Professional Documents

Culture Documents

Angmc 6026 Us

Uploaded by

Yusliamin YusofCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angmc 6026 Us

Uploaded by

Yusliamin YusofCopyright:

Available Formats

VALVES & CONTROLS

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

The intent of these instructions is to acquaint the user with the maintenance of this product.

Please read these instructions carefully.

Remove the pressure relief valve prior to performing any pressure testing of the

system.

The safety of lives and property often depends on the proper operation of the pressure

relief valve. The valve must be maintained according to appropriate instructions and

must be periodically tested and reconditioned to ensure correct function.

WARNING

Removal of the seal wires in an attempt to adjust and/or repair this product by

unauthorized or unqualified persons voids the product warranty and may cause

damage to equipment and serious injury or death to persons.

The product is a safety related component intended for use in critical applications.

The improper application, installation or maintenance of the product or the use of

parts or components not manufactured by Anderson Greenwood may result in a

failure of the product.

Any installation, maintenance, adjustment, test, etc. performed on the Product must

be done in accordance with the requirements of all applicable Anderson Greenwood

Procedures and Instructions as well as applicable National and International Codes

and Standards.

STORAGE AND HANDLING

Pressure relief valve performance may be adversely affected if the valve is stored for

SAFETY PRECAUTIONS an extended period without proper protection. Rough handling and dirt may damage,

When the pressure relief valve is under deform, or cause misalignment of valve parts and may alter the pressure setting and

pressure never place any part of your adversely affect valve performance and seat tightness. It is recommended that the

body near the pilot exhaust nor the outlet valve be stored in the original shipping container in a warehouse or as a minimum on a

of the main valve. dry surface with a protective covering until installation. Inlet and outlet protectors

should remain in place until the valve is ready to be installed in the system.

The main valve outlet should be piped or

vented to a safe location. 1.0 GENERAL VALVE DESCRIPTION (REFER TO FIGURE 1)

Always wear proper safety gear to protect The Anderson Greenwood Type 95 Valve consists of a main valve and pilot. The main

head, eyes, ears, etc. anytime you are valve has an unbalanced piston with O-ring seat. Tank pressure is applied to the top of

near pressurized valves. the piston by means of the pilot. The area of the top of the piston is larger than the

Never attempt to remove the pressure bottom and the valve remains closed.

relief valve from a system that is When the tank pressure increases to the set pressure of the pilot, the pilot opens and

pressurized. vents the pressure from the top of the piston. The force acting on the bottom of the

Never make adjustments to or perform piston is now greater than that acting on the top and the valve opens.

maintenance on the pressure relief valve When the tank pressure decreases to the closing pressure of the pilot, the pilot closes

while in service unless the valve is isolated and tank pressure is directed to the top of the piston. The force acting on the top of the

from the system pressure. If not properly piston is now greater than the force on the bottom and the valve closes.

isolated from the system pressure, the

pressure relief valve may inadvertently

open resulting in serious injury.

Engineering Doc. #05.9040.083 Rev. E

ANGMC-6026-US-1312 Copyright © 2013 Pentair WWW.PENTAIR.COM/VALVES

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

TABLE OF CONTENTS

1.0 General valve description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Accessory maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3.0 Main valve maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4.0 Pilot maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.0 Pilot set pressure adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.0 Pilot set pressure field test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.0 Valve diagnosis guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8.0 Soft goods repair kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FIGURE 1

Auxiliary

setting

device

Bonnet

Pilot vent

Field test

Pilot vent

Dome

(top of the piston)

Check

valve

P (Tank)

Tank pressure

Outlet sense line

Main

valve

Unbalanced

P (Tank) Piston

O-ring seat

Inlet

(tank pressure)

Engineering Doc. #05.9040.083 Rev. E

page 2 ANGMC-6026-US-1312 Copyright © 2013 Pentair

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

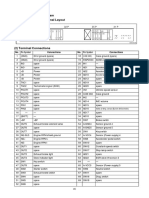

ITEM DESCRIPTION 2.0 ACCESSORY MAINTENANCE (REFER TO FIGURE 2)

