Professional Documents

Culture Documents

Medium Voltage AC Drive: ACS 2000, 400 - 1000 kVA, 6.0 - 6.9 KV

Uploaded by

marcelo cabral arrudaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Medium Voltage AC Drive: ACS 2000, 400 - 1000 kVA, 6.0 - 6.9 KV

Uploaded by

marcelo cabral arrudaCopyright:

Available Formats

Product brochure

Medium voltage AC drive

ACS 2000, 400 – 1000 kVA, 6.0 – 6.9 kV

2 ACS 2000 brochure | ABB

ACS 2000 – simple and reliable motor control

The ACS 2000 is the latest member of the ABB medium voltage

AC drives family providing reliable motor control for a wide

range of applications.

The ACS 2000 is designed for high reliability, easy installation Key product features

and fast commissioning reducing the total cost of ownership. –– Suitable for use with or without an input isolation transformer

With the integration of an Active Front End (AFE), line side –– Direct-to-line connection (transformerless) provides lowest

harmonics are minimized without the use of expensive, cost of ownership

specialized transformers and with the added benefit of power –– Active Front End (AFE) for minimal line side harmonics with

factor correction and regeneration. power factor correction and regeneration

–– Simple drive system integration

With its compact footprint, the ACS 2000 can be retrofitted

to control standard induction motors via a direct connection –– Three in – three out cabling technique for quick and easy

to 6.0 – 6.9 kV line supply (direct-to-line). Alternatively, a installation

simple two-winding input isolation transformer can be applied –– Suitable for new or existing induction motors

to allow for flexible line side supply voltages. –– High reliability and low maintenance costs

The ACS 2000 direct-to-line combines the cost savings of a

transformerless variable speed drive system with the benefits

of Voltage Source Inverters (VSIs), including excellent avail-

ability and reliability, high and constant power factor and

superior dynamic control performance.

The heritage of ABB’s VSI topology, along with a patented

IGBT-based multi-level control, provides a proven track

record for reliable and motor friendly medium voltage AC

drive solutions.

Fields of application

Industries Applications

Cement, mining and minerals Conveyors, crushers, mills, fans and pumps

Chemical, oil and gas Pumps, compressors, extruders, mixers and blowers

Metals Fans and pumps

Pulp and paper Fans, pumps, refiners, vacuum pumps and chippers

Power generation Fans, pumps, conveyors and coal mills

Water Pumps

Other applications Test stands and wind tunnels

ABB | ACS 2000 brochure 3

Key features

The ACS 2000 general purpose drive offers unique features

which provide superior application flexibility with a standard

solution.

Line supply connection flexibility

The ACS 2000 provides different line supply connection

options, each offering unique benefits. Depending on the

preference or the existing installation, the ACS 2000 is

available for connection to an external input isolation

transformer or for use without a transformer, the latter

allowing a direct connection to the industrial line supply

(direct-to-line).

Direct-to-line External transformer

The ACS 2000 direct-to-line can lower investment costs For applications where a voltage-matching input isolation

substantially. Due to its compact size and lighter weight transformer is needed or galvanic isolation from the line

compared to a drive requiring a transformer, it also results in supply is required, the ACS 2000 can be connected to a

lower transportation costs and needs less space in the conventional two-winding oil or dry-type input isolation

electrical room. transformer.

The ACS 2000 can be easily retrofitted to fixed speed

motors while the direct-to-line technology results in quick

and easy installation and commissioning.

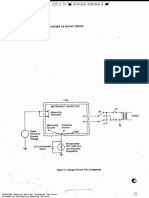

Main power supply

Input Active Front DC link Inverter unit

reactor End (AFE) (INU)

Cooling

Control

Topology of the ACS 2000 for direct-to-line connection

4 ACS 2000 brochure | ABB

Active Front End for network friendly and energy efficient Powerful performance with DTC

operation Precise and reliable process control, together with low energy

The ACS 2000 is equipped with an Active Front End (AFE) consumption, results in top performance. The ACS 2000 drive

which can be used in conjunction with a simple input isolation control platform uses ABB’s award-winning Direct Torque Control

transformer or for direct connection to 6.0 – 6.9 kV line supply. (DTC), resulting in the highest torque and speed performance

It provides low harmonics and enables four-quadrant operation as well as the lowest losses ever achieved in medium voltage

and reactive power compensation. AC drives. Control of the drive is immediate and smooth under all

conditions.

