Professional Documents

Culture Documents

Effect of The Concentrations of Maltogenic A-Amyla

Uploaded by

Stephen WillingtonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of The Concentrations of Maltogenic A-Amyla

Uploaded by

Stephen WillingtonCopyright:

Available Formats

a

ISSN 0101-2061 Food Science and Technology

DDOI: http://dx.doi.org/10.1590/1678-457X.6452

Effect of the concentrations of maltogenic α-amylase and fat on the

technological and sensory quality of cakes

Noelia Soledad Bedoya-Perales1*, Caroline Joy Steel1

Abstract

The characteristics that define cake quality can be improved by the use of adequate ingredients and a correct balance of the

formulation. Fat is used for its effect on softness and because it imparts flavor and calories. Enzymes such as maltogenic

a-amylase can also have a positive effect on cake texture during storage by decreasing amylopectin re-crystallization and thus

delaying starch retrogradation providing longer-lasting crumb softness. The objective of this study was to determine the effect

of different concentrations of maltogenic α-amylase and fat on the technological and sensory characteristics of cakes. Therefore,

balanced formulations with three different fat concentrations (20, 40, and 60 g/100 g, based on the flour content) were used to

evaluate the addition of maltogenic α-amylase (0, 500, and 1000 mg/kg). Technological quality determinations were carried

out on days 1, 7, 14, and 21 of storage. The best results in terms of cake quality (greater specific volume, higher crumb moisture

content, lower crumb firmness, and greater sensory acceptance) were obtained with the combination of 20 g/100 g fat and

1000 mg/kg maltogenic α-amylase (based on the flour content), which proved to be an alternative to reduce the fat levels in

the elaboration of this type of product.

Keywords: formulation balancing; cake quality; crumb firmness; retrogradation.

1 Introduction

In cake making, the formulation and balance of the (Ronda et al., 2009). Enzymes, in general, are widely used in

ingredients are fundamental to ensure quality of the final bakery products because they improve volume, flavor, aroma,

product, and they can be evaluated by determining parameters softness, crumb structure, and increase shelf life (Lagrain et al.,

such as volume, texture, moisture, and crumb structure among 2008; Guy & Sahi, 2006), but little is known about their effects

others (Sahin, 2008). Each ingredient has a specific function on cakes. Maltogenic α-amylase is used in baking to allow for

(Wilderjans et al., 2008; Indrani & Rao, 2008) and can be extensive hydrolysis of crystallizable amylopectin, preventing

grouped as follows: (i) those that provide strength and structure its recrystallization (retrogradation) during storage. This allows

to the cake, such as flour and eggs; (ii) those that open the for conservation of the soft crumb characteristics, prolonging

structure such as sugar, fat, and baking powder; and (iii) those the shelf life (Goesaert et al., 2009a).

that close the structure and reduce lightness, such as milk and

Considering the facts exposed, the objective of this study

water (the liquids). It is essential to use a formulation that has

was to determine the effect of different concentrations of

an adequate balance between ingredients that open the structure maltogenic α-amylase and fat on the technological (specific

and those that close it (Bennion & Bamford, 1997). volume, moisture content, and instrumental texture) and

In general, formulations that are rich in fat and sugar are sensory characteristics of cakes using balanced pound cake

soft, but an excess of these ingredients can cause the products formulations.

to crumble easily (Esteller et al., 2004). On the other hand, total

removal of fat can change flavor, texture, lightness, softness, 2 Material and methods

shape, and volume of cakes (Khalil, 1998; Sakiyan et al., 2004).

2.1 Materials

According to the amount of fat added, cakes can be divided

The wheat flour used had the following characteristics:

into two categories: cakes with high fat levels (pound cake) and

12.40% moisture content, 9.52% proteins, 1.28% lipids, 0.57%

those with low fat levels (chiffon or sponge cakes) (Sahi, 2008).

ash, and 76.23% total carbohydrates (Bunge Alimentos S.A.,

Regardless of the type of cake, in order to develop Poço Grande, SC, Brazil). The fat used was TRI HS-LT low

formulations that ensure products with desirable quality, trans vegetable fat, specific for cakes (Triângulo Alimentos,

additives such as emulsifiers and hydrocolloids can be included Itápolis, SP, Brazil), and the enzyme was Spring Cake line

(Indrani & Rao, 2008). However, enzymes are an interesting maltogenic α-amylase (Granotec do Brasil S/A, Curitiba,

alternative to chemical additives since they are considered PR, Brazil), consisting of a purified maltogenic α-amylase

a food processing aid and are generally recognized as safe from Bacillus stearothermophilus, produced by submerged

(GRAS), not remaining active in the product after baking fermentation of the microorganism Bacillus subtilis (minimum

Received 06 Aug., 2014

Accepted 01 Oct., 2014 (006452)

1

Department of Food Technology, School of Food Engineering, University of Campinas – UNICAMP, Campinas, SP, Brazil

*Corresponding author: noelia.bedoya@gmail.com

760 Food Sci. Technol, Campinas, 34(4): 760-766, Oct.-Dec. 2014

Bedoya-Perales; Steel

maltogenic α-amylase activity: 48,000 UAMG/g). The remaining (Hyppolito Ltda., Ferraz de Vasconcelos, Brazil) was used, and

ingredients used to make the cakes are shown in Table 1. the cakes were baked in an Ipanema IP4/80 oven (Haas Technik

do Brasil Ltda., Curitiba, Brazil). After cooling, the cakes were

2.2 Cake making packaged in low density polypropylene plastic bags sprayed

with an anti-fungal agent. The cakes were stored in a dry place

Table 1 shows the formulations used to make the cakes. The

at 22 ± 1 °C.

fat concentrations used were 20, 40, and 60 g/100 g (based on

the flour content), and the remaining ingredients were added

according to the ingredient balance proposed by Bennion & 2.3 Evaluation of batter quality

Bamford (1997). For each fat concentration used, the maltogenic The pH value and apparent density of the batters of all the

α-amylase was added in the concentrations of 0, 500, and

cake formulations were determined after final mixing (before

1000 mg/kg, resulting in a total of nine formulations. The

putting them in the cake tins).

formulations were identified as F20-0, F20-500, F20-1000, F40-0, F40-500,

F40-1000, F60-0, F60-500, and F60-1000, indicating the amounts of fat and

maltogenic α-amylase added. Batter pH value

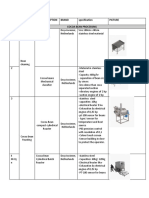

The cakes were made according to the flow diagram The pH value of the cake batters was determined using

shown in Figure 1. To prepare the batters, a Hypo HB25 mixer a Digimed DM-20 (Digicrom Analítica Ltda., São Paulo, SP,

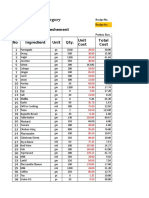

Table 1. Formulations used to make the cakes.

