Professional Documents

Culture Documents

BCS - SS-CRM 460 - 2 Jun2019

Uploaded by

Peterson SudlabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BCS - SS-CRM 460 - 2 Jun2019

Uploaded by

Peterson SudlabCopyright:

Available Formats

MAIN EDITION

BUREAU OF ANALYSED SAMPLES LTD

BRITISH CHEMICAL STANDARD CERTIFIED REFERENCE MATERIAL

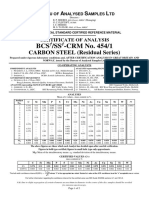

CERTIFICATE OF ANALYSIS

BCS/SS-CRM No. 460/2

CARBON STEEL (Residual Series)

Prepared under rigorous laboratory conditions and, AFTER CERTIFICATION ANALYSIS IN GREAT BRITAIN,

issued by the Bureau of Analysed Samples Ltd.

CO-OPERATING ANALYSTS

INDEPENDENT ANALYSTS ANALYSTS representing MANUFACTURERS and USERS

1 KATZ, A.M. and SUTCLIFFE, T.A., 4 REOCH, G., BSc, Weir Pumps Ltd., Glasgow.

Alfred H. Knight International Ltd., St. Helens. 5 FISHER, M., Corus Construction & Industrial, Scunthorpe.

2 MOLE, T.H., SGS (UK) Limited, Warley. 6 FOX G., Corus Engineering Steels, Stocksbridge.

3 PAGE-GIBSON, J.E., BSc, CChem, MRSC, 7 HUNT, M. and RAW, M.T., Corus Construction & Industrial, Redcar.

Ridsdale and Co. Ltd., Middlesbrough. 8 SYMONDS, J., Corus Strip Products, Llanwern.

9 SCRIMSHIRE, P.J., IncoTest, Hereford.

ANALYSES

Mean of 4 values - mass content in %.

NB: Although widely accepted within the industry “mass content in %” is neither an SI nor an IUPAC supported quantity. Multiplication by 104 will yield the value in µg/g.

Analyst Al Al

C Si Mn P S B Co Nb Pb V Sb Zr

No. (Total) (Acid Sol.)

1 0.3849 0.1194 0.6178 0.0361 0.0103 ... ... ... ... ... ... ... ... 0.0007

2 0.3838 0.1218 0.6248 0.0371 0.0097 ... ... ... ... ... ... ... ... ...

3 0.3888 0.1274 0.6184 0.0362 0.0097 0.0235 0.0196 0.0030 0.0103 0.0642 0.0004 0.0322 0.0006 0.0001

4 0.3873 0.1238 0.5960 0.0390 0.0101 ... ... ... ... ... ... ... ... ...

5 0.3831 0.1323 0.6194 0.0373 ... 0.0230 0.0193 0.0032 0.0104 0.0707 0.0006 0.0316 ... ...

6 ... ... ... ... ... ... ... 0.0027 0.0109 0.0695 0.0003 0.0325 0.0005 <0.0005

7 0.3828 0.1265 0.6224 0.0374 0.0094 0.0247 0.0194 0.0020 0.0109 0.0651 ... 0.0323 0.0007 <0 0005

8 0.3780 0.1320 0.6175 0.0397 0.0100 0.0247 0.0192 ... 0.0110 0.0683 0.0008 ... 0.0007 ...

9 0.3765 0.1280 0.6103 0.0360 0.0098 0.0243 0.0190 ... 0.0103 ... ... 0.0325 ... 0.0001

MM 0.3832 0.1264 0.6158 0.0374 0.0099 0.0240 0.0193 0.0027 0.0106 0.0676 0.0005 0.0322 0.0006 ...

sM 0.0043 0.0046 0.0091 0.0014 0.0003 0.0008 0.0003 0.0006 0.0004 0.0029 0.0003 0.0004 0.0001 ...

sW 0.0039 0.0033 0.0047 0.0006 0.0005 0.0011 0.0006 0.0001 0.0003 0.0008 0.0001 0.0004 0.0001 ...

The above figures are those which each Analyst has decided upon after careful verification.

Figures in bold type certified, figures in small italic type only approximate.

MM: Mean of the laboratory mean values. sM: standard deviation of the laboratory mean values, sW: average within laboratory standard deviation.

CERTIFIED VALUES (Cv)

mass content in %

C Si Mn P S Al Al B Co Nb Pb V Sb

(Total) (Acid Sol.)

