Professional Documents

Culture Documents

Gears: Rating Piolo Julius G. Cabagnot

Uploaded by

Cabagnot Piolo JuliusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gears: Rating Piolo Julius G. Cabagnot

Uploaded by

Cabagnot Piolo JuliusCopyright:

Available Formats

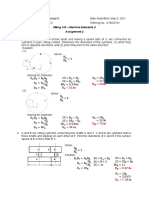

Problem

Design a gear drive of involute tooth profile to reduce the speed of a shaft from 1200 rpm to 130 rpm.

Pair 1 (Gear 1 & 2): Pair 2 (Gear 3 & 4): Pair 3 (Gear 5 & 6):

Pressure Angle = 14.5 Diametral Pitch = 0.2222 Whole Depth = 9.7065 Pressure Angle = 14.5 Diametral Pitch = 0.2222 Whole Depth = 9.7065 Pressure Angle = 14.5 Diametral Pitch = 0.2 Whole Depth = 10.785

Addendum = 4.5 Circular Pitch = 14.1372 Gear 1 Diameter = 90 Addendum = 4.5 Circular Pitch = 14.1372 Gear 3 Diamater = 81 Addendum = 5 Circular Pitch = 15.708 Gear 5 Diameter = 65

Dedendum = 5.2065 Tooth Thickness = 6.979 Gear 2 Diameter = 135 Dedendum = 5.2065 Tooth Thickness = 6.979 Gear 4 Diameter = 144 Dedendum = 5.785 Tooth Thickness = 7.754 Gear 6 Diameter = 225

Clearance = 0.7065 Tooth Space = 7.1586 Fillet Radius = 0.9405 Clearance = 0.7065 Tooth Space = 7.1856 Fillet Radius = 0.9405 Clearance = 0.785 Tooth Space = 7.954 Fillet Radius = 1.045

Base Circle θ = 87.1333 Backlash = 0.18 Working Depth = 9 Base Circle θ = 78.42 Backlash = 0.18 Working Depth = 9 Base Circle θ = 62.9296 Backlash = 0.2 Working Depth = 10

Gear Profile

Scale: 0.5:1 Gear 6

Common Tangent

Pressure Line

Tooth Space Gear 4

Gear 2

Tooth Thickness

Base Circle

Gear 1

Pitch Circle Gear 3

Gear 5

Addendum Circle

Shaft A Shaft B Shaft C Shaft D

Dedendum Circle

Clearance Circle

Involute Tooth Profile

Scale: 0.5:1 Base Circle

Tooth Profile

Base Circle

Pair 1 - Gear 1 & 2 Pair 2 - Gear 3 & 4 Pair 3 - Gear 5 & 6

A B C D

Piolo Julius G. Cabagnot Gears P RATING

Department of Mechanical Engineering

Visayas State University

Instructor: ENGR. ANDREW C. MERAFUENTES 3 MENG 142: Machine Elements II

Date Submitted: June 11, 2021

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rock Guitar BookletDocument12 pagesRock Guitar BookletAnthony ChewNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Champion Legal Ads: 03-30-23Document49 pagesThe Champion Legal Ads: 03-30-23Donna S. SeayNo ratings yet

- Diaphragm Wall PresentationDocument52 pagesDiaphragm Wall PresentationGagan Goswami100% (11)

- SEAFARERSDocument29 pagesSEAFARERSJohanna Arnaez100% (1)

- Linux Directory StructureDocument15 pagesLinux Directory StructureG.R.THIYAGU ; Oracle DBANo ratings yet

- Firelights PDFDocument2 pagesFirelights PDFEFG EFGNo ratings yet

- Operation and Maintenance of Power Plant PDFDocument31 pagesOperation and Maintenance of Power Plant PDFwonderstrikeNo ratings yet

- Collateral Asset DefinitionsDocument116 pagesCollateral Asset Definitionsapi-3748391100% (2)

- Ip Ls5 CabagnotDocument2 pagesIp Ls5 CabagnotCabagnot Piolo JuliusNo ratings yet

