Professional Documents

Culture Documents

Capacitive Liquid Detection: With The Help of Arduino

Uploaded by

maferOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capacitive Liquid Detection: With The Help of Arduino

Uploaded by

maferCopyright:

Available Formats

learn design share

Capacitive Liquid Detection

With the help of Arduino

By Paul Cordonnier (Belgium)

Some time ago, Elektor published my siphonic rain gauge with no moving parts, in which the water

that passes when a little siphon empties is detected by short-circuiting two electrodes [2]. At the same

moment, articles were in preparation showing that capacitive detection would have a decisive impact [3].

Here I investigate if the “approaches” can be joined.

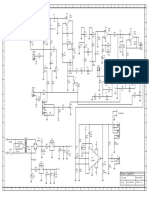

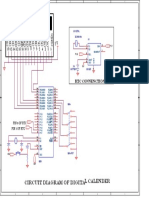

+5V +5V

1 K1

2

3

2

16 15 14 13 12 11 10 9

C1 1

ON

S1

100n

1 2 3 4 5 6 7 8

IC1 16

1 2 3 4 5 6 7 8

CTR14 7

R1 3

5

100k 4

K2 11 !G 4

R2 RCX 5

2 10 + 6

10k RX 6

1 9 14

CX 7

CT 13

8

15

9

1

11

A 12 2

CT=0 12

3

13

B

8

74HC4060

140130 - 11

The idea of a technical bridge between the above publications of code later, and the die was cast! And the right-hand corner of

only appeared in the comments posted on the Elektor Labs my forehead is a little flatter than before.

website. That was where I read the remark from a reader (I

later learnt it wasn’t just any reader) suggesting the capaci- I hope like me you’ll learn this lesson of the rain gauge: instead

tive approach [4] for detecting the water passing through the of falling flat on your face all alone with some stubborn idea,

pluviometer drain instead of a short-circuit on the electrodes. take a few minutes to talk about it on Elektor Labs website.

Then I recalled that a few years earlier I had myself success-

fully built a capacitive-detection water level monitor using a There’s water in the “condenser”

Basic Stamp. Why didn’t I think of this idea for the rain gauge? The type 4060 logic counter/divider (Figure 1) is cheerfully

The sparks of creativity are capricious and don’t just pop up open to the world: its three pins RCX, RX, and CX are acces-

to order. Whence the interest of working on ideas together. As sible from outside, and that’s exactly where we connect the

it happens, my neighbor and the author of the comment was capacitor made from the two pieces of copper foil stuck on

none other than David Ardouin, whose recent articles testify the walls of the pipe to be monitored. The capacitance of this

to the capabilities of capacitive. assembly will not be the same, depending on whether there is

water in the pipe or not. So with that, the oscillator frequency

I tested the idea successfully with the help of two small pieces will change too. To find out what is flowing or not in the pipe,

of self-adhesive copper foil (which you can find from Farnell, in all we have to do is measure the length of the pulses at the

particular) stuck opposite one another on the flexible tube. The counter/divider output. Do I need to point out that this will

advantage of this ultra-simple process, which can be applied work with rubber or silicone, but not with metal pipes?

in other fields for detecting the presence or absence of liquids

within pipes, is to eliminate drilling through the wall to insert The oscillator signal is not used as is for discrimination, but

the electrodes, as I had done for the rain gauge. No Stamp its frequency is first reduced using the divider in the 4060.

this time, I used an Arduino: a little “pulseIn” and a few lines The 8-way DIP switch lets us pick off one of the division fre-

108 November & December 2016 www.elektormagazine.com

labs project reader’s project

quencies available. Note: only turn one of S1’s eight switches

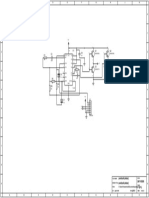

on at a time. This squarewave, applied via K1 to an Arduino, Component List

will be “analyzed” using a little detector evaluation program Resistors (0.25W)

(Listing 1). R2 = 10kΩ

R1 = 100kΩ

The “cleanness” of the information obtained will depend on the

construction of the detector, which affects the discrimination Capacitors

between the two extreme states (presence or absence of liq- C1 = 100nF

uid). The absolute values are trivial, the only thing that counts

Semiconductors

is the detection threshold mid-way between them. IC1 = 74HC4060N

By way of an example, on the Elektor Labs prototype, using

a 1 nF capacitor in place of the detector, the frequency noted Miscellaneous

K1 = 3-pin pinheader

on Q7 (pin 6 of IC1) was of the order of 2.5 kHz.

