Professional Documents

Culture Documents

MCC Room - Mezzanine Ac Reqt

Uploaded by

Mark Magadia IpaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

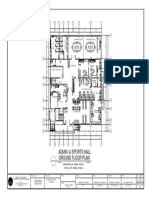

MCC Room - Mezzanine Ac Reqt

Uploaded by

Mark Magadia IpaCopyright:

Available Formats

GENERAL NOTES:

1. CONDENSATE DRAIN TO TAP INTO THE NEAREST DRAIN AVAILABLE ON SITE.

2. ALL WORKS HEREIN SHALL BE PROVIDED WITH WORKABLE SHOP DRAWING AS PER SITE CONDITION

出口:

A

Rc3/4

出口:

A

Rc3/4

Rc3/4

A

出口:

SYTZ60A

SYTZ60A

SYTZ60A

机尾

SYTC100A

FOR CLIENT ENGINEER'S APPROVAL PRIOR TO SITE EXECUTION.

机头

机头

机尾

R

Motor axis 3

710

EUROPACK

ABB KAST+

Motor axis 3

KAST

R710

PS

3. ALL WORKS HEREIN SHALL BE PROVIDED WITH PIPE AND EQUIPMENT SUPPORT NEEDED.

2.80

TCQYS100A-

Ⅱ

3.00

1205

24000 canopy

4. PIPE ROUTE SHALL BE VERIFIED ON SITE WORKABILITY, PROPOSED ALTERNATE SOLUTION IF

SHOWN CANNOT WORK AS PER SITE CONDITION.

5. REFER TO LATEST ARCHI PLAN FOR THE FINAL LOCATIONS AND LAYOUT OF LV, MCC & CONTROL ROOM.

6. REFER TO CD-ME-GN-MV-6004 FOR FURTHER INFORMATION.

7. THE SYSTEM DESIGN IS INTENDED FOR AUTOMATIC CONTROL AND MONITORING SET-UP THRU BMS.

IN THE EVENT THAT BMS IS NOT YET AVAILABLE ON SITE, THE SYSTEM SHALL BE CAPABLE TO RUN

MANUALLY PROVIDED THAT ALL MANUAL CONTROLS ARE INCLUDED TO ALL EQUIPMENT.

KEY PLAN

8. ALL MECHANICAL EQUIPMENTS SHALL BE CAPABLE AND HAVE BMS PROVISIONS FOR FUTURE BMS OPERATION.

VENTILATION, REFRIGERANT PIPE BUNDLED

& CONDENSATE DRAIN PIPE FROM & FROM

& TO BELOW POINT OF CONNECTION

(SEE GENERAL NOTES FOR FURTHER

INSTRUCTION) VENTILATION, REFRIGERANT PIPE BUNDLED & CONDENSATE

(SEE MCC RM LAYOUT FOR CONTINUATION) DRAIN PIPE FROM & T/A AT CONTROL ROOM FCU'S CONNECTION

(SEE GENERAL NOTES FOR FURTHER INSTRUCTION)