- Ip Ls6 CabagnotDocument2 pagesIp Ls6 CabagnotCabagnot Piolo JuliusNo ratings yet

- Meng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 8Document2 pagesMeng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 8Cabagnot Piolo JuliusNo ratings yet

- Ip Ls4 CabagnotDocument2 pagesIp Ls4 CabagnotCabagnot Piolo JuliusNo ratings yet

- Ip Ls5 CabagnotDocument2 pagesIp Ls5 CabagnotCabagnot Piolo JuliusNo ratings yet

- Meng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 2Document2 pagesMeng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 2Cabagnot Piolo JuliusNo ratings yet

- Ip Ls6 CabagnotDocument2 pagesIp Ls6 CabagnotCabagnot Piolo JuliusNo ratings yet

- Ip Ls4 CabagnotDocument2 pagesIp Ls4 CabagnotCabagnot Piolo JuliusNo ratings yet

- Meng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 1Document2 pagesMeng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 1Cabagnot Piolo JuliusNo ratings yet

- Meng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 8Document2 pagesMeng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 8Cabagnot Piolo JuliusNo ratings yet

- Meng 142 - Machine Elements Ii Assignment 1Document1 pageMeng 142 - Machine Elements Ii Assignment 1Cabagnot Piolo JuliusNo ratings yet

- Conceptual DevelopmentDocument10 pagesConceptual DevelopmentCabagnot Piolo JuliusNo ratings yet

- Cabagnot Assignment 3Document2 pagesCabagnot Assignment 3Cabagnot Piolo JuliusNo ratings yet

- Meng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 7Document2 pagesMeng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 7Cabagnot Piolo JuliusNo ratings yet

- Meng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 3Document2 pagesMeng 141.3 - Energy Engineering & Management Insight Paper For Lecture-Series 3Cabagnot Piolo JuliusNo ratings yet

- Meng 142 - Machine Elements Ii Assignment 2Document2 pagesMeng 142 - Machine Elements Ii Assignment 2Cabagnot Piolo JuliusNo ratings yet

- Meng 142 - Machine Elements Ii Assignment 4Document4 pagesMeng 142 - Machine Elements Ii Assignment 4Cabagnot Piolo JuliusNo ratings yet

- Cabuaynbt Mobjulius: Er Stat - 420.21 GDocument2 pagesCabuaynbt Mobjulius: Er Stat - 420.21 GCabagnot Piolo JuliusNo ratings yet

- Cabagnot MEng 142 Midterm ExamDocument7 pagesCabagnot MEng 142 Midterm ExamCabagnot Piolo JuliusNo ratings yet

- Cabagnot Assignment 4 ChainsDocument2 pagesCabagnot Assignment 4 ChainsCabagnot Piolo JuliusNo ratings yet

- Pacing Distance MeasurementDocument3 pagesPacing Distance MeasurementCabagnot Piolo JuliusNo ratings yet

- MATHEMATICS TEACHING-RESEARCH JOURNAL ONLINE VOL 7, N 4Document51 pagesMATHEMATICS TEACHING-RESEARCH JOURNAL ONLINE VOL 7, N 4Cabagnot Piolo JuliusNo ratings yet

- Cabagnot Final ExamDocument14 pagesCabagnot Final ExamCabagnot Piolo JuliusNo ratings yet

- Chain Drives: Meng 142 - Machine Elements Ii Assignment 5Document2 pagesChain Drives: Meng 142 - Machine Elements Ii Assignment 5Cabagnot Piolo JuliusNo ratings yet

- Cabagnot LearningTask#13 MEng136Document2 pagesCabagnot LearningTask#13 MEng136Cabagnot Piolo JuliusNo ratings yet

- Visayas State University: Geng 111G General Surveying IDocument3 pagesVisayas State University: Geng 111G General Surveying ICabagnot Piolo JuliusNo ratings yet