K2 = 2-way PCB screw terminal, 0.2’’ pitch

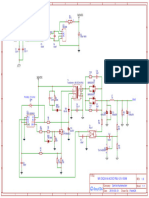

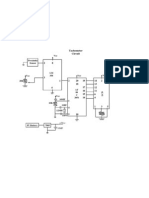

Using the detector in the photo (Figure 2) — the pipe is 6 mm S1 = 8-way DIP switch block

OD and 4 mm ID, and the two self-adhesive copper strips are PCB # 140130-1 v1.0

around 20 × 7 mm — the difference in frequency obtained

was of the order of 1.5%. It’s not much — but for a micro-

controller, it’s doable.

Listing 1.

Longer strips ought to make it possible to increase the sensi- int freqPin = 7; // probe input

tivity. On my own prototype, tested using water and diesel, at int beepPin = 6; // buzzer

appreciably lower frequencies, I obtained a clearer distinction

unsigned long duration;

(nearly 10%). The frequency with no water of 166 Hz gave

pulseIn = 3128, while 151 Hz with water gave pulseIn = 3229.

void setup()

I adopted 3178 as the switching point.

To be quite honest, here we’re only at the experimental stage; {

it’s going to be necessary not only to refine this measurement, Serial.begin(9600);

but also to carry out periodic calibration of the detector to pinMode(freqPin, INPUT);

compensate for likely drifts. Nonetheless, the project seemed pinMode(beepPin, OUTPUT);

serious enough for us to offer a PCB layout, the EAGLE format }

files for which can be downloaded [6].

Now it’s your turn now to tell us [1] about your own exper- void loop()

iments. {

(140130)

duration = pulseIn(freqPin, HIGH);

Web Links Serial.println(duration);

[1] www.elektormagazine.com/labs

// delay(1000);

[2] Siphonic Rain Gauge: www.elektormagazine.com/120554

if (duration > 3200)

[3] Touch-2-Switch, multi-purpose wall-mounting switch:

{

www.elektormagazine.com/130272

tone(beepPin, 600, 100);

[4] http://goo.gl/TcCE94

}

[5] Pattern Lock: www.elektormagazine.com/120579

[6] www.elektormagazine.com/140130 }

Advertisement

T choice is yours.

The

• Enclosure for all round

protection

Housings for Raspberry • Platform for all round

Pi, Arduino and many access

other bareboard • Design-specific versions

computers for all popular models

• Enclosure • Visit hammondmfg.com

• Platform for full details

+ 44 1256 812812

sales@hammondmfg.eu /1593HAM.htm /1593HAMEGG.htm

/15

593HAMEGG.htm

593HAMEGG.htm

HA

AMEGG ht

www.elektormagazine.com November & December 2016 109

You might also like

- Meteoro GS100Document1 pageMeteoro GS100Vítor Ávila75% (4)

- CQ56 Pavilion G56 DAAX3MB16A1 623909-001 Rev-A AX3E-DDR2 PDFDocument30 pagesCQ56 Pavilion G56 DAAX3MB16A1 623909-001 Rev-A AX3E-DDR2 PDFSheyla Perales0% (1)

- Dydacomp's Multichannel Order Manager 6 Learning GuideDocument194 pagesDydacomp's Multichannel Order Manager 6 Learning GuideDydacompNo ratings yet