* 1 Auxiliary setting device

2 Supply tubing

The accessories used on the Type 95 are the auxiliary setter, field test and backflow

preventer. The field test and backflow preventer are always used; the auxiliary setter

3 Pilot exhaust tubing is optional.

4 Pilot bracket bolt

* 5 Pilot

Only the backflow preventer, which consists of one (2) diaphragm type check valve and a

ball check valve requires maintenance. Normal maintenance is to clean the check

6 Pipe nipple valves and replace the diaphragm, washer, gasket, (1) and O-ring.

7 Field test hand valve

8 Field test plug

When replacing the diaphragm, care should be taken not to damage the diaphragm. To

9 Connector

assemble the diaphragm type valve, uniformly tighten the body bolts, first one side, then

the opposite side. Do not overtighten the bolts as this will distort the diaphragm and

10 Check valve cause leakage.

11 Connector

12 Connector

NOTES: (1) Gasket used on some check valves. If check valve has gasket, use gasket

supplied in repair kit - otherwise discard kit gasket.

13 Close tee

15 Check valve

(2) Some earlier model valves use two diaphragm check valves and no ball check valve.

16 Connector

17 Connector

FIGURE 2

18 Pipe plug

19 Body bolt

20 Lock washer

21 Upper body

* 22 Diaphragm

* 23 Washer

24 Spring pin

25 Lower body

26 Body

27 Spring

28 Ball

29 O-ring

(1) 30 Gasket

* Recommended spare parts for repairs

Auxiliary setter, with field test and backflow preventer

indexed in order of disassembly

Engineering Doc. #05.9040.083 Rev. E

Copyright © 2013 Pentair ANGMC-6026-US-1312 page 3

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

FIGURE 3 3.0 MAIN VALVE MAINTENANCE

(REFER TO FIGURE 3)

Normal valve maintenance will be to only

clean the parts. It may also be necessary

to replace the seat. The piston seal should

not need to be replaced. If the piston seal

is removed, a new seal must be installed.

The piston can be removed from the

cap/liner by pulling the piston out or by

pushing it out with a rod through the hole

in the top of the cap/liner.

No lubricant is required on the piston

seal. A small amount of thread sealant

should be used on the pipe threads to

prevent leakage. Teflon® tape is

recommended.

The piston should be assembled to the

cap/liner and the two parts should then be

assembled to the valve body. The piston

can be prevented from sliding out of the

cap/liner during assembly by covering or

plugging the hole in the top of the

cap/liner.

For marine service, the bolts in the

main valve and pilot exposed to the

environment should be replaced

during routine maintenance every five

ITEM DESCRIPTION

10 Lower bracket

20 Upper bracket

30 Bracket bolt

40 Washer

50 Hex nut

100 Body

110 Screw

140 Piston

150 Seat retainer

200 Washer (used on 6 x 8 only)

210 Cap/liner

420 Bolt

460 Nozzle

520 Nut

550 Washer

* 560 Guide seal

* 610 O-ring seat

* 620 Cap gasket

* 630 Nozzle gasket

Indexed in order of disassembly

* 640 Washer

700 Cap bolt - hex

710 Cap bolt - eye (1)

* Recommended spare parts for repairs

(1) not shown – used on ≥ 4"

Engineering Doc. #05.9040.083 Rev. E

page 4 ANGMC-6026-US-1312 Copyright © 2013 Pentair

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

4.0 PILOT MAINTENANCE (REFER TO FIGURE 4A)

Anderson Greenwood recommends the pilot be returned to the factory for repair or to

be repaired by a factory serviceman in the field.

Normal maintenance is to completely disassemble the pilot and replace all the

diaphragms, seals and seat. To facilitate assembly, place all parts removed in an

orderly arrangement so that the correct parts are assembled in the proper sequence.