Cv 0.383 0.126 0.616 0.0374 0.0099 0.0240 0.0193 0.0027 0.0106 0.068 0.0005 0.0322 0.0006

C(95%) 0.004 0.004 0.008 0.0012 0.0003 0.0010 0.0003 0.0009 0.0004 0.004 0.0004 0.0005 0.0002

The half width confidence interval, C(95%), is an expression of the uncertainty of the certified value.

t sM

C(95%) = where “t” is the appropriate two sided Student’s t value at the 95% confidence level for “n” acceptable mean values.

n

For further information regarding the confidence interval for the certified value see ISO Guide 35.

DESCRIPTION OF SAMPLE

British Chemical Standard, BCS-CRM 460/2, is sold in bottles containing 100g chips graded 1700 - 250µm (10 - 60 mesh) for chemical analysis.

Spectroscopic Standard, SS-CRM 460/2, is sold as 38 mm diameter x 19 mm thick discs for spectroscopic analysis.

Date of this edition: June 2019.

(The current edition is available at www.basrid.co.uk)

Page 1 of 2

BCS/SS-CRM 460/2 CARBON STEEL (Residual Series)

NOTES ON METHODS USED

CARBON

All Analysts, except Nos. 3 and 5 determined carbon using high frequency combustion and infrared absorption. Nos. 4 and 8 calibrated with pure chemicals. Analysts

Nos. 3 and 5 used non-aqueous titration according to B S 6200:3.8.2:1991.

SILICON

Analysts Nos. 1, 2, 3, 4, 5 and 8 used gravimetric methods. All Analysts, except No. 4, after dehydration with perchloric acid according to BS 6200:3.26.1:1995 (ISO

439-1994), Analyst No. 4 after dehydration with nitrosulphuric acid. Analysts Nos. 7 and 9 determined silicon by Inductively Coupled Plasma-Optical Emission Spectrometry

(ICP-OES). No. 9 calibrated with pure metal.

MANGANESE

Analysts Nos. 1, 2, 7, 8 and 9 determined manganese using ICP-OES, Nos. 1 and 9 calibrated with pure chemicals. Analysts Nos. 3 and 5 determined manganese

photometrically after oxidation with periodate according to BS 6200:3.18.2:1985 (ISO 629-1982). Analyst No. 4 used Flame Atomic Absorption Spectrometry (FAAS).

PHOSPHORUS

Analysts Nos. 1, 2, 7, 8 and 9 determined phosphorus using ICP-OES, Nos. 1 and 9 calibrated with pure chemicals. Analysts Nos. 3 and 5 determined phosphorus

photometrically as phosphovanadomolybdate according to BS EN 10184:1992. Analyst No. 4 used a titrimetric method after precipitation as phosphomolybdate.

SULPHUR

All Analysts, except No. 3, determined sulphur using high frequency combustion and infrared absorption. Nos. 4, 8 and 9 calibrated with pure chemicals. Analyst No. 3

determined sulphur gravimetrically as barium sulphate.

ALUMINIUM (TOTAL)

All Analysts determined total aluminium using ICP-OES. Nos. 5 and 9 calibrated with pure metal. Analyst No. 3 used FAAS according to BS6200:3.1.4:1990 (ISO

9658-1990).

ALUMINIUM (ACID SOLUBLE)

Analyst No. 3 determined acid-soluble aluminium using ICP-OES, Nos. 3, 5 and 9 calibrated with pure metal. Analyst No. 3 after dissolution according to BS

6200:3.1.4:1990 (ISO 9658-1990). The other Analysts after dissolution procedures as follows:-

Analyst No. 5, 1:1 hydrochloric acid and oxidation with nitric acid; Analyst No. 7, 1:1:2 hydrochloric and nitric acids and water; Analyst No. 8, 1:1 nitric acid and

Analyst No. 9, a mixture of hydrochloric, nitric and hydrofluoric acids.

Analyst No. 3 also determined the acid-insoluble aluminium using ICP-OES and obtained a mean value of 0.0039%.

BORON

All Analysts, except No. 7, determined boron photometrically with curcumin according to BS EN 10200:1992. Analyst No. 7 used ICP-OES.

COBALT

All Analysts, except No. 3, determined cobalt using ICP-OES. Nos. 5, 6 and 9 calibrated with pure metal. Analyst No. 3 used FAAS according to BS 6200:3.11.3:1997

(ISO 11652-1997).

