Professional Documents

Culture Documents

PRINCIPLES OF ACCIDENT PREVENTION: After Understanding The

Uploaded by

wojak0 ratings0% found this document useful (0 votes)

83 views2 pagesOriginal Title

Accident Prevention

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

83 views2 pagesPRINCIPLES OF ACCIDENT PREVENTION: After Understanding The

Uploaded by

wojakCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Principles of Accident Prevention

PRINCIPLES OF ACCIDENT PREVENTION: After understanding the

causation of accidents, it is obviously essential to understand the

principles and techniques of accident prevention. But before that we

will see the types of accidents first.

Types of Accidents:

1. First Aid: Injured Person is fit to work after giving First Aid

Treatment

2. Minor or Non-Reportable: Injured Person is disabled for 48

hours or less after the Accident

3. Major or Reportable: Injured Person is disabled for more than

48 hours after the Accident

4. Fatal: Injured person dies after the Accident or as a consequence

of the Accident

5. Near miss: Incident occur without injury

6. Disaster: Incident where there is extensive loss of property &

/or life

Fundamentals of Accident Prevention: As explained by Heinrich,

accident prevention is both, science and art. It represents control of

performance of man, machine and physical environment

(Ventilation, Light and Storage).The word ‘control’ includes

prevention as well as correction of unsafe conditions and actions.

Prevention is the first or initial part of ‘control’ which if practiced,

subsequent control for consequence or effect may not be needed.

Thus accident control is a vital factor in every industry, which if

ignored or practiced unskillfully, leads to needless human suffering

and business bankruptcy.

The accident-prevention task requires both, the short term

approach (direct control of personal performance and environment)

and the long-term approach of instruction, training and education.

This task must be performed before an accident and injury occur.

Subsequent efforts after accidents are also necessary.

Thus accident prevention may be defined as an integrated

programme, a series of co-ordinated activities, directed to the control

of unsafe acts and unsafe conditions and based on knowledge, attitude

and ability for safety. It aims to serve industry, country and humanity.

Five basic or fundamental steps for accident prevention (safe and

efficient production), suggested by H.W. Heinrich, are;

1. Organization. (Policy & Safety Structure)

2. Fact finding. (Investigation)

3. Analysis of the facts found (for immediate cause & Root cause)

4. Selection of remedy and (Corrective & Preventive action)

5. Application of the remedy (Actual Implementation for closure)

Sixth step of ‘Monitoring’ (i.e. measurement o: result, assessment

i.e. comparison with legal criteria or standard, feedback and

further improvement) is also suggested. Such review is

necessary after all safety programs.

You might also like

- How to Survive a Terrorist Attack – Become Prepared for a Bomb Threat or Active Shooter Assault: Save Yourself and the Lives of Others - Learn How to Act Instantly, The Strategies and Procedures After the Incident, How to Help the Injured & Be Able to Provide First AidFrom EverandHow to Survive a Terrorist Attack – Become Prepared for a Bomb Threat or Active Shooter Assault: Save Yourself and the Lives of Others - Learn How to Act Instantly, The Strategies and Procedures After the Incident, How to Help the Injured & Be Able to Provide First AidNo ratings yet

- Principles of accident preventionDocument2 pagesPrinciples of accident preventionwojakNo ratings yet

- T-MEET 004 Basic OSH Module 1 Principle HSDocument23 pagesT-MEET 004 Basic OSH Module 1 Principle HSCarl Louise RostataNo ratings yet

- All Accidents InvestigatedDocument6 pagesAll Accidents InvestigatedtemterNo ratings yet

- Assignment #3 Safety EngineeringDocument7 pagesAssignment #3 Safety EngineeringEmilio Joaquin FloresNo ratings yet

- Chapter 5 (Accident Causation and Investigation)Document22 pagesChapter 5 (Accident Causation and Investigation)Anonymous 8NSojGNo ratings yet

- CH 1Document30 pagesCH 1bawanlavaNo ratings yet

- Rueda de NertneyDocument9 pagesRueda de NertneyEdgardo Ismael Ramos PumacahuaNo ratings yet

- CHT 4331 - Chap 3 - Risk ManagementDocument12 pagesCHT 4331 - Chap 3 - Risk ManagementKatleho MohonoNo ratings yet