No lubricants are required in the pilot. A small amount of thread sealant should be

used on the pipe threads to prevent leakage. Teflon® tape is recommended.

Assembly is done in the reverse order of the disassembly. The following items should

be observed when assembling the pilot:

• The round metal diaphragm is the sense diaphragm. The clear teflon diaphragm is

the boost diaphragm.

• The holes in the spindle diaphragm must be aligned with all the holes in the body.

The small hole in the lower case must be aligned with the hole in the body.

• Two of the six case bolts must be assembled through the holes in the lower case

before it is attached to the body. After attachment there is insufficient clearance to

do so.

• Tighten the spindle nut snugly but not excessively. Three diaphragms are

sandwiched in the spindle/stack assembly and excessive tightening will damage

them. Hold the hex spacer when torquing the spindle nut to prevent the stack

from rotating.

After the pilot is assembled the set pressure must be adjusted. Refer to Section 5.0

for instructions.

Refer to Page 10 for Soft Goods Repair Kits Part Numbers.

For Figures 4A and 4B

ITEM DESCRIPTION ITEM DESCRIPTION ITEM DESCRIPTION

100 Body 380 Retainer plug 660 Spindle seal*

110 Nozzle 390 Blowdown bushing 680 Spindle gasket*

120 Hex spacer 400 Filter screen (not shown) 690 Spindle diaphragm gasket*

130 Boost spacer 420 Retainer seat 730 Seat base – Type 95

140 Sense spacer 430 Retainer ring 740 Ball

150 Sense plate 440A Hex nut 750 Hex nut

160 Boost plate 450 Bonnet insert (1) 760, 760A Cap

170 Spindle spacer 460 Wire (not shown) 770, 770A Bonnet bolt

190, 190A Pressure adjuster lock nut 470 Seal – 1/2" diameter (not shown) 780 Lock washer

200, 200A Bonnet assembly (1) 490 Washer shim (for stack height) 790, 790A Pressure adjustment screw

210 Upper diaphragm case 500 Spindle diaphragm* 800 Vent – body (not shown)

220 Lower diaphragm case 510 Sense/boost diaphragm* 805A Vent – plug

230 Spacer ring 520 Sense diaphragm* 810 Vent – connector

235A Adapter 550 Spindle 815 Vent – tube

240 Case bolt 555A Extension rod 820, 820A Spring washer

250 Lock washer 560 Check plate 830, 830A Spring disc

260 Hex nut 570 Seat 840, 840A Spring

320 Boost tube 580, 580A Bonnet gasket*

330 Connector elbow 610 Body bolt seal*

A = Used in Auxiliary Setter

340 Body bolt 620 Blowdown seal*

* Recommended spare parts for repairs

350 Blowdown needle 630 Bushing seal*

(1) Part of Item 200 Assembly

370 Hex jam nut 640 Case gasket*

Engineering Doc. #05.9040.083 Rev. E

Copyright © 2013 Pentair ANGMC-6026-US-1312 page 5

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

FIGURE 4A

Type 95 pilot with auxiliary setter

Engineering Doc. #05.9040.083 Rev. E

page 6 ANGMC-6026-US-1312 Copyright © 2013 Pentair

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

FIGURE 4B

Engineering Doc. #05.9040.083 Rev. E

Copyright © 2013 Pentair ANGMC-6026-US-1312 page 7

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

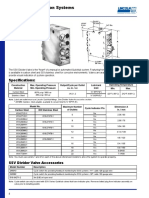

5.0 PILOT SET PRESSURE ADJUSTMENT (REFER TO FIGURE 5)

To adjust the opening and closing pressure of the pilot after the pilot has been

completely disassembled and reassembled, a test set-up similar to that shown in

Figure 5 should be used.

5.1 Check the position of the blowdown adjustment screw. It should be turned half

way in (approximately 5 turns).

