Professional Documents

Culture Documents

TWD1643GE: Volvo Penta Genset Engine

Uploaded by

mohsen_cumminsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TWD1643GE: Volvo Penta Genset Engine

Uploaded by

mohsen_cumminsCopyright:

Available Formats

VOLVO PENTA GENSET ENGINE

TWD1643GE

613 kW (834 hp) at 1500 rpm, 674 kW (917 hp) at 1800 rpm

The TWD1643GE is a powerful, reliable

and economical Generating Set Diesel

Engine built on the dependable in-line six

design.

Durability & low noise

Designed for easiest, fastest and most

economical installation. Well-balanced

to produce smooth and vibration-free

operation with low noise level.

To maintain a controlled working

temperature in cylinders and combustion

chambers, the engine is equipped with

piston cooling. The engine is also fitted

with replaceable cylinder liners and valve

seats/guides to ensure maximum durability

and service life of the engine.

Low exhaust emission

The state of the art, high-tech injection

and charging system with low internal

losses contributes to excellent combustion

and low fuel consumption.

The TWD1643GE is certified for EPA

Tier 2. An additional feature is that

TWD1643GE fulfils EU Stage 2 exhaust Features

emission levels. – Tropical cooling system (55°C)

– Fully electronic with Volvo Penta EMS 2

Easy service & maintenance – Dual frequency switch (between 1500 rpm and 1800 rpm)

Easily accessible service and maintenance – High power density

points contribute to the ease of service of – Emission compliant

the engine. – Low noise levels

– Low fuel consumption

Technical description – Gen Pac configuration

– Compact design for the power class

Engine and block

– Optimized cast iron cylinder block with op-

timum distribution of forces without the block – Gear type lubricating oil pump, gear driven – Intermediate charge air coolers for both

being unnessarily heavy. by the transmission turbo chargers

– Wet, replaceable cylinder liners – Waste gate system for the high pressure

Fuel system turbo charger

– Piston cooling for low piston temperature

– Non-return fuel valve

and reduced ring temperature Electrical system

– Electronic unit injectors

– Tapered connecting rods for reduce risk of – Engine Management System 2 (EMS 2), an

– Fuel prefilter with water separator and wa-

piston cracking electronically controlled processing system

ter-in-fuel indicator / alarm

– Crankshaft induction hardened bearing sur- which optimizes engine performance. It also

– Gear driven low-pressure fuel pump

faces and fillets with seven bearings for mod- includes advanced facilities for diagnostics

– Fine fuel filter with manual feed pump and

erate load on main and high-end bearings and fault tracing

fuel pressure switch

– Case hardened and Nitrocarburized trans- – The instruments and controls connect to the

– Fuel shut-off valve

mission gears for heavy duty operation engine via the CAN SAE J1939 interface,

– Keystone top compression rings for long Cooling system either through the Control Interface Unit

service life – New TWD-cooling system with optimized (CIU) or the Display Control Unit (DCU).

– Viscous type crankshaft vibration dampers to priority and cold start valves The CIU converts the digital CAN bus sig-

withstand single bearing alternator torsional – Two water cooled charge air coolers nal to an anolog signal, making it possible

vibrations – Efficient cooling with accurate coolant con- to connect a variety of instruments. The

– Replaceable valve guides and valve seats trol through a water distribution duct in the DCU is a control panel with display, engine

– Over head camshaft and four valves per cylinder block. Reliable sleeve thermostat control, monitoring, alarm, parameter setting

cylinder with minimum pressure drop and diagnostic functions. The DCU also

– Gear driven, maintenance-free coolant presents error codes in clear text.

Lubrication system pump with high degree of efficiency

– Full flow oil cooler – Sensors for oil pressure, oil temp, boost

– Coolant filter as standard pressure, boost temp, exhaust temp,

– Full flow disposable spin-on oil filter, for extra

high filtration Turbo charger coolant temp, fuel temp, water in fuel, fuel

– The lubricating oil level can be measured – Efficient and reliable dual stage turbo pressure and two speed sensors.

during operation chargers

TWD1643GE

Technical Data

General Standard equipment Engine Gen Pac

Engine designation....................................................................... TWD1643GE Engine

No. of cylinders and configuration........................................................ in-line 6 Automatic belt tensioner • •

Method of operation................................................................................ 4-stroke Lift eyelets • •

Bore, mm (in.)...................................................................................... 144 (5.67) Flywheel

Stroke, mm (in.)................................................................................... 165 (6.50) Flywheel housing with conn. acc. to SAE 1 • •