Low harmonic signature

The AFE provides a low harmonic signature which meets the Motor friendly output waveform for use with new or

most stringent requirements for harmonic distortion as defined existing motors

by relevant standards. This avoids the need for harmonic analysis The ACS 2000 provides near sinusoidal current and voltage

or the installation of network filters. waveforms making it compatible for use with standard motors and

cable insulation. This is achieved with ABB’s patented multilevel

Reduced energy consumption topology which utilizes one DC link enabling a multi-level output

For minimal energy consumption, the AFE enables four-quadrant waveform with a minimum number of power components.

operation which feeds back braking energy into the line supply.

Static VAR compensation

The AFE can also provide reactive power (VAR) compensation.

With static VAR compensation a smooth network voltage

profile can be maintained and reactive power penalties can be

avoided.

15000 200 15000 200

150 150

10000 10000

100 100

5000 5000

50 50

Amps

Amps

Volts

Volts

0 0 0

Volts

0

Volts Volts Volts

-50 -50

-5000 -5000

-100 -100

-10000 -10000

-150 -150

-15000 -200 -15000 -200

50 Hz operation point 50 Hz operation point

Line current Line voltage Motor current Motor voltage

Line and motor

Volts current and voltage

ABB | ACS 2000 brochure 5

ACS 2000

The air-cooled general purpose drive provides simple and

reliable motor control for a wide range of applications.

ACS 2000, 800 kW, 6.6 kV

Electromechanically

interlocked doors for

safety

DC bus grounding

switch for safety

User-friendly drive control panel for local operation

–– Keypad with multi-language display

–– Main supply on/off pushbuttons

–– Emergency stop pushbutton

6 ACS 2000 brochure | ABB

It is designed for easy installation, fast commissioning and

efficient maintenance reducing the total cost of ownership.

Inverter unit

(INU)

Control unit

Cable connection section

for top and bottom entry

Withdrawable

phase modules

Active Front End

(AFE)

ABB | ACS 2000 brochure 7

Features and benefits

Features Advantages Benefits

Operation without transformer (direct-to-line)

No transformer required Reduces capital expenditure

Easy retrofit to fixed-speed motors Minimizes investment

Easy and fast commissioning Lowers downtime

Lowers transportation costs; less

Compact and light drive system

space required in electrical room

Connection to external transformer

Easy integration into existing

Connection to any voltage level

infrastructure

Conventional two-winding oil or dry-type No special input isolation transformer

input isolation transformer required

Operation under ground fault without

Galvanic isolation to the line supply

impact on the drive

Heating losses are not dissipated

Transformer located outside into electrical room, reducing load

on HVAC system

Active Front End (AFE)

Harmonic emissions compliant with

Inherent low harmonic signature

all relevant standards

Reduces energy loss in distribution

Power factor adjusted to compensate

system, avoiding need for larger

for reactive power

cables and utility penalties

Allows operation with an input isolation

transformer or for direct connection to Flexibility of installation

the line supply

Four-quadrant operation (regenerative

Minimizes energy consumption

braking)

Multilevel topology

Low parts count, which boosts drive

Patented multilevel topology

availability

Provides near sinusoidal current and Compatible with standard new or

voltage waveforms existing motors

Voltage Source Inverter (VSI) topology

Excellent availability, reliability and

Higher uptime of plant or process

efficiency

High and constant power factor Eliminates utility penalties

Safe ride through during supply vol-

Superior dynamic control performance

tage dips and better process control

Direct Torque Control (DTC)

Precise and reliable process control with

Higher productivity

superior performance

Compact size

Requires less space in electrical room Frees up valuable floorspace

8 ACS 2000 brochure | ABB

Simple drive system integration

Installing a medium voltage AC drive could not be easier with

ABB’s three in – three out concept. Simply disconnect the direct-

on-line cable, connect the drive, and connect the drive to the motor.

Along with its flexible line supply connection options and DriveOPC

advanced software tools the ACS 2000 allows smooth and DriveOPC is a software package, which allows communication

simple drive system integration into any industrial environment. between ABB drives and the customer’s Windows®-based

applications.

Flexible control interface

ABB offers an open communication strategy, enabling connection Commissioning wizard

to higher-level process controllers. The ACS 2000 can be installed The commissioning wizard is an advanced tool which simplifies

with all major fieldbus adapters for smooth integration, monitoring and speeds-up commissioning, reducing plant downtime

and controlling of different processes, according to customer considerably.

requirements.

Maintenance

Simple and efficient maintenance is an important factor in

keeping operating costs down.