Formulations

Formulation code*

Ingredients

F20-0 – F20-500 – F20-1000 F40-0 – F40-500 – F40-1000 F60-0 – F60-500 – F60-1000

% grams % grams % grams

Wheat flour1 95.00 950.00 95.00 950.00 95.00 950.00

Corn starch1 5.00 50.00 5.00 50.00 5.00 50.00

Total 1(flour basis) 100.00 1000.00 100.00 1000.00 100.00 1000.00

Low trans fat2 20.00 200.00 40.00 400.00 60.00 600.00

Liquid egg2,4 25.00 250.00 50.00 500.00 75.00 750.00

Whole milk2,5 67.50 675.00 45.00 450.00 22.50 225.00

Refined sugar2,6 73.13 731.25 78.75 787.50 84.38 843.75

Baking powder2 2.50 25.00 2.50 25.00 2.50 25.00

Maltogenic α-amylase (mg/kg)2,8 Variable Variable Variable

Total 2 (total batter basis) 288.13 2881.25 316.25 3162.50 344.38 3443.75

Emulsifying gel3 2.00 57.63 2.00 63.25 2.00 68.88

Sodium propionate3,7 0.15 4.32 0.15 4.74 0.15 5.17

Salt3,7 0.20 5.76 0.20 6.33 0.20 6.89

Vanilla flavour3 0.50 14.41 0.50 15.81 0.50 17.22

* The formulations were coded as: F20-0: 20 g/100 g fat and 0 mg/kg maltogenic α-amylase; F20-500: 20 g/100 g fat and 500 mg/kg maltogenic α-amylase; F20-1000: 20 g/100 g fat and 1000

( )

mg/kg maltogenic α-amylase; F40-0: 40 g/100 g fat and 0 mg/kg maltogenic α-amylase; F40-500: 40 g/100 g fat and 500 mg/kg maltogenic α-amylase; F40-1000: 40 g/100 g fat and 1000 mg/kg

maltogenic α-amylase; F60-0: 60 g/100 g fat and 0 mg/kg maltogenic α-amylase; F60-500: 60 g/100 g fat and 500 mg/kg maltogenic α-amylase; F60-1000: 60 g/100 g fat and 1000 mg/kg maltogenic

α-amylase. The ingredients were added according to the balance proposed by Bennion & Bamford (1997): (1) The sum of the ingredients represents the flour weight basis; (2) Ingredients

added based on the weight of the flour; (3) Ingredients added based on the weight of the batter; (4) [%fat x 1.25]; (5) [(%flour - %egg) x 0.9]; (6) [(%flour + %fat + %egg + %milk)/4] + 20%];

(7)

Sum of sodium propionate and salt = approximately 1 g/100 g, flour basis (Grundy, 1996); (8) The maltogenic α-amylase was added in three concentrations: 0, 500 and 1000 mg/kg.

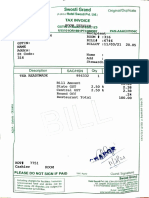

Figure 1. Flow diagram of the cake-making process.

Food Sci. Technol, Campinas, 34(4): 760-766, Oct.-Dec. 2014 761

Maltogenic α-amylase in cakes

Brazil) pH-meter by inserting the electrode directly into a the percentage of judges who attributed different scores. The

suspension of 10 g batter diluted in 100 mL distilled water. sensory analysis was carried out 7 days after manufacture to

identify any effects caused by storage considering a shelf life of

Batter density 21 days. This research project was approved by the University

of Campinas Research Ethics Committee, process number

The density of the cake batters was determined by the 0221.0.146.000-10, in accordance with Resolution 196/96 of

relationship between the batter weight (g) and its volume (cm3) the Brazilian Health Council.

using a cylindrical aluminum recipient (3.7 cm diameter and

6.8 cm height). The results were expressed in g/cm3. 2.5 Analysis of the results

2.4 Evaluation of cake quality The statistical analysis of the results was carried out using

the SAS 9.2 software (SAS Institute, Cary, NC, USA) and the

Cake specific volume Tukey’s test at 5% probability level.

The specific volume of the cakes, expressed in cm3/g, was

determined on the 1st day of storage. The cake volume was 3 Results and discussion

determined by millet seed displacement, and the weight was

measured using a semi-analytical balance. The specific volume 3.1 Batter pH and density

was obtained by the ratio between the cake volume and its Table 2 shows the pH and density results of the batters. With

weight (Griswold, 1972). respect to pH, the values found varied between 7.24 and 7.61,

corresponding to samples F20-1000 and F40-500, respectively. These

Crumb moisture content pH values are appropriate for cake making. According to Ash &

Colmey (1973) (apud Khalil, 1998), pH values in the range from

The moisture content of the cake crumbs was determined 6.50 to 7.70 are considered ideal for cake processing. According

on the 1st, 7th, 14th, and 21st days of storage, according to AACC to Pyler (1973), pH is of great importance in the definition of

method nº 44-15A (AMERICAN ASSOCIATION OF CEREAL color and texture of cakes. Texture tends to become softer as the

CHEMISTS, 2000). pH increases, but a very high pH value is undesirable because

it produces an undesirable alkaline taste. The density value of

Crumb instrumental texture 20 g/100 g fat batters was significantly higher (p < 0.05) than

Texture was analyzed using the TAXT2i (Texture that of the 40 and 60 g/100 g fat batters. Lower values of density

Technologies Corp., Scarsdale, NY, USA/Stable Micro Systems, indicate the incorporation of a greater amount of air into the

Godalming, Surrey, UK) texture analyzer, according to AACC batter (Kocer et al., 2007). The addition of maltogenic α-amylase

method nº 74-09 (AMERICAN ASSOCIATION OF CEREAL had no influence on density.

CHEMISTS, 2000). Two central slices, 1.25 cm thick each, placed

one on top of the other, were compressed to 40% of their original 3.2 Cake specific volume

height using a cylindrical aluminum probe of 36 mm diameter Table 2 shows the results of the specific volume of the

(P 36/R) and the following operational parameters: 1.0 m/s cakes. Comparing the specific volumes of cakes made without

pre-test speed; 1.7 m/s test speed, 10.0 m/s post-test speed; 5 g the addition of maltogenic α-amylase (p < 0.05), it can be

force; and 5 s counting cycle, measuring the compression force.

The samples were kept in their original packaging and removed

one by one before the analysis to avoid staling if exposed to the Table 2. Density and pH of the batters and specific volume of the cakes

environment, which could interfere with the texture results due made with different amounts of fat and maltogenic α-amylase.

to the sensitivity of the equipment. The analysis was carried out Formulation pH* Density (g/cm3)* Specific volume

in sextuplicate, and the parameter measured was firmness; the (cm3/g)*

results were expressed in gf. F20-0 7.49 ± 0.04 ab 0.90 ± 0.01 a

2.37 ± 0.07 cd

F20-500 7.31 ± 0.09 bc 0.88 ± 0.02 a

2.38 ± 0.02 cd

Sensory analysis: evaluation of acceptance and purchase F20-1000 7.24 ± 0.07 c 0.88 ± 0.01 a

2.87 ± 0.13 a

intention F40-0 7.50 ± 0.08 ab 0.82 ± 0.01 b

2.75 ± 0.06 ab

F40-500 7.61 ± 0.03 a 0.81 ± 0.00 bc

2.45 ± 0.04 cd

Based on the results obtained in the evaluation of the cakes F40-1000 7.45 ± 0.11 ab 0.81 ± 0.01 bc

2.49 ± 0.02cd

during 21 days of storage, a sensory analysis and determination F60-0 7.40 ± 0.05 bc 0.79 ± 0.01 cd

2.33 ± 0.03 d

of purchase intention was carried out for the 3 formulations with F60-500 7.43 ± 0.04 abc 0.79 ± 0.00 bcd

2.76 ± 0.13 ab

20 g/100 g fat and the 3 levels of maltogenic α-amylase (0, 500 and F60-1000 7.49 ± 0.09 ab 0.77 ± 0.01 d