Displacement, l (in³)..................................................................... 16.12 (983.7) Flywheel for 14” flex. plate and flexible coupling • •

Compression ratio...................................................................................... 16.5:1 Vibration dampers • •

Dry weight, kg (lb)........................................................................... 1700 (3748)

Dry weight with Gen Pac, kg (lb)................................................ 2200 (4850) Engine suspension

Wet weight, kg (lb)......................................................................... 1770 (3902) Fixed front suspension • •

Wet weight with Gen Pac, kg (lb)............................................... 2370 (5225) Lubrication system

Oil dipstick • •

Performance 1500 rpm 1800 rpm Full-flow oil filter of spin-on type • •

with fan, kW (hp) at: By-pass oil filter of spin-on type • •

Prime Power 536 (729) 585 (796) Oil cooler, side mounted • •

Max Standby Power 596 (811) 644 (876) Low noise oil sump • •

Fuel system

Lubrication system 1500 rpm 1800 rpm Fuel filters of spin-on type • •

Oil consumption, liter/h (US gal/h) at: Electronic unit injectors • •

Prime Power 0.10 (0.026) 0.10 (0.029) Pre-filter with water separator • •

Max Standby Power 0.11 (0.029) 0.11 (0.032) Intake and exhaust system

Oil system capacity incl filters, liter.................................................................48 Air filter without rain cover • •

Air restriction indicator • •

Fuel system 1500 rpm 1800 rpm Air cooled exhaust manifold • •

Specific fuel consumption at: Connecting flange for exhaust pipe • •

Prime Power, g/kWh (lb/hph) Exhaust flange with v-clamp • •

25 % 215 (0.349) 224 (0.363) Turbo chargers, dual stage, right side • •

50 % 196 (0.318) 201 (0.326) Cooling system

75 % 196 (0.318) 197 (0.319) TWD-cooling system, tropical • •

100 % 199 (0.323) 202 (0.327) Gear driven coolant pump • •

Max Standby Power, g/kWh (lb/hph) Fan hub • •

25 % 210 (0.340) 220 (0.357) Pusher fan • •

50 % 195 (0.316) 200 (0.324) Fan guard • •

75 % 196 (0.318) 198 (0.321) Belt guard • •

100 % 200 (0.324) 204 (0.331) Control system

Engine Management System (EMS) with

Intake and exhaust system 1500 rpm 1800 rpm CAN-bus interface SAE J1939 • •

Air consumption, m³/min (cfm) at: CIU, Control Interface Unit – –

Prime Power 44 (1541) 53 (1874) DCU, Display Control Unit – –

Max Standby Power 47 (1658) 55 (1937) Alternator

Max allowable air intake restriction, Alternator 80A / 24 V • •

kPa (In wc) 5 (20.1) 5 (20.1) Starting system

Heat rejection to exhaust, kW (BTU/min) at: Starter motor, 7.0kW, 24 V • •

Prime Power 415 (23601) 472 (26842) Connection facility for extra starter motor • •

Max Standby Power 463 (26330) 540 (30709) Instruments and senders

Exhaust gas temperature after low pressure turbine, Temp. and pressure for automatic stop/alarm • •

°C (°F) at: Other equipment

Prime Power 450 (842) 422 (792) Expandable base frame − •

Max Standby Power 463 (865) 461 (862) Engine Packing

Max allowable back-pressure in exhaust line, Plastic warpping • •

kPa (In wc) 10 (40.2) 10 (40.2)

Exhaust gas flow, m³/min (cfm) at: − optional equipment or not applicable

Prime power 101.6 (3586) 119 (4201) • included in standard specification

Max Standby Power 111.8 (3949) 130.1 (4593)

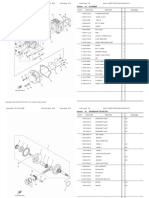

TURBO

A

CL

CL CRANKSHAFT

CRANK

SHAFT

B C

D

A* = 1930 mm / 76 in

B* = 1350 mm / 53.1 in

C = 2362 mm / 93 in

English 03-2007. © 2007 AB Volvo Penta

Note! Not all models, standard equipment and accessories are available in all countries. D = 2399 mm / 94.5 in (During transport)

All specifications are subject to change without notice. D = Max 3255 mm / 128.2 in

The engine illustrated may not be entirely identical to production standard engines. * Including radiator and intercooler

Power Standards Rating Guidelines

The engine performance corresponds to ISO 3046, BS PRIME POWER rating corresponds to ISO Standard Power for

