Professional Documents

Culture Documents

BCS-CRM 208 - 3 Nov2019

Uploaded by

Ishmael WoolooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BCS-CRM 208 - 3 Nov2019

Uploaded by

Ishmael WoolooCopyright:

Available Formats

BUREAU OF ANALYSED SAMPLES LTD

BRITISH CHEMICAL STANDARD CERTIFIED REFERENCE MATERIAL

CERTIFICATE OF ANALYSIS

4004

BCS-CRM No. 208/3

HIGH CARBON FERRO-MANGANESE

Prepared under rigorous laboratory conditions and, AFTER CERTIFICATION ANALYSIS IN

GREAT BRITAIN, ESTONIA, HUNGARY, INDIA, THE REPUBLIC OF NORTH MACEDONIA

and THE NETHERLANDS

issued by the Bureau of Analysed Samples Ltd.

ANALYSES

Mean of 4 values - mass content in %

Analyst C Si Mn P S

1 6.8459 0.5852 78.025 0.1294 0.0067

2 6.8475 0.6123 77.890 0.1345 0.0058

3 6.8208 0.5911 78.196 0.1285 0.0065

4 … 0.6070 77.960 0.1378 …

5 6.8540 0.5754 78.018 0.1396 0.0074

6 6.8090 0.6010 77.860 0.1465 0.0054

7 6.8675 … … … 0.0046

8 6.8075 0.6195 77.828 0.1365 0.0072

9 … 0.5825 … … …

10 6.8200 0.6168 77.748 0.1361 0.0061

11 … 0.6276 77.600 0.1365 …

12 … 0.6110 77.963 0.1400 …

MM 6.8340 0.6027 77.909 0.1365 0.0062

sM 0.0225 0.0170 0.165 0.0052 0.0010

sw 0.0133 0.0074 0.095 0.0022 0.0005

MM: Mean of the laboratory mean values. sM: standard deviation of the laboratory mean values. sW: average within laboratory standard

deviation.

Additional Information: Analyst No 3 also determined Fe using an in-house method based on B.S. 1121: Part 33:1955 and found 13.82%.

CERTIFIED VALUES (Cv)

mass content in %

C Si Mn P S

Cv 6.834 0.603 77.91 0.137 0.006

C(95%) 0.019 0.012 0.12 0.004 0.001

Minimum

0.2 1.0 0.5 0.2 0.2

weight (g)

The half width confidence interval, C(95%), is an expression of the uncertainty of the certified value.

C(95%) = t × s M where “t” is the appropriate two sided Student’s t value at the 95% confidence level for “n” acceptable mean values.

n

For further information regarding the confidence interval for the certified value see ISO Guide 35.

NB: Although widely accepted within the industry “mass content in %” is neither an SI nor an IUPAC supported quantity. Multiplication

of the certified value (Cv) by 104 will yield the value in µg/g.

Page 1 of 2 Date of this edition: November 2019

(The current edition is available at www.basrid.co.uk)

BCS -CRM 208/3

HIGH CARBON FERRO-MANGANESE

CO-OPERATING ANALYSTS

1 ATKINSON, M. J., Pattinson & Stead (2005) Ltd., Middlesbrough.

2 JONES, S. J., Ridsdale & Co Ltd., Middlesbrough.

3 POPOV, S. I., RZ Tehnicka Kontrola AD R, Republic of North Macedonia.

4 DERUITER, G., Alfred H Knight International, Prescot.

5 KRASNOPEVTSEV, G., Bureau Veritas, Tallinn, Estonia.

6 CHATTOPADHYAY, S., Inspectorate Griffith India Pvt Ltd., Bhubaneswar, India.

7 CLARK, J, NSG Technical Centre, Lathom.

8, 9 KONDOROSI, G., Dunaferr Labor Nonprofit Kft, Dunaújváros, Hungary.

