Professional Documents

Culture Documents

PQR 15

PQR 15

Uploaded by

saktheeswaran0 ratings0% found this document useful (0 votes)

35 views9 pagesOriginal Title

PQR-15

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views9 pagesPQR 15

PQR 15

Uploaded by

saktheeswaranCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

®

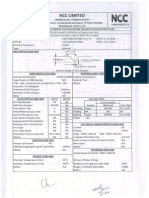

Format no: L&sT/KRNPP/MPCW/F-13]

LARSEN & TOUBRO LIMITED - HCI IC

NUCLEAR POWER CORPORATION OF INDIA LTD - KUDANKULAM

Construction of RB, RAB, TB, DGB and other safety related structures of KKNPP 3 & 4

[Company Name

Procedure Qualification Record (POR)

[Larsen tk Toubro Limited - HCI IC

Welding Procedure Specification No:

[ArT KKNPP/NPCW//WPS 015 ewe :0 [Date : 18/08/2017

Supporting POR Noto)

Last) KKNPP/MPCW/PQR O15, Rew.No 20 Date : 28/08/2007

|Weiding Process(es)

[SMAW [rvpets) [Manual

|Weld Category

[soines

[cost 5260-60 (825)

biota Bester

Double V groove

Backing

fees 7 No

Type of backing

eta Na,

Nom mevalie NA,

Non Fusing Metal NA,

locker NA,

lease meraLs

Group wo: =|

Teor

Specification Type & Grace

1S 2062 Gr BR E250

fro

Specification type & Grade

1S 2062 Gr BR Es

[chem Analysis and Mech. Prop.

NA

[chem Analysis and Mech. Prop,

NA

[HickWESS OF SAMPLE

[Base Metal

20mm Filer NA

pe Dia

NA Fillet, NA

fouer

FILLER METALS

Spec. No (ASME SEC ILC, SFA 5.1)

E7018

Size of Filer metals

25,4315

Weld meral Thickness

225 mm

[THICKNESS RANGE QUALIFIED

[croove & Diameter

Above 3 50 mm

Fier

a

[Consumable Insert

MA

Prepared by

Reviewed by ‘Approved by ‘Accepted by

[Company LAT QA

TET Qn Tat QA NPCIL, QA,

[Name Mic Prewin

W Balasubramanian Lee

BY

3 Viayaray

[Designation Engineer QA

Manager QA) 2.

[Signature

Date

2

z BPO 6)

Asstyhlanager On

Aticail

lot

Paze [of 5

Format no: KRNPP/MPCW/F-13]

‘®

LARSEN & TOUBRO LIMITED - HCIIC

NUCLEAR POWER CORPORATION OF INDIA LTD - KUDANKULAM

Construction of RB, RAB, TB, DGB and other safoty related structures of KKNFP 3 & 4

Procedure Qualification Record (QR)

[company Wame

Larsen & Toubro Limited - HCIIC

Wetaing Procedure Specification Nod ¥I/KKNPP/NPCW/WPS-015 [aovSov0 [Dates 18/08/3017

