Professional Documents

Culture Documents

Less Is More For Electrical Test Instruments: Figure 1 - Insulation Testing Is Made Easy by Color Coding and Detailed

Uploaded by

Mohammad Afiq AbidinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Less Is More For Electrical Test Instruments: Figure 1 - Insulation Testing Is Made Easy by Color Coding and Detailed

Uploaded by

Mohammad Afiq AbidinCopyright:

Available Formats

Less Is More For Electrical Test Instruments safer and more reliable way to do things is to simply

By: Jeff Jowett push the same button on a single instrument every time

a test result must be recorded and send it all to a single

A 21st century trend in electrical instrumentation has

file in a single operation. The costs and delays of annual

leaned toward smaller, lighter and easier to manipulate

calibration is significantly reduced when it can all be

testers through microcircuitry. Being portable and easy

accomplished in one operation.

to manipulate can be beneficial enough, but there’s

much more to it. Size reduction is not just for ease of

Safety First

manufacturing or an advertising gimmick. Multiple

A handheld instrument is the paragon of convenience,

instruments can be combined into a single handheld

but ease of operation is further enhanced by bold and

tester, so that an entire job can be completed with

robust selector switches. Multifunction membrane

a single piece of test equipment. The user can benefit

switches are fancy and appear futuristic, but they’re for

from notable cost savings and job improvement. This

the lab, not for the jobsite. Selector switches are clearer

article will examine how many of the functions found

in function, less prone to operator error and can be

in multiple different instruments can be included in just

manipulated even with safety gloves. But there is a safety

one handheld tester.

consideration with handheld units that it is imperative

to understand and observe. Small overall size condenses

Less Is More

the distances between circuits and components, posing

Testing electric motors for repair, maintenance and

the threat of internal arcing under the impact of voltage

installation can take up to six different instruments.

spikes and faults on the utility serving the site. Not to

There is added expense in acquisition, the time spent on

worry. All quality instruments are protected from this

the job changing from one instrument to another with

danger by the IEC61010 rating. The rating tells the

attendant hookup and the possibility of traveling to a job

operator in what environment and on what operating

only to find that one of the testers has been left. These

voltage the tester can be safely used, without threat of

instruments may have different degrees of accuracy,

arc flash/blast. Learn to interpret this rating and always

creating an added challenge to coordinating all results

apply it correctly to the job environment. If an instrument

into a coherent picture for regulatory conformance or

does not prominently indicate the IEC rating, don’t buy

for the client. Similarly, there is often the requirement

it.

to record test results into a data base for personal use or

submit them to a third party, and this can be inordinately

complicated by multiple data bases. The much easier,

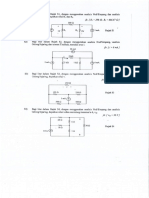

Figure 1 – Insulation testing is made easy by color coding and detailed results on display

Article appeared in Utility Products - March 2021 edition 1

Testing Insulation further refined with a top-of-line tester that has almost

An important and fundamental electrical test is the infinite voltage selection. These models can be set up in

insulation test, and many models are built around this. 1V increments across the range so that, for instance, 600V

The test applies a selected voltage across the insulation equipment can be tested at 600V, not 500V. Setup should

and measures how much…or, more practically, how also include a pass/fail buzzer, so that testing can speed

little…current it pulls. This is converted by Ohm’s Law up when merely meeting a compliance requirement.

into resistance. The unit of measurement is the Megohm, Continuity

or one million ohms. Good insulation should not measure The opposite of insulation is continuity, so the two

less than a Megohm. functions commonly come together. And they should.