- Visayas State University: Geng 111G General Surveying IDocument3 pagesVisayas State University: Geng 111G General Surveying ICabagnot Piolo JuliusNo ratings yet

- Geng 123 Property Survey I: Ok, Cor of Bdry Ok, Cor of Bdry Ok, Cor of Bdry For OrientationDocument1 pageGeng 123 Property Survey I: Ok, Cor of Bdry Ok, Cor of Bdry Ok, Cor of Bdry For OrientationCabagnot Piolo JuliusNo ratings yet

- Using calculators to teach calculus conceptsDocument9 pagesUsing calculators to teach calculus conceptsCabagnot Piolo JuliusNo ratings yet

- T TableDocument7 pagesT TableMaguz GurniwaNo ratings yet

- Mitigating Contractor's Claim On Loss and Expense Due To The Extension of Time in Public Projects: An Exploratory SurveyDocument12 pagesMitigating Contractor's Claim On Loss and Expense Due To The Extension of Time in Public Projects: An Exploratory SurveyWeei Zhee70No ratings yet

- Ahu KitDocument37 pagesAhu KitLaurentiu LapusescuNo ratings yet

- Firm vs. Environment: May Florence J. Yaranon Edric P. Oloresisimo Mba-IDocument28 pagesFirm vs. Environment: May Florence J. Yaranon Edric P. Oloresisimo Mba-IMay YaranonNo ratings yet

- Airworthiness StandardsDocument15 pagesAirworthiness StandardsJason RossNo ratings yet

- BBVA OpenMind Book Change 19 Key Essays On How Internet Is Changing Our Lives Technology Internet InnovationDocument7 pagesBBVA OpenMind Book Change 19 Key Essays On How Internet Is Changing Our Lives Technology Internet InnovationSissiErricoNo ratings yet

- WMA14 01 Rms 20220199 UNUSEDDocument17 pagesWMA14 01 Rms 20220199 UNUSEDVanessa NgNo ratings yet

- Partial Molar PropertiesDocument6 pagesPartial Molar PropertiesNISHTHA PANDEYNo ratings yet

- SMPP Gateway Interface Programming GuideDocument21 pagesSMPP Gateway Interface Programming GuideVamsi Krishna TalasilaNo ratings yet

- Chem 101 Fall17 Worksheet 2Document2 pagesChem 101 Fall17 Worksheet 2mikayla sirovatkaNo ratings yet

- PTE Academic Lesson Plan Ideas: Test Taking Strategies: Vikki Weston, Vessela GasperDocument2 pagesPTE Academic Lesson Plan Ideas: Test Taking Strategies: Vikki Weston, Vessela GasperStanley AlexNo ratings yet

- Campus Event ReflectionDocument2 pagesCampus Event ReflectiondntbenfordNo ratings yet

- Antioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. LeavesDocument7 pagesAntioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. Leavespasid harlisaNo ratings yet

- BE InstallGuide RooftopSeries12R ZXDocument80 pagesBE InstallGuide RooftopSeries12R ZXAlexandreau del FierroNo ratings yet

- Induction Motor StarterDocument5 pagesInduction Motor StarterAnikendu MaitraNo ratings yet

- 0809 KarlsenDocument5 pages0809 KarlsenprateekbaldwaNo ratings yet

- Polycab PVCDocument32 pagesPolycab PVCshilpidangiNo ratings yet

- HAM Processing Technique for Ocular Surface ReconstructionDocument4 pagesHAM Processing Technique for Ocular Surface ReconstructionJoel JohnsonNo ratings yet

- Village Panchayat Secretary ApplicationDocument2 pagesVillage Panchayat Secretary Applicationsrpk serverNo ratings yet

- Library ClassificationDocument10 pagesLibrary ClassificationKakeembo NasiifuNo ratings yet

- Aluminum Wire Data and PropertiesDocument31 pagesAluminum Wire Data and PropertiesMaria SNo ratings yet

- Pod Graphics Processor Users GuideDocument71 pagesPod Graphics Processor Users GuideAsmaNo ratings yet