- Bipolar Stepper Motor Control: Summer CircuitscollectionDocument1 pageBipolar Stepper Motor Control: Summer CircuitscollectionRadunNo ratings yet

- Index: Circuit Diagram Working Principle Description Comparision With Other Application Disadvantages ReferenceDocument26 pagesIndex: Circuit Diagram Working Principle Description Comparision With Other Application Disadvantages Referenceinfinite2towersNo ratings yet

- Stepper Motor Controller: Gert BaarsDocument2 pagesStepper Motor Controller: Gert BaarsJosé ManuelNo ratings yet

- Rev Counter: PDF Created With Pdffactory Trial VersionDocument1 pageRev Counter: PDF Created With Pdffactory Trial VersionVictor RoblesNo ratings yet

- Buffer, Driver & RelayDocument6 pagesBuffer, Driver & RelayramNo ratings yet

- AAZE100004: Rex R, R/F SeriesDocument1 pageAAZE100004: Rex R, R/F SeriesVlad RacuNo ratings yet

- 18517-Figure 1 PDFDocument1 page18517-Figure 1 PDFM Usman RiazNo ratings yet

- Expansion For Universal Interface: Roland PlischDocument1 pageExpansion For Universal Interface: Roland PlischJohn SmithNo ratings yet

- Laporan ETSDocument7 pagesLaporan ETSFajri Dzulfiqar RosmanaNo ratings yet

- Priyanka ProjectDocument1 pagePriyanka ProjectPriyanka DeshpandeNo ratings yet

- Schematic - WX-DC2416 PSU - 2020-07-27 - 10-27-00Document1 pageSchematic - WX-DC2416 PSU - 2020-07-27 - 10-27-00smang10No ratings yet

- Capture Mach PhatDocument1 pageCapture Mach PhatTrần Việt HỷNo ratings yet

- GH 13Document2 pagesGH 13DanLucca Fernando SamosirNo ratings yet

- PC10Document1 pagePC10margono akurasi100% (2)

- EVM Circuit DiagramDocument1 pageEVM Circuit Diagramsantosh ghadeiNo ratings yet

- Circuit Collections 001-030Document30 pagesCircuit Collections 001-030zawmintun1No ratings yet

- FFRDocument1 pageFFRprathyushareddyNo ratings yet

- Schematic ENC28J60 Ethernet Board 2022-12-14Document1 pageSchematic ENC28J60 Ethernet Board 2022-12-14samsularief03No ratings yet

- U1 R1 Q1 Q2 C6 C2: Pushpull - PDSPRJ 26/11/2020 Pushpull - PDSPRJDocument1 pageU1 R1 Q1 Q2 C6 C2: Pushpull - PDSPRJ 26/11/2020 Pushpull - PDSPRJmy dreamNo ratings yet

- How To Draw Circuit DiagramDocument1 pageHow To Draw Circuit DiagramSAMARJEETNo ratings yet

- Tatmainnah Ainun Haq - MH 17.054: D8 D9 D10 D11 D12 D13 VCC Aref GND A0 A1 A2 A3 A4 A5Document1 pageTatmainnah Ainun Haq - MH 17.054: D8 D9 D10 D11 D12 D13 VCC Aref GND A0 A1 A2 A3 A4 A5tatmainnahainunhaqNo ratings yet

- N2 ProyectoDocument1 pageN2 ProyectoJose Luis Sovero AstoamanNo ratings yet

- Byte Generator: For Testing Dacs and Digital ControlsDocument2 pagesByte Generator: For Testing Dacs and Digital ControlsRadunNo ratings yet

- P0 P1 P2 P3 CLK Q0 Q1 Q2 Q3 CO CIN PE RST U/D: Vacuo1 Vacuo2Document1 pageP0 P1 P2 P3 CLK Q0 Q1 Q2 Q3 CO CIN PE RST U/D: Vacuo1 Vacuo2Shalon MeloNo ratings yet

- Probador rj45Document1 pageProbador rj45Manuel Rivas100% (1)