Continuity is a simple test, where low voltage and a small

There may be an exception for insulation that is buried test current verify that circuits are intact and without

inside additional layers, such as insulating varnish on wiring errors. But even this simple test can enjoy added

motor windings. A good tester will have a sharp voltage advantages. Sophisticated testers show color coded lead

rise up to full selected voltage by the time it reaches 1 hookup on the display, so that simple connection errors

MΩ. Poorly designed testers will show a slower voltage are generally the result of haste and are spotted and

rise, and this is deceptive because on the critical low end corrected without additional error or test time. Uni- and

of the MΩ range, where equipment may be wearing out, bi-directional testing without having to switch leads,

the insulation isn’t being fully stressed and the results combined with a diode test, allows for quick proofing of

can be misleading. An on-board thermocouple greatly startup circuits and the like.

increases the accuracy and effectiveness of these tests,

as the measurements can be automatically corrected There’s More to Low Resistance Testing

to a common temperature and entered in a data base. However, there’s more to low resistance testing than

Temperature has a profound effect on insulation basic continuity. The ability to pass a milli-amp or

readings, but the tediousness of hand correction has two only establishes contact. It doesn’t prove that a

often led to its omission. connection can perform its function well, such as by

producing excessive heat or vibrating loose. Genuine

Common Utility Voltage Kelvin bridge measurements below 1Ω with a robust

Equipment running from common utility voltage…120, current and micro-ohm resolution have traditionally

240, 480…can all be tested with a 1 kV tester. Industry called for a separate tester, with two current terminals

standard has been 500V for maintenance tests, 1 kV for on the outside and two potential terminals on the inside,

troubleshooting that can pull arcs from damaged spots that did nothing else. Full-featured motor and electrical

or further exploit other weaknesses. Testing can be testers now include this feature, with test currents of 0.1

Figure 2 - Motor hookup is facilitated by on-screen guidance

Article appeared in Utility Products - March 2021 edition 2

Figure 3 – Clearly marked selector switches and color coding help to eliminate operator error

A and measurement to 1 mΩ with 0.01 mΩ resolution. Test Leads Are Important

This enables the operator to spot joints and connections Test leads are an indispensable part of electrical testing,

that are in process of weakening well before they become and as often overlooked as they are important. They

a problem. Graphic displays again show correct setup and become worn and, without damage being noticeable to

bi-directional testing can be done from the front panel the eye, can ‘leak’. Manipulating the leads should not

without physically switching leads. affect the reading on the display, nor should squeezing

them together. Modern testers minimize potential lead

Motor Rotation Is Important errors with color displays. A color display isn’t just for

An important but overlooked function on electric motors looks. It can guide the operator by color coding with the

is motor rotation. Traditionally, this requires a separate leads and specific functions, cutting down or eliminating

piece of equipment; often a small, handheld item easily incorrect hookups that can be costly in time, accuracy

left behind. Now, this function can be included in a and reliability.

multifunction tester. Again, a sophisticated display can

show the operator the lead setup and then a manual Additional Safety Features are Necessary

turn of the shaft will indicate if the connections are With so many functions, all-in-one testers should include

correct for that rotation (L1 L2 L3). AC/DC voltmeter redundant safety features. In addition to those already

and frequency measurement facilitate correct supply mentioned there should be automatic discharge of

connections for desired shaft rotation. A built-in LCR stored charge on the test item, live voltage warning, test

meter measures inductance, capacitance and resistance, inhibition in the presence of extraneous voltage, and

for more advanced troubleshooting in components such terminal lockout voltages. This latter protection permits

as motor and transformer windings. A sophisticated testing to proceed in the presence of harmless low

tester will further assist troubleshooting by determining voltages, such as crosstalk in telecom, while still safely

the principal component of the load free of operator blocking test initiation at higher voltages.

involvement and posting that measurement to the

display. A wise man once observed that time is money, and that

is certainly true in electrical maintenance, installation

and repair. A compact, multi-function test instrument

can save test time while preventing costly errors and

saving data for future comparison. Not only electric

motor testing, but general maintenance, prevention

Article appeared in Utility Products - March 2021 edition 3

and troubleshooting of the entire electrical plant can be

implemented. All operations can be performed well and

accurately, without compromising the quality of results

you would get from dedicated instruments.

About the author: Jeff Jowett is currently a senior applications

engineer at Megger in Norristown, PA. He holds a B.S. Ursinus

College, Collegeville, PA in biology, chemistry.

