tendency to saponification.

Please observe also the applicable standards and codes (e.g. ATV), the regulations for the prevention of accidents

and the regulations of the professional associations.

Air valves contain compressed air. Therefore, before starting any maintenance work the valve must be depressurized via the ball valve!

2. Product description

The Hawle air valve Order No. 986 is an air valve both aerating lines and removing air enclosed in pipelines. The

valve operates automatically and is designed to reduce water hammers. The seat of this air valve is not in contact

with the medium. The air valve is rated for a maximum operating pressure PFA = 16 bar.

3. Installation

The air valve assembly Order No. 986 must be installed on a vertical outlet of the pressure pipeline. Installation

should be as close to the pipeline as possible to reduce the danger of freezing. Note: The lateral arrangement of

air valves may considerably influence the control behaviour of the valve. Moreover, in case of heavy contamination

there may be problems in the pipeline area upstream of the air valve. A laterally displaced arrangement of air valves

shall be avoided.

In case of large pipeline dimensions care should be taken that the air is actually carried to the air valve (see also

DVGW W 334). Therefore it is recommended to choose the connection to the pipeline as large as possible and to

subsequently provide for reduction to the valve and its nominal width by means of a double flanged taper simultaneously acting as an air dome holding a larger amount of air (example: pipeline DN 200, outlet at the pipeline DN

150 or DN 200, double flanged taper reducing to DN 80, air valve DN 80.)

There should always be a shut-off facility below the air valve to allow maintenance work.

The air valve is intended for installation in shafts. Please observe the applicable standards and guidelines for this

shaft, especially the regulations for the prevention of accidents in case of access to the shaft.

At the air relief outlet of the Hawle air valve a pipe can be connected. Please note that the connection of a vent

line may possibly influence the control behaviour of the air valve. The same applies to any odor filters that may be

installed. In this case it is important to use sufficiently large components to avoid backwater in the valve.

4. Start-up and pressure testing

During pressure testing of the pipeline air valves should be generally put out of service. To this end the shut-off facility below the valve shall be closed. There is always some residual air enclosed even in a properly vented pipeline. If

the air valve is placed correctly, this residual air is carried to the valve possibly causing it to blow off during pressure

testing. As a consequence the pipeline and/or the air valve is wrongly assumed to be leaking.

Air valves are tested by the manufacturer so that they need not be included in the pressure testing. After completion

of pressure testing of the pipeline the shut-off facility is opened slowly and the air valve and its flange connections

are visually inspected under operating pressure.

For filling the pipelines please make sure not to exceed the maximum filling rates. Before filling the pipelines it

should be checked if the vent holes of the air shafts concerned are actually free. If necessary, the covers should be

opened.

Note: Before scavenging with compressed air the valve should be put out of service.

05/2006

-1-

Subject to alteration without notice

5. Service maintenance of air valve 986

The reliability of the Hawle air valve can be considerably increased by checking it for possible contamination at

regular intervals. Please make sure to isolate the air valve from the pipeline system before starting any maintenance

work by closing the shut-off valve and to reduce any overpressure possibly existing in the valve via the ball valve

of the flushing line.

When entering shaft constructions the general safety precautions must always be observed. When working in

shafts we recommend to provide for forced ventilation of the construction and to perform maintenance only with

the pumps switched off.

Due to its coating the Hawle air valve is well protected against deposits. Nevertheless, depending on the properties

of the medium, the operatability of the valve should be checked at regular intervals and possible contamination

should be removed, especially in case of larger bodies of dirt that cannot be flushed out via the lateral flushing

connections.

All work at Hawle air valves should be performed by trained personnel only!

We recommmend the first maintenance to be done after a period of approx. 4 8 weeks and to define further

maintenance intervals on the basis of the result of this first maintenance. To this end open the valve according to

the below description.

In the course of maintenance, please check also the ball valve and all other components for leakage and contamination.

Procedure

1. Open body screws.

2. Pull the flange together with the complete valve

mechanism upward and out and put it upright on a

solid base.

Remove cap nut SW 13 at the air exit by means of

socket spanner (valve must be in closed position).

3. Pull the flange upward and screw off the retaining

nut at the flange bottom side.

Take the mechanism apart and pull the valve block

out of the flange.

4. Clean the slots of the valve cage and rinse them.

If necessary (heavy contamination or damage) the

valve cage can be dismantled from the valve block

after opening the threaded ring by means of a pin

spanner.

5. Turn the cup seal at the screw inside out of the valve case and check it for deposits and mechanical damage.

Wipe deposits off by means of a damp rag.

If the cup seal must be exchanged, then the plastic retaining ring must be taken out first. For easier dismantling of

the plastic ring put the whole mechanism for 3 minutes headfirst into hot water of about 50C. Then pull the ring

upward and off, remove the cup seal and insert the plastic screw from the old cup seal into the new one.