5.2 With the pressure adjustment screw turned most of the way in, increase the

supply pressure to the desired set pressure. Back the pressure adjustment

screw out until the pilot “snaps” open. The dome pressure should decrease to

25% or less of the supply pressure.

When the pilot opens and flows, the supply pressure will decrease due to the

pressure drop in the lines to the accumulator. The set pressure is the highest

pressure recorded on the supply pressure gauge.

Auxiliary set

5.3 Decrease the supply pressure to the correct reseat pressure and back the pressure

adjustment

blowdown adjustment screw out until the dome pressure “snaps” back. The under cap

supply pressure at which this occurs is the reseat pressure and it should be

about 90% of the set pressure.

When the pilot reseats, the supply pressure will increase due to reduced flow

through the supply line. The reseat pressure will be the lowest pressure read

on the supply gauge. Tighten the jam nut after each setting for accurate readings.

Recycle the pilot valve to verify the settings. A small interaction between the

blowdown adjustment and the pressure adjustment will occur.

Primary set

pressure

FIGURE 5 adjustment

under cap

Supply

Supply

pressure

Supply port Blowdown

adjustment

Vent

1/2" [1.5 mm] pipe 1/2"[1.5 mm] pipe

6" to 12" long

Accumulator

(1/4 Cubic Ft.)

Dome

pressure

gauge

Type 95 pilot test set-up

Engineering Doc. #05.9040.083 Rev. E

page 8 ANGMC-6026-US-1312 Copyright © 2013 Pentair

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

6.0 PILOT SET PRESSURE FIELD TEST PROCEDURE (REFER TO FIGURE 6)

This procedure is for measuring the pressure where the valve will open. It will not

measure where the valve closes. To measure the closing pressure, use the procedure in

Section 5.0.

6.1 Remove the pilot discharge tube from the pilot and replace with a cap that has

a .06" diameter [1.5 mm] hole in it.

6.2 Connect the test equipment to the field test valve.

6.3 With the metering and vent valve closed, open the gas bottle and adjust the

regulator pressure to about 200 psi [14 kp/cm2].

6.4 Open the field test valve. Slowly open the metering valve and observe the test

gauge. Increase the pressure until gas flow at the pilot discharge fitting increases

rapidly. The pressure at which this occurs is the set pressure of the valve.

6.5 To adjust the opening pressure turn the spring adjusting screw under the

cap/adapter “IN” to increase pressure or “OUT” to decrease pressure.

6.6 The IMO (International Maritime Organization) Rule set pressure tolerances are:

+ 10% 0 - 21.3 psi [0 - 1.5 kp/cm2]

+ 6% 21.3 - 42.7 psi [1.5 - 3.0 kp/cm2]

+ 3% 42.7 psi or 3.0 kp/cm2 and above

FIGURE 6 Auxiliary set

pressure

adjustment

under cap

Auxiliary setter

Primary set

pressure

adjustment

Unscrew here under cap

for removal

(install hand-tight only –

lubricate threads) Bonnet

vent

Pilot Pilot Test gauge

discharge Field

fitting test

valve Metering

Pilot valve

discharge

tube

High

Nitrogen

pressure

bottle with

hose

Vent shutoff

valve valve and

regulator

Adapter fitting to

1/2" NPT port on

field test valve

Main valve

Type 95 pilot recommended field test set-up Engineering Doc. #05.9040.083 Rev. E

Copyright © 2013 Pentair ANGMC-6026-US-1312 page 9

ANDERSON GREENWOOD TyPE 95 POSRV

MAINTENANCE INSTRUCTIONS

7.0 VALVE DIAGNOSIS GUIDE

Problem Causes

Valve does not close (Refer to Figure 1)

on start-up with little or Main valve piston in lift position,

no cargo tank pressure pressurize dome through field test

handvalve [0.5 to 1.0 kp/cm2] to

close piston.

Valve opens at a Set pressure incorrect

pressure below

nameplate set pressure Auxiliary setter device incorrect

one for valve.