Jeff has 40+ years continuous employment, beginning with

James G. Biddle Co., then Biddle Instruments, then AVO

International, and now Megger. Last 25 years in Marketing

Dept., Distribution Sales.

Jeff has written numerous trade journal articles, conducted

training of distributors’ sales staffs and customers, and given

seminars, training sessions and talks to various electrical

societies [including Nat’l Electrical Testing Ass’n (NETA) and

Nat’l Joint Apprenticeship Training Committee (NJATC)], and to

those open to the general industry public.

Member IEEE, and committee for the revision of Standard 81,

Recommended Guide for Measuring Ground Resistance and

Potential Gradients in the Earth.

Megger - Valley Forge - 2621 Van Buren Ave. Norristown, PA 19403

T 866-254-0962

Article appeared in FUtility

610-676-8610

Products - March 2021 edition

us.megger.com

4

You might also like

- Fluke Electrical Testing Safety (3392477 6003 ENG C W)Document4 pagesFluke Electrical Testing Safety (3392477 6003 ENG C W)jmarrero488307No ratings yet

- Insulation Resistance Cheat SheetDocument1 pageInsulation Resistance Cheat SheetRahulNo ratings yet

- Advances in Partial Discharge Monitoring: Utility Week ExplainsDocument6 pagesAdvances in Partial Discharge Monitoring: Utility Week ExplainsMohamedHussein MohamedHusseinNo ratings yet

- Article Testing The State of High Voltage Insulation Hummel ENUDocument6 pagesArticle Testing The State of High Voltage Insulation Hummel ENUarnenylundNo ratings yet

- Cable DiagnosticsDocument1 pageCable DiagnosticsRakesh KumarNo ratings yet

- Electric and Hybrid Vehicles Need A Special Testing Regime: Picture: BoschDocument2 pagesElectric and Hybrid Vehicles Need A Special Testing Regime: Picture: BoschMosa Elnaid ElnaidNo ratings yet

- 9.2 Electronic Testing RevDocument88 pages9.2 Electronic Testing RevHasan KayaNo ratings yet

- HV Lab 2019 Isulation Tester: Types of Insulation Resistance Tests 1Document5 pagesHV Lab 2019 Isulation Tester: Types of Insulation Resistance Tests 1حسن علي جاسمNo ratings yet

- HV Lab 2019 Isulation Tester: Types of Insulation Resistance Tests 1Document5 pagesHV Lab 2019 Isulation Tester: Types of Insulation Resistance Tests 1حسن علي جاسمNo ratings yet

- HV Lab 2019 Isulation Tester: Types of Insulation Resistance Tests 1Document5 pagesHV Lab 2019 Isulation Tester: Types of Insulation Resistance Tests 1حسن علي جاسمNo ratings yet

- 5kV 10kV Test Lead An en V01Document16 pages5kV 10kV Test Lead An en V01walcalNo ratings yet

- Component Tests: Insulation Test SystemDocument12 pagesComponent Tests: Insulation Test System1382aceNo ratings yet

- SEP LEM012SD User ManualDocument11 pagesSEP LEM012SD User ManualkillimandjarogeeettNo ratings yet

- IDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHDocument58 pagesIDC - HV Conf - Perth 2015 - Condition Monitoring of High Voltage Switchgear - KHbmwr1100s_055542No ratings yet

- Microscanner Series Getting Started Guide - 1Document14 pagesMicroscanner Series Getting Started Guide - 1Eldar IsgenderovNo ratings yet

- Electric Motor Testing: Offline: Jan Michael B. Castaneda College of Engineering University of Rizal SystemDocument8 pagesElectric Motor Testing: Offline: Jan Michael B. Castaneda College of Engineering University of Rizal SystemJMNo ratings yet

- Theory Megger Basic Insulation TestingDocument7 pagesTheory Megger Basic Insulation TestingNick Kenworthy100% (1)

