Professional Documents

Culture Documents

Hard Drive Sander: Instructables

Uploaded by

Alexis NamagapOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hard Drive Sander: Instructables

Uploaded by

Alexis NamagapCopyright:

Available Formats

instructables

Hard Drive Sander

by ThomasVDD

Many people have an old hard drive laying around. In this project we will put it to good use by turning it into a

powerful disk sander! It's a cheap and easy project, but it has already proven to be very useful when sharpening

tools and sanding though materials.

Let's get building!

https://youtu.be/jPIP9cthOrA

https://youtu.be/wuXoOF3thto

Hard Drive Sander: Page 1

Step 1: Parts & Tools

Parts

Old harddrive (although a new one would also work :p)

Electronic Speed Controller (about $4)

Servo tester (about $1.5)

Sandpaper

2 Banana terminals

Total cost: less than $10!

Tools

Torx screwdrivers

Soldering iron

Dremel / rotary tool

Drill

Multimeter

Hard Drive Sander: Page 2

Step 2: Disassembly

The first step of the build is disassembling the Small bonus project

harddrive. Simply remove all the screws; there will

probably be one under the sticker as well. These strong magnets are ideal to make a magnetic

parts tray. You can remove the protruding metal bits

Next, we'll need to take out the guts. Undo all the with a pair of pliers. They will break off quite easily,

screws you see and remove the components. since they are quite brittle.

You might have to use some force to remove the

magnets, but these are worth keeping! I had a lid of an old metal pen case, to which I

attached the magnets; et voila!

Also remove the hard drives and spacers themselves,

since we'll have to restack them.

Hard Drive Sander: Page 3

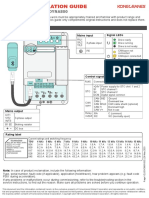

Step 3: Wiring the Motor

The crucial step of this project is controlling the motor name implies, it is used to test servo motors.

of the harddrive. However, the type of control signal for a ESC and a

servo are the same: it's a simple PWM signal. In case

The motor inside a harddrive is a brushless DC motor of the servo, this corresponds to a motor position; for

(BLDC). They come in 2 variants: triangle and star the ESC it corresponds to a speed.

topology. For the full explanation, take a look at the

Wikipedia page, I will focus on the wiring. Let's focus on the wiring of the motor, depending on

your harddrive you will have 1 of 2 types:

A BLDC motor can easily be controlled by an

Electronic Speed Controller (ESC), and while we 3 Pins

could have made this ourselves, it's far easier and

cheaper to buy a speed controller. Furthermore, they If your motor has 3 pins, it's triangle topology: there is

can easily be controlled by a servo tester; as the a coil between every pair of pins. This is the easy

case: just solder the 3 wires of the ESC (the blue After soldering the ESC, mount it inside the hard

ones) to the 3 pins of the motor (a,b,c on the diagram) drive case where the reading head was. Every

and call it a day. harddrive is different, so try to find a way of attaching

it securely; I just some scraps of aluminium, although

4 Pins glue would have also worked.

In case there are 4 pins on the motor, you have a star Attach 2 banana terminals to the red an black wires of

topology. We will need to connect the ESC to points the ESC. Drill 2 holes in the enclosure to mount them.

a,b,c on the diagram. To do this, we have to identify You could also use a barrel jack if you want to use it

to which 3 of the 4 pins they correspond. with a 12 V wall adapter instead of a bench

To achieve this, we'll have to bust out the multimeter powersupply.

and measure the resistance between the pins. As we

can see on the picture, 3 combinations give a You can already connect the servo tester to the 3 pin

resistance of 1 Ohm, while 3 others give 2 Ohms. 1 connector of the ESC, plug the banana jacks into 12

Ohm is the resistance of 1 coil (1 of the Z's on the V and give the motor a try. That's the electronics

diagram), while the 2 Ohms is the resistance of 2 basically done!

coils in series.

Conclusion: the combinations where we measured 2

Ohms are the ones we need (a,b,c on the diagram)!

Hard Drive Sander: Page 4

Hard Drive Sander: Page 5

Step 4: Enclosure

Now that our motor spins, we can turn it into a to make it more usable. Therefore, we will reinstall

sander! the original lid, with a cutout for the harddisk. Since

the cover is very hard and reasonably thick steel, it is

Start by taking a piece of sandpaper and cut out a preferable to use a thin cutoff wheel on your rotary

circle that fits your hard drive platter. Attach it to the tool. Wear some kind of face protection and a

platter with double sided tape. This will allow us to breathing mask while doing this: it produces dust and

easily replace it in the future. the cutoff wheel can easily break and fly away!