- Probador rj45Document1 pageProbador rj45Manuel Rivas100% (2)

- Schematic - 4017 Kademeli Led - 2021-12-29Document1 pageSchematic - 4017 Kademeli Led - 2021-12-29Luis Eduardo RibeiroNo ratings yet

- Interfacing 8251 With 8086 PDFDocument10 pagesInterfacing 8251 With 8086 PDFMurthyNo ratings yet

- BDM PDDocument1 pageBDM PDppm01No ratings yet

- Semester Project Report: Department of Electrical Electronic EngineeringDocument4 pagesSemester Project Report: Department of Electrical Electronic EngineeringNabeel MuqarrabNo ratings yet

- JDM Prog ModificadoDocument1 pageJDM Prog ModificadoJose HerreraNo ratings yet

- LCD Name DisplayingDocument1 pageLCD Name DisplayingVijayNo ratings yet

- By Sunil Malekar (Elektor Labs India) : March & April 2015Document4 pagesBy Sunil Malekar (Elektor Labs India) : March & April 2015Agnivesh PandeyNo ratings yet

- Lampada AutomaticaDocument1 pageLampada AutomaticaLuiz FigueiredoNo ratings yet

- TachometerDocument1 pageTachometerAbhinav KabraNo ratings yet

- Circuit Diagram of DC Motor Control Using A Single SwitchDocument1 pageCircuit Diagram of DC Motor Control Using A Single Switchravirajsinhvaja100% (1)

- Modulo 11Document1 pageModulo 11charlyNo ratings yet

- TermometroDocument1 pageTermometroRafael Macfú100% (1)

- Gsynth 2Document1 pageGsynth 2subcomandantemarcosNo ratings yet

- Wiring Chemistry AnalyzerDocument2 pagesWiring Chemistry Analyzerfurqan entengoNo ratings yet

- Boxer-100-AT-Ktec-1998-2000 AR-BAJAJDocument52 pagesBoxer-100-AT-Ktec-1998-2000 AR-BAJAJJuan Manuel Ortega100% (5)

- 4026 Single SSDDocument1 page4026 Single SSDBond JamesNo ratings yet

- DDS SchmaticDocument1 pageDDS SchmaticmichNo ratings yet

- CO3 CO1: Lcot8Document10 pagesCO3 CO1: Lcot8AlvianIqbalFahmiNo ratings yet

- Designed by Checked by Approved by Date DateDocument1 pageDesigned by Checked by Approved by Date DateĐoàn bsNo ratings yet

- CD4013 Exercise LabDocument1 pageCD4013 Exercise LabAhmedNo ratings yet

- ADC0804Document1 pageADC0804Norival Maske100% (1)

- SENSORDocument1 pageSENSORnoctuaryNo ratings yet

- Iprog Can AdapterDocument1 pageIprog Can AdapterAndrésFelipeCevallos100% (1)

- Digital CalenderDocument1 pageDigital CalenderGarvitt BhatnagarNo ratings yet

- So Do On AP LiOa (Nen)Document1 pageSo Do On AP LiOa (Nen)Anhtu Pham100% (1)

- Miss Pulse DetectorDocument1 pageMiss Pulse Detectorv2brotherNo ratings yet

- ELEGOO Uno Kit Proto Shield Prototype Expansion BoardDocument4 pagesELEGOO Uno Kit Proto Shield Prototype Expansion BoardMaria Cordoba IglesiasNo ratings yet

- Relais1: D1 Tesys GV2-ME 07 - Front ViewDocument2 pagesRelais1: D1 Tesys GV2-ME 07 - Front ViewMustapha ElhajjajiNo ratings yet

- Moog TaurusDocument1 pageMoog TaurusTomy Daniel Ramirez AlvarezNo ratings yet

- Budget ProcessDocument3 pagesBudget ProcessMargz CafifgeNo ratings yet

- Building Ideas: An Architectural Guide to the University of ChicagoFrom EverandBuilding Ideas: An Architectural Guide to the University of ChicagoRating: 4.5 out of 5 stars4.5/5 (2)