Sopporting POR Hoe La /AKWPR/MPCW/PQR-015 _[revsvi0 [Date 26/06/2017

frosrrions POST WELD HEAT TREATHENT

Fositonia of Gre [56 Femperatire Range [NA

reng Progression —[Uphi eating & Cooling Rate [NA

fostonsorrter a ans

PRE HEAT eae Gastes) Mixture | Flow Rate|

reheat Temp Nin [Rabient Temperire ieiing mA

larerpas empanar[¥A rating wa

reheat iaienanee [NA Backing wa

[ELECTRICAL CHARECTRASTICS

erene aC or BC De [Pear DoE

ps Rane) Bo-r10 [vos Range 2.28

fangsten excrode Se ant ype [NA

FreceNrQuE

Singer or Weave Bend Bringer oe Rot pase & Weaving for her pee

ontce o Gas Cup Sse a

nti and interpuss Cleaning Wire Bring

pietiod ef ack Gouging Ganaing

Osean Ra

conzac ube To Work ditance |v

tite or Sng averioe ie) [uli

psp or Sng Biro [Fleeing

rave Speed Range) 7-100 aT

Peening [sa

omer hex

Tavel

rier meats | Corent teed

Weld Layers | Process —— fom | owe | pines | others

case | (P| rope | Potty mm/min

Outside Weaing

Ror pass suaw [evo [2s [ve] er | 0008 | 2008 | sive

ot pase suaw | evoxs_| 25 | ve | er | 95-110] 28-39 | 50-82

pas SHAW | ~eroxe—[ ars | pea 5-07 [37 P 93-0

Fiat Pose suav—|—ero1e | sas] oe [—er [77-79 | -o3-25- [91-102

Final Foss 2 saw —|—eroie | 3.18 |-pe [gr [80-53 32-105

Inside Welding After Rack Gouging

oot pase sway [ero [28 | ve | ep | 870s | 2300 | aoa

suaw_|~ero1e | as | pe | er] a9-92 [27-31 | 91-100

i saw | e7oie | sas] pe | ep | 80-81 | 23-28 [90-102

Pint Pass 2 smaw [e701 | a.is [pe [er | 82-85 [22-27 [91-109

Fecpeedby| Reviewed by Aoprovedby Accepted bY

oman iat tat ar PCL @

rae Hien HR | Svar |W aanvbremanian | 27] p=

Designation Engreey OX —RepaMagaae Tanager G5 ia

signtare

Zales se

Page 2 oS

Format no: L&T KKNPD/MPCW]F-13]

LARSEN & TOUBRO LIMITED - HCI IC

t@

NUCLEAR POWER CORPORATION OF INDIA LTD - KUDANKULAM

Construction of RB, RAB, TB, DGB and other safety related stmctures of KKNPP 3 & 4

Procedure Qualification Record (PQR)

Company Rane Larsen & Toubro Limited - HOLIC

Welding Procedure Specification No | LAT/RKNPR/MPCW/WPS-O15 Revno-0 [bate 18/08/2017

Supporting POR Not. TAT /KNPP,/ MPOW/POR-OIS evo: 0 [Date 28/08/2017

frewsine TEST

ace [utate) ae | yp ane

seinen No ‘Thick with *, |rotat tonal stress Result

a ‘Rohieved | 7 Location

(Ka) | Requires | Achieve

(Mpa)

1 1934 aaa faraca| ana | ao | si Base | accepted

12 19.36 ase [areas] ae | a0 | sir Base | accepted

comED BEND TEST

“Type and Figure No Obeeration Revalt

Fea No open discontinuities observed Tovepted

782 No open diconlinitis observed Accepted

emMICAL ANALYEIS (eta)

Elements e a i P 3

wire 3.057 3.285 125 0035 0008

RERORT DETAILS"

1 DPT Report Ne Lasr/wor/D-18, pt 18/08/2017

a er repore No ¥ML19921/9/17-18 De-28 Aug 2017

5 ur Report No ‘ML13921/3/17-18 De-28 Aug 2017

Js) Tene, Bend. Chemical &etmpact ext eport No: ML/19921/3/17-18 Dt-28 Aug 2017

51 Macro Test Report No ML13921/3/17-18 De-28 Au 2017

+ at above reports are enclosed

sare ta wor/sMaw/s8/180817

Werier's Name sisson

rest Conducted by L&T OA Drewin MK Date: 18/08/2017

Test Witnessed by NPCIL Qa urn A

We certify thatthe statements inthis record are correct and that the test welds were prepared

sslded and tested in accordance with requriements of GOST 6996-66 standard and PNAE-O-7-10-89

company iat Tat iat NCI QA

ame Mi Prewn SVinvaral NBabsubramanian SVR

Designation | Oc Syeneer TastManager QR Manager Qa weg

[Signature = py hea Noe

Date ie ae EP\alcaie 2a fos lz —

Page or

IK microns

ANISSD/EC 705 METALLUNGIAL SECES

‘Accredited by NABL Dep. of Scence & Technology, Govt. of India.

SP 101, 2 Main Road, Ambattr Industral Estate, Chenna ~ 600058.

Phone: 044 2624 2525, Fax: 044 2624 4872. STTA LT-STIB:

Email: ere@microlabchennai.com, web: wiv. microfabchennai.com

TEST REPORT

Customer ReportNo/ Date__| ML/13921/9/17-18 DL-28 Aug 2017

Mis.Larsen & Toubro Limited (KKNPP) ‘Your ref/ Date Rel LTKKNPP 34/M/TPT/28 Dt-19 Aug 2017

Heavy Civil Infrastructure, KKNPP-384,

Kudankulam-PO, Rachapuram Taluk, Tirunelveli Dist, | Ou ret! Date TOOR :13021/17-18 Ot: 22 Aug 2017

Tamilnadu - 627 106 Date of Testing | 22 Aug 2017 - 28 Aug 2017

Sample Drawn By _| Customer

‘Sample Description | Procedure Qualification Test Specimen

ID: WOT/SMAW/JB/180817

Plate Size: 20mm Thick X 300mm X 300m

‘Material IS 2062 €250 Grade BR to 1S 2062

250 Grate BR

WPS No: LATIKKNPPIMPCWAYPS-15

Position: 36.