NIOBIUM

All Analysts, except No. 3, determined niobium using ICP-OES. Nos. 5, and 6 calibrated with pure metal or metal oxide. Analyst No. 3 used a photometric method with

4-(2-pyridylazo) resorcinol after separation with phenylarsonic acid according to BS EN 10178:1989.

LEAD

Analysts Nos. 3, 5 and 6 determined lead using FAAS. Analyst No. 8 used ICP-OES. Analysts Nos. 3, 5, and 9 calibrated with pure metal.

VANADIUM

All Analysts, except No. 3, determined vanadium using ICP-OES. Nos. 5, 6 and 9 calibrated with pure chemicals. Analyst No. 3 used a photometric method with N-

benzoylphenyl-hydroxylamine according to BS 6200:3.34.2:1989 (ISO 4942:1988).

ANTIMONY

Analyst No. 3 determined antimony using FAAS. Analyst No. 6 also used FAAS after separation of antimony with hydride generation. Analysts Nos. 7 and 9 used ICP-

OES. Analysts Nos. 3 and 6 calibrated with pure metal.

ZIRCONIUM

All Analysts, except No. 3, determined zirconium using ICP-OES. Analyst No. 3 used a photometric method with arsenazo III.

INTENDED USE

BCS-CRM 460/2 is intended for uses such as the verification of the accuracy and repeatability of analytical methods, such as those used by the participating laboratories,

for the calibration of analytical instruments, for establishing values for secondary reference materials and for training purposes. The sample should be mixed thoroughly before

each use.

SS-CRM 460/2 is intended for establishing and checking the calibration of Optical Emission and X-Ray Spectrometers for the analysis of similar materials. The “as-

received” working surface should be linished before use to remove any protective coating. N.B. Due to slight segregation of certain elements an area 6mm in diameter in the

centre of the disc sample should be avoided for emission spectrometry. Users of optical emission spectrometry should also be aware that a minimum of three sparks should be

made before calculating mean values.

STABILITY

BCS-CRM 460/2 will remain stable provided that the bottle remains sealed and is stored in a dry atmosphere. When the bottle has been opened the lid should be secured

immediately after use. SS-CRM 456/2 will remain stable provided that it is not subjected to excessive heat (e.g. during preparation of the working surfaces).

TRACEABILITY

The characterisation of BCS/SS-CRM 460/2 has been achieved by chemical analysis involving inter-laboratory study, each laboratory using the method of their choice,

details of which are given above. Most of the analytical methods used in the characterisation of this CRM were either international or national standard methods or methods

which are technically equivalent. All laboratories used either stoichiometric analytical techniques or methods which were calibrated predominantly against pure metals or

stoichiometric compounds, ensuring traceability of the individual results to the SI.

MEASUREMENT UNCERTAINTY

The uncertainty of each of the certified values of BCS/SS-CRM 460/2 has been established by multiplying the standard error arising from the chemical analysis by the

appropriate two sided Student’s t value at the 95% confidence level for the number of results. Homogeneity has been assessed in accordance with ASTM E826 – 85 and found

to be acceptable. Homogeneity has not, therefore, been included in the calculated measurement uncertainty. The stability of this CRM and its transportation also make negligible

contributions to the overall uncertainty of the certified values.

COMMUTABILITY

BCS-CRM 460/2 is intended to be used in the same physical form as that used by the participating Analysts and therefore commutability is not of relevance in respect of

this CRM.

In the case of SS-CRM 460/2 it has been established that, when using optical emission spectrometers, materials of similar composition from different sources may respond

differently. The user should be aware that the metallurgical history of this SS-CRM may not accurately reflect the metallurgical history of the user’s own materials.

Further information and advice on this or other Certified Reference Materials or Reference Materials produced by Bureau of Analysed Samples Ltd may be obtained from

the address below.

NEWHAM HALL, NEWBY, MIDDLESBROUGH, ENGLAND, TS8 9EA For BUREAU OF ANALYSED SAMPLES LTD

Email: enquiries@basrid.co.uk Website: www.basrid.co.uk R.P. MEERES, Managing Director

Preliminary Edition ...................................................................................................................................................................................................................... January 1999

Main Edition ..................................................................................................................................................................................................................................... May 2001

Main Edition (revised with editorial changes) ................................................................................................................................................................................. June 2019

Page 2 of 2

You might also like

- BCS 406 - 2Document2 pagesBCS 406 - 2lehdruk7100100% (1)

- The Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionFrom EverandThe Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionNo ratings yet