2.56 ± 0.01 bc

1000 mg/kg). The analyses were carried out with 50 non-trained F20-0: 20 g/100 g fat and 0 mg/kg maltogenic α-amylase; F20-500: 20 g/100 g fat and 500 mg/kg

judges, potential cake consumers. The following parameters maltogenic α-amylase; F20-1000: 20 g/100 g fat and 1000 mg/kg maltogenic α-amylase; F40‑0:

were evaluated in the acceptance analysis: appearance, aroma, 40 g/100 g fat and 0 mg/kg maltogenic α-amylase; F40-500: 40 g/100 g fat and 500 mg/

taste, texture, and overall acceptance, using a 9-point hedonic kg maltogenic α-amylase; F40-1000: 40 g/100 g fat and 1000 mg/kg maltogenic α-amylase;

F60-0: 60 g/100 g fat and 0 mg/kg maltogenic α-amylase; F60-500: 60 g/100 g fat and 500 mg/

scale (1 = disliked immensely; 9 = liked immensely). The kg maltogenic α-amylase; F60-1000: 60 g/100 g fat and 1000 mg/kg maltogenic α-amylase.

results were expressed as the mean of the scores. A 5-point * The values of pH, apparent density and specific volume are the means of triplicates.

( )

scale was used for purchase intention (1 = would certainly not Means with the same letter in the same column do not differ statistically according to

buy; 5 = would certainly buy). The results were expressed as Tukey’s test (p < 0.05).

762 Food Sci. Technol, Campinas, 34(4): 760-766, Oct.-Dec. 2014

Bedoya-Perales; Steel

seen that the highest value was obtained with the 40 g/100 g fat were significantly moister (p < 0.05), followed by those

fat formulation, 2.75 cm3/g. A similar result was reported by formulated with 40 and 60 g/100 g fat, respectively. This

Sakiyan et al. (2004), who studied the effect of the addition behavior can be explained by the fact that when determining

of different fat concentrations (from 0 to 50%) and two types the best formulation according to the ingredient balance rules,

of emulsifiers (at 3% dosage) in the production of cakes, the amount of sugar increased with the increase in the fat

demonstrating that specific volume increased with the increase concentration, thus increasing the total solids content.

of fat in the formulation. It is known that the main role of

Of all cakes made with 20 g/100 g fat, those made with

fat in cakes is to incorporate air in the batter allowing gas

1000 mg/kg maltogenic α-amylase lost the least amount

cells to expand during the baking phase enabling the cake to

of moisture during storage (12 g/100 g), decreasing from

rise uniformly with an adequate volume of the final product

28.90 g/100 g (day 1) to 25.53 g/100 g (day 21). This could have

(Hoseney, 1998; Ghotra et al., 2002; Sakiyan et al., 2004;

been a consequence of the enzymatic hydrolysis of the starch due

Kocer et al., 2007). However, an excess of fat can weaken the

to the action of the maltogenic α-amylase with the formation

structure and lead to collapse (Bennion & Bamford, 1997).

of hygroscopic dextrins, as explained by Van der Maarel et al.

When the enzyme was added at a concentration of (2002). This amount of moisture loss was low compared to

500 mg/kg, the highest value of specific volume obtained that of the other samples, such as F40-500 and F40-1000, in which

was 2.76 cm3/g corresponding to the cakes formulated with moisture loss was about 20 and 24 g/100 g, respectively, in the

60 g/100 g, but when the enzyme was added at a concentration same period.

of 1000 mg/kg, the highest value obtained was 2.87 cm3/g,

corresponding to the cakes formulated with 20 g/100 g fat. 3.4 Crumb instrumental texture

This could indicate that it is possible to make cakes with lower

fat contents and quality similar to that of cakes with the higher Table 4 shows the behavior of the cakes according to

fat contents using the enzyme maltogenic α-amylase. When a enzyme concentration with respect to crumb firmness during

cake batter is placed in the oven, continuous heating promotes the 21 days of storage. It can be seen that the firmness of the

starch gelatinization (Kocer et al., 2007; Sablani, 2009) and, nine formulations of cake increased during storage. According

the higher the gelatinization temperature, the more time to Fadda et al. (2014), after baking, bakery products undergo

available for the cake to rise before the structure sets (Gaonkar various chemical and physical changes that are related to staling,

& Mcpherson, 2006). Accordingly, delayed gelatinization can but this phenomenon is a complex process that has not yet

occur with the presence of lipids (Ghiasi et al., 1982), sugars, been fully understood. The most important factors responsible

and proteins (Şumnu et al., 1999). Furthermore, maltogenic for these changes are starch transformation, starch-gluten

α-amylase reduces batter viscosity during starch gelatinization, interactions, and moisture redistribution. On the 1st day of

prolonging oven rise and resulting in cakes with higher volumes storage, the values of firmness varied between 637.35 gf (sample

(Mathewson, 2000; Goesaert et al., 2009b); this is a characteristic F20-1000) and 1684.19 gf (sample F60-0), and on the 21st day, between

of high quality cakes (Esteller & Lannes, 2005). 988.47 gf (sample F20-1000) and 1940.59 gf (sample F60-0), showing

that both fat and the maltogenic α-amylase contents had an

influence on cake texture. The addition of the enzyme had a

3.3 Crumb moisture content

positive effect on the cakes, softening the crumb and avoiding an

Table 3 shows the results of the analysis of the moisture increase in firmness during storage. The effect of the fat content

content of the cake crumbs during 21 days of storage. It can can be observed when comparing samples without the enzyme

be seen that on each day of analysis, the cakes with 20 g/100 g maltogenic α-amylase. Cakes with 40 g/100 g fat were the softest

Table 3. Moisture contents of the cake crumbs with different amounts of fat and maltogenic α-amylase during 21 days of storage.

Moisture content*

Formulation Days of storage

1st day 7th day 14th day 21st day

F20-0 29.63 ± 0.56 a,AB 28.42 ± 0.15 b,A 26.94 ± 0.57 c,A 25.37 ± 0.10 d,A

F20-500 30.14 ± 0.09 a,A 27.27 ± 0.35 b,B 26.87 ± 0.31 b,A 25.38 ± 0.24 c,A

F20-1000 28.90 ± 0.34 a,AB 27.47 ± 0.38 b,AB 27.52 ± 0.23 b,A 25.53 ± 0.12 c,A

F40-0 27.38 ± 0.67 a,CD 24.79 ± 0.21 b,C 23.52 ± 0.15 bc,B 22.67 ± 0.35 c,B

F40-500 28.31 ± 0.55 a,BC 24.60 ± 0.45 b,C 24.21 ± 0.37 b,B 21.51 ± 0.36 c,C

F40-1000 26.79 ± 0.22 a,D 24.29 ± 0.21 b,C 23.77 ± 0.49 b,B 21.38 ± 0.25 c,CD

F60-0 24.32 ± 0.49 a,E 21.37 ± 0.53 b,D 21.13 ± 0.01 b,C 20.56 ± 0.29 b,CD

F60-500 24.95 ± 0.38 a,E 22.29 ± 0.52 b,D 21.26 ± 0.41 bc,C 20.64 ± 0.48 c,D

F60-1000 23.42 ± 0.60 a,F 21.76 ± 0.32 b,D 21.51 ± 0.33 b,C 19.50 ± 0.47 c,E

F20-0: 20 g/100 g fat and 0 mg/kg maltogenic α-amylase; F20-500: 20 g/100 g fat and 500 mg/kg maltogenic α-amylase; F20-1000: 20 g/100 g fat and 1000 mg/kg maltogenic α-amylase; F40‑0:

40 g/100 g fat and 0 mg/kg maltogenic α-amylase; F40-500: 40 g/100 g fat and 500 mg/kg maltogenic α-amylase; F40-1000: 40 g/100 g fat and 1000 mg/kg maltogenic α-amylase; F60-0:

60 g/100 g fat and 0 mg/kg maltogenic α-amylase; F60-500: 60 g/100 g fat and 500 mg/kg maltogenic α-amylase; F60-1000: 60 g/100 g fat and 1000 mg/kg maltogenic α-amylase. (*) The

values of moisture content represent the means of triplicates. Means with the same small letter in the same line, or capital letter in the same column, do not differ statistically according

to Tukey’s test (p < 0.05).