10 BANHIDI, O., Metalcontrol KFT, Miskolc, Hungary.

11 BLUNDELL, P., ALS Inspection Limited, Prescot.

12 CULLEY, N., LMA, Sleeuwijk, The Netherlands.

NOTES ON METHODS USED

CARBON

Analysts No. 1 and 2 determined carbon gravimetrically following combustion in a stream of oxygen. The remaining Analysts used combustion/infra-red

methods, calibrating with pure chemicals.

SILICON

Analyst No. 4 determined silicon using used Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES) after digestion in Aqua-Regia and Lab

No. 12 used X-Ray Fluorescence Spectrometry (XRF) on a fused bead. The remaining Analysts determined silicon gravimetrically, Nos. 6, 8 and 10 dehydrating

with hydrochloric acid (No. 6 following ISO 1559) and the others using perchloric acid (No. 4 following ISO 4158:1987 and No. 5 ISO 5890:1981).

MANGANESE

All Analysts determined manganese volumetrically by titration with Mn(VII). No. 11 used a potentiometric method in pyrophosphate, the rest used a zinc

oxide separation. No. 1 used a potentiometric method, Nos. 3, 5, 6 and 12 followed ISO 4159 whilst Nos. 8 and 10 followed EN 24159:1994.

PHOSPHORUS

Analysts Nos. 1, 2 and 3 determined phosphorus using a photometric method, extracting the yellow phosphovanadomolybdate complex, all three following

BS 6200-3.24.2:1992. Analysts Nos. 4, 8, 10 and 11 used ICP-OES. Analyst No. 5 used the molybdenum blue method in ASTM E1070 17a. No 6 followed IS:

1559 in which the phosphorus is determined by acidimetric titration of ammonium phosphomolybdate. Analyst No. 12 used XRF.

SULPHUR

Analysts Nos 1 and 2 determined sulphur using an acid-base titration following combustion in a stream of oxygen. The remaining Analysts /used

combustion infrared methods calibrated with pure chemicals or stoichiometric compounds, No. 5 according to ISO 4935:1989

DESCRIPTION OF SAMPLE

British Chemical Standard BCS-CRM 208/3 is sold in the form of a powder passing a nominal 150µm aperture sieve. It is supplied in bottles containing

100g.

The preparation of representative samples for chemical analysis and the certification by co-operative analysis was undertaken by Bureau of Analysed

Samples Ltd.

Bureau of Analysed Samples Ltd is a United Kingdom Accreditation Service (UKAS) Accredited Reference Material Producer, No 4004, and, as the

Producer of BCS-CRM 208/3 as defined in BS EN ISO 17034, is fully responsible for assigning the certified values and their uncertainties in accordance with BS

EN ISO 17034 and ISO Guide 35.

INTENDED USE

BCS-CRM 208/3 is intended for the verification of analytical methods, such as those used by the participating laboratories, for the calibration of analytical

instruments, for establishing values for secondary reference materials and for training purposes.

In order to ensure that a fully representative sample is taken users should take not less than the minimum weight stated on the certificate for that element, this

being the lowest sample mass used by any of the Co-operating Analysts contributing to the certified value. Users of this material should be aware that the use of a

smaller sub-sample size may invalidate the certified values and the associated 95% confidence limits.

The sample should be mixed thoroughly before each use.

STABILITY

BCS-CRM 208/3 will remain stable provided that the bottle remains sealed and is stored in a dry atmosphere. Once the bottle has been opened the lid should

be secured immediately after use.

TRACEABILITY

The characterisation of this material has been achieved by chemical analysis involving inter-laboratory study, each laboratory using the method of their

choice, details of which are given above.

Most of the analytical methods used in the characterisation of this CRM were either international or national standard methods or methods which are

technically equivalent.

MEASUREMENT UNCERTAINTY

The uncertainty of each of the certified values of BC-CRM 208/3 has been established by multiplying the standard error arising from the chemical analysis

by the appropriate two sided Student’s t value at the 95% confidence level for the number of results. Homogeneity has been assessed in accordance with ASTM

E826 – 85 and found to be acceptable. Homogeneity has not, therefore, been included in the calculated measurement uncertainty. The stability of this CRM and

its transportation also make negligible contributions to the overall uncertainty of the certified values.