- BCS - SS-CRM 111 - 1 Jan2018Document3 pagesBCS - SS-CRM 111 - 1 Jan2018Ishmael WoolooNo ratings yet

- BCS-CRM 113 Mar2014Document3 pagesBCS-CRM 113 Mar2014Ishmael WoolooNo ratings yet

- Polymer Characterization: Laboratory Techniques and AnalysisFrom EverandPolymer Characterization: Laboratory Techniques and AnalysisNo ratings yet

- SCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisDocument2 pagesSCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisPeterson SudlabNo ratings yet

- Ss CRM 495 - 4Document2 pagesSs CRM 495 - 4lehdruk7100No ratings yet

- BCS /SS - CRM No. 405/2 Low Alloy Steel: B A S LDocument2 pagesBCS /SS - CRM No. 405/2 Low Alloy Steel: B A S LPeterson SudlabNo ratings yet

- 0.8% Carbon Steel Reference MaterialDocument2 pages0.8% Carbon Steel Reference MaterialIshmael WoolooNo ratings yet

- Certified Low Alloy Steel AnalysisDocument3 pagesCertified Low Alloy Steel AnalysisIshmael WoolooNo ratings yet

- SS-CRM No. 493/3 High Manganese Steel: Certificate of AnalysisDocument2 pagesSS-CRM No. 493/3 High Manganese Steel: Certificate of Analysislehdruk7100No ratings yet

- BCS-CRM 111 Mar2014Document3 pagesBCS-CRM 111 Mar2014Ishmael WoolooNo ratings yet

- High Manganese Steel Certified Reference MaterialDocument2 pagesHigh Manganese Steel Certified Reference Materiallehdruk7100No ratings yet

- BCS-CRM 183 - 4 Jun2013Document2 pagesBCS-CRM 183 - 4 Jun2013Ishmael WoolooNo ratings yet

- BCS-CRM 180 - 2 Aug2012Document2 pagesBCS-CRM 180 - 2 Aug2012Ishmael WoolooNo ratings yet

- BCS-CRM No. 206/3 (ECRM 453-1) : High Si and P Cast IronDocument2 pagesBCS-CRM No. 206/3 (ECRM 453-1) : High Si and P Cast IronIshmael WoolooNo ratings yet

- BCS-CRM 114 Mar2014Document3 pagesBCS-CRM 114 Mar2014Ishmael WoolooNo ratings yet

- SCRM No. 656/9 Low Phosphorus Engineering Iron: Certificate of AnalysisDocument2 pagesSCRM No. 656/9 Low Phosphorus Engineering Iron: Certificate of AnalysisPeterson SudlabNo ratings yet

- BCS-CRM 208 - 3 Nov2019Document2 pagesBCS-CRM 208 - 3 Nov2019Ishmael WoolooNo ratings yet

- Certified Lead-Base White Metal AnalysisDocument2 pagesCertified Lead-Base White Metal AnalysisIshmael WoolooNo ratings yet

- Certified Reference Material AnalysisDocument2 pagesCertified Reference Material AnalysisIshmael WoolooNo ratings yet

- BCS - SS-CRM 475Document2 pagesBCS - SS-CRM 475mangalamtestingbureaNo ratings yet

- BCS - SS-CRM 405 - 1 Dec2009Document2 pagesBCS - SS-CRM 405 - 1 Dec2009Ishmael WoolooNo ratings yet

- BCS-CRM 178 - 2 Aug2012Document2 pagesBCS-CRM 178 - 2 Aug2012Ishmael WoolooNo ratings yet

- BCS-CRM 182 - 3 Aug2015Document2 pagesBCS-CRM 182 - 3 Aug2015Ishmael WoolooNo ratings yet

- BCS-CRM 381Document2 pagesBCS-CRM 381mangalamtestingbureaNo ratings yet

- SUS Katalog enDocument19 pagesSUS Katalog endev-nullNo ratings yet

- BCS - SS-CRM 452 - 1 Aug2010Document2 pagesBCS - SS-CRM 452 - 1 Aug2010Ishmael WoolooNo ratings yet

- BCS-CRM 181 - 3 Jun2013Document2 pagesBCS-CRM 181 - 3 Jun2013Ishmael WoolooNo ratings yet

- Imz 123Document4 pagesImz 123dheeraj chawlaNo ratings yet

- B.S. 187A Certificate of Analysis for Steel Alloy 20 Reference MaterialDocument4 pagesB.S. 187A Certificate of Analysis for Steel Alloy 20 Reference MaterialIshmael WoolooNo ratings yet