- Scribed 4Document3 pagesScribed 4zayed shbanNo ratings yet

- Portable Appliance Tester - Model 6201Document24 pagesPortable Appliance Tester - Model 6201chockanan suwanprasertNo ratings yet

- Zero Defect TestingDocument4 pagesZero Defect TestingNagamuthu PandianNo ratings yet

- The Importance of The Guard Terminal in Insulation TestingDocument5 pagesThe Importance of The Guard Terminal in Insulation TestingAlex parejas ayuqueNo ratings yet

- Picture of Device Name The Use: Megger TesterDocument3 pagesPicture of Device Name The Use: Megger TesterYousef AliNo ratings yet

- 2461452d Usen Insulation Brochure WDocument12 pages2461452d Usen Insulation Brochure WAnonymous u0wETydF100% (1)

- 6 Common Problems When Testing Sliprings - Brochure - FINAL MinDocument10 pages6 Common Problems When Testing Sliprings - Brochure - FINAL MinudhayNo ratings yet

- 34NPS10 2012-02-09 EN ColorDocument8 pages34NPS10 2012-02-09 EN ColorydeNo ratings yet

- UPS Fails Insulation Resistance Test - 5E67Document2 pagesUPS Fails Insulation Resistance Test - 5E67JaviTron74No ratings yet

- Midas Micro 2883 - Mobile Insulation Diagnosis and Analysing SystemDocument6 pagesMidas Micro 2883 - Mobile Insulation Diagnosis and Analysing SystemChristian EstebanNo ratings yet

- CIRED2007 0230 PaperDocument4 pagesCIRED2007 0230 PaperAries dNo ratings yet

- High Volume Armature Testing: Lance Straughn Slaughter CompanyDocument10 pagesHigh Volume Armature Testing: Lance Straughn Slaughter Companyronald allan liviocoNo ratings yet

- MODEL 6011A: Instruction ManualDocument32 pagesMODEL 6011A: Instruction ManualRktBatamNo ratings yet

- Diagnostic Insulation Testing Digest 5 and 10 KV PDFDocument2 pagesDiagnostic Insulation Testing Digest 5 and 10 KV PDFIsrael JosueNo ratings yet

- O&M Manual: Date: 01.02.2021 Department: Technical Service EuropeDocument11 pagesO&M Manual: Date: 01.02.2021 Department: Technical Service Europekaltoum elmnaouarNo ratings yet

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationjorge castilloNo ratings yet

- Relay and Multifunctional Substation Test System: Sverker 900Document12 pagesRelay and Multifunctional Substation Test System: Sverker 900Stelvio QuizolaNo ratings yet

- Integrated Partial Discharge Testing and Monitoring SolutionsDocument4 pagesIntegrated Partial Discharge Testing and Monitoring SolutionsThien Nguyen VanNo ratings yet

- EE-153 IEE Lab Manual Jan 2022Document71 pagesEE-153 IEE Lab Manual Jan 2022Maqsood Ahmad KhanNo ratings yet

- Carrying Out Fault Diagnosis On Electrical Equipment and CircuitsDocument9 pagesCarrying Out Fault Diagnosis On Electrical Equipment and CircuitsJordan Leah100% (3)

- Manual de Uso Micro-Ohmímetro Digital Digital Micro-Ohmmeter User GuideDocument49 pagesManual de Uso Micro-Ohmímetro Digital Digital Micro-Ohmmeter User Guidejavier salazar raveloNo ratings yet

- UT501A User Manual PDFDocument2 pagesUT501A User Manual PDFAlban Abazi100% (1)

- 2.1 - Cec342Document9 pages2.1 - Cec342Sriram Sundar SubramanianNo ratings yet

- Testing Equipment Manual PDFDocument114 pagesTesting Equipment Manual PDFSelva MaharajanNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument10 pagesFree Digital Multimeter Calibration ProcedureGordinhorsNo ratings yet