Auxiliary setter device not screwed

down all the way.

Pilot sense diaphragm leaks. Check

for gas flow through pilot spring

bonnet vent.

Backflow preventer check valve

leaks. (Item 15, Figure 2) Check

for gas flow at discharge tube to

main valve outlet. No gas flow

should be detected.

Valve opens at Pilot not sensing correct tank pressure

correct pressure

but does not close Check valve in tank pressure sense

line (Figure 1) restricted.

Filter screen in pilot or small orifices

in pilot restricted.

IMPORTANT

IN AN EMERGENCy, MAIN VALVE

CAN BE CLOSED By PRESSURIZING

DOME (TOP OF PISTON) THROUGH

CLOSE TEE (ITEM 13, FIGURE 2) REMOVE

PLUG (ITEM 18) AND APPLy PRESSURE

EQUAL TO TANK PRESSURE.

8.0 REPAIR KITS

Soft goods Bolt

2x3 04.4744.810 04.4744.330

Main valve size kit part number kit part number

3x4 04.4744.804 04.4744.331

4x6 04.4744.834 04.4744.332

6x8 04.4744.835 04.4744.333

Pilot 04.4744.025 04.4744.333

Backflow preventer (diaphragm) 04.4744.781 04.4744.335

Check valve (ball check) 04.4744.782 None

Engineering Doc. #05.9040.083 Rev. E

page 10 ANGMC-6026-US-1312 Copyright © 2013 Pentair

You might also like

- 05-9040-070 Angmc-6028-UsDocument2 pages05-9040-070 Angmc-6028-Ustxlucky80No ratings yet

- Installation and Maintenance Instructions: Anderson Greenwood Series 93T Pilot Operated Safety Relief ValvesDocument8 pagesInstallation and Maintenance Instructions: Anderson Greenwood Series 93T Pilot Operated Safety Relief Valvesharshkumar patelNo ratings yet

- BPRVDocument18 pagesBPRVPatel UsamaNo ratings yet

- Power Plant and Calculations - Safety Valves and Its Basic ConceptsDocument4 pagesPower Plant and Calculations - Safety Valves and Its Basic ConceptsV U P RaoNo ratings yet

- SV Pilot Crosby Type-93Document22 pagesSV Pilot Crosby Type-93MarcelocrossNo ratings yet

- OpTB Product Instruction ManualDocument8 pagesOpTB Product Instruction ManualSergio Gana GonzalezNo ratings yet

- 05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDocument33 pages05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDIONNY VELASQUEZNo ratings yet

- Fisherr GX Control Valve and Actuator System: Scope of ManualDocument68 pagesFisherr GX Control Valve and Actuator System: Scope of Manualابزار دقیقNo ratings yet

- Contoh Soal Psikotes Kerja Dan Kunci JawabanDocument8 pagesContoh Soal Psikotes Kerja Dan Kunci JawabanArie BfmvNo ratings yet

- Graco 308 017 User ManualDocument32 pagesGraco 308 017 User Manualvals valsNo ratings yet

- AG Tank Blanketing RegulatorDocument3 pagesAG Tank Blanketing Regulatormicroco4No ratings yet

- Vaas Automation C47 cryogenic valve manualDocument8 pagesVaas Automation C47 cryogenic valve manualKannan KrisNo ratings yet

- TM 90 21Document21 pagesTM 90 21enrique RiosNo ratings yet

- IOM-PA SeriesDocument4 pagesIOM-PA SeriesKike PadillaNo ratings yet

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- Series 800 Posrv IomDocument20 pagesSeries 800 Posrv IomCristiam BejaranoNo ratings yet

- F70Pr Series Pilot-Operated Pressure Relief Valve: Installation, Operation, & Maintenance ManualDocument22 pagesF70Pr Series Pilot-Operated Pressure Relief Valve: Installation, Operation, & Maintenance ManualMoca PhoenixNo ratings yet