COMMUTABILTY

BCS-CRM 208/3 is intended to be used in the same physical form as that used by the participating analysts and therefore commutability is not of relevance in

respect of this CRM.

Further information and advice on this or other Certified Reference Materials or Reference Materials produced by Bureau of Analysed Samples Ltd may be

obtained from the address below.

NEWHAM HALL, NEWBY For BUREAU OF ANALYSED SAMPLES LTD

MIDDLESBROUGH

ENGLAND R P MEERES,

TS8 9EA Managing Director

Email: enquiries@basrid.co.uk November 2019

Website: www.basrid.co.uk

Page 2 of 2

You might also like

- 0.8% Carbon Steel Reference MaterialDocument2 pages0.8% Carbon Steel Reference MaterialIshmael WoolooNo ratings yet

- SCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisDocument2 pagesSCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisPeterson SudlabNo ratings yet

- Theory and application of Microbiological AssayFrom EverandTheory and application of Microbiological AssayRating: 2 out of 5 stars2/5 (1)

- BCS - SS-CRM 460 - 2 Jun2019Document2 pagesBCS - SS-CRM 460 - 2 Jun2019Peterson SudlabNo ratings yet

- BCS 406 - 2Document2 pagesBCS 406 - 2lehdruk7100100% (1)

- SS-CRM No. 493/3 High Manganese Steel: Certificate of AnalysisDocument2 pagesSS-CRM No. 493/3 High Manganese Steel: Certificate of Analysislehdruk7100No ratings yet

- Ss CRM 495 - 4Document2 pagesSs CRM 495 - 4lehdruk7100No ratings yet

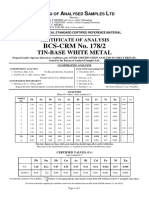

- BCS-CRM 178 - 2 Aug2012Document2 pagesBCS-CRM 178 - 2 Aug2012Ishmael WoolooNo ratings yet

- BCS - SS-CRM 475Document2 pagesBCS - SS-CRM 475mangalamtestingbureaNo ratings yet

- BCS-CRM 183 - 4 Jun2013Document2 pagesBCS-CRM 183 - 4 Jun2013Ishmael WoolooNo ratings yet

- BCS-CRM 113 Mar2014Document3 pagesBCS-CRM 113 Mar2014Ishmael WoolooNo ratings yet

- P42004 - Factor-Automobile DataDocument4 pagesP42004 - Factor-Automobile DataAbhishek PatelNo ratings yet

- Certified Low Alloy Steel AnalysisDocument3 pagesCertified Low Alloy Steel AnalysisIshmael WoolooNo ratings yet

- BCS /SS - CRM No. 405/2 Low Alloy Steel: B A S LDocument2 pagesBCS /SS - CRM No. 405/2 Low Alloy Steel: B A S LPeterson SudlabNo ratings yet

- BCS-CRM 182 - 3 Aug2015Document2 pagesBCS-CRM 182 - 3 Aug2015Ishmael WoolooNo ratings yet

- Relationship Between Student Marks and CGPADocument4 pagesRelationship Between Student Marks and CGPAGeetha. MNo ratings yet

- BCS - SS-CRM 111 - 1 Jan2018Document3 pagesBCS - SS-CRM 111 - 1 Jan2018Ishmael WoolooNo ratings yet

- Correlation, Regression and Test of Signficance in RDocument16 pagesCorrelation, Regression and Test of Signficance in RpremNo ratings yet

- MR Factor Analysis 12-11-2020Document3 pagesMR Factor Analysis 12-11-2020vaibhavNo ratings yet

- Ihs Agustus 2021Document42 pagesIhs Agustus 2021Ashar AsisNo ratings yet

- FT Vidrio Plomado MEDX-GAMMADocument2 pagesFT Vidrio Plomado MEDX-GAMMACarlos Manuel Alban RuizNo ratings yet

- Ainul Mardiah 180342618063 Off G Biologi 2018 Jawaban No.3Document4 pagesAinul Mardiah 180342618063 Off G Biologi 2018 Jawaban No.3Rey JannahNo ratings yet