Signed by L&T (QA) and Stamped by NPCIL

(aa)

iy: 1No,

1 | Chemical Analysis (Fe) (Weld)

‘Test Parameters ‘Observation

Carbon (C) (%) 0.097

Silicon (Si) (%) 0.286

Manganese (Mn) (2) 1.25

Phosphorus (P) (2%) 0.025

‘Sulphur (S) (%) 0.002

Chromium (Cr) (6) 0.028

Molybdenum (Mo) (%) 0.007

Nickel (Ni) (%) 0.010

‘Aluminium (Ai) (%) 0.00

Cobalt (Co) (%) 0.008

‘Copper (Cu) (2) 0.009

Nobium (Nb) (2%) 0.022

Thanium (7) (%) ots

Vanadium (V) (9) 0.006

Carbon Equivalent (CE) (2% ots

2 | Radiography Test” PNAE-G-07-10-88

‘Test Conditions Value

FFOISFD 20 Inches

JK wicrovae

‘/S0/EC 17095 METALLURGICAL SERVICES

Accredited by NABL, Dept. of Science & Technology, Govt. of India,

5P 101, 2 Main Road, Ambattur Industria Estate, Chennai ~ 600 058. oe

Phone: 044 2624 2525, Fax: 044 2624 4872, aera ore

Email: cre@microlabchennal.com, web: www.microlabchennal.com

NLI1392 19/17-18 04-28 Aug 2017.

Source ir 92

strength 0c:

Tectnique swsi

Leod Sereens 041mm, 0.15mm

Fim AGFAOT

Thickness 20mm

Density 24

ra 612

Sersitvty 025mm

Parameters ‘Observation

Observation (68) No Signifleant Defect

Remarks : Accoptable. As por Sexion 117 of PNAE-G-07-10:69

3 | Uttrasonie Test PNAE-G.07-140-69

‘est Parameters ‘Observation

Observation No Recorcabe indication Observed

Remarks : Accopable. As por Section 118 of PNAE-G-07. 10-69

4 | transverse Tensile Test_(T1) (G0ST-6996-66*

Test Conditions Value

Gauge Wiatn (ram) 2449

Gauge Thickness (mm) 1934

Cross Sectional Area _(mm2) 47364

Test Parameters ‘Observation

Utimate Tensile Load. (kN) 243.20

Tensile Svengin (Nim? or Mpa) 513.00

Fracture Appearance Ductile

Fracture Location ase

Remarks : The above Tensile values Acceptable as per PNAE 6-07-1069 Clause 11.103

5 | transverse Tensile Test (12) GOST-6996-66'

Test Conditions Value

Gauge Wieth_ (rm) 24.00

Gauge Thickness (mm) 10.36

Cross Sectional Aroa_(nim2) 47626

‘Test Parameters Observation

Utimate Tensile Load (kN) 246,00

JE icrotas

Ws f'S0/EC 17005 METALLURGICAL SERVICES

Accredited by NABL, Dept. of Science & Technology, Govt. of india

SP 101, 2% Main Road, Ambattur Industrial Estate, Chennai ~ 600 058

Phone: 044 2624 2525, Fax: 044 2624 4872.

Email cre@mierolabchennai.com, web: www. mierolabchennai.com

NL/19921/9/17-18 D128 Aug 2017

Tensile Sength (Nimm2 or Mpa) 517.00

Fracture Appearance Ductile

Fracture Location Base

Remarks : The above Tensile values Acceptable - as per PNAE G-07-10-89 Clause 1110.3

6 | Transverse Bend Test (Face/Root) GOST-6996-66*

‘Test Conditions Value

‘Specimen Dimension (mm) 300%40,00x20.00

Mandrel Dia (mm) 40.00

Angle of bend (Degree) 180

Parameters ‘Observation

Observation

‘Sample 1D-FB 1} No openings or discontinuities observed on Bend Area

Including Weld & HAZ

Sample 1D-F8 {2} No openings or ciscontinuities observed on Bend Aree

Including Weld & HAZ

Remarks : Bend Test Found Satisfactory

7 | charpy impact Test (88) GOST 6996-86

‘Test Conditions Value

Specimen size (mm) 10x10355

Notch Type v

Test temperature _(Degree Celcius) Roam Temperature (24)

‘Tost Parameters Observation

Location Wea

Absorbed Energy Semple 1 (Joules) 160

Absorbed Energy - Sample 2 (Joules) 178

Absorbed Energy Sample 3. (Joules) 174

‘Average Value (Joules) 170.00

8 | charpy impact Test (88) GOST 6996-86

‘Test Conditions Value

Specimen size (mm) 10x10%55

Notch Type v

Test temperature _(Degree Celcius) Roon Temperature (24)

‘Tost Parameters Observation

Locaton Haz

Formato Mus 2040/0

areas

IK microuas

roves MEARE sms

Accredited by NABL, Dept. of Stience & Technology, Govt. of India,

SP 101, 2° Main Road, Ambattur Industrial Estate, Chennai ~ 600 058.

