Professional Documents

Culture Documents

21a Pallet Load Testing To en ISO 8611 PDF

21a Pallet Load Testing To en ISO 8611 PDF

Uploaded by

Muhammad MustahsinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

21a Pallet Load Testing To en ISO 8611 PDF

21a Pallet Load Testing To en ISO 8611 PDF

Uploaded by

Muhammad MustahsinCopyright:

Available Formats

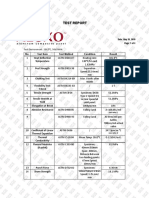

PalletLink Datasheet Ref: 21a

Tel: 01494 558282 fax: 01494 558383 palletlink.co.uk mail@palletlink.co.uk

PALLET LOAD TESTING TO EN ISO 8611

PalletLink carry out pallet testing to the current Standard most

popular in Europe which is BS ISO 8611: 1991 General - purpose

flat pallets for through transit of goods - Test methods. This has been

the focal point of pallet testing for many years for all materials and

remains the best analytical tool for users or manufacturers to know

exactly how pallets perform. The acceptance levels are set by ISO

TR 10233: 1989 General purpose flat pallets for through transit of

goods - Performance requirements. The new 2009 version of ISO

8611 is still not finalised but is more flexible and involves lower test

loadings, we can test to either but generally recommend the newer

version.

PalletLink load testing of pallets and components comprises

hydraulic compression and bending testing up to loads of several

tons. Separate tests on pallet components, nails, joints and wood

density support basic reporting. No charge is made for facilities used

when using in-house equipment, simply our time. We use external

facilities for larger tests and we use UKAS calibration laboratories to

maintain equipment accuracy standards on deflection and load. The

example in the top photo here is from our tests to BS EN 12674-3:

2004: Roll containers - Part 3 - Test Methods where a horizontal

deflection transducer is shown and a pair of matched 1000 kg load

measurement transducers acting in tandem.

To most clients the most informative pallet test is the deck bending

test which is shown in the centre photo applied to a plastic pallet

where the hydraulic loading heads are just out of the picture above

the load board. Our maximum size capacity for pallet tests is 1300 x

1300 mm. The lower photo shows a compression test on a single

plastic block with distortion and exact load measured

simultaneously.

After testing of wood or composite pallets we conduct small specimen oven-dried density tests to BS 373 to

be able to accurately define the wood moisture content and quality used in the specimen. For paper and steel

pallets other supporting tests are carried out. We normally do more than the basic pallet test calls for in order

to assist clients achieve a given level or improve quality. Test results are strictly confidential to clients.

For potato box and roll container testing see the relevant pages on this website.

Copyright PalletLink® While every effort is made to ensure accuracy of the data given, PalletLink cannot accept liability for loss or damage

arising out of the use of the information. The details supplied are relevant as at the date of this publication which is one example in an extensive

series of Datasheets. Members are advised to contact PalletLink if in doubt over any aspect of pallet or case manufacture or usage.

21a/A/JH/JN/30/06/09 strength testing flexural testing flexural strength flexural stiffness testing stiffness testing safe load safe working load swl

You might also like

- Performance Testing of Packages For Single Parcel Delivery SystemsDocument10 pagesPerformance Testing of Packages For Single Parcel Delivery SystemsAlevj Db100% (1)

- Astm D5276-19Document13 pagesAstm D5276-19Nick Ngo100% (1)

- D 1921 - 01 - Rde5mjeDocument5 pagesD 1921 - 01 - Rde5mjejamaljamal20100% (1)

- PV 3 3 3Document3 pagesPV 3 3 3Francesco Vignali100% (1)

- Textiles - Test Methods For Nonwovens - Part 18: Determination of Breaking Strength and Elongation of Nonwoven Materials Using The Grab Tensile Test (ISO 9073-18:2007)Document7 pagesTextiles - Test Methods For Nonwovens - Part 18: Determination of Breaking Strength and Elongation of Nonwoven Materials Using The Grab Tensile Test (ISO 9073-18:2007)Fahmi Fuadul0% (1)