- Chapter 5: Factor Analysis: 5.1 KMO & Bartlett's TestDocument7 pagesChapter 5: Factor Analysis: 5.1 KMO & Bartlett's TestRayhan TanvirNo ratings yet

- Assignment 1 Stat Eval of DataDocument2 pagesAssignment 1 Stat Eval of DataLily KimNo ratings yet

- Marshall Test Results for Road Preservation ProjectDocument14 pagesMarshall Test Results for Road Preservation ProjectIndrawan MattaldiNo ratings yet

- BCS-CRM 176 - 3 Sep2015Document3 pagesBCS-CRM 176 - 3 Sep2015Ishmael WoolooNo ratings yet

- Auto Auto Auto Auto-B - D Liquicolor Liquicolor Liquicolor LiquicolorDocument7 pagesAuto Auto Auto Auto-B - D Liquicolor Liquicolor Liquicolor LiquicolorNelson Puita Sandoval100% (1)

- Auto Auto Auto Auto-B - D Liquicolor Liquicolor Liquicolor LiquicolorDocument7 pagesAuto Auto Auto Auto-B - D Liquicolor Liquicolor Liquicolor LiquicolorNelson Puita SandovalNo ratings yet

- Analytical Reference Materials International: Certificate of AnalysisDocument2 pagesAnalytical Reference Materials International: Certificate of AnalysisDuong PhạmNo ratings yet

- Statistical Evaluation of Weighing Data LabDocument2 pagesStatistical Evaluation of Weighing Data LabGwendolyn CalatravaNo ratings yet

- 10- Chapter 6Document24 pages10- Chapter 6Ziad Lutfi AlTahaynehNo ratings yet

- Uric Acid Liquicolor: Design VerificationDocument9 pagesUric Acid Liquicolor: Design VerificationMidecal LABsNo ratings yet

- Tugas - Data Preparation and AnalysisDocument4 pagesTugas - Data Preparation and AnalysisAndersonkevin GwenhureNo ratings yet

- Lampiran AminDocument5 pagesLampiran Aminrahmat ariNo ratings yet

- Exploratory Factor Analysis Results for 10 ItemsDocument2 pagesExploratory Factor Analysis Results for 10 ItemsJose Achicahuala MamaniNo ratings yet

- NSSC Process Optimization: Ii. Spent Liquors: AbstractDocument8 pagesNSSC Process Optimization: Ii. Spent Liquors: AbstractKarteek KandalaNo ratings yet

- Title of The Experiment: Response Mean Standard Purity 1.008 RSD Standard Mass (MG)Document2 pagesTitle of The Experiment: Response Mean Standard Purity 1.008 RSD Standard Mass (MG)lkglaxmanNo ratings yet

- BCA AnalysisDocument6 pagesBCA AnalysisJanavi MotwaniNo ratings yet

- BCS - SS-CRM 451 - 1 Aug2010Document2 pagesBCS - SS-CRM 451 - 1 Aug2010Ishmael Wooloo100% (2)

- Office No 312-313, Edcon Mindspace Opposite Vivanta Campal, Panaji, GoaDocument14 pagesOffice No 312-313, Edcon Mindspace Opposite Vivanta Campal, Panaji, GoaCasilda FernandesNo ratings yet

- Financial Ratios Analysis of Top 5 Indian CompaniesDocument6 pagesFinancial Ratios Analysis of Top 5 Indian CompaniesnishaNo ratings yet

- Seminar 1 gr.2Document3 pagesSeminar 1 gr.2Oana DumitrescuNo ratings yet

- Implementation of Taguchi Method With Hybrid Decision Making Tools For Prediction of Surface Characteristics For Powder-Mixed EDM of WCDocument4 pagesImplementation of Taguchi Method With Hybrid Decision Making Tools For Prediction of Surface Characteristics For Powder-Mixed EDM of WCJAYAKRISHNAN J K IPE2ANo ratings yet