- Osha OPIEDocument3 pagesOsha OPIEmaizansofiaNo ratings yet

- Unit - 4Document16 pagesUnit - 4402 ABHINAYA KEERTHINo ratings yet

- Definition Sho Module 1Document6 pagesDefinition Sho Module 1shah100% (1)

- The DuPont ModelDocument9 pagesThe DuPont ModelScribdTranslationsNo ratings yet

- The DuPont ModelDocument9 pagesThe DuPont ModelTanaka MurekachiroNo ratings yet

- Security Manual 2009Document31 pagesSecurity Manual 2009Liviu LiviuNo ratings yet

- Gulf Training Institute Safety Course Chapter on Developing an Effective Safety Management SystemDocument7 pagesGulf Training Institute Safety Course Chapter on Developing an Effective Safety Management SystemRavikant Pandey100% (2)

- JiaPei CaseStudyDocument11 pagesJiaPei CaseStudyDat NguyenNo ratings yet

- Hsg245 - Investigating Accident & IncidentsDocument89 pagesHsg245 - Investigating Accident & IncidentsJohn MaynardNo ratings yet

- Element 5Document5 pagesElement 5yasinNo ratings yet

- Risk Assessment: Julia WaygoodDocument30 pagesRisk Assessment: Julia WaygoodOana PNo ratings yet

- Functional Definition of SafetyDocument7 pagesFunctional Definition of Safetyjaved.saeed2024No ratings yet

- OSHA BookDocument40 pagesOSHA Bookvicky khanNo ratings yet

- HIRARCDocument2 pagesHIRARCasiahNo ratings yet

- A Health Care Worker's GuideDocument76 pagesA Health Care Worker's GuideJeniffer DanialNo ratings yet

- 10 QuestionsDocument4 pages10 QuestionsyasinNo ratings yet

- Accident ReportingDocument26 pagesAccident ReportinggerryfmarrNo ratings yet

- Individual Assignment Health and Safety ShepherdDocument27 pagesIndividual Assignment Health and Safety ShepherdShepherd NhangaNo ratings yet

- Accident Causation Theories and ConceptDocument4 pagesAccident Causation Theories and ConceptShayne Aira AnggongNo ratings yet

- Healt and Safety Assign3Document7 pagesHealt and Safety Assign3Suboh Victor NashNo ratings yet

- Quality Control in Occupational Safety and HealthDocument27 pagesQuality Control in Occupational Safety and HealthNecklal SoniNo ratings yet

- Principles of Accidents Prevention-DIS-1.6Document10 pagesPrinciples of Accidents Prevention-DIS-1.6parthaNo ratings yet

- Report workplace hazardsDocument8 pagesReport workplace hazardsKhey GambeNo ratings yet

- "Accident" As Defined by The National Safety Council: An Accident Is An Undesired EventDocument9 pages"Accident" As Defined by The National Safety Council: An Accident Is An Undesired EventCharlyn FloresNo ratings yet

- Describe How To Identify Injury, Illness or IncidentDocument5 pagesDescribe How To Identify Injury, Illness or IncidentGladys CaramoanNo ratings yet

- ISC 112 Chapter 1 and 2Document3 pagesISC 112 Chapter 1 and 2James WootenNo ratings yet

- HSE HSG 245 Investigation Accidents 2011Document89 pagesHSE HSG 245 Investigation Accidents 2011romedic36100% (1)

- CO2: Explain The Measurement and Monitoring TechniquesDocument41 pagesCO2: Explain The Measurement and Monitoring TechniquesSreejith S NairNo ratings yet

- Nebosh IGC Element 6 Principles of Control (Notes)Document6 pagesNebosh IGC Element 6 Principles of Control (Notes)kkalvi100% (26)

- 9.0. Safety ManagementDocument39 pages9.0. Safety ManagementPraz AarashNo ratings yet

- Industrial Safety FundamentalsDocument184 pagesIndustrial Safety FundamentalsAkash TiwariNo ratings yet

- Nebosh Award in Hs at Work SampleDocument0 pagesNebosh Award in Hs at Work SampleMuhammad SaeedNo ratings yet

- Accident Losses: Topic: Accidents, Losses and A Ccident TheoriesDocument30 pagesAccident Losses: Topic: Accidents, Losses and A Ccident TheoriesRamadan ZeitounNo ratings yet