- Motor InsulationDocument3 pagesMotor InsulationsickosatNo ratings yet

- 5 KV & 10 KV Insulation Tester Lead Sets: Application NoteDocument16 pages5 KV & 10 KV Insulation Tester Lead Sets: Application Notetunglee091No ratings yet

- Surge Protection Catalogue of AustraliaDocument44 pagesSurge Protection Catalogue of AustraliaSrikanth NakkaNo ratings yet

- EasyPact CVS Brochure-2013Document9 pagesEasyPact CVS Brochure-2013nooruddinkhan1No ratings yet

- Agilent E7495B Base Station Test Set: Technical OverviewDocument16 pagesAgilent E7495B Base Station Test Set: Technical OverviewJuergen PlagaNo ratings yet

- Man Sicam Q100 UsDocument376 pagesMan Sicam Q100 UsHuy Truong GiaNo ratings yet

- Reliability and Quality Testing of Materials: B.K. JonesDocument4 pagesReliability and Quality Testing of Materials: B.K. JonesveficilNo ratings yet

- The Basics of Insulation TestingDocument6 pagesThe Basics of Insulation TestingbhpNo ratings yet

- LS2208 Datasheet PDFDocument2 pagesLS2208 Datasheet PDFPop-Coman SimionNo ratings yet

- Omron Relay DatasheetDocument4 pagesOmron Relay DatasheetFrilya Andarni Saragih SumbayakNo ratings yet

- 10 Best Multimeters For Home Use and Professional WorkDocument16 pages10 Best Multimeters For Home Use and Professional WorkOluwafemi Olarinde0% (1)

- Hi POT Testing OptionsDocument3 pagesHi POT Testing Optionspaolomike1No ratings yet

- Measurement of Adjustable Speed Drives With Fluke MetersDocument28 pagesMeasurement of Adjustable Speed Drives With Fluke MetersnaveedfndNo ratings yet

- PRODUCT TESTING FILE Mahidlawon Decreased QuestionsDocument3 pagesPRODUCT TESTING FILE Mahidlawon Decreased QuestionsJeffcaster ComelNo ratings yet

- ISA DRTS 6 AplicationDocument53 pagesISA DRTS 6 Aplicationmertoiu8658100% (1)

- Training Presentation - Elcometer 266Document17 pagesTraining Presentation - Elcometer 266shabbir626No ratings yet

- A Brief Biography of Ytm Tunku Abdul RahmanDocument2 pagesA Brief Biography of Ytm Tunku Abdul RahmanAhmad RabbaniNo ratings yet

- Senarai Nama Rumah SukanDocument5 pagesSenarai Nama Rumah SukanMohammad Afiq AbidinNo ratings yet

- Tray and Ladder Practice GuideDocument73 pagesTray and Ladder Practice GuidemariusrotaruNo ratings yet

- Ent Assignment 2 Syue 2Document13 pagesEnt Assignment 2 Syue 2hyebibie75% (4)

- Multiplexing: Figure 1: Concept of MultiplexingDocument4 pagesMultiplexing: Figure 1: Concept of MultiplexingMohammad Afiq AbidinNo ratings yet

- Megger InsulationtesterDocument67 pagesMegger InsulationtesterNh Chuminda YapaNo ratings yet

- Leb21903@40503 MicroprocessorDocument8 pagesLeb21903@40503 MicroprocessorMohammad Afiq AbidinNo ratings yet

- Task 3 Tank Traffic TempDocument15 pagesTask 3 Tank Traffic TempMohammad Afiq AbidinNo ratings yet

- EC AssignmentDocument7 pagesEC AssignmentMohammad Afiq AbidinNo ratings yet

- Ford 350 Navistar 6.0 Diesel Diagnostic PDFDocument83 pagesFord 350 Navistar 6.0 Diesel Diagnostic PDFChristopher Ramos93% (14)

- Course-Syllabus (Electricity and Magnetism)Document6 pagesCourse-Syllabus (Electricity and Magnetism)Kenneth Roy MatuguinaNo ratings yet

- Codigos de Erro Ar SplitDocument9 pagesCodigos de Erro Ar SplitJeremiasPereiraNo ratings yet