The ACS 2000 is designed to maximize uptime as well as to

facilitate quick repair. The modular design lends itself to quick and

effective replacement of components, resulting in industry leading

Mean Time to Repair (MTTR).

Reliable components

ABB drive technologies, such as the multilevel VSI topology, provide

a low parts count, which increases reliability, extends Mean Time

Between Failures (MTBF) and improves availability.

Easy access

The ACS 2000 has been designed to allow easy front access to all

drive components.

Redundant cooling

The ACS 2000 is available with redundant fans which increases

availability.

ABB | ACS 2000 brochure 9

Service and support

The ACS 2000 is backed by unrivalled service and support from

the customer’s initial enquiry throughout the entire life cycle of

the drive system.

Installation and commissioning Training

Proper installation and commissioning of the equipment, done by ABB provides extensive training for its medium voltage AC drives.

qualified and certified commissioning engineers, reduces start-up A range of training programs is offered from basic tutorials to

time, increases safety and reliability and decreases life cycle costs. programs tailored to the customer’s specific needs.

In addition, operators can be given practical training by experienced

specialists on site. Global network, local presence

After-sales service is an integral part of providing the customer

With its three in – three out principle, flexible line supply connection with a reliable and efficient drive system. The ABB Group of

options and advanced software tools, such as the commissioning companies operates in more than 100 countries and has a

wizard, start-up of the ACS 2000 is easy and fast, thereby worldwide network of service operations.

minimizing plant downtime.

Services for ABB‘s medium voltage AC drives

Life cycle management – – Supervision of installation and commissioning

ABB’s drive life cycle management model maximizes the value of

– – Local support

the equipment and maintenance investment by maintaining high

availability, eliminating unplanned repair costs and extending – – Worldwide service network

the lifetime of the drive. – – Spare parts and logistics network

– – Training

Life cycle management includes:

–– providing spare parts and expertise throughout the life cycle – – Remote diagnostics

–– providing efficient product support and maintenance for – – 24 x 365 support line

