Professional Documents

Culture Documents

PQR 17

PQR 17

Uploaded by

saktheeswaran0 ratings0% found this document useful (0 votes)

41 views7 pagesOriginal Title

PQR-17

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views7 pagesPQR 17

PQR 17

Uploaded by

saktheeswaranCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

S

Format nor

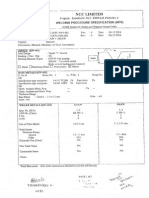

LARSEN & TOUBRO LIMITED - HCI IC

NUCLEAR POWER CORPORATION OF INDIA LTD - KUDANKULAM

Construction of RB, RAB, TB, DGB and other safety related structures of KKNPP 3 & 4

Procedure Qualification record (POR)

LRT /RRNPP/MPCW/F-13|

[Company Name

[Larsen & Toubro Limited - HCLIC

lwelding Procedure Specification No

LAAT/ KENPP/MPOW/WPS-17

[Rev.No: 0 DATE:15.11.2017

[Supporting POR No(s).

[List KRNPP/MPCW/PQR-I7

fRev.No:0 [DATE:16.02.2018

Welding Proc

[SMaW Frome

‘Manual

Weta Category

o

points

lost 5264-80 (817)

[Tone Design

[pure Joint

faacking

[yes 7 No

[Type of backing

erat NA

NA

A

Non metallic

[Non Fusing Metal

other NA

[BASE METALS

[Group No: -

106

[Specification Type & Grade

182062 6250 GrOR

Specification Type & Grade

ASTM SA 240 G21

[Chem.Analvsis and Mech. Prop.

NA.

[Chem Analysis and Mech. Prop,

NA

[THICKNESS OF SAMPLE,

[Base Metal

10mm

illet

Pipe Dia Range

lother

[FILLER METALS

[Spee. No (ASME SEC 1-0)

E3091

Size of Filler metals

2.5mm, 3.151

Weld metal Thickness

lSmm

[THICKNESS RANGE QUALIFIED

laroove

‘Above 9-10 mm

tet

All fillet sizes

[Consumable insert

NA

Prepared by.

Reviewed by Approved by

Accepted by

jcompany

LUT QA L&T QA

NPCIL A.

Name G.

S.VWAYARAS —_ [N.GALASUBRAMANIAN,

SS Ravinmngil

Designation ASST. MANAGER QA

ASST.-MANAGER OA HEAD 03,

TOD. QA

[signature |

N.

oh

Date

oxhe T

Dalek

Jexji¥

Page 1 ofS

° Format no: L&T KKNPP/MPCW/

@® LARSEN & TOUBRO LIMITED = HCIIC

NUCLEAR POWER CORPORATION OF INDIA LTD - KUDANKULAM

Construction of RB, RAB, TB, DGB and other safety related structures of KKNPP 3 & 4

Procedure Qualification record (PQR)

[Company Name Larsen & Toubro Umited- Herc

Weiding Procedure Specification No LPP PCW /WPS-17 RovNos 0 [Dues 16.12007

Supporting POR Note LAT /RENPP /MPCW/POR 17 fRevito= 0 [Date 16022018

Posmions [POST WELD HEAT TREATATENT

Postion(a of Groowe [SG Temperature Range i

Welding Progression [UPHIET Heating & Coling Rae [NA

Positions of Fer [NA cas

PRE HEAT Compose! | Gates) | Purig%| mixure | Flow Rate

Pechcas Temp Min [Anion Temperaare Sheltng WA

ncerpass temp ax [NA rain WA

Peat aincenance [NA Backing WA

ELECTRICAL CHARECTRASTICS

current AC or DC Be Polar DoeP

JAmps (Range) Ea 65-110 Volts Range 24-31

Hrungsten eeerode Sze and Tipe na

lrecrMouE:

Stringer or Weave Bead [Suing for Root pase & Weaving for farther pases

orice oF Gas Cup Sie a

rail and icerpass Cleaning Wire Brushing

ethod of Back Cousin Na

Oseiation Na

[Contac ube we Work aitance NA

Null o Single lyertper side) mutate

Muluple or Single lectrodes / Fier single

Hravel Speed Range) 67-99 mm/min

Peering ra

other NA

Travel

ier Met ern pie

Weld Layers Process “me ee) aoe | ats Latkes | omen

ase | om | Pope] Poarey ‘mm/min

Root pass SwAw waoot_| a8 | be | ee | e560 | o406| 67

ot pase SMAW wav | as | pe | ep | 67-60 | 24-26] 67

Fut pase (i SMAW Fao | ais | ve | ee | 71-78 | 24-28 | 74

Fa ass (2) MAW Boos | 3.18 | pe | ep | 80-84 | 26-00] 77

Pinal pase SMAW Baoan | as | pe | ep | ss-99 | 28-01 | 99

Final pase SAW zoos | 3.18 | pc | ep | 92-110 | 28-31 | 94

Prepared by Reviewed by “Approved by Tecepted by

company lar Qa tar oa lat 08 NPCIL QA

ame CSARTHEESWARAN | —SVUAYARAT NBALASUBRAMANTAT Si Kaviongl

Designation ASST.MANAGER QA | ASSTYMANAGER OA HEAD OA TS 1D QA

Signature a ee

Date spatial Bojer [ir

Page 203

Format no: LAT/RRNPP/MPCW]F-13]

@

LARSEN & TOUBRO LIMITED - HCIIC

NUCLEAR POWER CORPORATION OF INDIA LTD - KUDANKULAM

Construction of RB, RAB, TB, DGB and other safety related structur

Of KKNPP 3 & 4

Procedure Qualification Record (PQR)

[company Name

Larsen & Toubro Limited - HCL IC

Welding Procedure Specification No | LAT/KKNPP/MPCW/WS-17 frev.no 0 [ate 18.11.2017

supporting POR oleh Lacr/wKNPR/ PCW) AQR-I7 evo: [Dates 1.022008

rensite rest

Uitimate

vitimats wait) “unit | Type of

opecines Thiet recive] See, | Fale / | Revue

(oP

Tr 981mm 49a [Base | Accepted

12 976m sor [Base | Accept

[GUIDED BEND TEST

“Type and Figure No Observation Rerult

Faq) No Openings And Discontnuities Observed Accepted

Fa (ai ‘No Openings And Discntinuities Obsered Aceeped

criicaL ANALYSIS

Bienenis € P 3

wee 0.08 0% aoe

IREPORT DETAILS*

1) Radiography test report No Lat/KNPP/MPCW/FQR/RT-O39 Date: 03.02.18

Der Repor No: LAT/SKNPR/MPCW/FQR/DPT-062 Date : 05.02.18

Jo) ur Report:

ls) tense, Biches, pace test report No ML/91797/1/17-18 Dave 14.02.18,

+ ait above reports are enclose.

Samp 1: SMAW\POR\AM\950218

veers Name : ADIMULAN

FOR Tes Conducted by

‘We certify hat the statements in this ecod ae correct and thatthe test welds were prepare,

welded and tested in accordance with requsements of GOST 6996.69 standard and PNAE-C-7-10-89,

Prepared by ‘Approved by Accepted by

company ust ga LT QA NPCIL A

ame ‘O.SAKTHEESWARAN N.BALASUBRAMANIAN S Kavionngl

Pesignatio ASSTIMANACEROA | _ASSRMANAGER OA HEAD Qa TS Oa

signature

pate a fie 2Siea]F

Fo

Format Nos LAT RRNDR/ POW /F-TO

HOGI "HY TEST REPORT [WP No :L&T/KKNPP/MPCW/WP-41

Projeet:Kudankulam Nuclesr power Project 384 — Main Pant Chil Works [ReportNo LAT] RAID | gouge]

