Professional Documents

Culture Documents

BUS 1220E Operations Management Study Sheet: I. Task Analysis

Uploaded by

kuma;lOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BUS 1220E Operations Management Study Sheet: I. Task Analysis

Uploaded by

kuma;lCopyright:

Available Formats

BUS 1220E

OPERATIONS MANAGEMENT

STUDY SHEET

I. TASK ANALYSIS

Based on the customer’s needs, define and prioritize the core and non-core process outcomes.

Quality, Quantity, Price, Service, Features

What implications does this have for production?

II. PROCESS IDENTIFICATION

Continuous

Project Job Shop Batch Line Flow

Flow

Experts,

LABOUR High / Moderate Skill Low Skill

Trades people

Unique, One

General, Less automation, Low Specialized, High degree of

EQUIPMENT function, High

investment

investment automation, High investment

Is the appropriate production

process being used? Discuss

PRODUCTION

TRIGGERS

Customer Triggered Produce to Anticipated Demand any relevant implications.

PRODUCT Unique design,

Very high High Low None

VARIATIONS One of a kind

PRODUCT Very high

One or very few Low volumes Low volumes High volumes

VOLUMES volumes

III. PROCESS ANALYSIS

Capacity is the volume of output that a process can produce.

Calculate capacity and compare this to demand. Consider the bottleneck and any possible line

balancing that can occur. Are any changes necessary?

IV. TRADEOFF ANALYSIS

Net Benefit = Incremental Benefits – Incremental Costs

The annual income associated with an investment

Payback = Investment ÷ Net Benefit

The length of time required to recoup the cost of an investment

Qualitative discussion of pros and cons of each option

V. DECISION

“As _______, I will make the following recommendations…”

Draw on important areas of analyses to support your decision. Make whatever recommendations you

deem necessary. Overcome any issues or risks.

© BUS 1220E/1299E

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SEQI - IATF16949 - Internal Auditor - Training - Evaluation - QuestionnaireDocument11 pagesSEQI - IATF16949 - Internal Auditor - Training - Evaluation - QuestionnaireR.BALASUBRAMANINo ratings yet

- Ten Principles CollectionDocument268 pagesTen Principles Collectionramesh bhatNo ratings yet

- DODD-IAM - Declaration of Original Depository and Deposit of I AM-pac-06130973Document2 pagesDODD-IAM - Declaration of Original Depository and Deposit of I AM-pac-06130973DODD-IAM-pac-06131973No ratings yet

- Zycus - P2P Benchmark StudyDocument32 pagesZycus - P2P Benchmark StudyIndu Shekhar100% (2)

- 3 Inventory Managementupdated 11-6-20Document5 pages3 Inventory Managementupdated 11-6-20kuma;lNo ratings yet

- Naïve Approach: ForecastingDocument5 pagesNaïve Approach: Forecastingkuma;lNo ratings yet

- 1a POM IntroductionDocument2 pages1a POM Introductionkuma;lNo ratings yet

- Cost-Profit Volume AnalysisDocument6 pagesCost-Profit Volume Analysiskuma;lNo ratings yet

- Bus 152A-2 Marketing Management: Mondays and Wednesdays 5:00 - 6:20 PMDocument25 pagesBus 152A-2 Marketing Management: Mondays and Wednesdays 5:00 - 6:20 PMkuma;lNo ratings yet

- Assignment#2 ADRIANOCAÑADADocument3 pagesAssignment#2 ADRIANOCAÑADAADRIANO, Glecy C.No ratings yet

- Essay On Mother Teresa For KidsDocument4 pagesEssay On Mother Teresa For KidsafhbgdmbtNo ratings yet

- HR Leave Request FormDocument1 pageHR Leave Request FormRichard R M ThodéNo ratings yet

- AISSVOL4NO10 p52Document9 pagesAISSVOL4NO10 p52張麥思No ratings yet

- Arms Length PrincipleDocument18 pagesArms Length PrincipleMARY IRUNGUNo ratings yet

- Order RatioDocument22 pagesOrder RatioKH IFFTI HASANNo ratings yet

- 454516-Marketing ManagementDocument4 pages454516-Marketing ManagementAnannya SinhaNo ratings yet

- Barak CommDocument1 pageBarak CommTula rashi videosNo ratings yet

- UiPath Certified Advanced RPA Developer v1.0 - EXAM DescriptionDocument7 pagesUiPath Certified Advanced RPA Developer v1.0 - EXAM DescriptionabhaysisodiyaNo ratings yet

- Answers: 高顿财经ACCA acca.gaodun.cnDocument12 pagesAnswers: 高顿财经ACCA acca.gaodun.cnIskandar BudionoNo ratings yet

- GM Midterm AnswerDocument4 pagesGM Midterm Answerthet su sanNo ratings yet

- Civics NoteDocument59 pagesCivics NoteBetsegaw DemekeNo ratings yet

- RPS Analisa Laporan Keuangan Agustus 2020Document24 pagesRPS Analisa Laporan Keuangan Agustus 2020Shiel VhyNo ratings yet

- Hazard Identification Process For A Chlor Alkali Operation: AlbertoDocument17 pagesHazard Identification Process For A Chlor Alkali Operation: AlbertoRathish RagooNo ratings yet

- IGCSE BusinessDocument4 pagesIGCSE Businesstimes tongNo ratings yet

- Chapter - 3: Agricultural DevelopmentDocument2 pagesChapter - 3: Agricultural DevelopmentGhalib HussainNo ratings yet

- 2016 03 04 HPCL Analyst Pres - Mumbai PDFDocument78 pages2016 03 04 HPCL Analyst Pres - Mumbai PDFHemant KumarNo ratings yet

- TM Application FormDocument1 pageTM Application FormNancy VelascoNo ratings yet

- SBI Genral Claim Form & Check List (1) SssDocument6 pagesSBI Genral Claim Form & Check List (1) Ssspshantanu123No ratings yet

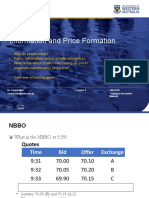

- Information and Price FormationDocument36 pagesInformation and Price FormationDylan AdrianNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)saranNo ratings yet

- Research The Impact of AI On The Banking IndustryDocument9 pagesResearch The Impact of AI On The Banking IndustryVenom BhaiyaNo ratings yet

- Two Wheeler Workshop Project ReportDocument8 pagesTwo Wheeler Workshop Project Reportparth sarthyNo ratings yet

- Sustainable Development Goals: Goal 8: Decent Work and Economic Growth Group 3Document17 pagesSustainable Development Goals: Goal 8: Decent Work and Economic Growth Group 3Toby ChungNo ratings yet

- Political Virtue and Economic Leadership - Lee Kuan Yew and Ferdinand Marcos ComparedDocument20 pagesPolitical Virtue and Economic Leadership - Lee Kuan Yew and Ferdinand Marcos ComparedRheyNo ratings yet

- CHAPTER 9 Ethics, Corporate Social Responsibility, Environmental Sustainability, and StrategyDocument45 pagesCHAPTER 9 Ethics, Corporate Social Responsibility, Environmental Sustainability, and Strategysafira dindaNo ratings yet