- D 4649 - 03 - RDQ2NDKDocument11 pagesD 4649 - 03 - RDQ2NDKStuartNo ratings yet

- 21a Pallet Load Testing To en ISO 8611Document1 page21a Pallet Load Testing To en ISO 8611Debreteni FlorinNo ratings yet

- Astm D 6880-2005Document5 pagesAstm D 6880-2005Jarvis Wang0% (1)

- Mechanical Handling of Unitized Loads and Large Shipping Cases and CratesDocument5 pagesMechanical Handling of Unitized Loads and Large Shipping Cases and CratesGabriel Herrera Gonzalez100% (1)

- Iso 3874Document34 pagesIso 3874BRIJITHNo ratings yet

- Compressive Properties of Rigid Cellular Plastics: Standard Test Method ForDocument4 pagesCompressive Properties of Rigid Cellular Plastics: Standard Test Method ForannisawidaningsihNo ratings yet

- Poly (Vinyl Chloride) (PVC) Gaskets For Drain, Waste, and Vent (DWV), Sewer, Sanitary, and Storm Plumbing SystemsDocument3 pagesPoly (Vinyl Chloride) (PVC) Gaskets For Drain, Waste, and Vent (DWV), Sewer, Sanitary, and Storm Plumbing SystemsveintavoNo ratings yet

- E 1730 - 99 - Rte3mzatotkDocument4 pagesE 1730 - 99 - Rte3mzatotkEric GozzerNo ratings yet

- ISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringDocument6 pagesISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringibrahimNo ratings yet

- Sampling Procedure and Tables For InspectionDocument43 pagesSampling Procedure and Tables For InspectionAnonymous AoTZuNvxNo ratings yet

- Production of Rigid PU and PIR SlabstockDocument9 pagesProduction of Rigid PU and PIR Slabstockvitapur1No ratings yet

- Bridge Impact Testing: Standard Test Method ForDocument5 pagesBridge Impact Testing: Standard Test Method ForAlevj DbNo ratings yet

- Skip Waste06Document6 pagesSkip Waste06Moath M. KassabNo ratings yet

- ASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFDocument5 pagesASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFAndre Rodriguez SpirimNo ratings yet

- ASTM D6179-07 (2014) Standard Test Methods For Rough Handling of Unitized Loads and Large Shipping Cases and CratesDocument6 pagesASTM D6179-07 (2014) Standard Test Methods For Rough Handling of Unitized Loads and Large Shipping Cases and Crates陳明仁No ratings yet

- Charpy ASTM and ISO TestsDocument2 pagesCharpy ASTM and ISO TestsPrashant PuriNo ratings yet

- Testing StandardsDocument5 pagesTesting StandardsRitesh BijawatNo ratings yet

- D6477Document4 pagesD6477Luana PalmaNo ratings yet

- Iso 7854 en PDFDocument6 pagesIso 7854 en PDFSantosh ShettyNo ratings yet

- D 6207-97 Test Method For Dimensional Stability of Fabrics TDocument6 pagesD 6207-97 Test Method For Dimensional Stability of Fabrics TAnonymous UoRu4s0% (1)

- Astm D 4169Document11 pagesAstm D 4169Angus CHUNo ratings yet

- Test Report: Page: 1 of 4 Date: May 26, 2010Document4 pagesTest Report: Page: 1 of 4 Date: May 26, 2010rqfsiypisnvabmtusrNo ratings yet

- Iso 178 - 2001Document8 pagesIso 178 - 2001ANKUSHNo ratings yet

- Mil PRF 85285eDocument24 pagesMil PRF 85285emurphygtNo ratings yet

- 16 CFR 1500.44Document2 pages16 CFR 1500.44Milagros WieczorekNo ratings yet

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoNo ratings yet

- Astm D5199-01Document4 pagesAstm D5199-01thaiduyduc123No ratings yet

- 68 25 Haze Gard I PDFDocument6 pages68 25 Haze Gard I PDFshubhendra mishraaNo ratings yet