Ø350 FAD AT H/L

SEE LV ROOM LAYOUT FOR

CONTINUATION

23100

CONDENSATE DRAIN AT H/L TO

NEAREST DRAIN CONNECTION 6000 4500 6000 6600

AND REFRIGERANT PIPE BUNDLED

TO ACCU AREA NEAR INDOOR

SUBSTATION SEE LV ROOM FD

LAYOUT FOR CONTINUATION

300 x 250 FAG MD

AT H/L

UP MD

MUTZ600X3J

FCU

W-1 500 x 300 SAD AT

MEZZANINE H/L

预埋角钢

EXISTING

6000

CONTROL TLSUs25 TLSUs25 VD

ROOM DS

5T AHU-2 REFRIGERANT AND VD

CONDENSATE DRAIN STARTER

270

FCU CONNECTION AT MEZZANINE L/L

AHU

TDTG5028

TDTG5028

W-2

2

TDTG4028

TDTG4028

AHU AT MCC ROOM

MEZZANINE LEVEL MD

12000

WEIGHT: 1550KG

19T D01 19T D02 19T D03 LENGHT: 3890mm VD

LINE OF EXISTING WALL 700 x 350 RAD AT

TO BE REMOVED 28T F1 28T F2

TDTG4028

WIDTH: 1350mm 700 x 400 SAD FROM MEZZANINE AT H/L

TDTG4028

FCU 19T D04 19T D05 19T D6 HEIGHT: 1070mm H/L TO BELOW

W-3 MEZZANINE AT H/L

+4.50

REFRIGERANT PIPE

TDTG4028

RC Plinth of: VD VD

BUNDLE & CONDENSATE 37T D07 37T D08 37T D09

TDTG4028

4090 x 1550 x 100

6000

DRAIN TAP INTO WALL 28T F3 28T F4

MOUNTED TYPE FCU AT H/L 300 x 250 RAG

(TYP TO 4 Nos) 300 x 250 SAG TYP TO 4 Nos

TYP TO 5 Nos

CONTROL

ROOM FCU

EXTENSION 25T F5 25T F6 500 x 300 SAD AT

W-4 37T D10 37T D11 37T D12 MEZZANINE H/L VD VD

A B

GE-MV-1008 GE-MV-1008

INTERIM AC & VENTILATION SYSTEM PLAN LAYOUT

1 FOR CONTROL ROOM (3RD FLR @ PELLET MILL) INTERIM AC & VENTILATION SYSTEM PLAN LAYOUT

GE-MV-1008 SCALE: 1:100 3 FOR MCC ROOM (2ND FLR @ PELLET MILL)

GE-MV-1008 SCALE: 1:100

FRESH AIR

VENTILATION FOR

CONTROL ROOM

300 x 250 RAG

E 500 x 300 SAD TYP TO 4 Nos

Ø250 FAD

700 x 400 SAD MD FD

VD

PREMIX

VD

AREA

WORKSHOP

Y6 MD Ø350 FAD

700 x 350 RAD AT

300 x 250 SAG AHU MEZZANINE AT H/L AHU

REFRIGERANT &

TYP TO 5 Nos 2 2 CONDENSATE DRAIN

PROVISION FOR

REFRIGERANT CONTROL RM FROM

VD VD VD VD & CONDENSATE AND TO ABOVE

DRAIN AT L/L

500 x 300 SAD REFRIGERANT &

500 x 300 SAD

CONDENSATE

DRAIN AT L/L

Ø450 SAD

FROM ABOVE ROOF

T/B AT L/L MCC ROOM MCC ROOM

ROOM

ELECTRICAL

Y7

SECTION - A NOTE: SECTION - B

LV ROOM

MD SCALE 1:100 1. ENSURE THE MEZZANINE FLOOR LEVEL SHALL BE CHECKED SCALE 1:100

IN REFERENCE TO ADM MCC FINAL REQUIREMENT.

2. PROVIDE SHOP DRAWING FOR CLIENT APROVAL PRIOR TO

SITE EXECUTION.

AHU Ø350 FAD

3 AT H/L

Ø250 FAD FROM H/L DS

TO AHU CONNECTION LEVEL MD STARTER

CONDENSATE DRAIN AT H/L TO NEAREST

Y8 DRAIN CONNECTION AND REFRIGERANT

MD Ø400 RAD PIPE BUNDLED TO MCC & CONTROL RM

FROM BELOW ROOF SEE MCC ROOM LAYOUT FOR

Ø32CONDENSATE DRAIN TO AHU CONNECTION LEVEL

EMPTY CONTINUATION

TAP TO NEAREST POINT

PALLETMAGAZINE

OF DISCHARGE

Ø400 FAD

AT H/L FROM

SF/VA-7

FRESH AIR DUCT AND REFRIGERANT BUNDLE

FROM ACCU AREA AND SF/VA-7

SEE CD-ME-SH-AC-7005 FOR CONTINUATION

INTERIM AC & VENTILATION SYSTEM PLAN

2 LAYOUT FOR LV ROOM

GE-MV-1008 SCALE: 1:100

FOR CONSTRUCTION

OWNER'S NAME: DRAWING NAME: CHECKED

PRC NO. 4544 NOTE: PROJECT NAME NO. ISSUED FOR DATE SHEET NO.:

BY

THIS DRAWING, AS AN INSTRUMENT OF

SERVICE, IS AN INTELLECTUAL PROPERTY 0 CONSTRUCTION 04.30.2021

T.I.N 272-243-076 OF ARCHETYPE PHILIPPINES WHETHER THE

OBJECT FOR WHICH IT IS MADE IS NEOVIA Philippines, Bulacan NEOVIA PHILIPPINES, INC. INTERIM AC & VENTILATION CD-ME-GE-MV-1008