- Certificate of Analysis: (Batch A) Certified Reference Material InformationDocument4 pagesCertificate of Analysis: (Batch A) Certified Reference Material InformationrahulNo ratings yet

- Design Project Description (7.3 Is Processingcapacity)Document44 pagesDesign Project Description (7.3 Is Processingcapacity)Eden Joy GollemNo ratings yet

- 12X 352 E CertificateDocument4 pages12X 352 E Certificatedheeraj chawlaNo ratings yet

- Certificate of Analysis: (Batch F) Certified Reference Material InformationDocument4 pagesCertificate of Analysis: (Batch F) Certified Reference Material InformationKailtech Lab IndoreNo ratings yet

- Statistics Report on CU Variable Distribution and PropertiesDocument2 pagesStatistics Report on CU Variable Distribution and PropertiesNando YarangaNo ratings yet

- Knowledge management processes in Spanish banksDocument2 pagesKnowledge management processes in Spanish banksDani JaramilloNo ratings yet

- OT SurveyDocument21 pagesOT SurveyStefan Natanael PardedeNo ratings yet

- ThermoooDocument15 pagesThermoooNor Hamizah HassanNo ratings yet

- Section B - C - Computer ApplicationDocument6 pagesSection B - C - Computer ApplicationMaas1No ratings yet

- SEM DepresiDocument13 pagesSEM DepresiThojing D PallaqiNo ratings yet

- CHM 414: Errors, Statistics, and Calibration (Homework 1) : Computed Using Excel and Scientific CalculatorDocument3 pagesCHM 414: Errors, Statistics, and Calibration (Homework 1) : Computed Using Excel and Scientific CalculatorPre by JeriNo ratings yet

- S14 Quantitative Research (Rstudio Video)Document14 pagesS14 Quantitative Research (Rstudio Video)Andrés Espinoza100% (1)

- AR-Caps Technical Data Sheet (PR00373576)Document8 pagesAR-Caps Technical Data Sheet (PR00373576)Nina KoychevaNo ratings yet

- Tema 1.v.oDocument3 pagesTema 1.v.oOana DumitrescuNo ratings yet

- Viscosity Standard n4000 5181005110Document1 pageViscosity Standard n4000 5181005110Rachel McArdleNo ratings yet

- BCS-CRM No. 179/2: High-Tensile Brass (Cast)Document2 pagesBCS-CRM No. 179/2: High-Tensile Brass (Cast)Ishmael WoolooNo ratings yet

- BCS-CRM 182 - 3 Aug2015Document2 pagesBCS-CRM 182 - 3 Aug2015Ishmael WoolooNo ratings yet

- BCS-CRM 183 - 4 Jun2013Document2 pagesBCS-CRM 183 - 4 Jun2013Ishmael WoolooNo ratings yet

- BCS-CRM No. 206/3 (ECRM 453-1) : High Si and P Cast IronDocument2 pagesBCS-CRM No. 206/3 (ECRM 453-1) : High Si and P Cast IronIshmael WoolooNo ratings yet

- BCS-CRM 203 - 6 Feb2019Document4 pagesBCS-CRM 203 - 6 Feb2019Ishmael WoolooNo ratings yet

- BCS-CRM 204 - 6 Sep2017Document4 pagesBCS-CRM 204 - 6 Sep2017Ishmael WoolooNo ratings yet

- Certified Reference Material AnalysisDocument2 pagesCertified Reference Material AnalysisIshmael WoolooNo ratings yet

- BCS-CRM 180 - 2 Aug2012Document2 pagesBCS-CRM 180 - 2 Aug2012Ishmael WoolooNo ratings yet

- Certified Lead-Base White Metal AnalysisDocument2 pagesCertified Lead-Base White Metal AnalysisIshmael WoolooNo ratings yet

- BCS-CRM 176 - 3 Sep2015Document3 pagesBCS-CRM 176 - 3 Sep2015Ishmael WoolooNo ratings yet

- BCS-CRM 178 - 2 Aug2012Document2 pagesBCS-CRM 178 - 2 Aug2012Ishmael WoolooNo ratings yet