Food Sci. Technol, Campinas, 34(4): 760-766, Oct.-Dec. 2014 763

Maltogenic α-amylase in cakes

throughout the whole storage period. The addition of the combined effect of the fat and the enzyme retarding the increase

enzyme maltogenic α-amylase, especially at the concentration in firmness.

of 1000 mg/kg, resulted in cakes with reduced firmness on all

the days of analysis, minimizing the effect of the fat content. 3.5 Sensory analysis: evaluation of acceptance and purchase

Thus, one can obtain cakes with lower fat contents (20 g/100 g) intention

with firmness similar to that of cakes with 40 g/100 g fat, which

could be beneficial from the nutritional point of view. Table 5 shows the results of the acceptance test for cakes

with 20 g/100 g fat and the addition of 0, 500, and 1000 mg/kg

As explained by Goesaert et al. (2009b), the anti-firmness maltogenic α-amylase. Figure 2 shows pictures of a slice of each

mechanism of maltogenic α-amylase is fundamentally attributed of these cakes. The results of the acceptance of the attributes of

to the extensive degradation of the crystallizable fraction of aroma and taste indicated that there was no significant difference

amylopectin, inhibiting the formation of a stable amylopectin (p < 0.05) between the samples evaluated by the consumers,

network during storage, thus inhibiting retrogradation. It can and although no difference was found for overall impression,

therefore be said that in cakes made with a smaller amount the sample with 20 g/100 g fat and 1000 mg/kg maltogenic

of fat (20 g/100 g), the effect of maltogenic α-amylase was α-amylase (sample F20-1000) stood out in a positive way, in terms

more apparent, but as the amount of fat increased, there was a of appearance.

Table 4. Comparison of the behavior of crumb firmness of the cakes with (a) 0, (b) 500, and (c) 1000 mg/kg of maltogenic α-amylase in the

formulations with 20, 40, and 60 g/100 g fat, during 21 days of storage.

Firmness (gf)*

Formulation Days of storage

1st day 7th day 14th day 21st day

F20-0 1293.14 ± 93.05 c,B 1389.65 ± 58.56 bc,B 1469.73 ± 58.08 b,A 1741.32 ± 77.25 a,B

F20-500 792.82 ± 64.30 d,E 921.59 ± 37.64 c,E 1249.64 ± 83.43 b,B 1483.74 ± 66.27 a,C

F20-1000 637.35 ± 53.24 b,F 907.15 ± 17.58 a,E 930.82 ± 34.18 a,D 988.47 ± 85.45 a,E

F40-0 1037.75 ± 60.39 b,C 1196.69 ± 52.37 ab,CD 1136.76 ± 78.9 b,BC 1345.74 ± 60.69 a,CD

F40-500 956.46 ± 63.0 b,CD 959.14 ± 40.48 ab,E 1091.69 ± 83.16 a,BCD 1038.42 ± 93.52 ab,E

F40-1000 866.08 ± 59.22 b,DE 925.60 ± 56.78 b,E 1177.74 ± 53.53 a,BC 1111.17 ± 94.44 a,E

F60-0 1684.19 ± 110.14 b,A 1546.34 ± 26.33 b,A 1606.05 ± 153.01 b,A 1940.59 ± 91.24 a,A

F60-500 1063.41 ± 46.85 b,C 1294.12 ± 78.08 a,BC 1226.04 ± 33.73 a,B 1315.64 ± 103.50 a,CD

F60-1000 918.97 ± 61.54 c,CDE 1094.41 ± 65.84 ab,D 1025.14 ± 33.26 bc,CD 1157.59 ± 86.23 a,DE

F20-0: 20 g/100 g fat and 0 mg/kg maltogenic α-amylase; F20-500: 20 g/100 g fat and 500 mg/kg maltogenic α-amylase; F20-1000: 20 g/100 g fat and 1000 mg/kg maltogenic α-amylase; F40-0:

40 g/100 g fat and 0 mg/kg maltogenic α-amylase; F40-500: 40 g/100 g fat and 500 mg/kg maltogenic α-amylase; F40-1000: 40 g/100 g fat and 1000 mg/kg maltogenic α-amylase; F60-0: 60 g/100 g

fat and 0 mg/kg maltogenic α-amylase; F60-500: 60 g/100 g fat and 500 mg/kg maltogenic α-amylase; F60-1000: 60 g/100 g fat and 1000 mg/kg maltogenic α-amylase. (*) The values of firmness

represent the means of six replicates. Means with the same small letter in the same line, or capital letter in the same column, do not differ statistically according to Tukey’s test (p < 0.05).

Table 5. Mean acceptance scores of the sensory attributes of cakes with 20 g/100 g fat and the addition of 0, 500, and 1000 mg/kg maltogenic

α-amylase.

Attribute*

Sample

Appearance Aroma Taste Texture Overall Impression

F20-0 6.58 ± 1.68b 7.26 ± 1.23a 7.12 ± 1.22a 6.66 ± 1.52b 7.00 ± 1.29a

F20-500 6.52 ± 1.83b 7.54 ± 1.11a 7.12 ± 1.31a 7.34 ± 1.14a 7.10 ± 1.30a

F20-1000 7.54 ± 1.26a 7.36 ± 1.29a 7.22 ± 1.27a 7.50 ± 1.20a 7.38 ± 1.12a

F20-0: 20 g/100 g fat and 0 mg/kg maltogenic α-amylase; F20-500: 20 g/100 g fat and 500 mg/kg maltogenic α-amylase; F20-1000: 20 g/100 g fat and 1000 mg/kg maltogenic α-amylase. (*) Means

followed by the same letters in the same column do not differ statistically according to Tukey’s test (p < 0.05).

Figure 2. Slices of the cakes with 20 g/100 g fat and (a) 0, (b) 500, and (c) 1000 mg/kg maltogenic α-amylase.

764 Food Sci. Technol, Campinas, 34(4): 760-766, Oct.-Dec. 2014

Bedoya-Perales; Steel

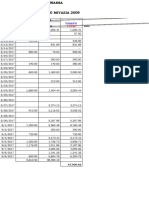

Figure 3. Purchase intention of the cakes with 20 g/100 g fat with the three levels of maltogenic α-amylase (0, 500 and 1000 mg/kg). F20-0:

20 g/100 g fat and 0 mg/kg maltogenic α-amylase; F20-500: 20 g/100 g fat and 500 mg/kg maltogenic α-amylase; F20-1000: 20 g/100 g fat and 1000 mg/kg

maltogenic α-amylase.