- Baumann 24000SB Barstock Control Valve: Scope of ManualDocument16 pagesBaumann 24000SB Barstock Control Valve: Scope of ManualusamaNo ratings yet

- Operating and Service Manual For Hyd. Act. Series 4000,5000,6500Document24 pagesOperating and Service Manual For Hyd. Act. Series 4000,5000,6500Mehdi Norouzi100% (1)

- Rt500 1 Service AdjustmentsDocument29 pagesRt500 1 Service AdjustmentsjulianmataNo ratings yet

- Fisher EZ Control Valve-Instruction ManualDocument36 pagesFisher EZ Control Valve-Instruction ManualPark SataveeNo ratings yet

- Installation & Maintenance Instructions: Series F210Document3 pagesInstallation & Maintenance Instructions: Series F210Mar SolNo ratings yet

- 2007 Manitou Shock Service Manual - Rev NCDocument35 pages2007 Manitou Shock Service Manual - Rev NCMaikelNo ratings yet

- Manual VREL Valve - Sentry PDFDocument12 pagesManual VREL Valve - Sentry PDFMarcoGomesNo ratings yet

- Universal Excess Pressure Valve SAMSON Type 41-73Document37 pagesUniversal Excess Pressure Valve SAMSON Type 41-73Bata ZivanovicNo ratings yet

- F7000 / 8000 SERIES Pilot-Operated Safety Relief Valve: Installation, Operation, & Maintenance ManualDocument43 pagesF7000 / 8000 SERIES Pilot-Operated Safety Relief Valve: Installation, Operation, & Maintenance ManualMoe MozhganNo ratings yet

- Enviro Seal System Rotary ValavesDocument16 pagesEnviro Seal System Rotary ValavesJhne OkNo ratings yet

- Steady Rest Installation Manual: Self-Centering Steady Rests Hydraulic AXI, ASI, AXE, ASE, ANE-seriesDocument14 pagesSteady Rest Installation Manual: Self-Centering Steady Rests Hydraulic AXI, ASI, AXE, ASE, ANE-seriesAbdu RokmanNo ratings yet

- Series 400 Piston Pilot POPRV Maintenance InstructionsDocument26 pagesSeries 400 Piston Pilot POPRV Maintenance InstructionsCristiam BejaranoNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- TSM 1445 - 75 Series™, 475 Series™Document18 pagesTSM 1445 - 75 Series™, 475 Series™Planeador de Mantenimiento SomerosNo ratings yet

- Standard Gate Valves ManualDocument8 pagesStandard Gate Valves ManualmechanikyNo ratings yet

- Vciom 06208 enDocument18 pagesVciom 06208 enElver AmesquitaNo ratings yet

- Pressure Reducing Valve: ModelDocument2 pagesPressure Reducing Valve: Modeljuliancardona77No ratings yet

- Thermo scuba valve maintenance guideDocument24 pagesThermo scuba valve maintenance guideCarlos Arturo Martinez SalcedoNo ratings yet

- Technical Service Manual: Section TSM 144 1 OF 10 Issue EDocument10 pagesTechnical Service Manual: Section TSM 144 1 OF 10 Issue EMao LeeNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- Q&M GeneralDocument0 pagesQ&M GeneralPhu NguyenNo ratings yet

- IOM-P14-R0 Quarter Turn BVDocument9 pagesIOM-P14-R0 Quarter Turn BVDonovan BonnerNo ratings yet

- PED - Operating Safety Instructions for Direct Spring Safety ValvesDocument2 pagesPED - Operating Safety Instructions for Direct Spring Safety ValvesndngnngdngngNo ratings yet

- 2007 Manitou Shock Service Manual - Rev NCDocument35 pages2007 Manitou Shock Service Manual - Rev NCJose Maria Montes100% (2)

- 90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControlDocument2 pages90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControllesterNo ratings yet