Phone: 044 2624 2525, Fax; 044 2624 4872.

Email: ere@microlabchennai.com, web: www.microlabchennai.com

10774 / T0775

MU1302169/17-18 D&-28 Aug 2017

‘Test temperature _(Dearee Ceicius)

‘Absorbed Energy - Sample 1 (Joules) 54

‘Absorbed Energy - Sample 2 (Joules) 54

‘Absorbed Energy - Sample 3 (Joules) 76

‘Average Value (Joules) 61.33

9 | charpy impact Test (BS) GOST 6996-66"

Test Conditions Value

Specimen size (mm) 40x10%55

Noten Type v

Room Temperature (24)

‘Test Parameters Observation

Location Base

Absorbed Energy - Sample 1 (Joules) 40

‘Absorbed Energy - Sample 2 (Joules) 56

‘Absorbed Energy - Sample 3. (Joules)

‘Average Value (Joules) 50.00

10 | Macro Examination (W) PNAE- G-07-10-89

Test Conditions Value

MagiEtchant '5x/10% Ammonium per sulphate

‘Test Parameters Observation

(Observation Macro examination of ie specimen did not reveal any crack

or otter deeds, Observed complete wot fusion nal

Photo ‘The Macro Photograph is exhibited in Annoxuro-A.

Remarks : Sample id: M1 (Acceptabla-Maots the customer specication of PNAE. G.07-10-80

14 | Macro Examination (W) PNAE- G-07-10-89

Test Conditions Value

|__Magiétcnant '5x/10% Ammonium per sulphate

‘Test Parameters Observation

Observation Macro examination of tne specimen did not reveal any crack

or other deeds, Observed compete wot fusion al

Photo ‘The Macro Photograph is exhibited in Annexure-A.

Remarks : Sample id: M2 (Acceptable-Meets the customer specification of PNAE- G-07-10-89),

aie

ii

y

JK icrovas

An p80) 17025 METAMUACIEN scees

Accreited by NABL, Dept. of Science & Technology, Govt of India.

SP 101, 2" Main Road, ambattur Industrial Estate, Chena 60008

Phone: 044 2624 2525, Fax: 044 2628 4872

Emit: cre@microlachennai.com, web: wora.mirolabchennai.com

1-074 / 7.0775

ML/19921/3117-18 01-28 Aug 2017

Verified By

For MICROLAB

End of the test report

SRBalasubramaniam, ME., (Met. Engg)

‘Authorized Signatory

Ferme nem 340702

“sini

pnt

te MIcROLAB

snore as auc sents

‘ecedted by HAS Dept of Slence& Technolgy, Goto hla

‘SP 101, 2 Main Road, Ambattur Industrial Estate, Chennai ~ 600 058,

Phone O48 2528 2525, Fx O44 26244872 oe

Email: cre@microlabchennai.com, web: www.microlabchennai.com 10774 {T-0775,

Page Lof 1

ANINEXURE ~ A

Supplement to the test Report No: ML/13921/3/17-18 / Dt: 28.08.2017

Macro Photographs

wz

For MICROLAS

S.RBalasubramaniam, M.E., (Met. Engg)

Authorized Signatory

Test Uertncnr Chedye pVonted

Found Satisizctory to Yho ted

‘ot sep ees ony teatime smite Ancarecnin ep wl

cap Sipe ested ater 1S

{ry romte tao conten es as ir teeter ky comps sb hs ep shud ae

rep er erat

Fat no: 20780/7001

vers neon USING Bs pena deste te atone Kamae ted. MDE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Approved Wps & PQR Ss To CsDocument6 pagesApproved Wps & PQR Ss To Cssaktheeswaran100% (4)

- Ss DuplexDocument4 pagesSs Duplexsaktheeswaran100% (3)

- PQR 17Document7 pagesPQR 17saktheeswaranNo ratings yet

- Approved WPS& PQR For P91Document8 pagesApproved WPS& PQR For P91saktheeswaran100% (3)

- Approved 316-L WPSDocument12 pagesApproved 316-L WPSsaktheeswaran100% (1)

- Approved WPS&PQR q345Document6 pagesApproved WPS&PQR q345saktheeswaranNo ratings yet