This fact represents a positive outcome and is related to the showed the best results (greater specific volume, lower moisture

cake quality results obtained, in which this same sample had a loss, better texture, better sensory evaluation), representing a

higher specific volume than that of the cakes with 20 g/100 g fat beneficial alternative from the nutritional point of view since

and 0 or 500 mg/kg of enzyme. With respect to the acceptance the addition of the enzyme provided quality improvements

of the attribute texture, the sample with no enzyme received a maintaining the fat level at 20 g/100 g.

lower score than the other two samples, confirming the results

for texture obtained instrumentally (Table 4), which showed that

the addition of maltogenic α-amylase produced a softer product. References

American Association Of Cereal Chemists – AACC. 2000. Approved

Figure 3 shows the purchase intention of the judges with

methods of analysis. 10th ed. St. Paul: AACC.

respect to the samples evaluated.

Bennion, E. B., & Bamford, G. S. T. (1997). The technology of cake

Purchase intention was greater for the samples with making. 6th ed. London: Blackie Academic and Professional. 421

maltogenic α-amylase, and the sample F 20-1000 stood out. p. http://dx.doi.org/10.1007/978-1-4757-6690-5.

Correlating these results with the scores obtained in the Esteller, M. S., Yoshimoto, R. M. O., Amaral, R. L., & Lannes, S. C.

acceptance test, the samples with 500 and 1000 mg/kg of S. (2004). Uso de açúcares em produtos panificados. Ciência e

enzyme showed the same characteristics of aroma, taste, texture, Tecnologia de Alimentos, 24(4), 602-607. http://dx.doi.org/10.1590/

and overall impression. However, the cake with 1000 mg/kg S0101-20612004000400021.

maltogenic α-amylase showed the highest score for the attribute

Esteller, M. S., & Lannes, S. C. S. (2005). Parâmetros complementares

appearance, which influenced consumer purchase intention. para fixação de identidade e qualidade de produtos panificados.

Ciência e Tecnologia de Alimentos, 25(4), 802-806. http://dx.doi.

4 Conclusions org/10.1590/S0101-20612005000400028.

High concentrations of fat in the cake formulations, Fadda, C., Sanguinetti, A. M., Del Caro, A., Collar, C., & Piga, A.

independent of the addition of the enzyme maltogenic (2014). Bread Staling: Updating the View. Comprehensive Reviews

α-amylase, led to a product with less desirable quality. in Food Science and Food Safety, 13(4), 473-492. http://dx.doi.

org/10.1111/1541-4337.12064.

The effect of the maltogenic α-amylase was evident on the

Gaonkar, A. G., & Mcpherson, A. (2006). Ingredient interactions: effects

results of specific volume, texture, and sensory evaluation of

on food quality. In J. J. Mitolo (Ed.), Starch selection and interaction

the cakes.

in foods (pp. 140-164). Boca Raton: CRC Press.

The fat and maltogenic α-amylase combinations that best Ghiasi, K., et al (1982). Gelatinization of wheat starch. I. Excess-water

maintained the softness of the cake during 21 days of storage systems. Cereal Chemistry, 59(4), 81-85.

correspond to the formulations with a fat to maltogenic Ghotra, B. S., Dyal, S. D., & Narine, S. S. (2002). Lipid shortenings:

α-amylase ratio (in g/100 g to mg/kg) of 20/1000, 40/500, and a review. Food Research International, 35(10), 1015-1048. http://

40/1000. dx.doi.org/10.1016/S0963-9969(02)00163-1.

In general, the formulation with 20 g/100 g fat and Goesaert, H., Leman, P., Bijttebier, A., & Delcour, J. A. (2009a).

1000 mg/kg maltogenic α-amylase (flour basis) was the one that Antifirming effects of starch degrading enzymes in bread crumb.

Food Sci. Technol, Campinas, 34(4): 760-766, Oct.-Dec. 2014 765

Maltogenic α-amylase in cakes

Journal of Agricultural and Food Chemistry, 57(6), 2346-2355. http:// Pyler, E. J. (1973). Bakery shortenings. In E. J. Pyler (Ed.), Baking

dx.doi.org/10.1021/jf803058v. PMid:19239186 science and technology (pp. 223-285). Kansas: Sosland Publishing.

Goesaert, H., Slade, L., Levine, H., & Delcour, J. A. (2009b). Amylases Ronda, F., Gomez, M., Caballero, P. A., Oliete, B., & Blanco, C. A.

and bread firming: an integrated view. Journal of Cereal Science, (2009). Improvement of quality of gluten-free layer cakes. Food

50(3), 345-352. http://dx.doi.org/10.1016/j.jcs.2009.04.010. Science & Technology International, 15(2), 193-202. http://dx.doi.

Griswold, R. M. (1972). Estudo experimental dos alimentos. São Paulo: org/10.1177/1082013208105170.

Ed. Universidade de São Paulo. 469 p. Sablani, S. S. (2009). Gelatinization of starch. In M. S. Rahman (Ed.),

Grundy, J. G. (1996). Preservatives. In R. E. Hebeda & H. F. Zobel (Eds.), Food properties handbook (pp. 287-314). 2nd ed. Boca Raton: CRC

Baked goods freshness (pp. 189-203). New York: Marcel Dekker. Press.

Guy, R. C. E., & Sahi, S. S. (2006). Application of a lipase in cake Sahi, S. S. (2008). Cake emulsions. In S. G. Sumnu & S. Sahin (Eds.),

manufacture. Journal of the Science of Food and Agriculture, 86(11), Food engineering aspects of baking sweet goods (pp. 81-98). Boca

Raton: CRC Press/Taylor & Francis Group.

1679-1687. http://dx.doi.org/10.1002/jsfa.2540.

Sahin, S. (2008). Cake batter rheology. In S. G. Sumnu & S. Sahin (Eds.),

Hoseney, R. C. (1998). Principles of cereal science and technology. 2nd

Food engineering aspects of baking sweet goods (pp. 99-117). Boca

ed. St. Paul: American Association of Cereal Chemistry. 378 p.

Raton: CRC Press/Taylor & Francis Group.

Indrani, D., & Rao, V. G. (2008). Functions of ingredients in the baking

Sakiyan, O., Sumnu, G., Sahin, S., & Bayram, G. (2004). Influence of

of sweet goods. In S. G. Sumnu & S. Sahin (Eds.), Food engineering

fat content and emulsifier type on the rheological properties of cake

aspects of baking sweet goods (pp. 32-45). Boca Raton: CRC Press/

batter. European Food Research and Technology, 219(6), 635-638.

Taylor & Francis Group.

http://dx.doi.org/10.1007/s00217-004-1020-4.

Khalil, A. H. (1998). The influence of carbohydrate-based fat replacers

Şumnu, G., Ndife, M. K., & Bayındırlı, L. (1999). Effects of sugar, protein

with and without emulsifiers on the quality characteristics of lowfat

and water content on wheat starch gelatinization due to microwave

cake. Plant Foods for Human Nutrition, 52(4), 299-313.

heating. European Food Research and Technology, 209(1), 68-71.