- SD840S PDF, SD840S Description, SD840S Datasheets, SD840S View - ALLDATASHEET - PDFDocument2 pagesSD840S PDF, SD840S Description, SD840S Datasheets, SD840S View - ALLDATASHEET - PDFOralia MendezNo ratings yet

- Electrical Circuits and Circuit AnalysisDocument147 pagesElectrical Circuits and Circuit AnalysisGuruKPO100% (3)

- r1858b89dd c8f6 41da b2d4 3a8c18e129a4 Gc1f Eng Designers Reference Handbook LDocument123 pagesr1858b89dd c8f6 41da b2d4 3a8c18e129a4 Gc1f Eng Designers Reference Handbook Lناجى ابوعورةNo ratings yet

- Reference 1Document17 pagesReference 1Abu-Zar GhaffariNo ratings yet

- 1985 EwdDocument113 pages1985 Ewdcircuitkev00No ratings yet

- Engineering Utilities 1Document21 pagesEngineering Utilities 1Julia Jaffa ChavezNo ratings yet

- Current and VoltageDocument1 pageCurrent and VoltageSuresh SenanayakeNo ratings yet

- GalvanometerDocument8 pagesGalvanometerAnkit ChauhanNo ratings yet

- SS350 ManualDocument6 pagesSS350 ManualDennis VenturaNo ratings yet

- Swift Sensors APAC Retail Price List 2018.11.30Document2 pagesSwift Sensors APAC Retail Price List 2018.11.30Krishnakumar GanesanNo ratings yet

- ENGLISH 2 - M D Djuric - Texts For TranslationDocument198 pagesENGLISH 2 - M D Djuric - Texts For TranslationДраган ВујчићNo ratings yet

- Suspension Fault CodesDocument7 pagesSuspension Fault CodeskamalNo ratings yet

- Unilap Iso 5 KV: The Insulation ExpertDocument2 pagesUnilap Iso 5 KV: The Insulation Expertflorin071100% (1)

- Docslide - Us Solucionario Capitulo 26 Paul e TippensDocument16 pagesDocslide - Us Solucionario Capitulo 26 Paul e TippensoscarNo ratings yet

- Single Phase TransformerDocument10 pagesSingle Phase Transformerঅন্বেষা সেনগুপ্তNo ratings yet

- Service Manual: 20J-S100/S100S CJ20S10 21MJ50Document30 pagesService Manual: 20J-S100/S100S CJ20S10 21MJ50Francisco BandresNo ratings yet

- Standard Test Format CSDDocument843 pagesStandard Test Format CSDtonyNo ratings yet

- Megger S1568-S11068-S11568 - Ug - en - V02Document33 pagesMegger S1568-S11068-S11568 - Ug - en - V02Cesar Gonzalo Vitali DinamarcaNo ratings yet

- Sample SOPDocument1 pageSample SOPoverseasraghuNo ratings yet

- NGR SizingDocument14 pagesNGR SizingSibolis Naburju0% (1)

- CSKTDocument8 pagesCSKThuy PhamNo ratings yet

- A11) ShortageReportDocument3,439 pagesA11) ShortageReportNhàn BeeNo ratings yet

- Misc 8DNL 8MPL 8MPN B PDFDocument41 pagesMisc 8DNL 8MPL 8MPN B PDFVesica PiscesNo ratings yet

- Chapter 1-1 - Intro and Part 1 and 2Document59 pagesChapter 1-1 - Intro and Part 1 and 2Hanis SyafiqNo ratings yet

- BIL ED0-P060A-01-S75 Order Code: BIL0003Document3 pagesBIL ED0-P060A-01-S75 Order Code: BIL0003LeonardNo ratings yet

- Functional Testing of G60-A Test Results EngroDocument14 pagesFunctional Testing of G60-A Test Results EngroAnonymous zxtBoTT100% (2)

- EMP GeneratorDocument30 pagesEMP GeneratorRed100% (2)