- BCS-CRM 176 - 3 Sep2015Document3 pagesBCS-CRM 176 - 3 Sep2015Ishmael WoolooNo ratings yet

- Certified Low Alloy Steel AnalysisDocument3 pagesCertified Low Alloy Steel AnalysisIshmael WoolooNo ratings yet

- BCS-CRM 208 - 3 Nov2019Document2 pagesBCS-CRM 208 - 3 Nov2019Ishmael WoolooNo ratings yet

- BCS-CRM 113 Mar2014Document3 pagesBCS-CRM 113 Mar2014Ishmael WoolooNo ratings yet

- BCS-CRM 176 - 3 Sep2015Document3 pagesBCS-CRM 176 - 3 Sep2015Ishmael WoolooNo ratings yet

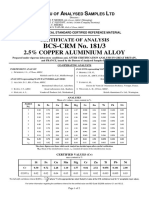

- BCS-CRM 181 - 3 Jun2013Document2 pagesBCS-CRM 181 - 3 Jun2013Ishmael WoolooNo ratings yet

- BCS-CRM 114 Mar2014Document3 pagesBCS-CRM 114 Mar2014Ishmael WoolooNo ratings yet

- BCS-CRM 463 May2016Document2 pagesBCS-CRM 463 May2016Ishmael WoolooNo ratings yet

- BCS-CRM 111 Mar2014Document3 pagesBCS-CRM 111 Mar2014Ishmael WoolooNo ratings yet

- BCS-CRM 182 - 3 Aug2015Document2 pagesBCS-CRM 182 - 3 Aug2015Ishmael WoolooNo ratings yet

- BCS-CRM 178 - 2 Aug2012Document2 pagesBCS-CRM 178 - 2 Aug2012Ishmael WoolooNo ratings yet

- Certified Lead-Base White Metal AnalysisDocument2 pagesCertified Lead-Base White Metal AnalysisIshmael WoolooNo ratings yet

- BCS-CRM 180 - 2 Aug2012Document2 pagesBCS-CRM 180 - 2 Aug2012Ishmael WoolooNo ratings yet

- BCS-CRM 183 - 4 Jun2013Document2 pagesBCS-CRM 183 - 4 Jun2013Ishmael WoolooNo ratings yet

- BCS-CRM 203 - 6 Feb2019Document4 pagesBCS-CRM 203 - 6 Feb2019Ishmael WoolooNo ratings yet

- BCS-CRM 181 - 3 Jun2013Document2 pagesBCS-CRM 181 - 3 Jun2013Ishmael WoolooNo ratings yet

- BCS-CRM No. 179/2: High-Tensile Brass (Cast)Document2 pagesBCS-CRM No. 179/2: High-Tensile Brass (Cast)Ishmael WoolooNo ratings yet

- BCS-CRM 208 - 3 Nov2019Document2 pagesBCS-CRM 208 - 3 Nov2019Ishmael WoolooNo ratings yet

- WRD Ot Do and Bod Analysis - 445265 - 7Document105 pagesWRD Ot Do and Bod Analysis - 445265 - 7Sunita makadiaNo ratings yet

- Influence of Alloying Conditions On The Properties of White Cast IronDocument6 pagesInfluence of Alloying Conditions On The Properties of White Cast IronSarvar TursunbaevNo ratings yet

- Integrated Science Rusting Nail ProjectDocument12 pagesIntegrated Science Rusting Nail ProjectTimaro BrownNo ratings yet

- Elingham DiagramDocument3 pagesElingham DiagramAnant MadhavNo ratings yet

- Monographie Sucrose - British PharmacopoeiaDocument5 pagesMonographie Sucrose - British Pharmacopoeiaasmae.labindusNo ratings yet

- Exam 26030 E16 SolutionsDocument5 pagesExam 26030 E16 SolutionsChristian CederhornNo ratings yet

- Ecet - Welding, Forging and Foundry1Document13 pagesEcet - Welding, Forging and Foundry1GENESIS ENGINEERS ACADEMYNo ratings yet