05/2006

-2-

Subject to alteration without notice

6. Turn the cup seal over completely.

7. Pull the cup seal over the cup.

8. Push on the preheated ring (3 minutes in hot water

of approx. 50C).

9. Centre the cup seal by pulling it back to the moulded

bead and slip it into the valve case.

10. Further installation is performed in reverse order to dismantling.

11. Leakage test!

If you have any more questions or need more detailed information please dont hesitate to contact us:

Hawle Armaturen GmbH

- Anwendungstechnik Liegnitzer Str. 6

83395 Freilassing

Phone: ++49 (0)8654 6303-0

Fax:

++49 (0)8654 6303-222

E-mail: anwendungstechnik@hawle.de

Internet: www.hawle.de

05/2006

-3-

Subject to alteration without notice

You might also like

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Industrial Training ReportDocument10 pagesIndustrial Training ReportMuhammad Firdaws100% (1)

- Instructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air ValvesDocument15 pagesInstructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air Valvessure_iitdNo ratings yet

- Safety Valves For Power PlantDocument56 pagesSafety Valves For Power Planttek_surinder100% (1)

- Rofi Operation and Maintenance ManualDocument3 pagesRofi Operation and Maintenance ManualSteve NewmanNo ratings yet

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocument12 pagesFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalNo ratings yet

- Hopkinson Valves IOM ManualDocument7 pagesHopkinson Valves IOM ManualGiorgiana RosuNo ratings yet

- Hopkinson Valves IOM Manual PDFDocument7 pagesHopkinson Valves IOM Manual PDFGiorgiana RosuNo ratings yet

- Valves Gate DamperDocument54 pagesValves Gate DamperLalit MeenaNo ratings yet

- MiniVac OIM ManualDocument10 pagesMiniVac OIM ManualGiorgiana RosuNo ratings yet

- Jones Hydrant OM 8-21-09Document6 pagesJones Hydrant OM 8-21-09RktBatamNo ratings yet

- 2) Air Start VV & Indicator VVDocument13 pages2) Air Start VV & Indicator VVHrishikesh MoreNo ratings yet

- VAAS Fig 740 and 730 Series IOMDocument9 pagesVAAS Fig 740 and 730 Series IOMCarlos GutierrezNo ratings yet

- Sempell: Before Installation These Instructions Must Be Fully Read and UnderstoodDocument1 pageSempell: Before Installation These Instructions Must Be Fully Read and UnderstoodDGWNo ratings yet

- Operation and Maintenance ManualDocument14 pagesOperation and Maintenance ManualmehtahemalNo ratings yet

- IOM Manual For Air Cylinder Operated ValvesDocument21 pagesIOM Manual For Air Cylinder Operated Valvesjhon riosNo ratings yet

- 3-5400 SERIES Safety Relief Valves: Instruction ManualDocument16 pages3-5400 SERIES Safety Relief Valves: Instruction ManualPrashant ChauhanNo ratings yet

- Instructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air ValvesDocument15 pagesInstructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air ValvesElias TascaNo ratings yet

- W.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsDocument51 pagesW.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsSri VasanNo ratings yet

- User-Maintenance Manual: Double Flanged Butterfly ValvesDocument27 pagesUser-Maintenance Manual: Double Flanged Butterfly ValvesKYAWNo ratings yet

- Muller CoDocument12 pagesMuller CoRamSalunkheNo ratings yet

- Weflo Nrs Gate Op and MaintDocument5 pagesWeflo Nrs Gate Op and MaintyusufNo ratings yet

- Forged Floating & Trunnion-Mounted Ball Valves: Installation, Operation & Maintenance ManualDocument66 pagesForged Floating & Trunnion-Mounted Ball Valves: Installation, Operation & Maintenance ManualKYAWNo ratings yet

- Best Practices For Steam Control Valve InstallationDocument4 pagesBest Practices For Steam Control Valve InstallationBen MusimaneNo ratings yet

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Iom MVT ValvesDocument5 pagesIom MVT ValvesNaser JahangiriNo ratings yet

- HSE Executive - Guidance On Balanced Bellows Pressure Relief ValvesDocument3 pagesHSE Executive - Guidance On Balanced Bellows Pressure Relief ValvespbanerjeeNo ratings yet

- Well Maintenance ProcedureDocument14 pagesWell Maintenance ProcedureVlassis Sarantinos100% (1)

- Nipple Tube DiffusersDocument11 pagesNipple Tube Diffusersiyappan i.p.sNo ratings yet

- 260 enDocument3 pages260 enlesonspkNo ratings yet

- Boiler Safety ValveDocument11 pagesBoiler Safety ValveAayush Agrawal100% (1)

- Well Testing StudyDocument29 pagesWell Testing StudyDavid LutmangNo ratings yet