- D 333 - 96Document6 pagesD 333 - 96PoyoeberNo ratings yet

- En Standard SpecificationDocument33 pagesEn Standard SpecificationSimbu ArasanNo ratings yet

- SSPC PA 2 Measurement DFTDocument8 pagesSSPC PA 2 Measurement DFTBayu TirtaNo ratings yet

- Astm D1621-00Document4 pagesAstm D1621-00hegiro1974No ratings yet

- F 1319 - 94 R00 - RjezmtkDocument4 pagesF 1319 - 94 R00 - RjezmtkshamrajjNo ratings yet

- Tensile Stress-Strain of Carbon and Graphite: Standard Test Method ForDocument12 pagesTensile Stress-Strain of Carbon and Graphite: Standard Test Method Forsj19330No ratings yet

- F913 Gaskets For Joining Plastic PipeDocument5 pagesF913 Gaskets For Joining Plastic Pipelepm30No ratings yet

- Packing Standard PDFDocument9 pagesPacking Standard PDFMuthuswamyNo ratings yet

- ASTM D1990 - pdqv6897Document26 pagesASTM D1990 - pdqv6897Nayth Andres Galaz100% (1)

- ASTM C272 Water Absorption of Core Materials For Sandwich PDFDocument4 pagesASTM C272 Water Absorption of Core Materials For Sandwich PDFSílvio Xavier SantosNo ratings yet

- Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesDocument8 pagesBurst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining PlatesraulNo ratings yet

- D 5448 - D 5448M - 93 Rdu0ndgtotmDocument12 pagesD 5448 - D 5448M - 93 Rdu0ndgtotmJuanNo ratings yet

- Certification To Standards Relating To Equipment For Use inDocument6 pagesCertification To Standards Relating To Equipment For Use ingopinadh57No ratings yet

- International Standard: Plastics - Smoke Generation - Determination of Optical Density by A Single-Chamber TestDocument11 pagesInternational Standard: Plastics - Smoke Generation - Determination of Optical Density by A Single-Chamber TestAMITNo ratings yet

- ADS Corrugated Heavy Duty Pipe Data SheetDocument4 pagesADS Corrugated Heavy Duty Pipe Data Sheetiask5275No ratings yet

- Astm Volume 04 07Document10 pagesAstm Volume 04 07ANo ratings yet

- ASTM A123 and G90 Specifications - American Galvanizers AssociationDocument3 pagesASTM A123 and G90 Specifications - American Galvanizers AssociationwinarnobNo ratings yet

- D2990 01Document20 pagesD2990 01alifaramarzNo ratings yet

- ASTM E84 Flame Spread Report - 18586 - Final With MSDS PDFDocument18 pagesASTM E84 Flame Spread Report - 18586 - Final With MSDS PDFStephania HurtadoNo ratings yet

- GANA TD Roll Wave Measurement 04-03-26Document8 pagesGANA TD Roll Wave Measurement 04-03-26Cristopher John TolentinoNo ratings yet

- Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureDocument2 pagesLinear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureStevenf2002No ratings yet

- QCVN 25 2015-EnglishDocument9 pagesQCVN 25 2015-EnglishTommy NguyenNo ratings yet

- Composite Material Machining Guide Aerospace PDFDocument22 pagesComposite Material Machining Guide Aerospace PDFXu WeixingNo ratings yet

- 21a Pallet Load Testing To en Iso 8611 CompressDocument1 page21a Pallet Load Testing To en Iso 8611 CompresshamzaNo ratings yet

- Packaging Test RequirementDocument54 pagesPackaging Test Requirementjinmao100% (1)

- Pallet Racking GuideDocument33 pagesPallet Racking GuideAnonymous 1gbsuaafddNo ratings yet

- Toughness of Wood-Based Structural Panels: Standard Test Method ForDocument3 pagesToughness of Wood-Based Structural Panels: Standard Test Method ForRufo CascoNo ratings yet

- ISS - FirewallDocument10 pagesISS - FirewallgferantaNo ratings yet

- Manitou 1Document3 pagesManitou 1seb21yNo ratings yet

- David Leder ResumeDocument3 pagesDavid Leder Resumedavel77No ratings yet

- Beam Bending Tutorial in Abaqus CAEDocument5 pagesBeam Bending Tutorial in Abaqus CAEChristian Chinedu100% (1)