- Chapter 2 - Alkanes PDFDocument54 pagesChapter 2 - Alkanes PDFSITI NUR ALISSA BINTI AHMAD RASMANNo ratings yet

- Emesol 50/100 Material Safety Data SheetDocument2 pagesEmesol 50/100 Material Safety Data SheetBharat ChatrathNo ratings yet

- 860 Moldable Polymer GasketingDocument2 pages860 Moldable Polymer GasketingprajanegaraNo ratings yet

- Ultrasonic Effect On The Desizing Efficiency of - Amylase On Starch-Sized Cotton FabricsDocument7 pagesUltrasonic Effect On The Desizing Efficiency of - Amylase On Starch-Sized Cotton FabricsMuhammad Jawad Ul RehmanNo ratings yet

- Octane NumberDocument4 pagesOctane NumberIbrahimNo ratings yet

- Luviskol VA GradesDocument14 pagesLuviskol VA GradesLezza007No ratings yet

- C1 4.3 4.4 4.5 Using FuelsDocument28 pagesC1 4.3 4.4 4.5 Using FuelsniaNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Chem HHW Tip ChartDocument16 pagesChem HHW Tip ChartasdfghNo ratings yet

- 3 1 Eight Forms CorrosionDocument20 pages3 1 Eight Forms Corrosionmpptanks100% (1)

- Antidote Indication Mode of ActionDocument5 pagesAntidote Indication Mode of ActionRegalado AguhayonNo ratings yet

- PowdersDocument3 pagesPowdersAyeshaNo ratings yet

- Indonesia: Exor-1: This Refinery Is Designed To Run 100,000 B/D of Duri - A Highly Viscous, Heavy/sweetDocument19 pagesIndonesia: Exor-1: This Refinery Is Designed To Run 100,000 B/D of Duri - A Highly Viscous, Heavy/sweetSreelal SukumaranNo ratings yet

- Mole Concept PDF, Super 3000 BatchDocument29 pagesMole Concept PDF, Super 3000 BatchKaran RathodNo ratings yet

- ASTM A563 - Portland BoltDocument5 pagesASTM A563 - Portland BoltamrNo ratings yet

- Activity of Solid Acid Catalysts For Biodiesel Production: A Critical ReviewDocument23 pagesActivity of Solid Acid Catalysts For Biodiesel Production: A Critical ReviewMạnh BùiNo ratings yet

- T OFFER Fish Bones Sunscreen L2BDocument2 pagesT OFFER Fish Bones Sunscreen L2BPortfolio ESBNo ratings yet

- Fuel Properties TablesDocument11 pagesFuel Properties TablesSaravanapriya KarthikNo ratings yet

- Grados de HPCDocument3 pagesGrados de HPCpops3No ratings yet

- FFKM Simriz BrochureDocument5 pagesFFKM Simriz Brochureemperor_vamsiNo ratings yet

- Oxidation Roasting of Sulfide OreDocument6 pagesOxidation Roasting of Sulfide OreKrisna Bagtasos100% (1)

- A Level Paper 1 Exams 2022 77izmgDocument69 pagesA Level Paper 1 Exams 2022 77izmgMal ChenNo ratings yet

- Mega General Knowledge 3Document192 pagesMega General Knowledge 3Qamar Nangraj89% (9)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (63)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (699)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraFrom EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraRating: 3 out of 5 stars3/5 (10)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanFrom EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanNo ratings yet

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- Gathering Moss: A Natural and Cultural History of MossesFrom EverandGathering Moss: A Natural and Cultural History of MossesRating: 4.5 out of 5 stars4.5/5 (347)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- Eels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishFrom EverandEels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishRating: 4 out of 5 stars4/5 (30)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (222)

- Winged Obsession: The Pursuit of the World's Most Notorious Butterfly SmugglerFrom EverandWinged Obsession: The Pursuit of the World's Most Notorious Butterfly SmugglerRating: 3.5 out of 5 stars3.5/5 (67)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)