- Installation, Operation, Maintenance Instructions For Severn Glocon Control & Choke ValvesDocument4 pagesInstallation, Operation, Maintenance Instructions For Severn Glocon Control & Choke ValvesEderson Santos67% (3)

- Install, Operate and Maintain Your GA-160 Gas AmplifierDocument8 pagesInstall, Operate and Maintain Your GA-160 Gas AmplifierAldo Marcelo Soliz AngolaNo ratings yet

- TDS010 - 400 Series Pneumatic Actuators Technical DataDocument6 pagesTDS010 - 400 Series Pneumatic Actuators Technical DataRicardoBalderasNo ratings yet

- Instructions-Parts: - KING@ and Bulldog@ Shovel PumpsDocument22 pagesInstructions-Parts: - KING@ and Bulldog@ Shovel PumpsRoman MalyNo ratings yet

- Series 200 POSRV Maintentance InstructionsDocument13 pagesSeries 200 POSRV Maintentance InstructionsCristiam BejaranoNo ratings yet

- 2004 Swinger Service Manual: PN 042133, REV NCDocument47 pages2004 Swinger Service Manual: PN 042133, REV NCGraku MartínNo ratings yet

- Volvo TAD 620VE Workshop Manual Technical DataDocument88 pagesVolvo TAD 620VE Workshop Manual Technical DataGORD67% (3)

- TSC 400 Man 0575 G 16884Document4 pagesTSC 400 Man 0575 G 16884Carolina Vanessa Miranda FritzNo ratings yet

- Ewco Alves: NEWCO/OIC Cast Valve Operation & Maintenance ManualDocument22 pagesEwco Alves: NEWCO/OIC Cast Valve Operation & Maintenance ManualSebastian Jerez UrquietaNo ratings yet

- Amort Hydril KDocument21 pagesAmort Hydril KFernando Aybar100% (1)

- 755Document19 pages755JOHNNo ratings yet

- 2006 Swinger Shock Service Manual - Rev NC PDFDocument45 pages2006 Swinger Shock Service Manual - Rev NC PDFMuad DibNo ratings yet

- CV1500 - Control Valves Installation and Operation ManualDocument16 pagesCV1500 - Control Valves Installation and Operation ManualMohammad Safdar SadatNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationFrom EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationRating: 4.5 out of 5 stars4.5/5 (21)

- Risk AssessmentDocument2 pagesRisk AssessmentAsep SaefurrohmanNo ratings yet

- HSE Flow Activities Roles ResponsibilitiesDocument2 pagesHSE Flow Activities Roles ResponsibilitiesYusliamin YusofNo ratings yet

- Mohdronlaftiaz 060248 D 12 TTPDocument28 pagesMohdronlaftiaz 060248 D 12 TTPYusliamin YusofNo ratings yet

- Mohdronlaftiaz 060248 D 12 TTPDocument28 pagesMohdronlaftiaz 060248 D 12 TTPYusliamin YusofNo ratings yet

- Ship Building SteelDocument4 pagesShip Building SteelYusliamin YusofNo ratings yet

- Surface PreparationDocument11 pagesSurface PreparationYusliamin YusofNo ratings yet

- Cover LetterDocument1 pageCover LetterYusliamin YusofNo ratings yet

- Partslist Brother RH-981ADocument109 pagesPartslist Brother RH-981AMaskusyaniNo ratings yet

- 310SK FolletoDocument6 pages310SK FolletoOmar Flores MedinaNo ratings yet

- Emerson Pressure Vacuum Relief Valves Series 2010b-2020b-Varec-En-En-2722484Document20 pagesEmerson Pressure Vacuum Relief Valves Series 2010b-2020b-Varec-En-En-2722484Khasin FuadiNo ratings yet

- Vaccum Pump DatasheetDocument6 pagesVaccum Pump DatasheetQuietRideNo ratings yet

- 1997 Blazer Fuse BoxDocument5 pages1997 Blazer Fuse BoxTina EvansNo ratings yet