- Pioneer Avh-P3400bh p2400bt 2450bt 2490bt PDFDocument152 pagesPioneer Avh-P3400bh p2400bt 2450bt 2490bt PDFCitroen FreireNo ratings yet

- Commercial Brochure PS200Document4 pagesCommercial Brochure PS200Mashur Al JunaibiNo ratings yet

- 2013 New Fujitsu ProductsDocument6 pages2013 New Fujitsu ProductsChris HaukNo ratings yet

- Onde A ''Grande Multidao'' Serve A Deus - Jon MitchellDocument53 pagesOnde A ''Grande Multidao'' Serve A Deus - Jon Mitchellsantos07>100% (1)

- Software Accelerated GNSS ReceiverDocument30 pagesSoftware Accelerated GNSS ReceiverAnisha Cecili100% (1)

- How OFDM WorksDocument9 pagesHow OFDM WorksmuseNo ratings yet

- Enbridge 09 Marshfield South - Project - VC3-ReportDocument9 pagesEnbridge 09 Marshfield South - Project - VC3-ReportLaura DiazNo ratings yet

- 966F Wheel Loader Electrical SystemDocument2 pages966F Wheel Loader Electrical SystemAhmed Nahrawy82% (11)

- CN LP U1 T5Document22 pagesCN LP U1 T5etasureshNo ratings yet

- Waves F6 ManualDocument16 pagesWaves F6 ManualWalterCruz74783No ratings yet

- 2 SJ 117Document3 pages2 SJ 117Nacho ConsolaniNo ratings yet

- Tracer-AN Series: EpeverDocument2 pagesTracer-AN Series: EpeverSyahdun NurzaqiNo ratings yet

- VLT FC Series - Safe Torque OffDocument16 pagesVLT FC Series - Safe Torque OffAlexNo ratings yet

- Toshiba PU 200 ZE User ManualDocument32 pagesToshiba PU 200 ZE User ManualRohith Mohan0% (1)

- 04 Crystal DefectsDocument40 pages04 Crystal Defectsnitesh_n2840No ratings yet

- En Acs880 FW Manual P A4Document570 pagesEn Acs880 FW Manual P A4ivanNo ratings yet

- HP DeskJet F2280Document225 pagesHP DeskJet F2280polovneNo ratings yet

- Imscim v1 ManualDocument8 pagesImscim v1 ManualFiroDjinsoNanoNo ratings yet

- OptiSystem 2009Document10 pagesOptiSystem 2009Kapilachander ThangavelNo ratings yet

- ELF 3234 ELF 3234 3 ConzervDocument2 pagesELF 3234 ELF 3234 3 ConzervManish Kumar SinghNo ratings yet

- Manual Purificator de Aer XiaomiDocument10 pagesManual Purificator de Aer XiaomiPerfectreviewNo ratings yet

- ME132S15 Class Notes PDFDocument227 pagesME132S15 Class Notes PDFAndy MeyersNo ratings yet

- Ex2100 PDFDocument118 pagesEx2100 PDFMohammed FaresNo ratings yet

- Telangana ECET 2016 Model Question Paper With Answers: A. Zero B. Sin QDocument11 pagesTelangana ECET 2016 Model Question Paper With Answers: A. Zero B. Sin QJammula Sivanaga Chowdary100% (1)

- Element 9 PDFDocument50 pagesElement 9 PDFravi010582No ratings yet

- Slide MT9083C2 Training - SlidesDocument36 pagesSlide MT9083C2 Training - SlidesCông ĐườngNo ratings yet

- Manual DSR Pd170Document413 pagesManual DSR Pd170Javier Fernando Ayasta VenturaNo ratings yet

- 1 - Composing For VideogamesDocument16 pages1 - Composing For Videogameslory100% (1)

- ABB HT FAT ProceedureDocument19 pagesABB HT FAT ProceedureHow Peter How100% (3)