[lient = Ns Nuclear Power Corporation indi La Date: 03-93- 20/8

[Contractor : Larsen & Toubro Limited -HCLIC [Type of Report: > rmywrtt™

raving Ro we

ya category? [I

1. KS Code iis 7. Unit Bx4

}2.Bquipment/System Category —-NK- 8. Material ' aa

Location Room No. 1 Fb Shep 9 Thickness : [Crm

a sure conden As wach dae] 10. Diameter © PRE Coo0 nn

5-Temperature bo Amiga jet 11. Weld Category vr

6. Acceptance Criteria + PNNEL-oF-e1e- 8g

Technique Deseriton ‘Equipmest and Material

Exposure Technique: SSI pwst_—DwD1_JRadiation Source se

QU type & Location: DIN \o IO 16 y eS Source Strength 90 ky

vo?

Fim Size @ Grade: ASKS" Q nescR cs 4 [Source Size P29 %200 mwa

Fit Density: as 2.9 itm Processing Wasco eh

sro: 6650 nine

aint Result

S.No} HemNo, Welder} IP" Isegment —_finterpretation Ls ear Remark

A |smMawlpaey |- | - | a-w | nse Ace | Ab | 200%10 me

Am [030218

CR-Crack, P-Porsity, CP- Cluster Porosity, I-Incomplete Fusion, IP-Incomplete Penetration, SI-Slag Inclusion, TI- Tungsten Inclusion,

JUC- Undercut, CON-Concavity, EP. Excess Penetration, S#D-Source to Film Distance, 1QI- Image Quality Indiator, SWSI- Single Wall

single Image, DWSI- Double Wall Single Image, DWDI- Double Wall Double Image

Name of the NDT o K Rondel

aie

ot

hs eet Se aon te wd

nr teenican pie vA wronlg rd

DRE EERE TRANE TEST RerOne [WP No: [CT JKKNPP/MPCWWP.39,

ct Rania Wacenr Power Project J CT RP OTE TCT

[elent Hs Rucear Peer Corporation of india Ie ‘ ?

[Contractor : Larsen & Toubro Limite ae

Larson & Toubro Limited -HCIIC feo: | eovnnen

Drawing No

1. kxs cope wet unit pas

|2.Equipment/System category au ‘7.Dwell Time sum

I tocaon/ Room No CxK ARe 8. devebping tine: S-Rary,

surface Condition Ae weortedh 9. Weld Category

5.remperacure Arwrciewe 10. QA Category =

Nake/brana Bach Ne Date of Nanafactare Date of pin

tana Mn Gree 211 36% Aue.ia

Penetrant Non Cn < Ney. SSu.1a

peeve lWrocnath Gry soo] Va wes oa A

Result

Is. vo tem No Joint No, | Obserstion Remark

‘ecepted | Repair

0 eae = Nex | AL Ni =

Awa: ais [Ca

iE alll. e

NDT Technician Laren NPCIL-QA

basi Some ec Ss Kasinnisel

Designavon Suen =| D

— ae “ob

bate SB/sals e3/e2fIt

3k microtas

ANIS)SO/E ERs METALURGALSEAVCES

Accredited by NABL, Dept. of Science & Technology, Govt of India.

SP 101, 2" Main Road, Ambattur Industrial Estate, Chennai ~- 690056.

Phone: 04a 2624 2525, Fax: 086 2624 4872

Email cre@microlabchennai.com, web: www mieraolabehenna com

TC-6815

TEST REPORT

Customer Report No/ Date | MU/31707/1/17-18 DLt4 Feb 2018

Mis.Larson & Toubro Limited (KKNPP) YourretDate__| Ref: TIKKNPP 34IM/TPTI43 DLO6 Feb 2018

il infastcture, :