improved reliability

– – Customized maintenance contracts

–– adding functionality to the initial product

10 ACS 2000 brochure | ABB

Data sheet ACS 2000 for direct-to-line connection

Motor data Converter Converter data

Voltage * Shaft power ** Type code Power *** Current Length Approx. weight

kV kW hp kVA A mm kg

6‘000 V

6.0 315 430 ACS 2060-1T-AN1-a-0E 430 40 1'740 2'000

6.0 355 480 ACS 2060-1T-AN1-a-0G 470 45 1'740 2'000

6.0 400 540 ACS 2060-1T-AN1-a-0J 530 50 1'740 2'000

6.0 450 610 ACS 2060-1T-AN1-a-0L 590 55 1'740 2'000

6.0 500 680 ACS 2060-1T-AN1-a-0N 650 60 1'740 2'000

6.0 560 760 ACS 2060-1T-AN1-a-0Q 730 70 1'740 2'000

6.0 630 860 ACS 2060-1T-AN1-a-0S 820 80 1'740 2'000

6.0 710 970 ACS 2060-1T-AN1-a-0U 910 90 1'740 2'000

6.0 800 1'090 ACS 2060-1T-AN1-a-0W 1020 100 1'740 2'000

6‘600 V

6.6 315 430 ACS 2066-1T-AN1-a-0E 430 38 1'740 2'000

6.6 355 480 ACS 2066-1T-AN1-a-0G 470 41 1'740 2'000

6.6 400 540 ACS 2066-1T-AN1-a-0J 530 45 1'740 2'000

6.6 450 610 ACS 2066-1T-AN1-a-0L 590 50 1'740 2'000

6.6 500 680 ACS 2066-1T-AN1-a-0N 650 55 1'740 2'000

6.6 560 760 ACS 2066-1T-AN1-a-0Q 730 65 1'740 2'000

6.6 630 860 ACS 2066-1T-AN1-a-0S 820 70 1'740 2'000

6.6 710 970 ACS 2066-1T-AN1-a-0U 910 80 1'740 2'000

6.6 800 1'090 ACS 2066-1T-AN1-a-0W 1020 90 1'740 2'000

6‘900 V

6.9 315 430 ACS 2069-1T-AN1-a-0E 430 35 1'740 2'000

6.9 355 480 ACS 2069-1T-AN1-a-0G 470 40 1'740 2'000

6.9 400 540 ACS 2069-1T-AN1-a-0J 540 45 1'740 2'000

6.9 450 610 ACS 2069-1T-AN1-a-0L 590 50 1'740 2'000

6.9 500 680 ACS 2069-1T-AN1-a-0N 650 55 1'740 2'000

6.9 560 760 ACS 2069-1T-AN1-a-0Q 730 60 1'740 2'000

6.9 630 860 ACS 2069-1T-AN1-a-0S 820 70 1'740 2'000

6.9 710 970 ACS 2069-1T-AN1-a-0U 910 75 1'740 2'000

6.9 800 1'090 ACS 2069-1T-AN1-a-0W 1030 85 1'740 2'000

Notes: Main power supply

* 6.0 / 6.6 kV according to IEC; 6.9 kV according to ANSI/NEMA

** Indicative information referring to typical 4-pole motor, under nominal supply voltage conditions.

Input Active Front DC link Inverter unit

*** Overload (10% / 60 sec.) margin included reactor End (AFE) (INU)

Dimensions:

Cooling

Control

Height: 2100 mm cabinet height

2490 mm (incl. cooling fans on top)

2700 mm with redundant cooling fans

Depth: 1140 mm

Topology of the ACS 2000 for direct-to-line connection

ABB | ACS 2000 brochure 11

Data sheet ACS 2000 for connection to external transformer

Motor data Converter Converter data

Voltage * Shaft power ** Type code Power *** Current Length Approx. weight

kV kW hp kVA A mm kg

6‘000 V

6.0 315 430 ACS 2060-1A-AN1-a-0E 430 40 1'740 1'500

6.0 355 480 ACS 2060-1A-AN1-a-0G 470 45 1'740 1'500

6.0 400 540 ACS 2060-1A-AN1-a-0J 530 50 1'740 1'500

6.0 450 610 ACS 2060-1A-AN1-a-0L 590 55 1'740 1'500

6.0 500 680 ACS 2060-1A-AN1-a-0N 650 60 1'740 1'500

6.0 560 750 ACS 2060-1A-AN1-a-0Q 730 70 1'740 1'500

6.0 630 860 ACS 2060-1A-AN1-a-0S 820 80 1'740 1'500

6.0 710 970 ACS 2060-1A-AN1-a-0U 910 90 1'740 1'500

6.0 800 1'090 ACS 2060-1A-AN1-a-0W 1020 100 1'740 1'500

6‘600 V

6.6 315 430 ACS 2066-1A-AN1-a-0E 430 38 1'740 1'500

6.6 355 480 ACS 2066-1A-AN1-a-0G 470 41 1'740 1'500

6.6 400 540 ACS 2066-1A-AN1-a-0J 530 45 1'740 1'500

6.6 450 610 ACS 2066-1A-AN1-a-0L 590 50 1'740 1'500

6.6 500 680 ACS 2066-1A-AN1-a-0N 650 55 1'740 1'500

6.6 560 760 ACS 2066-1A-AN1-a-0Q 730 65 1'740 1'500

6.6 630 860 ACS 2066-1A-AN1-a-0S 820 70 1'740 1'500

6.6 710 970 ACS 2066-1A-AN1-a-0U 910 80 1'740 1'500

6.6 800 1'090 ACS 2066-1A-AN1-a-0W 1020 90 1'740 1'500

6‘900 V

6.9 315 430 ACS 2069-1A-AN1-a-0E 430 35 1'740 1'500

6.9 355 480 ACS 2069-1A-AN1-a-0G 470 40 1'740 1'500

6.9 400 540 ACS 2069-1A-AN1-a-0J 540 45 1'740 1'500

6.9 450 610 ACS 2069-1A-AN1-a-0L 590 50 1'740 1'500

6.9 500 680 ACS 2069-1A-AN1-a-0N 650 55 1'740 1'500

6.9 560 760 ACS 2069-1A-AN1-a-0Q 730 60 1'740 1'500

6.9 630 860 ACS 2069-1A-AN1-a-0S 820 70 1'740 1'500

6.9 710 970 ACS 2069-1A-AN1-a-0U 910 75 1'740 1'500

6.9 800 1'090 ACS 2069-1A-AN1-a-0W 1030 85 1'740 1'500

Notes: Main power supply

* 6.0 / 6.6 kV according to IEC; 6.9 kV according to ANSI/NEMA

** Indicative information referring to typical 4-pole motor, under nominal supply voltage conditions. Input

transformer Active Front DC link Inverter

*** Overload (10% / 60 sec.) margin included End (AFE)

Dimensions:

Cooling

Control

Height: 2100 mm cabinet height

2490 mm (incl. cooling fans on top)

2700 mm with redundant cooling fans

Depth: 1140 mm

Topology of the ACS 2000 for connection to an external transformer

ABB | ACS 2000 brochure 12

Data sheet ACS 2000

Inverter type Ambient temperature

Voltage Source Inverter (VSI), 9 levels line-to-line, with high voltage + 1 oC to 40 oC (higher with derating)

IGBT (Integrated Gate Bipolar Transistor) power semiconductors

Enclosure classes

Motors IP21 to IP42

Induction motors; 315 – 800 kW (430 – 1090 hp)

Control interface (optional)

Standards All common fieldbuses including Profibus, Modbus, DeviceNet,

All common standards including EN, IEC, CE, NEMA Ethernet, ACS Drivebus, ABB Advant Fieldbus AF100, others

Input Standard protection functions

5-level self-commutated IGBT Active Front End (AFE) for opera- Auxiliary voltage fault, cabinet temperature supervision,

tion with two-winding input isolation transformer or direct-to-line overcurrent, short circuit detection, motor overload, motor stall

(DTL), i.e. without transformer and overspeed protection, communication fault (I/O watchdog),

earth fault, main circuit breaker supervision/tripping, emergency

Rated input voltages: off signal supervision

6000 / 6600 V, +10% to -10% (-30% with derating)

6900 V, +5% to -10% (-35% with derating) Example options

– – Motor supervision I/Os

Input frequency 50 / 60 Hz –– Fault/alarm: overtemperature, vibration of bearings

–– PT 100: winding and bearing temperatures

Auxiliary voltage – – Transformer supervision I/Os

Common 400 – 480 VAC, 3-phase, 50 Hz/60 Hz –– Fault/alarm: overtemperature, Buchholz

–– PT 100: winding temperatures

UPS (Uninterruptible Power Supply) – – Hardwired signals for remote drive control

If available, a UPS can be connected for control power supply, –– References: start/stop, speed/torque etc.

110 – 240 VAC, single phase or 110/220 VDC. Alternatively, –– Status feedback signals: ready/running

the drive can be equipped with an internal UPS. –– Analog signals: current/voltage/power etc.

–– Redundant cooling fans with automatic switch over for duty

Output frequency cycling and upon fan failure

0 to 75 Hz – – ABB DriveWindow service and diagnostic software

– – ABB DriveMonitorTM for remote monitoring and diagnostics

Rated output voltage

6.0 – 6.9 kV

Efficiency of converter

Typically 97.5%

Input power factor

Controlled to 1 or adjustable to compensate for reactive power

of other loads connected to the same network

13 ACS 2000 brochure | ABB

Contact us

ABB Switzerland Ltd

© Copyright 2009 ABB. All rights reserved. Specifications subject to change without notice. 3BHT490640R0001

Medium Voltage Drives

CH-5300 Turgi

Phone: +41 58 589 27 95

Fax: +41 58 589 27 84

E-Mail: mvdrives@ch.abb.com

www.abb.com/drives

You might also like

- ACS 2000 Medium Voltage Drives: Technical DataDocument24 pagesACS 2000 Medium Voltage Drives: Technical DataDaigo CfNo ratings yet

- ABB Medium Voltage Drives: ACS 2000 4kV Frames 1 & 2 Spare Parts CatalogDocument36 pagesABB Medium Voltage Drives: ACS 2000 4kV Frames 1 & 2 Spare Parts Catalogmarcelo cabral arrudaNo ratings yet

- Acs2000 Brochure 3bht490640r0001 en RevhDocument28 pagesAcs2000 Brochure 3bht490640r0001 en RevhSanjay PandaNo ratings yet

- 2UEB000131 REV D Spare Part Manual Web PDFDocument52 pages2UEB000131 REV D Spare Part Manual Web PDFDavid PortugalNo ratings yet

- Abb - Technical Guide VFDDocument44 pagesAbb - Technical Guide VFDThejas HK100% (1)

- ABB Control SystemDocument36 pagesABB Control Systemhagh_mostafa2787No ratings yet

- ABB - Technical Guide No.7 - REVCDocument40 pagesABB - Technical Guide No.7 - REVCgafscottNo ratings yet

- Disconnector Catalogue PDFDocument44 pagesDisconnector Catalogue PDFroom liveNo ratings yet