I also added an upright piece out of thin aluminium

My harddrive had 2 platters with some spacers in that seals off the side and glued it in place.

between. Put the spacers down first and then add the

2 platters on top of each other for extra strength. As a last step, attach the servo tester to the 3 pin

Screw it tightly in place, this bracket will also keep the connector of the ESC. I decided to leave it external,

sandpaper firmly in place (that's why we didn't glue since there was not enough place inside the

the sandpaper). enclosure, and since it allows me to use it to test

actual servo's when I'm not sanding.

The last thing is to cover up and protect the ESC and

Hard Drive Sander: Page 6

Step 5: Test & Enjoy

We're done! The only thing left to do is to test our new I hope you liked the project and have found a good

hard drive sander. use for that unused old hard drive!

Connect the servo tester and plug it into a 12 V

supply which can deliver about 1 A (see how I made Feel free to check out my other instructables:

one from an old ATX powersupply here, or a fancy https://www.instructables.com/member/ThomasVDD/

digital one here). Make sure the servo tester is in

manual mode and turn the knob, the sander should

start spinning!

https://youtu.be/STQVwwb0wsE

Hard Drive Sander: Page 7

You might also like

- Haywired: Pointless (Yet Awesome) Projects for the Electronically InclinedFrom EverandHaywired: Pointless (Yet Awesome) Projects for the Electronically InclinedRating: 3.5 out of 5 stars3.5/5 (3)

- Construction TipsDocument2 pagesConstruction TipsANdreaNo ratings yet

- DVD To Laser EngraverDocument24 pagesDVD To Laser EngraverTaofik HidayatNo ratings yet

- 8x8x8 LED Cube PART NO. 2168940: Bill of MaterialsDocument13 pages8x8x8 LED Cube PART NO. 2168940: Bill of MaterialsLuis Gutierrez MaganNo ratings yet

- Repairing Faulty EMV Backlight Inverter.: Table 1 Parts Required For RepairDocument11 pagesRepairing Faulty EMV Backlight Inverter.: Table 1 Parts Required For RepairJulian SchmitzNo ratings yet

- Uselessbox Manual v13 Gm3 Oct122011Document16 pagesUselessbox Manual v13 Gm3 Oct122011pqr1100% (1)

- Mechanical 7 Segment Display PDFDocument8 pagesMechanical 7 Segment Display PDFSergio Velasquez BonillaNo ratings yet

- Adafruit Motor Shield Arduino User GuideDocument27 pagesAdafruit Motor Shield Arduino User GuidePaco AngelesNo ratings yet

- My Replication of Windows BendiniDocument14 pagesMy Replication of Windows BendinimaramdiNo ratings yet

- Flex-circuit Soldering GuideDocument18 pagesFlex-circuit Soldering GuidecaptnskydiverNo ratings yet

- Build Powerful Laser 12 Steps PicturesDocument7 pagesBuild Powerful Laser 12 Steps PicturesCarl MacCordNo ratings yet

- Acoustic LevitatorDocument64 pagesAcoustic LevitatorEthrigan DaemonicusNo ratings yet

- Solid State 83 Tube ReplacementDocument6 pagesSolid State 83 Tube ReplacementWiwy TransmitNo ratings yet

- (Ebook) - Diy - How To Build Your Own CNC Machine - O'BrienDocument28 pages(Ebook) - Diy - How To Build Your Own CNC Machine - O'Brienzaoioaz100% (1)

- Connecting Your Telescope to Your PCDocument14 pagesConnecting Your Telescope to Your PCJordi ArroyoNo ratings yet

- Replace Capacitors On EcuDocument9 pagesReplace Capacitors On EcuHomar Mur100% (3)

- MagnetizerDocument10 pagesMagnetizersacopNo ratings yet

- Coil Gun Kit Instructions From Disposable CameraDocument3 pagesCoil Gun Kit Instructions From Disposable CameraPhilip Henson0% (1)

- Sidewinder-X1 BTT SKR 1.4 Guide by AstralDocument15 pagesSidewinder-X1 BTT SKR 1.4 Guide by Astraloscar tebarNo ratings yet

- Alternator: Savonius VAWTDocument9 pagesAlternator: Savonius VAWTTamir ItetNo ratings yet

- Dunlop Wah True-BypassDocument8 pagesDunlop Wah True-Bypassasdfasdfsa3459No ratings yet

- Acoustic LevitatorDocument62 pagesAcoustic LevitatorJulianSalazarNo ratings yet

- Instructables Com FAN RepairDocument9 pagesInstructables Com FAN RepairOtk ManuscriptNo ratings yet

- Share What You MakeDocument16 pagesShare What You MakeSameer ChakoleNo ratings yet

- AA Battery Powered Tesla Coil PDFDocument13 pagesAA Battery Powered Tesla Coil PDFNaren ArchaNo ratings yet