- Accident Investigation HSG245Document4 pagesAccident Investigation HSG245Evren SenerNo ratings yet

- OHS ProceduresDocument34 pagesOHS ProceduresJyoti SharmaNo ratings yet

- Handouts BOSHDocument3 pagesHandouts BOSHMark Cristian CaraleNo ratings yet

- RISK ASSESSMENTSDocument5 pagesRISK ASSESSMENTSAz CorkerNo ratings yet

- Employee Safety Manual: (Enter Your Company Name)Document26 pagesEmployee Safety Manual: (Enter Your Company Name)AbdulSamadNo ratings yet

- IntroductionDocument47 pagesIntroductionarpna sjsNo ratings yet

- Notes IGC-I PortraitDocument38 pagesNotes IGC-I PortraitasanNo ratings yet

- Your health and safety at work controlling hazardsDocument5 pagesYour health and safety at work controlling hazardsTeodoro EsquilloNo ratings yet

- Hazards, risks, fire classes, PSM elementsDocument4 pagesHazards, risks, fire classes, PSM elementsSadia MujeebNo ratings yet

- Accident InvestigationDocument12 pagesAccident InvestigationanasNo ratings yet

- Unit 1 Introduction To OSHDocument24 pagesUnit 1 Introduction To OSHRaiza GuergioNo ratings yet

- Occupational Health and SafetyDocument7 pagesOccupational Health and Safetysubbu2raj3372No ratings yet

- ISE Mod 1Document29 pagesISE Mod 1Atul DrawsNo ratings yet

- Q& HseDocument26 pagesQ& HsebalajirajasekaranNo ratings yet

- CHE 534 Module 1Document37 pagesCHE 534 Module 1Precious JamesNo ratings yet

- Heinrich's Domino Model of Accident CausationDocument3 pagesHeinrich's Domino Model of Accident CausationwojakNo ratings yet

- Safety Committee: General Functions of The Safety Committee Can IncludeDocument3 pagesSafety Committee: General Functions of The Safety Committee Can IncludewojakNo ratings yet

- Accident Causation Models ExplainedDocument1 pageAccident Causation Models ExplainedwojakNo ratings yet

- Accident Causation Models ExplainedDocument1 pageAccident Causation Models ExplainedwojakNo ratings yet

- Accident Causation Models ExplainedDocument1 pageAccident Causation Models ExplainedwojakNo ratings yet

- Comparing signals with comparatorsDocument4 pagesComparing signals with comparatorswojakNo ratings yet

- Take Your Sports Passion to the Next Level with IISM's ProgramsDocument4 pagesTake Your Sports Passion to the Next Level with IISM's ProgramswojakNo ratings yet

- Accident Causation Models ExplainedDocument1 pageAccident Causation Models ExplainedwojakNo ratings yet

- Labview Experiment 2 Motor Speed Control Using Usb and Arduino DaqsDocument11 pagesLabview Experiment 2 Motor Speed Control Using Usb and Arduino DaqsTanNguyễnNo ratings yet

- PIDs Best Practices PDFDocument80 pagesPIDs Best Practices PDFmawooaNo ratings yet

- CHAPTER 60 SINGLE TRANSISTOR AMPLIFIERS - PPT DownloadDocument9 pagesCHAPTER 60 SINGLE TRANSISTOR AMPLIFIERS - PPT DownloadwojakNo ratings yet

- Compressed Gas Cylinder Training PresentationDocument33 pagesCompressed Gas Cylinder Training PresentationwojakNo ratings yet

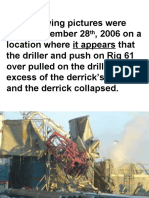

- 100 Rig CollapseDocument15 pages100 Rig CollapsewojakNo ratings yet

- IPAG Elementary School Mother Tongue BudgetDocument14 pagesIPAG Elementary School Mother Tongue BudgetRuby-Anne Joy Baltazar DiazNo ratings yet

- Ngoveni - Mlambya - HluviDocument6 pagesNgoveni - Mlambya - HluviMorris BilaNo ratings yet

- Konseling Tentang Kesehatan ReproduksiDocument2 pagesKonseling Tentang Kesehatan ReproduksiClarissa JulianaNo ratings yet