- Transformer Components and Insulation - ABB - Brochure - EN20200421 PDFDocument20 pagesTransformer Components and Insulation - ABB - Brochure - EN20200421 PDFVENKATA RAJUNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- En Dishwasher: ESL 7220RO User ManualDocument20 pagesEn Dishwasher: ESL 7220RO User ManualMarcos PereiraNo ratings yet

- GES 21 SpecDocument7 pagesGES 21 SpecBrillyanNo ratings yet

- Product Card - Fill - Coolfilm - SNCS 0.3 & 0.35Document1 pageProduct Card - Fill - Coolfilm - SNCS 0.3 & 0.35AsifNo ratings yet

- High Voltage - WikipediaDocument47 pagesHigh Voltage - WikipediaDamilare Daniel OlaniyiNo ratings yet

- Empanelment FormDocument5 pagesEmpanelment FormBalaji RNo ratings yet

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) APUDocument232 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) APUjuanNo ratings yet

- Stepper Motors BasicsDocument18 pagesStepper Motors BasicsAhmed KalasNo ratings yet

- SUNICE SL Series】: - Refrigeration Oil for HFC Refrigerant -Document2 pagesSUNICE SL Series】: - Refrigeration Oil for HFC Refrigerant -Gayuh Wahyu Eska NegaraNo ratings yet

- Weighing Basement Finishing Cost OptionsDocument2 pagesWeighing Basement Finishing Cost OptionsRownok FerdousNo ratings yet

- Deye Approved Battery List (DY-LV48-0006)Document3 pagesDeye Approved Battery List (DY-LV48-0006)BoNo ratings yet

- Global Climate Agreements - Successes and Failures - Council On Foreign RelationsDocument11 pagesGlobal Climate Agreements - Successes and Failures - Council On Foreign RelationsMuhammad nawazNo ratings yet

- HVACDocument216 pagesHVACAvinash NathNo ratings yet

- Plasma: A State of MatterDocument18 pagesPlasma: A State of MatterDevNo ratings yet

- LLCPDocument2 pagesLLCPDiego SotoNo ratings yet

- Policy Research Corporation. 2008. The Role of Maritime Clusters To Enhance The Strength and Development of Maritime Sectors. Report On ResultsDocument42 pagesPolicy Research Corporation. 2008. The Role of Maritime Clusters To Enhance The Strength and Development of Maritime Sectors. Report On ResultsAleksei LassikovNo ratings yet

- Ansi C39 5Document20 pagesAnsi C39 5Boris AguilarNo ratings yet

- Technical DataDocument27 pagesTechnical Datasatria ghaniNo ratings yet

- Manual Partes HDKCA HDKCBDocument68 pagesManual Partes HDKCA HDKCBgiovanny sanchezNo ratings yet

- Sun Shading DevicesDocument4 pagesSun Shading DevicesjabezNo ratings yet

- RVI in Power GenDocument21 pagesRVI in Power Genwebs.usuarioNo ratings yet

- Design and Simulation of A PV System With Battery Storage Using Bidirectional DC DC Converter Using Matlab SimulinkDocument9 pagesDesign and Simulation of A PV System With Battery Storage Using Bidirectional DC DC Converter Using Matlab SimulinkMohd Mohsin SohailNo ratings yet

- IS 1180 Amendment 4 Notice From BISDocument3 pagesIS 1180 Amendment 4 Notice From BISPrathap -Kalpa100% (1)

- OVP Test ProceduresDocument3 pagesOVP Test Proceduresحجت زارعNo ratings yet

- Combustion Lessons - Ch5 (Ed6)Document89 pagesCombustion Lessons - Ch5 (Ed6)hassan ghNo ratings yet

- Doosan Engine Dl08c Maintenance ManualDocument10 pagesDoosan Engine Dl08c Maintenance Manualkathleen100% (50)

- ARDUINODocument13 pagesARDUINOGagleen RissamNo ratings yet

- NPCIL Personal - Details - FormatDocument2 pagesNPCIL Personal - Details - FormatpraveenNo ratings yet

- RI-9000 English Manual 2019.12.03Document209 pagesRI-9000 English Manual 2019.12.03steven MelgarejoNo ratings yet

- Thayer US-Vietnam Relations Post Mortem - 5Document4 pagesThayer US-Vietnam Relations Post Mortem - 5Carlyle Alan ThayerNo ratings yet

- Boiler Pressure PartsDocument32 pagesBoiler Pressure PartsavtarsinghsandhuNo ratings yet