- Basic Methods of Troubleshooting or Faultfinding Components On A Printed Circuit BoardDocument2 pagesBasic Methods of Troubleshooting or Faultfinding Components On A Printed Circuit Boardstevembe430No ratings yet

- How To Build The Seth PP2A3Document36 pagesHow To Build The Seth PP2A3nqtruongNo ratings yet

- Arduino Bedini Charger Guide Setup Replication TestsDocument8 pagesArduino Bedini Charger Guide Setup Replication TestsBastien Gall de Sillé0% (1)

- Brauduino Controller Build1Document18 pagesBrauduino Controller Build1Marlon G. AguiarNo ratings yet

- Rewinding A Brushless MotorDocument8 pagesRewinding A Brushless Motorflieger horstNo ratings yet

- Node 2 PC Build UpDocument11 pagesNode 2 PC Build Uptintin plataNo ratings yet

- Casio DM100 Sample ExpansionDocument17 pagesCasio DM100 Sample ExpansionSesan del futuroNo ratings yet

- Stompbox WorkshopDocument18 pagesStompbox Workshopchris_holden249580% (10)

- Rewind Motor BrushlessDocument11 pagesRewind Motor Brushlesssharingiscaring69No ratings yet

- Knock Sensor Rewire Write-Up (Code 52) : Boosted SupraDocument4 pagesKnock Sensor Rewire Write-Up (Code 52) : Boosted Supraes9857No ratings yet

- Solenoid Motor With Long Throw: InstructablesDocument6 pagesSolenoid Motor With Long Throw: InstructablesClóvis MorNo ratings yet

- SMD Soldering Guide Part IIDocument37 pagesSMD Soldering Guide Part IIz4rm4rNo ratings yet

- Acoustic LevitatorDocument26 pagesAcoustic LevitatorBilisuma ZewduNo ratings yet

- Acoustic Levitator PDFDocument26 pagesAcoustic Levitator PDFfranklin david100% (2)

- Openb0Xx V1.0 Guide: NotesDocument7 pagesOpenb0Xx V1.0 Guide: NotesEEMM25No ratings yet

- Acoustic LevitatorDocument26 pagesAcoustic LevitatorBilisuma ZewduNo ratings yet

- AA Battery Powered Tesla Coil 1Document12 pagesAA Battery Powered Tesla Coil 1Sumit MishraNo ratings yet

- Relogio TranmanualDocument61 pagesRelogio TranmanualJorge FarinhaNo ratings yet

- Building A Slot Car Test Bench Part One: by Matt AgnewDocument5 pagesBuilding A Slot Car Test Bench Part One: by Matt AgnewJoao JunqueiraNo ratings yet

- Rewinding A Brushless MotorDocument10 pagesRewinding A Brushless MotorUday WankarNo ratings yet

- Build your own CNC machine with parts from old printersDocument11 pagesBuild your own CNC machine with parts from old printersfjagorNo ratings yet

- How To Build Your Own CNC Machine DIYDocument27 pagesHow To Build Your Own CNC Machine DIYBhagya WickramasingheNo ratings yet

- Step 0 - Prepare The Materials.: How To Build Pedalshield UnoDocument6 pagesStep 0 - Prepare The Materials.: How To Build Pedalshield UnoSatrio Ongis NadeNo ratings yet

- Diy Minipro DC/DC ConverterDocument14 pagesDiy Minipro DC/DC Convertermrcinek01No ratings yet

- DIY Pickup Winder 8 Steps (With Pictures) - InstructablesDocument33 pagesDIY Pickup Winder 8 Steps (With Pictures) - InstructablesMaddy SjiicroNo ratings yet

- Rewinding and Renovation of The Electric MotorDocument50 pagesRewinding and Renovation of The Electric Motorkhaled ahned100% (2)

- LM3875 Gainclone DIY Amp Building GuideDocument49 pagesLM3875 Gainclone DIY Amp Building GuideJaco HerholdtNo ratings yet

- DIY Coil WinderDocument7 pagesDIY Coil WinderWilson F SobrinhoNo ratings yet

- BUILDING YOUR FROG GUITAR EFFECT PEDAL PCB - A General GuideDocument7 pagesBUILDING YOUR FROG GUITAR EFFECT PEDAL PCB - A General GuideGladson GoesNo ratings yet

- HG Manhat2 PDFDocument11 pagesHG Manhat2 PDFNikola DulgiarovNo ratings yet

- Frankenstein Laser Engraver: InstructablesDocument38 pagesFrankenstein Laser Engraver: InstructablesKon ArvaNo ratings yet

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinFrom EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinNo ratings yet