EXECUTED OR NOT. IT SHALL BE UNLAWFUL

ARTHUR Q. MERILLO JR. PTR NO. 8122831

FOR ANY PERSON TO DUPLICATE OR TO

MAKE COPIES OF THIS DOCUMENT FOR USE

Plant Animal Livestock Pellet Line CAGAYAN VALLEY ROAD, SAN ROQUE, SYSTEM PLAN LAYOUT FOR

SAN RAFAEL, BULACAN, PHILIPPINES

Professional Mechanical Engineer

IN THE REPETITION OF AND FOR OTHER

PROJECTS, WHETHER EXECUTED PARTLY Expansion LV, MCC & CONTROL ROOM PROJECT REFERENCE:

ISSUED ON 8-JAN-2020 OR IN WHOLE WITHOUT THE WRITTEN

ARCHITECTURE ENGINEERING PLANNING PROJECT MANAGEMENT COST MANAGEMENT CONSENT OF ARCHETYPE PHILIPPINES. ADM-BEP

Archetype Manila

SCALE : AS INDICATED

Chatam House, 11A, Corner of V. A. Rufino Streets, Salcedo Village, Makati Manila Philippines

T: +63 2 328 21 50

CHECKED BY: RM ISSUED AT MAKATI CITY REPUBLIC ACT 9266

.....................................................................................

CONSTRUCTION DESIGN

DATE REV.

E: info.mnl@archetype-group.com

www.archetype-group.com DRAWN BY: GF IAPOA

CAGAYAN VALLEY ROAD, SAN ROQUE,

SAN RAFAEL, BULACAN, PHILIPPINES

CLIENT'S SIGNITURE

MECHANICAL 04.30.2021 0

SHEET ISSUED DATE: 04/30/21 ADM-BEP-ADM-BEP-CD-ME-GE-MV-1008

You might also like

- Strangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindFrom EverandStrangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindNo ratings yet

- If I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)From EverandIf I Were Born Here Volume II (Greece, India, Kenya, Mexico, Israel)No ratings yet

- Extreme Rhyming Poetry: Over 400 Inspirational Poems of Wit, Wisdom, and Humor (Five Books in One)From EverandExtreme Rhyming Poetry: Over 400 Inspirational Poems of Wit, Wisdom, and Humor (Five Books in One)No ratings yet

- Special and Different: The Autistic Traveler: Judgment, Redemption, & VictoryFrom EverandSpecial and Different: The Autistic Traveler: Judgment, Redemption, & VictoryNo ratings yet

- What Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoFrom EverandWhat Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoNo ratings yet

- Colonial Comics, Volume II: New England, 1750–1775From EverandColonial Comics, Volume II: New England, 1750–1775Rating: 3 out of 5 stars3/5 (1)

- (Column Size) : (Grey Mat Tile Finish)Document1 page(Column Size) : (Grey Mat Tile Finish)Prdeep SinghNo ratings yet

- Topology Optimization of Building Bracing Schemes: Zhen John GooDocument66 pagesTopology Optimization of Building Bracing Schemes: Zhen John GooMark Magadia IpaNo ratings yet

- Seismic - Shear WallsDocument13 pagesSeismic - Shear WallsVasil GeorgievNo ratings yet

- Seismic - Shear WallsDocument13 pagesSeismic - Shear WallsVasil GeorgievNo ratings yet

- Steel Plate Shear WallDocument43 pagesSteel Plate Shear WallMark Magadia IpaNo ratings yet

- Steel Plate Shear WallDocument43 pagesSteel Plate Shear WallMark Magadia IpaNo ratings yet

- Pelleting Line MCCDocument17 pagesPelleting Line MCCMark Magadia IpaNo ratings yet

- Premix Line MCCDocument15 pagesPremix Line MCCMark Magadia IpaNo ratings yet

- Title Block1Document1 pageTitle Block1Mark Magadia IpaNo ratings yet

- Second Floor Plan Admin. & Sports Hall: A C E G H I B D FDocument1 pageSecond Floor Plan Admin. & Sports Hall: A C E G H I B D FMark Magadia IpaNo ratings yet

- Ground Floor Plan Admin. & Sports Hall: A C E G H I B D FDocument1 pageGround Floor Plan Admin. & Sports Hall: A C E G H I B D FMark Magadia IpaNo ratings yet