- ACME AHX Water-Cooled Condenser - 06.10 PDFDocument3 pagesACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002No ratings yet

- Iron Gate Globe Check I OmDocument1 pageIron Gate Globe Check I OmRobert DickNo ratings yet

- Hoer HowandwhyvalvesfailDocument4 pagesHoer HowandwhyvalvesfailpathakshashankNo ratings yet

- Vane Presiune DN40 - DN250Document28 pagesVane Presiune DN40 - DN250iza66bellNo ratings yet

- Corsbysek PDFDocument16 pagesCorsbysek PDFMargaret DaughertyNo ratings yet

- With Bonnet: ModelDocument11 pagesWith Bonnet: ModelSamet BabaNo ratings yet

- Ssicap Om ManualDocument19 pagesSsicap Om Manualsianuli_936086174No ratings yet

- Relief Valves: Gases and Gas EquipmentDocument22 pagesRelief Valves: Gases and Gas EquipmentInspection EngineerNo ratings yet

- Welded Body Ball ValveDocument20 pagesWelded Body Ball ValveBisoyiNo ratings yet

- Basic Function of Breather ValveDocument29 pagesBasic Function of Breather ValveManojkumarNo ratings yet

- 1063 Forged Brass Spring Check ValveDocument5 pages1063 Forged Brass Spring Check ValveSyed FazluNo ratings yet

- Bulletin 4002 O&M Manual For CL-16-26-56 Revised 10-15-2014Document15 pagesBulletin 4002 O&M Manual For CL-16-26-56 Revised 10-15-2014Docente 361 UMECITNo ratings yet

- Zurn Aquaflush z6000 ManualDocument8 pagesZurn Aquaflush z6000 ManualrosaearlNo ratings yet

- Manual Zetkama Fig.215 - 216Document8 pagesManual Zetkama Fig.215 - 216George_Wabag_2014No ratings yet

- Prevent MaintenanceDocument15 pagesPrevent Maintenancemecanico_ipnNo ratings yet

- Iom Cam Ball t31Document20 pagesIom Cam Ball t31Albino Felix HernandezNo ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- Flowvalves KSB Va Pn16Document11 pagesFlowvalves KSB Va Pn16JavierNo ratings yet

- Equipment Used During VentingDocument9 pagesEquipment Used During VentingRahulChoudharyNo ratings yet

- Reliableb1acc 1Document6 pagesReliableb1acc 1salajeanuNo ratings yet

- Apollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualDocument9 pagesApollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualErcan YilmazNo ratings yet

- Checks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlDocument4 pagesChecks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlSyko GuyNo ratings yet

- ValvesDocument44 pagesValvesأحمد محمد قدريNo ratings yet

- Control Valve Norriseal - Series2200 O&MDocument16 pagesControl Valve Norriseal - Series2200 O&MJairo AlonsoNo ratings yet

- IOM Wastewater Air Valves SCF 2Document9 pagesIOM Wastewater Air Valves SCF 2adamaso09No ratings yet

- Cooling Water TowersDocument10 pagesCooling Water Towerssteepa22No ratings yet

- SOP Gas AbsorptionDocument19 pagesSOP Gas AbsorptionKevin EsmunaldoNo ratings yet

- Performance Pipe ''PE3608 and PE4710 Materials Designation Codes and Pipe Pressure Ratings'' 2007Document7 pagesPerformance Pipe ''PE3608 and PE4710 Materials Designation Codes and Pipe Pressure Ratings'' 2007nathanielbabiakNo ratings yet

- 00-GFCP FabCat CompleteDocument62 pages00-GFCP FabCat Completetanbqtb03No ratings yet

- Atomac Lined Ball Valve: For Top Performance, Reliability and SafetyDocument32 pagesAtomac Lined Ball Valve: For Top Performance, Reliability and SafetyhoseyliauNo ratings yet

- Atomac Lined Ball Valve: For Top Performance, Reliability and SafetyDocument32 pagesAtomac Lined Ball Valve: For Top Performance, Reliability and SafetyhoseyliauNo ratings yet

- Axial AXBDocument20 pagesAxial AXBhoseyliauNo ratings yet

- Atomac Lined Ball Valve: For Top Performance, Reliability and SafetyDocument32 pagesAtomac Lined Ball Valve: For Top Performance, Reliability and SafetyhoseyliauNo ratings yet

- Acrylic Paint - Technical DataDocument3 pagesAcrylic Paint - Technical DatahoseyliauNo ratings yet

- Sight Glasses Features: Reservoir AccessoriesDocument2 pagesSight Glasses Features: Reservoir AccessorieshoseyliauNo ratings yet