- HBO - End Term NotesDocument40 pagesHBO - End Term NotesAryan BokdeNo ratings yet

- Lesson Plan 1 Articles of ConfederationDocument5 pagesLesson Plan 1 Articles of Confederationapi-434731744No ratings yet

- (Re - Work) Google's Unconscious Bias at Work Workshop SlidesDocument41 pages(Re - Work) Google's Unconscious Bias at Work Workshop SlidesbouliouNo ratings yet

- Michael Irving Jensen - The Political Ideology of Hamas - A Grassroots Perspective (Library of Modern Middle East Studies) - I. B. Tauris (2009)Document217 pagesMichael Irving Jensen - The Political Ideology of Hamas - A Grassroots Perspective (Library of Modern Middle East Studies) - I. B. Tauris (2009)Andreea Toma100% (1)

- Economy Shipping Case AnswersDocument72 pagesEconomy Shipping Case Answersreduay67% (3)

- MGT301 - Assignment - GROUP ADocument31 pagesMGT301 - Assignment - GROUP ARahim HossainNo ratings yet

- Nutritional Value Functional Properties Industri Application of Fruit JuiceDocument11 pagesNutritional Value Functional Properties Industri Application of Fruit JuiceLSPRO LAMPUNGNo ratings yet

- Pelagio - Fs Module Lesson 2 6Document7 pagesPelagio - Fs Module Lesson 2 6api-613019400No ratings yet

- List of 400 English Synonyms & Antonyms - Practice To Beat Competition PDFDocument18 pagesList of 400 English Synonyms & Antonyms - Practice To Beat Competition PDFSaket SaxenaNo ratings yet

- Formal Vs Informal VocabDocument14 pagesFormal Vs Informal VocabLudmilaRaciula100% (1)

- Group 1 Math 100L Hqt2 HWDocument5 pagesGroup 1 Math 100L Hqt2 HWAmelie HernandezNo ratings yet

- Approach Paper: It-Enabled Financial InclusionDocument28 pagesApproach Paper: It-Enabled Financial InclusionAbdoul FerozeNo ratings yet

- Flying Creatures ZoologyDocument29 pagesFlying Creatures ZoologyJamie Parker SnufferNo ratings yet

- Hospital Sector Data Analysis: Price, Market Cap, Sales & Valuation RatiosDocument3 pagesHospital Sector Data Analysis: Price, Market Cap, Sales & Valuation RatiosYash SinghalNo ratings yet

- Schedule of SSB InterviewDocument5 pagesSchedule of SSB InterviewMayank AshokNo ratings yet

- Argumentative Essay - Sample 2 - Students Should Spend Less Time Listening To MusicDocument2 pagesArgumentative Essay - Sample 2 - Students Should Spend Less Time Listening To MusicRidhwan AfiffNo ratings yet

- A Literature Survey On The Accuracy of Software Effort Estimation ModelsDocument6 pagesA Literature Survey On The Accuracy of Software Effort Estimation Modelsutkarsh sharmaNo ratings yet

- Pasan Ko Ang DaigdigDocument1 pagePasan Ko Ang DaigdigJermaine Rae Arpia Dimayacyac0% (1)

- Summary Covers Exam MaterialDocument30 pagesSummary Covers Exam MaterialWriting ServiceNo ratings yet

- Literature Review 1Document10 pagesLiterature Review 1FahimAnwar100% (1)

- Long Call Vs Short Put: Presented byDocument9 pagesLong Call Vs Short Put: Presented bygovardhanNo ratings yet

- Central Luzon Doctors' Hospital Nursing Drug StudyDocument7 pagesCentral Luzon Doctors' Hospital Nursing Drug StudyJane BautistaNo ratings yet

- Yellow Cab LawsuitDocument38 pagesYellow Cab LawsuitMichael RobertsNo ratings yet

- Bully Kutta Price and DetailsDocument4 pagesBully Kutta Price and DetailsDr Dogs 4 UNo ratings yet

- Population and Responsible Parenthood ReportDocument15 pagesPopulation and Responsible Parenthood ReportJo Anne May BalnajaNo ratings yet

- Building Rapport 2Document13 pagesBuilding Rapport 2Kuldeep KumarNo ratings yet