‘Terriicndda - G27 106 Date of Testing 10 Feb 2018 - 14 Feb 2018

Sample Orawn By _| Customer

Sample Description | Procure Guatonon Tet Specimen

1D PoRsvAWnwoseate

Pale Size: fon YX X 0mm X tm

Natoat 1 200 2200 rae SR ASTIN SA20

Grado 22

Wis No LaTHGPPRIPCHINS-17

pastor 36 f

‘Signed by L&T (QA) and 2

Sunoed by NPIL ION) ome

ayo "yr

+ | chemical Analysis (Fe) ASTM E1086-2014

‘Test Parameters: Observation

Carbon (C) (%) 0.040

Silicon (Si) (%) 0.964

Manganese (Mn) (%) 1.26

Phosphorus (P) (%) 0.032

‘Sulphur (S) (%) be 0.014

Chromium (Cr) (%) “ 20.73,

Molyadenum (Mo) (6) 0.404

Nickel (N)(%) 175

Copper (Cu) (%) 0.089

Titanium (Ti) _(%) 0.011

2 | Transverse Tensile Test_(T1) Gost 6996-66

Test Conditions Value

Gage Wrath (nm) 19.59

Gauge Thickness (vm) 96a

Cross Sectional Area_(mm2) 192.57,

‘Tost Parametors Observation

Ultimate Tensile Load (kN) 94.85

Tense Strength. (Nimm2 or Mpa) 493.00

ema eS 3080/2

Page 1 of2

> microLas

Accredited by NABL Dept. of SCence& Technology, Govt. of

‘SP 101, 2" Main Road, Ambattur Industrial Estate, Chennai ~ 600 058.

Pane 8a 26242825 Fox: O44 26244872 a

Email ce@micolabchenal.com, web: wsicracabchencom Tc- 6815

MU31797/1/17-18 Dt14 Feb 2018

Fracture Appearance Ductile

Fracture Location Base (Gr E2508R)

3 The above Tensile values Acceptable - as per PNAE G-07-10-89 Clause 11.103,

3 | Transverse Tensile Test _(T2) Gost 6996-66

Test Conditions: Value

Gauge Width (mm) 19.63

Gauge Thickness (mm) 9.76

Cross Sectional Area_(mm2) 191.59

‘Test Parameters Observation

Uimate Tensile Load (KN) 95.90

Tensile Strength (Nimm2 or Mpa) 501.00

Fracture Appearance Ductile

Fracture Location Base (Gr E250BR)

Remarks : Tho above Tensile values Acceptable - as per PNAE G-07-10-89 Clause 11.10.3

4 | Transverse Bend Test (Face/Root) Gost 6996-66

‘Test Conditions Value

Specimen Dimension (mm) 300x30,00x10.00

Mandrel Dia (mm) 20.00

Angle of bend_(Degree) 180

‘Test Parameters ‘Observation

Observation

Sample ID-FB (1], No openings or discontinuities observed on Bend Area

Including Weld & HAZ

Sample ID-FB (2} No openings or discontinuities observed on Bend Area

Including Weld & HAZ

Remarks : Bend Test Found Satisfactory

Verified By

End of the test report

S.R Balasubramaniam, ME., (Met. Engg)

‘Authorized Signatory

ep ites ry oh pr ee ited ret A coatan nthe mgr lina therapeu wi cod ae 36

Foxmat Ne: M/S 1YABIR/OL Page 20f2

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Approved WPS& PQR For P91Document8 pagesApproved WPS& PQR For P91saktheeswaran100% (3)

- PQR 15Document9 pagesPQR 15saktheeswaranNo ratings yet

- Approved Wps & PQR Ss To CsDocument6 pagesApproved Wps & PQR Ss To Cssaktheeswaran100% (4)

- Approved 316-L WPSDocument12 pagesApproved 316-L WPSsaktheeswaran100% (1)

- Approved WPS&PQR q345Document6 pagesApproved WPS&PQR q345saktheeswaranNo ratings yet

- Ss DuplexDocument4 pagesSs Duplexsaktheeswaran100% (3)