- GenAPI ExclusionsDocument1 pageGenAPI ExclusionsAlexis NamagapNo ratings yet

- Technological Innovations To Identify and Reduce CorruptionDocument8 pagesTechnological Innovations To Identify and Reduce CorruptionAnurag MishraNo ratings yet

- Pkactical Physiology PDFDocument508 pagesPkactical Physiology PDFAlexis NamagapNo ratings yet

- Creierul, O Enigma Descifrata by Moisa, Dorin TeodorDocument156 pagesCreierul, O Enigma Descifrata by Moisa, Dorin TeodorGutenberg.orgNo ratings yet

- Epstein & Klinkenberg, 2001Document20 pagesEpstein & Klinkenberg, 2001Alexis NamagapNo ratings yet

- AT93C46Document20 pagesAT93C46Alexis NamagapNo ratings yet

- Shanghai Liquid Resistance Starter GuideDocument15 pagesShanghai Liquid Resistance Starter GuideAlpha AgustinusNo ratings yet

- Catalogo Siprotec 7sj80Document30 pagesCatalogo Siprotec 7sj80Florencio TorresNo ratings yet

- KSEB Power Application LT FormDocument2 pagesKSEB Power Application LT FormJoel Joy100% (1)

- MATLAB Matrices and DC Circuits AnalysisDocument5 pagesMATLAB Matrices and DC Circuits AnalysisAhmad Ash SharkawiNo ratings yet

- Segmentacion ScientificDocument20 pagesSegmentacion ScientificJuan ZapataNo ratings yet

- 1 Toshiba 2151 TB: General InformationDocument3 pages1 Toshiba 2151 TB: General InformationGoranNo ratings yet

- JWI-3000 Service ManualDocument23 pagesJWI-3000 Service ManualGabriel Spinato100% (1)

- W461Document188 pagesW461Achmad Fadhillah KurniawanNo ratings yet

- Meaning of Operating System: Using Software and Physical PartsDocument22 pagesMeaning of Operating System: Using Software and Physical PartsReshmaNo ratings yet

- Norge Av Max Nov 07 ReviewDocument3 pagesNorge Av Max Nov 07 ReviewbabanpNo ratings yet

- Voltage Drop CalculatorDocument6 pagesVoltage Drop CalculatorMariano SanchezNo ratings yet

- CTV Sva05a En603servicealertDocument6 pagesCTV Sva05a En603servicealertGustavo Scherman100% (3)

- Isa 71.02 1991 PDFDocument16 pagesIsa 71.02 1991 PDFQuang Duan NguyenNo ratings yet

- ACS800 Stand Alone Single Drives Rev A W Bookmarks Updated13012005Document48 pagesACS800 Stand Alone Single Drives Rev A W Bookmarks Updated13012005Jose MellaNo ratings yet

- Elmeasure - ATES - Automatic Transfer Switch Manufacturers in IndiaDocument6 pagesElmeasure - ATES - Automatic Transfer Switch Manufacturers in Indiaanoop ajayNo ratings yet

- Microprocessors & Interfacing Techniques Assignment No. 2Document2 pagesMicroprocessors & Interfacing Techniques Assignment No. 2Abdullah Nasir100% (4)

- PSSE ReleaseDocument34 pagesPSSE ReleaseAshutosh SharmaNo ratings yet

- External Interface (XINTF)Document38 pagesExternal Interface (XINTF)AlonsoNo ratings yet

- Eaom-36r Eng v05Document8 pagesEaom-36r Eng v05Khaled KamelNo ratings yet

- r05320401 Telecommunication Switching Systems and NetworksDocument6 pagesr05320401 Telecommunication Switching Systems and NetworksSRINIVASA RAO GANTA100% (2)

- Utc1316 PDFDocument3 pagesUtc1316 PDFLuis ArdilaNo ratings yet

- d43256 Memorie de 256kDocument25 pagesd43256 Memorie de 256kapi-252724932No ratings yet

- E IDocument7 pagesE Ivims1248993No ratings yet

- Druck PT Data SheetDocument7 pagesDruck PT Data Sheethits289No ratings yet

- DOC665105Document2 pagesDOC665105DeivisNo ratings yet

- 64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionDocument21 pages64-Kbit (8K × 8) Serial (SPI) F-RAM: Features Functional DescriptionsupNo ratings yet

- Electrical Design Engineer ResumeDocument2 pagesElectrical Design Engineer ResumeMukesh KumarNo ratings yet

- Electromagnetic Induction Chapter SummaryDocument15 pagesElectromagnetic Induction Chapter SummaryBeverly PamanNo ratings yet

- GV D200/d200e/d800/d800eDocument166 pagesGV D200/d200e/d800/d800esvestasNo ratings yet

- Radio TechModifications 7bDocument197 pagesRadio TechModifications 7bJuan Marcelo Rodriguez Pereyra100% (2)