- Appendix 11a - Secondary Beam Design CheckDocument2 pagesAppendix 11a - Secondary Beam Design CheckMark Magadia IpaNo ratings yet

- Accounting For Non Specialists Australian 7th Edition Atrill Test BankDocument26 pagesAccounting For Non Specialists Australian 7th Edition Atrill Test BankJessicaMitchelleokj100% (49)

- Sapamine CSN Textile Softener: Technical Data SheetDocument5 pagesSapamine CSN Textile Softener: Technical Data SheetsaskoNo ratings yet

- LogDocument15 pagesLogandrew_hm925635No ratings yet

- Cultures of Learning: Language Classrooms in China: Martin Cortazzi Lixian JinDocument54 pagesCultures of Learning: Language Classrooms in China: Martin Cortazzi Lixian JinyhoulhandhariNo ratings yet

- 2006fileaveo MTDocument63 pages2006fileaveo MTeurospeed2100% (1)

- St. Augustine School of Nursing: Republic of The Philippines Department of Education SASN - Las PiñasDocument2 pagesSt. Augustine School of Nursing: Republic of The Philippines Department of Education SASN - Las PiñasCarl Joseph MasujerNo ratings yet

- Project management software enables collaborationDocument4 pagesProject management software enables collaborationNoman AliNo ratings yet

- GRP 10 JV'sDocument43 pagesGRP 10 JV'sManas ChaturvediNo ratings yet

- Modigliani MillerDocument12 pagesModigliani MillerAlvaro CamañoNo ratings yet

- Developing Website Information ArchitectureDocument39 pagesDeveloping Website Information ArchitectureBizuNo ratings yet

- ISO 13485 Version 2016 Requirements NotesDocument24 pagesISO 13485 Version 2016 Requirements Notesda_reaper_dasNo ratings yet

- Integrated Marketing Communication PlanDocument5 pagesIntegrated Marketing Communication Planprojectwork185No ratings yet

- Acrogym: by Ahana AnandDocument9 pagesAcrogym: by Ahana AnandAhana AnandNo ratings yet

- BCG ReportDocument9 pagesBCG Reportjlgjlj ljglkhNo ratings yet

- Challenges Faced by Irregular StudentsDocument13 pagesChallenges Faced by Irregular StudentsTicag Teo80% (5)

- Edited SCHOOL IN SERVICE TRAINING FOR TEACHERS MID YEAR 2023Document11 pagesEdited SCHOOL IN SERVICE TRAINING FOR TEACHERS MID YEAR 2023Lordennisa MacawileNo ratings yet

- The Life of The Last Pharaoh of EgyptDocument16 pagesThe Life of The Last Pharaoh of EgyptShanelle BarrilNo ratings yet

- Nursing Care Plans for ChildrenDocument4 pagesNursing Care Plans for ChildrenAlexander Rodriguez OlipasNo ratings yet

- Christopher Westra - Laws of Attraction PDFDocument3 pagesChristopher Westra - Laws of Attraction PDFZachary LeeNo ratings yet

- Strategic Marketing Plan for British American TobaccoDocument31 pagesStrategic Marketing Plan for British American TobaccoAli Abbas50% (2)

- Mutual FundDocument2 pagesMutual Fundkum_praNo ratings yet

- Mercer Role and Job Analysis InfoDocument3 pagesMercer Role and Job Analysis InfojehaniaNo ratings yet

- Foundations On Expansive Soils: 3.1. BackgroundDocument31 pagesFoundations On Expansive Soils: 3.1. BackgroundbiniNo ratings yet

- Articulos 2022-2Document11 pagesArticulos 2022-2Nilser Enrique Valle HernandezNo ratings yet

- Bachelor of Arts (Psychology HR Management) Y3 V2Document1 pageBachelor of Arts (Psychology HR Management) Y3 V2Kenny sylvainNo ratings yet

- Opera Arias and Sinfonias: VivaldiDocument22 pagesOpera Arias and Sinfonias: VivaldiDardo CocettaNo ratings yet

- OlayDocument36 pagesOlayrachit.chaudharyNo ratings yet

- IruvarDocument5 pagesIruvarKarthikeya KaredlaNo ratings yet

- Group ActDocument3 pagesGroup ActRey Visitacion MolinaNo ratings yet