Kocer, D., Hicsasmaz, Z., Bayindirli, A., & Katnas, S. (2007). Bubble and http://dx.doi.org/10.1007/s002170050459.

pore formation of the high-ratio cake formulation with polydextrose Van der Maarel, M. J., Van der Veen, B., Uitdehaag, J. C., Leemhuis,

as a sugar and fat-replacer. Journal of Food Engineering, 78(3), 953- H., & Dijkhuizen, L. (2002). Properties and applications of

964. http://dx.doi.org/10.1016/j.jfoodeng.2005.11.034. starch-converting enzymes of the α-amylase family. Journal of

Lagrain, B., Leman, P., Goesaert, H., & Delcour, J. A. (2008). Impact of Biotechnology, 94(2), 137-155. http://dx.doi.org/10.1016/S0168-

thermostable amylases during bread making on wheat bread crumb 1656(01)00407-2. PMid:11796168

structure and texture. Food Research International, 41(8), 819-827. Wilderjans, E., Pareyt, B., Goesaert, H., Brijs, K., & Delcour, J. A. (2008).

http://dx.doi.org/10.1016/j.foodres.2008.07.006. The role of gluten in a pound cake system: A model approach based

Mathewson, P. R. (2000). Enzymatic activity during bread baking. on gluten-starch blends. Food Chemistry, 110(4), 909-915. http://

Cereal Foods World, 45(3), 98-101. dx.doi.org/10.1016/j.foodchem.2008.02.079.

766 Food Sci. Technol, Campinas, 34(4): 760-766, Oct.-Dec. 2014

You might also like

- Acid Ascorbic - Xylanase - AmylaseDocument7 pagesAcid Ascorbic - Xylanase - AmylaseTrinh LamNo ratings yet

- Biscuits Fortified With Microencapsulated Shrimp Oil-Characteristics and Storage StabilityDocument11 pagesBiscuits Fortified With Microencapsulated Shrimp Oil-Characteristics and Storage Stabilityaisyah_asyrafNo ratings yet

- Protein Enrichment of Wheat Flour DoughsDocument9 pagesProtein Enrichment of Wheat Flour DoughsLennon BarrosNo ratings yet

- Zambrano Et Al 2004.the Use of Guar And....... X (1) ArtDocument9 pagesZambrano Et Al 2004.the Use of Guar And....... X (1) ArtKevine Kenmoe MocheNo ratings yet

- Pan Harina de AlgasDocument6 pagesPan Harina de AlgasJoans MatusNo ratings yet

- Tire Ki 2021Document12 pagesTire Ki 2021hoangvipro99No ratings yet

- Rochasaraiva 2019Document9 pagesRochasaraiva 2019Nicolas LesmesNo ratings yet

- The Physicochemical Characteristics of Nonfat Set Yoghurt Containing Some HydrocolloidsDocument8 pagesThe Physicochemical Characteristics of Nonfat Set Yoghurt Containing Some HydrocolloidsAzizah MunitaNo ratings yet

- Studies On Effect of Additives On Protein Profile, Microstructure and Quality Characteristics of PastaDocument9 pagesStudies On Effect of Additives On Protein Profile, Microstructure and Quality Characteristics of PastaYovana CallisayaNo ratings yet

- Characterisation of Bovine and Buffalo Anhydrous Milk Fat Fractions AlongDocument10 pagesCharacterisation of Bovine and Buffalo Anhydrous Milk Fat Fractions AlongJeferson Lopez RomeroNo ratings yet

- Eleonora Loffredi, Maria Eletta Moriano, Letizia Masseroni, Cristina AlampreseDocument8 pagesEleonora Loffredi, Maria Eletta Moriano, Letizia Masseroni, Cristina AlampreseMagdalenaNo ratings yet

- Cocoa Fibre and Its Application As A Fat Replacer in Chocolate MuffinsDocument8 pagesCocoa Fibre and Its Application As A Fat Replacer in Chocolate MuffinscristianepatriciaNo ratings yet

- 10.2478 - Acs 2013 0040Document12 pages10.2478 - Acs 2013 0040mdhaidersheikh63No ratings yet

- Artigo W - 092230Document7 pagesArtigo W - 092230Carlos Rafael Brito XavierNo ratings yet

- Effect of Emulsifier and Guar Gum On Micro Structural, Rheological and Baking Performance of Frozen Bread DoughDocument9 pagesEffect of Emulsifier and Guar Gum On Micro Structural, Rheological and Baking Performance of Frozen Bread DoughEric GabrielNo ratings yet

- International Dairy Journal: Mustafa Kadir Esen, Nuray GüzelerDocument9 pagesInternational Dairy Journal: Mustafa Kadir Esen, Nuray Güzelerhans tafurNo ratings yet

- 551 2015-CJFSDocument7 pages551 2015-CJFSCarolina ChicaNo ratings yet

- 2017 Article 2942Document10 pages2017 Article 2942Muhammad AbrarNo ratings yet

- Optimization of Non-Fermented Gluten-Free Dough Composition Based On Rheological Behavior For Industrial Production of "Empanadas" and Pie-CrustsDocument8 pagesOptimization of Non-Fermented Gluten-Free Dough Composition Based On Rheological Behavior For Industrial Production of "Empanadas" and Pie-CrustsDiana Gz-BsNo ratings yet

- Renzetti 2015Document9 pagesRenzetti 2015nhiNo ratings yet

- Pão Clean Label Com Suco de Limão e EnzimasDocument10 pagesPão Clean Label Com Suco de Limão e EnzimasLennon BarrosNo ratings yet

- Ascorbic Op ÃoDocument8 pagesAscorbic Op ÃoIsabela M P NaritaNo ratings yet

- Int J of Food Sci Tech - 2006 - Dogan - Effects of Interesterified Palm and Cottonseed Oil Blends On Cake QualityDocument8 pagesInt J of Food Sci Tech - 2006 - Dogan - Effects of Interesterified Palm and Cottonseed Oil Blends On Cake QualityPaulo De Tarso CarvalhoNo ratings yet

- Dairy By-Products in Ice CreamDocument14 pagesDairy By-Products in Ice CreamHugo SerafiniNo ratings yet

- Ice CreamDocument8 pagesIce CreamIN BOLD بالخط العريضNo ratings yet

- 6 fr-2021-763 AbdullahDocument5 pages6 fr-2021-763 AbdullahwidyaNo ratings yet

- 924 Otro 1715 1 10 20180820Document7 pages924 Otro 1715 1 10 20180820Vanesa PereiraNo ratings yet

- Tesoro Investigacion 2 PDFDocument6 pagesTesoro Investigacion 2 PDFJorge GutierrezNo ratings yet

- LWT - Food Science and Technology: Priscilla Nuernberg Rossa, Vívian Maria Burin, Marilde T. Bordignon-LuizDocument7 pagesLWT - Food Science and Technology: Priscilla Nuernberg Rossa, Vívian Maria Burin, Marilde T. Bordignon-LuizGRACIELANo ratings yet

- LWT - Food Science and Technology 157 (2022) 113103Document9 pagesLWT - Food Science and Technology 157 (2022) 113103Naveed AkramNo ratings yet

- Ripe Banana Flour As A Source of Antioxidants in Layer and Sponge CakesDocument7 pagesRipe Banana Flour As A Source of Antioxidants in Layer and Sponge CakesErika -No ratings yet

- 10 1016@j Jcs 2020 103056Document8 pages10 1016@j Jcs 2020 103056Sourav GargNo ratings yet

- Formulation & Analysis of Papaya Fortified Biscuits: Rupanjali Pathak, Vandana Thakur and Rajinder Kumar GuptaDocument4 pagesFormulation & Analysis of Papaya Fortified Biscuits: Rupanjali Pathak, Vandana Thakur and Rajinder Kumar GuptaRizki Aulia NuzullinaNo ratings yet