- Logam Berat Ikan Danau PascatambangDocument70 pagesLogam Berat Ikan Danau PascatambangrojakNo ratings yet

- BCS - SS-CRM 451 - 1 Aug2010Document2 pagesBCS - SS-CRM 451 - 1 Aug2010Ishmael Wooloo100% (2)

- ProfileDocument23 pagesProfileMd Monirul IslamNo ratings yet

- Certificate of Analysis: (Batch C) Certified Reference Material InformationDocument4 pagesCertificate of Analysis: (Batch C) Certified Reference Material InformationrahulNo ratings yet

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsAtiqur RahmanNo ratings yet

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocument4 pagesHome About Us Products & Market Media Contact: Minimum Standard RequirementsMohamed AlkharashyNo ratings yet

- OE-AN41282 ARL easySpark-Alu-1016Document4 pagesOE-AN41282 ARL easySpark-Alu-1016Christian RomeroNo ratings yet

- BCS - SS-CRM 454 - 1 Aug2010Document2 pagesBCS - SS-CRM 454 - 1 Aug2010Ishmael WoolooNo ratings yet

- Measuring Protein Concentration and StabilityDocument11 pagesMeasuring Protein Concentration and StabilityKatarina Kaca GacevicNo ratings yet

- Report Test Tensile GP 11Document24 pagesReport Test Tensile GP 11syabaniah khipliNo ratings yet

- ULLAGE REPORT FOR M.T. INDIRA CARRYING BITUMEN VG 40Document1 pageULLAGE REPORT FOR M.T. INDIRA CARRYING BITUMEN VG 40Manpreet paddaNo ratings yet

- Repeatability and Reproducibility: Add To CartDocument3 pagesRepeatability and Reproducibility: Add To CartBALAJINo ratings yet

- AISI 4330 Alloy Certificate of AnalysisDocument3 pagesAISI 4330 Alloy Certificate of AnalysisDuong PhạmNo ratings yet

- MS1723 Performance Evaluation of Mechanical Dust Collector PDFDocument36 pagesMS1723 Performance Evaluation of Mechanical Dust Collector PDFSyahfiq YusofNo ratings yet

- CL21F223ZBANNNCDocument48 pagesCL21F223ZBANNNCsam2976No ratings yet

- Certificate of Analysis: BS Number CC-17Document4 pagesCertificate of Analysis: BS Number CC-17Sidneide Ferreira SantosNo ratings yet

- BS4942Document4 pagesBS4942Sukamal GhoshNo ratings yet

- Practical Considerations For Conductivity and Total Dissolved Solids MeasurementDocument5 pagesPractical Considerations For Conductivity and Total Dissolved Solids MeasurementVarun KumarNo ratings yet

- Oss CatalogDocument44 pagesOss CatalogMayowa BuariNo ratings yet

- ACC Concrete Modulus of Elasticity Test ReportDocument4 pagesACC Concrete Modulus of Elasticity Test ReportSabyasachi BangalNo ratings yet

- MOE Test Result of Acc ConcreteDocument4 pagesMOE Test Result of Acc ConcreteSabyasachi BangalNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- Analytical Reference Materials International: Certificate of AnalysisDocument2 pagesAnalytical Reference Materials International: Certificate of AnalysisDuong PhạmNo ratings yet

- Certificate of Analysis: National Institute of Standards & TechnologyDocument7 pagesCertificate of Analysis: National Institute of Standards & TechnologyCesar BarretoNo ratings yet

- BCS-CRM 204 - 6 Sep2017Document4 pagesBCS-CRM 204 - 6 Sep2017Ishmael WoolooNo ratings yet

- Cim SRK 2015 V2Document24 pagesCim SRK 2015 V2张程No ratings yet

- Additive AravinthDocument15 pagesAdditive AravinthAravinth subramanianNo ratings yet

- Vanadium Microalloying Boosts Strength of Long Steel ProductsDocument6 pagesVanadium Microalloying Boosts Strength of Long Steel ProductsUlises Quintana CarhuanchoNo ratings yet

- Nickel Alloy Forgings: Standard Specification ForDocument11 pagesNickel Alloy Forgings: Standard Specification ForClaudio Di GioseffoNo ratings yet

- Ornl 2440Document325 pagesOrnl 2440jesusNo ratings yet

- Materials Science & Engineering A: Z.R. Khayat, T.A. PalmerDocument12 pagesMaterials Science & Engineering A: Z.R. Khayat, T.A. PalmerVikrant Saumitra mm20d401No ratings yet