- North America Customer Loyalty Report 2022 by AntavoDocument23 pagesNorth America Customer Loyalty Report 2022 by AntavovilmaNo ratings yet

- Evaluating The Factors Influencing Online ShoppingDocument24 pagesEvaluating The Factors Influencing Online ShoppingAravindNo ratings yet

- Intelligent AgentsDocument18 pagesIntelligent Agentshiphuc91No ratings yet

- SSL Stripping Technique DHCP Snooping and ARP Spoofing InspectionDocument7 pagesSSL Stripping Technique DHCP Snooping and ARP Spoofing InspectionRMNo ratings yet

- Mbax Project Guidance 2022-23Document15 pagesMbax Project Guidance 2022-23Rajni KumariNo ratings yet

- Compiler Design Lab Manual: Malla Reddy College of Engineering & TechnologyDocument49 pagesCompiler Design Lab Manual: Malla Reddy College of Engineering & TechnologyKR KrishnaNo ratings yet

- Is3c 2020 Abstract 2.0Document1 pageIs3c 2020 Abstract 2.0Fathria Nurul FadillahNo ratings yet

- 1 N 5818Document6 pages1 N 5818Kattadinesh KumarNo ratings yet

- Print ShopDocument2 pagesPrint ShopAsrar Hussain BhatNo ratings yet

- World War Ii Fighter: AerodDocument7 pagesWorld War Ii Fighter: AerodPatrick Miceli100% (1)

- 7-3d-Pythagoras-And-Trigonometry (Dragged)Document7 pages7-3d-Pythagoras-And-Trigonometry (Dragged)Dmytro PalamarNo ratings yet

- Niraj ProjectDocument31 pagesNiraj ProjectNehul PatilNo ratings yet

- EKH UserGuide Inposer v13Document19 pagesEKH UserGuide Inposer v13D Cy4No ratings yet

- Product: 44432 Current Date (Do Not Change/delete)Document25 pagesProduct: 44432 Current Date (Do Not Change/delete)Joyce ShiNo ratings yet

- Copy Folder Log 03-15-2022Document5 pagesCopy Folder Log 03-15-2022Roman RomeroNo ratings yet

- Anam Ur RehmanDocument13 pagesAnam Ur RehmanANAMUR REHMANNo ratings yet

- 44 Recognizing Your Data Types: Structured and Unstructured DataDocument8 pages44 Recognizing Your Data Types: Structured and Unstructured DataManjush RangaswamyNo ratings yet

- Film Station UP-DF500: DICOM Conformance StatementDocument19 pagesFilm Station UP-DF500: DICOM Conformance StatementNelson AltuveNo ratings yet

- Lawsuit State, FDRLST, DW, Preliminary Injunction. Feb, 6, 2024Document51 pagesLawsuit State, FDRLST, DW, Preliminary Injunction. Feb, 6, 2024Gabe Kaminsky100% (1)

- Alexa - Top Sites in Cote D'ivoire - AlexaDocument11 pagesAlexa - Top Sites in Cote D'ivoire - AlexaIvan BosseyNo ratings yet

- Radio 2203 DatasheetDocument2 pagesRadio 2203 DatasheetHuỳnh Tấn Lợi100% (2)

- Shelf StockerDocument1 pageShelf StockerShirley AribeNo ratings yet

- Urimeter BrochureDocument2 pagesUrimeter BrochureawakkoNo ratings yet

- LogDocument7 pagesLogMatchaa WarshaNo ratings yet

- Electronics: Asynchronous Floating-Point Adders and Communication Protocols: A SurveyDocument23 pagesElectronics: Asynchronous Floating-Point Adders and Communication Protocols: A SurveyHappu SahabNo ratings yet

- Leading-Edge Technologies To Visualize 3D ImagesDocument2 pagesLeading-Edge Technologies To Visualize 3D ImagesCata LinNo ratings yet