- Molecules: Quality Characteristics and Volatile Profile of Macarons Modified With Walnut Oilcake By-ProductDocument19 pagesMolecules: Quality Characteristics and Volatile Profile of Macarons Modified With Walnut Oilcake By-ProductDanaNo ratings yet

- Anna Pęksa, Joanna Miedzianka, Agnieszka Kita, Agnieszka Tajner-Czopek, Elżbieta RytelDocument6 pagesAnna Pęksa, Joanna Miedzianka, Agnieszka Kita, Agnieszka Tajner-Czopek, Elżbieta RytelBafi IkhzaNo ratings yet

- Improvement of Quality Characteristics of Gluten-FDocument7 pagesImprovement of Quality Characteristics of Gluten-FMarko AdamovicNo ratings yet

- Research PaperDocument12 pagesResearch PaperKiran Niazi100% (1)

- Ajila Mango Peel BiscoitosDocument8 pagesAjila Mango Peel BiscoitosMonica FigueiraNo ratings yet

- Improving Dough Rheology and Cookie Quality by Protease EnzymeDocument7 pagesImproving Dough Rheology and Cookie Quality by Protease EnzymeMichelle RomeroNo ratings yet

- J Sci Food Agric - 2005 - Lakshminarayan - Effect of Maltodextrin and Emulsifiers On The Viscosity of Cake Batter and OnDocument7 pagesJ Sci Food Agric - 2005 - Lakshminarayan - Effect of Maltodextrin and Emulsifiers On The Viscosity of Cake Batter and OnPaulo De Tarso CarvalhoNo ratings yet

- 1 s2.0 S0023643820303674 MainDocument8 pages1 s2.0 S0023643820303674 MainJelle VeldhoenNo ratings yet

- Artigo Produto Resíduo de CacauDocument10 pagesArtigo Produto Resíduo de CacaucristianepatriciaNo ratings yet

- Cozonac Margarina Ulei de MaslineDocument18 pagesCozonac Margarina Ulei de MaslineScripca LauraNo ratings yet

- Texto 4Document10 pagesTexto 4Anonymous EHi0mR54No ratings yet

- Snacks HorneadosDocument8 pagesSnacks Horneadosfaty hdezNo ratings yet

- Dello Staff Olo 2017Document12 pagesDello Staff Olo 2017BEATRIZ ROSARIO SULCA QUILCANo ratings yet

- International Dairy Journal: E. Sulejmani, O.S. Boran, T. Huppertz, A.A. HayalogluDocument9 pagesInternational Dairy Journal: E. Sulejmani, O.S. Boran, T. Huppertz, A.A. Hayalogluleo06031314No ratings yet

- 1 s2.0 S0260877412001434 MainDocument8 pages1 s2.0 S0260877412001434 MainSumit Kumar SinghNo ratings yet

- Food Hydrocolloids: Alejandra Agudelo, Paula Varela, Teresa Sanz, Susana FiszmanDocument11 pagesFood Hydrocolloids: Alejandra Agudelo, Paula Varela, Teresa Sanz, Susana Fiszmanmax693No ratings yet

- Artigo Final Das Farinhas PublicadoDocument9 pagesArtigo Final Das Farinhas PublicadoLala MouraNo ratings yet

- Susbtituição Com Proteina de Soja Isolata, Xantana e EmulsificantesDocument11 pagesSusbtituição Com Proteina de Soja Isolata, Xantana e EmulsificantesLennon BarrosNo ratings yet

- Physico-Chemical and Sensory Properties of Yogurt From Ultrafiltreted Soy MilkDocument6 pagesPhysico-Chemical and Sensory Properties of Yogurt From Ultrafiltreted Soy MilkShreyas DhuliyaNo ratings yet

- Food Chemistry: Emmanuel Ohene Afoakwa, Alistair Paterson, Mark Fowler, Angela RyanDocument8 pagesFood Chemistry: Emmanuel Ohene Afoakwa, Alistair Paterson, Mark Fowler, Angela RyanDavid Joel TintayaNo ratings yet

- Evaluation of Rice Flour For Use in Vani PDFDocument11 pagesEvaluation of Rice Flour For Use in Vani PDFIda Anne Cacharel FuentespinaNo ratings yet

- Gomes E. R Et. Al - 2021 - Effect of Sugar Reduction and Addition of Corn Fibre and PolydextroseDocument6 pagesGomes E. R Et. Al - 2021 - Effect of Sugar Reduction and Addition of Corn Fibre and Polydextroselarissamirellemm2No ratings yet

- Jurnal Penilaian InderawiDocument8 pagesJurnal Penilaian InderawiDavid Tri PambudiNo ratings yet

- Giacomo ZZ I 2018Document11 pagesGiacomo ZZ I 2018Iram CisnerosNo ratings yet

- Mooncake Sensory ArticleDocument7 pagesMooncake Sensory Articlebenjaminwong8029No ratings yet

- Fatty Acid Composition of Cocoa Beans FR c4f47870Document9 pagesFatty Acid Composition of Cocoa Beans FR c4f47870Mohamad ArifNo ratings yet

- Handbook of Food Science and Technology 3: Food Biochemistry and TechnologyFrom EverandHandbook of Food Science and Technology 3: Food Biochemistry and TechnologyNo ratings yet

- Samsung Galaxy S20+ 5G 256GB Gray in Bole - Mobile Phones, Mike JR - Jiji - Com.etDocument1 pageSamsung Galaxy S20+ 5G 256GB Gray in Bole - Mobile Phones, Mike JR - Jiji - Com.etStephen WillingtonNo ratings yet

- Soresa Tefera Wagari Marema Zeleke Ali Aregahegn Bamlak Misgana AberaDocument2 pagesSoresa Tefera Wagari Marema Zeleke Ali Aregahegn Bamlak Misgana AberaStephen WillingtonNo ratings yet

- Production ProcessDocument1 pageProduction ProcessStephen WillingtonNo ratings yet

- Samsung Galaxy S20+ 5G 256GB Gray in Bole - Mobile Phones, Mike JR - Jiji - Com.etDocument1 pageSamsung Galaxy S20+ 5G 256GB Gray in Bole - Mobile Phones, Mike JR - Jiji - Com.etStephen WillingtonNo ratings yet

- Samsung Galaxy Note 20 Ultra 5G 256GB Black in Bole - Mobile Phones, Redu Rediet - Jiji - Com.etDocument1 pageSamsung Galaxy Note 20 Ultra 5G 256GB Black in Bole - Mobile Phones, Redu Rediet - Jiji - Com.etStephen WillingtonNo ratings yet

- Goods Transfer FormDocument2 pagesGoods Transfer FormStephen WillingtonNo ratings yet

- Job Title: Room Division Manager Responsible To: General/Operation Manager Supervises: Housekeeping, Front Office, Laundry and Public Area AttendantsDocument3 pagesJob Title: Room Division Manager Responsible To: General/Operation Manager Supervises: Housekeeping, Front Office, Laundry and Public Area AttendantsStephen WillingtonNo ratings yet

- Hot DrinksDocument1 pageHot DrinksStephen WillingtonNo ratings yet

- Recipe Category: Recipe No. Recipe For. Portion Size. OneDocument42 pagesRecipe Category: Recipe No. Recipe For. Portion Size. OneStephen WillingtonNo ratings yet

- Mesala Hotel and Tourism PLC: To Whom It May ConcernDocument2 pagesMesala Hotel and Tourism PLC: To Whom It May ConcernStephen WillingtonNo ratings yet