- Alain Hazotte - Solid State Transformation and Heat Treatment-Wiley-VCH (2005)Document195 pagesAlain Hazotte - Solid State Transformation and Heat Treatment-Wiley-VCH (2005)Ridvan GecuNo ratings yet

- Common Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsDocument8 pagesCommon Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsKipper KimNo ratings yet

- Microstructural Characterization of Modified 25Cr-35Ni Almeida2002Document11 pagesMicrostructural Characterization of Modified 25Cr-35Ni Almeida2002Andrea CalderaNo ratings yet

- Astm B805Document7 pagesAstm B805Jonicus-DextoreNo ratings yet

- Cleanlant S-Clean ENG 170113Document56 pagesCleanlant S-Clean ENG 170113DIEGONo ratings yet

- Improving Cylindrical Inconel 718 Ingots Produced at PAO RuspolimetDocument5 pagesImproving Cylindrical Inconel 718 Ingots Produced at PAO RuspolimetJH ShinNo ratings yet

- Transition Metal Oxides - Crystal Chemistry, Phase Transition and Related AspectsDocument144 pagesTransition Metal Oxides - Crystal Chemistry, Phase Transition and Related AspectsHeiddy Paola Quiroz G.100% (1)

- Investment Opportunities in Strategic and Critical MineralsDocument34 pagesInvestment Opportunities in Strategic and Critical MineralsCenk GultekinNo ratings yet

- A941-13b Standard Terminology Relating To Steel, Stainless Steel, Related Alloys, and FerroalloysDocument8 pagesA941-13b Standard Terminology Relating To Steel, Stainless Steel, Related Alloys, and FerroalloysChuthaNo ratings yet

- Structural Steel For BridgesDocument9 pagesStructural Steel For Bridgesalucard375No ratings yet

- Astm A 297 PDFDocument5 pagesAstm A 297 PDFMuhammad Harits100% (1)

- UTP A 3545 NB PDFDocument1 pageUTP A 3545 NB PDFNNo ratings yet

- Microstructural Development in Equiatomic Multicomponent AlloysDocument6 pagesMicrostructural Development in Equiatomic Multicomponent Alloyssensoham03No ratings yet

- Tube Material DataDocument8 pagesTube Material DatasemetayNo ratings yet

- Tác dụng của các nguyên tố hợp kim trong thép không gỉDocument24 pagesTác dụng của các nguyên tố hợp kim trong thép không gỉNguyen Duc Thanh (EVPC)No ratings yet

- Physical Properties of Various Metals and Alloys (Melting Points, DensitiesDocument2 pagesPhysical Properties of Various Metals and Alloys (Melting Points, Densitiesshyam sundarNo ratings yet

- A 705 - A705m - 95 R00 Qtcwns9bnza1tqDocument7 pagesA 705 - A705m - 95 R00 Qtcwns9bnza1tqRuiz D. AntonioNo ratings yet

- Enzyme Leach MineralsDocument6 pagesEnzyme Leach Mineralsrmiguelmera4733No ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- Indian Standard: Specification FOR Filler Rods For Gas WeldingDocument22 pagesIndian Standard: Specification FOR Filler Rods For Gas WeldingMuthusamy ArumugamNo ratings yet

- A 131 - A131m - 94 Qtezms05naDocument5 pagesA 131 - A131m - 94 Qtezms05nafekihassanNo ratings yet

- AMS 5589 F-2013 - Eng.Document7 pagesAMS 5589 F-2013 - Eng.TetianaNo ratings yet

- Iron Ore BeneficiationDocument155 pagesIron Ore BeneficiationMukesh Ranjan BeheraNo ratings yet

- PVD HardCoating PDFDocument20 pagesPVD HardCoating PDFsatanjrNo ratings yet

- Astm A216-A216m-08Document4 pagesAstm A216-A216m-08selcukxNo ratings yet

- NiobiumDocument12 pagesNiobiumjosevitorromualdoNo ratings yet

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Chemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)From EverandChemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)No ratings yet

- Transformer: The Deep Chemistry of Life and DeathFrom EverandTransformer: The Deep Chemistry of Life and DeathRating: 4.5 out of 5 stars4.5/5 (13)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeFrom EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeRating: 5 out of 5 stars5/5 (1)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireFrom EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireRating: 4 out of 5 stars4/5 (129)