- Compair lb55 90062013aeDocument4 pagesCompair lb55 90062013aeBranko BoskovicNo ratings yet

- Pressure Drop Table For HosesDocument1 pagePressure Drop Table For Hosesparthasarathyk69@gmail.comNo ratings yet

- Hydrostatic ForcesDocument27 pagesHydrostatic ForcesSumit SahrawatNo ratings yet

- Thermal Power Plant Overview and ComponentsDocument176 pagesThermal Power Plant Overview and ComponentsChandramohan GNo ratings yet

- Design of Permanent Joints: Version 2 ME, IIT KharagpurDocument11 pagesDesign of Permanent Joints: Version 2 ME, IIT Kharagpurk.ramakrishnaNo ratings yet

- Water Cycle Stages & Plumbing Systems MCQ PracticeDocument101 pagesWater Cycle Stages & Plumbing Systems MCQ Practicegeraint phaeton100% (1)

- Engineering Technician Diploma ProgramsDocument4 pagesEngineering Technician Diploma ProgramsJadeLamorellNo ratings yet

- Daewoo Lanos ECM (Engine Control Module) - ITMS-6F-07-01Document1 pageDaewoo Lanos ECM (Engine Control Module) - ITMS-6F-07-01Jhon Sanchez LopezNo ratings yet

- ECU Common Rail System For HINO J05D-J08EDocument4 pagesECU Common Rail System For HINO J05D-J08Ekidskung100% (2)

- STREAKDocument41 pagesSTREAKVikas KumarNo ratings yet

- Es10 22MM PDS22D Operation Manual PDFDocument37 pagesEs10 22MM PDS22D Operation Manual PDFניקולאי איןNo ratings yet

- Report of Railway Workshop Parel 44Document35 pagesReport of Railway Workshop Parel 44informaadil05No ratings yet

- 2013 Jupiter-Z1 1n1dy460e1Document65 pages2013 Jupiter-Z1 1n1dy460e1Rio Wawo58% (12)

- WCB Customized Superior Quality Slewing Ring GearDocument173 pagesWCB Customized Superior Quality Slewing Ring GearWCB BEARINGNo ratings yet

- Quick-Connect Moment Connection: Technical Design Guide Issued by Forest and Wood Products AustraliaDocument28 pagesQuick-Connect Moment Connection: Technical Design Guide Issued by Forest and Wood Products AustraliaJoseph BookerNo ratings yet

- 12 - Globe - 2 in To 6 in - Class 150 - WCB - Trim 16 - RF - Gl01-c020-468 Rev2Document1 page12 - Globe - 2 in To 6 in - Class 150 - WCB - Trim 16 - RF - Gl01-c020-468 Rev2satphoenixNo ratings yet

- Fixed Wind Turbine WebsiteDocument32 pagesFixed Wind Turbine WebsiteBalakumaran NatarajanNo ratings yet

- B14Document36 pagesB14Surya AnjuNo ratings yet

- AP-38 Leg B Foundation AnalysisDocument24 pagesAP-38 Leg B Foundation AnalysisHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- CP2811Document2 pagesCP2811jodarear0% (1)

- 9876 155 CHP PVM W 155 01Document62 pages9876 155 CHP PVM W 155 01Caspian DattaNo ratings yet

- Divider Valves: Quicklub Lubrication SystemsDocument4 pagesDivider Valves: Quicklub Lubrication SystemsBehi BshNo ratings yet

- Specification Jumbo Drill Sandvik DD311-40Document4 pagesSpecification Jumbo Drill Sandvik DD311-40Nathania Boas E S100% (4)

- King Quad 700 Tips 101 Ver 1.2Document36 pagesKing Quad 700 Tips 101 Ver 1.2Andy House100% (1)

- Kwik Bolt 3 Exp Anchor Hilti PDFDocument21 pagesKwik Bolt 3 Exp Anchor Hilti PDFarturoncNo ratings yet