- Rori Hotel Hawassa: Daily Kithen Consumption Vs Sales Followup SheetDocument1 pageRori Hotel Hawassa: Daily Kithen Consumption Vs Sales Followup SheetStephen WillingtonNo ratings yet

- Fresh Bazaar Memo: Date Ref No No Item Unit Qty Unit PriceDocument16 pagesFresh Bazaar Memo: Date Ref No No Item Unit Qty Unit PriceStephen WillingtonNo ratings yet

- Refreshmet HayalDocument60 pagesRefreshmet HayalStephen WillingtonNo ratings yet

- Rori Hotel Hawassa Daily Hot Beverage Control Sheet: 1 Coffee 2 Milk 3 Tea 4 Macchiato 5 Capuchin 6 Fasting MacchiatoDocument1 pageRori Hotel Hawassa Daily Hot Beverage Control Sheet: 1 Coffee 2 Milk 3 Tea 4 Macchiato 5 Capuchin 6 Fasting MacchiatoStephen WillingtonNo ratings yet

- Fresh Bazaar Memo: Date Ref No No Item Unit Qty Unit PriceDocument16 pagesFresh Bazaar Memo: Date Ref No No Item Unit Qty Unit PriceStephen WillingtonNo ratings yet

- In Total Out Delivery Wastage Bal Beginning Bal.: Butchery - Approved byDocument1 pageIn Total Out Delivery Wastage Bal Beginning Bal.: Butchery - Approved byStephen WillingtonNo ratings yet

- Lalo Hotel Beakry Lobour Pay Roll Sheet MONTH OF NOV 1 - 15/2010Document5 pagesLalo Hotel Beakry Lobour Pay Roll Sheet MONTH OF NOV 1 - 15/2010Stephen WillingtonNo ratings yet

- Event Buffet Consupmtion Vs Recipe Record Sheet Buffet Class - 1 Class BuffetDocument1 pageEvent Buffet Consupmtion Vs Recipe Record Sheet Buffet Class - 1 Class BuffetStephen WillingtonNo ratings yet

- COST REPORT (FOOD Megabit ) 1Document33 pagesCOST REPORT (FOOD Megabit ) 1Stephen WillingtonNo ratings yet

- Brecfast BufftDocument69 pagesBrecfast BufftStephen WillingtonNo ratings yet

- Beverage Cost Control Sheet 1Document887 pagesBeverage Cost Control Sheet 1Stephen WillingtonNo ratings yet

- Bar ControlDocument1 pageBar ControlStephen WillingtonNo ratings yet

- Recetas HeladosDocument14 pagesRecetas HeladosPaulina InterianNo ratings yet

- Seven Grain Bakery Layout BY CHEF STEVENDocument2 pagesSeven Grain Bakery Layout BY CHEF STEVENStephen WillingtonNo ratings yet

- Chocolate Machines by Chef SteveDocument14 pagesChocolate Machines by Chef SteveStephen WillingtonNo ratings yet

- Bakery and Pastry IngredientsDocument3 pagesBakery and Pastry IngredientsStephen WillingtonNo ratings yet

- GRN SIV BAR Milk Products Date: Today'SDocument7 pagesGRN SIV BAR Milk Products Date: Today'SStephen WillingtonNo ratings yet

- GRN SIV BAR Milk Products Date: Today'SDocument7 pagesGRN SIV BAR Milk Products Date: Today'SStephen WillingtonNo ratings yet

- Punjab: A Culinary DelightDocument198 pagesPunjab: A Culinary Delightimparamveer864No ratings yet

- Masquerade Mystery: Character Guide (4 - 8 Players) The StagDocument12 pagesMasquerade Mystery: Character Guide (4 - 8 Players) The StagasfsdfsdfNo ratings yet

- Taller Simple Past 2023Document3 pagesTaller Simple Past 2023Milena BarriosNo ratings yet

- The Luncheon Study GuideDocument4 pagesThe Luncheon Study GuideYanira ChaparroNo ratings yet

- Nutrition & Diet Therapy ActivityDocument6 pagesNutrition & Diet Therapy ActivityGwyneth FisherNo ratings yet

- Bordelaise Sauce - Chef - AlfredoKBDocument4 pagesBordelaise Sauce - Chef - AlfredoKBAlfredo RodriguezNo ratings yet

- Triplet Alphas 61-65Document36 pagesTriplet Alphas 61-65Bea Sibayan100% (1)

- Skills For Food Handlers - FinalDocument1 pageSkills For Food Handlers - FinalMMNo ratings yet

- Meals: by Ryan FischerDocument10 pagesMeals: by Ryan FischerNidhin JoseNo ratings yet

- Research - Chapter 1 Wetwew 1Document13 pagesResearch - Chapter 1 Wetwew 1Jollie Ann GapolNo ratings yet

- Snacks Bill 110321Document1 pageSnacks Bill 110321Brahmananda ChakrabortyNo ratings yet

- Refined SugarDocument8 pagesRefined SugarFoodNo ratings yet

- Bochure Catalase Enzyme Test PDFDocument2 pagesBochure Catalase Enzyme Test PDF08-Pimlada JakpingNo ratings yet

- Ch-1 Meeting CezanneDocument4 pagesCh-1 Meeting CezanneSushma YadavNo ratings yet

- Portion ControlDocument11 pagesPortion ControldaringchennaiNo ratings yet

- Instructions: Read. Then Choose The Correct Answers. Losing WeightDocument6 pagesInstructions: Read. Then Choose The Correct Answers. Losing WeightTotti CruzNo ratings yet

- Careers in Food ManagementDocument52 pagesCareers in Food ManagementralieghNo ratings yet

- 3rdunified - Cookery12 - Ramon E. Bacaltos NHSDocument3 pages3rdunified - Cookery12 - Ramon E. Bacaltos NHSClaudine AlbiteNo ratings yet

- Scrapbook Stocks, Sauces, Soups RecipesDocument14 pagesScrapbook Stocks, Sauces, Soups RecipesNeryna Faith Samson93% (15)

- Guide To Raising Dairy SheepDocument6 pagesGuide To Raising Dairy Sheeptazokaka1005No ratings yet

- 8th Grades - Unit 3 - Revision Worksheet by Mete - EltDocument2 pages8th Grades - Unit 3 - Revision Worksheet by Mete - EltEce GunesNo ratings yet

- Acts of Desperation Meg 02 An No LDocument255 pagesActs of Desperation Meg 02 An No LAndrei Teleaga100% (12)

- 2017 - 0928 - Soy LecithinDocument2 pages2017 - 0928 - Soy Lecithincarlos floresNo ratings yet

- Cours 1 Agronomist Job DescriptionDocument2 pagesCours 1 Agronomist Job Descriptionvictor.grandhenryNo ratings yet

- 1L To 5L Packaging Container Specification - PET and HDPE ContainersDocument11 pages1L To 5L Packaging Container Specification - PET and HDPE Containershabtamu yilmaNo ratings yet

- Structure Items SampleDocument3 pagesStructure Items Samplesyafri naldiNo ratings yet

- Bing ChilinDocument9 pagesBing ChilinHector ciscar alfonsoNo ratings yet

- BRM2012ADocument412 pagesBRM2012ALuthfie Wahyu WidodoNo ratings yet

- Business PlanDocument5 pagesBusiness PlanJeru Salem Albotra Jr.No ratings yet

- Karnataka High Court Online Liquor 389434Document51 pagesKarnataka High Court Online Liquor 389434AnilKumar MalchapureNo ratings yet