- SD596142 ModelDocument1 pageSD596142 ModelhoseyliauNo ratings yet

- E GlazeDocument4 pagesE GlazehoseyliauNo ratings yet

- 1200 774-NRSDocument1 page1200 774-NRShoseyliauNo ratings yet

- Modular Sectional Tank Three - Piece TankDocument4 pagesModular Sectional Tank Three - Piece TankhoseyliauNo ratings yet

- Country and CapitalDocument3 pagesCountry and CapitalhoseyliauNo ratings yet

- Nibco T413irDocument1 pageNibco T413irhoseyliauNo ratings yet

- Table ADocument1 pageTable AhoseyliauNo ratings yet

- La Cascata Set MenuDocument7 pagesLa Cascata Set MenuhoseyliauNo ratings yet

- Api Spec 1bDocument42 pagesApi Spec 1bhoseyliauNo ratings yet

- Anchor Fluid Power CatalogDocument128 pagesAnchor Fluid Power CatalogJustinNo ratings yet

- 3-Way High Pressure Ball Valves: Carbon SteelDocument5 pages3-Way High Pressure Ball Valves: Carbon Steel劉功暹No ratings yet

- 3 Piece Ball Valves PDFDocument16 pages3 Piece Ball Valves PDFShaik Mudassar Nazar100% (1)

- Wuzhou & Foowell Latest Profile PDFDocument77 pagesWuzhou & Foowell Latest Profile PDFAmiti AlisaNo ratings yet

- Series 520 Ball Valves U.L. ListedDocument5 pagesSeries 520 Ball Valves U.L. ListedDerlan MarzelaNo ratings yet

- 2-Way Manual Ball Valves 3" & 4": Series MBVDocument2 pages2-Way Manual Ball Valves 3" & 4": Series MBVrickbolgerNo ratings yet

- District CoolingDocument28 pagesDistrict Coolinggehgeray100% (3)

- Velan Ball Valve 1 PDFDocument9 pagesVelan Ball Valve 1 PDFMilena Lemus FonsecaNo ratings yet

- Uploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFDocument8 pagesUploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFMonica CarrenoNo ratings yet

- 2 VBN - EspecificacionesDocument36 pages2 VBN - EspecificacionesPaola Andrea Osorio GNo ratings yet

- Pressure Reducing Control Valve: Model: KVS - 801GDocument3 pagesPressure Reducing Control Valve: Model: KVS - 801GThúy VyNo ratings yet

- F Series - Floating Ball ValvesDocument8 pagesF Series - Floating Ball ValvesCarlos Alberto Aguilera MendezNo ratings yet

- Types of ValvesDocument31 pagesTypes of ValvesZarnab Rauf78% (9)

- Apollo TechDocument259 pagesApollo Techashish_pradhan75No ratings yet

- GP-03!12!01 Valve SelectionDocument30 pagesGP-03!12!01 Valve SelectionabenitechNo ratings yet

- COMEVAL Ball ValvesDocument52 pagesCOMEVAL Ball ValvesCardoso MalacaoNo ratings yet

- Trunnion Mounted Ball Valves: Flow-TekDocument8 pagesTrunnion Mounted Ball Valves: Flow-TekJuan RodriguezNo ratings yet

- Flowserve PDFDocument12 pagesFlowserve PDFnadrivNo ratings yet

- 6DB Series Double Block and Bleed Ball Valve CatalogDocument12 pages6DB Series Double Block and Bleed Ball Valve Catalogpedro torresNo ratings yet

- BOQ For Bought Out Items (Purified Water) PDFDocument1 pageBOQ For Bought Out Items (Purified Water) PDFsppatilNo ratings yet

- TMBV CatalogDocument26 pagesTMBV Catalogajv112No ratings yet

- ValveDocument8 pagesValveCosminNo ratings yet

- Symbols of Valve and FittingDocument6 pagesSymbols of Valve and Fittingrerenemahardika100% (2)

- Operation and Maintenance Instructions: 334 SERIES THREE-PIECE BALL VALVES - 1/4" To 2-1/2"Document5 pagesOperation and Maintenance Instructions: 334 SERIES THREE-PIECE BALL VALVES - 1/4" To 2-1/2"MASOUDNo ratings yet

- LIPU - Valve PDFDocument71 pagesLIPU - Valve PDFLê Trung Kiên100% (1)

- IntroductionDocument114 pagesIntroductionBahish VadakkanNo ratings yet

- Control Valves CatalogueDocument20 pagesControl Valves Cataloguenikhil_barshettiwat100% (1)

- Brunnbauer World of ValvesDocument6 pagesBrunnbauer World of ValvesAdrian PetrascuNo ratings yet

- Catalog AP Apm UkDocument16 pagesCatalog AP Apm UkPhongsak SihanatNo ratings yet

- Ball Valve PN63 ErhardDocument1 pageBall Valve PN63 ErhardM MNo ratings yet