5514 and DIN 6271. The technical data applies to an engine continuous operation. It is applicable for supplying electrical power

without cooling fan and operating on a fuel with calorific at variable load for an unlimited number of hours instead of com-

value of 42.7 MJ /kg (18360 BTU/lb) and a density of 0.84 mercially purchased power. A10 % overload capability for govering

kg/liter (7.01 lb/US gal), also where this involves a deviation purpose is available for this rating.

from the standards. Power output guaranteed within 0 to MAXIMUM STANDBY POWER rating corresponds to ISO

+2% att rated ambient conditions at delivery. Ratings are Standard Fuel Stop Power. It is applicable for supplying standby

based on ISO 8528. electrical power at variable load in areas with well established

Engine speed governing in accordance with ISO 3046/IV, electrical networks in the event of normal utility power failure. No

class A1 and ISO 8528-5 class G3 overload capability is available for this rating.

Exhaust emissions 1 hp = 1 kW x 1.36

The TWD1643GE is certified for EPA Tier 2. An aditional Information

feature is that TWD1643GE fulfils EU Stage 2 exhaust emis- For more technical data and information, please look in the Gener- AB Volvo Penta

sion levels. ating Set Engines Sales Guide. SE-405 08 Göteborg, Sweden

www.volvopenta.com

You might also like

- TAD1641GE: Volvo Penta Genset EngineDocument2 pagesTAD1641GE: Volvo Penta Genset EnginesIMPEX sHARMANo ratings yet

- (Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIDocument170 pages(Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIAngelo RuedaNo ratings yet

- A400 PDFDocument25 pagesA400 PDFArturo FuentesNo ratings yet

- Abb Transfer Şalteri̇Document56 pagesAbb Transfer Şalteri̇AdemEfeNo ratings yet

- EG-3000 Governor Controller Operation ManualDocument7 pagesEG-3000 Governor Controller Operation ManualrepelindNo ratings yet

- Ricardo 6105AZLD PDFDocument2 pagesRicardo 6105AZLD PDFLogistician MALCOMSONNo ratings yet

- GOB EG1065x Manual en PDFDocument8 pagesGOB EG1065x Manual en PDFRonaldCarrasquelNo ratings yet

- Gu301 ADocument3 pagesGu301 AJosé Da Silva MataNo ratings yet

- Catalogue Cummins 6LTAA8.9 G3Document5 pagesCatalogue Cummins 6LTAA8.9 G3José Diaz100% (2)

- WEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRDocument50 pagesWEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRJuan I. Meza Lozano100% (1)

- QSG12-G2: Specification SheetDocument3 pagesQSG12-G2: Specification SheetAlejandro Dominado100% (1)

- Caterpillar - 3412 - 750kVADocument2 pagesCaterpillar - 3412 - 750kVAPrashant NaikNo ratings yet

- Dse 8610Document119 pagesDse 8610Akhmad FatoniNo ratings yet

- Perkins 1006TAGDocument2 pagesPerkins 1006TAGNathia Roa100% (1)

- Linz - New Product - AlumenDocument4 pagesLinz - New Product - AlumenTTIBCCANo ratings yet

- Operation Manual for EG3000 Electronic Engine Governor ControllerDocument7 pagesOperation Manual for EG3000 Electronic Engine Governor ControllerVinhNo ratings yet

- EG2000 Manual PDFDocument620 pagesEG2000 Manual PDFHendra WibowoNo ratings yet

- QSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Document3 pagesQSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Franyusmid Gomez Bolivar100% (1)

- AGC 200 Manual de Instalação PDFDocument67 pagesAGC 200 Manual de Instalação PDFMarco Olivetto100% (1)

- Gac Esd5500Document7 pagesGac Esd5500christramNo ratings yet

- C87 Te4Document3 pagesC87 Te4Daniel MuratallaNo ratings yet

- QC4003 ESF Zaragoza Application Datasheet EN 2954567001 LTODocument2 pagesQC4003 ESF Zaragoza Application Datasheet EN 2954567001 LTOmoises100% (1)

- QSX15-G8 XpiDocument3 pagesQSX15-G8 XpiMd ShNo ratings yet

- Powerwizard 2.0: Total ControlDocument2 pagesPowerwizard 2.0: Total Controliko57No ratings yet

- M060279-Deep Sea 5510 Insufficient Capacity Protection UpgradeDocument8 pagesM060279-Deep Sea 5510 Insufficient Capacity Protection UpgradelilyricardoseamanNo ratings yet

- DYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFDocument8 pagesDYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFSyed Mohammad NaveedNo ratings yet

- 542931c Atys T M Nmo EN PDFDocument32 pages542931c Atys T M Nmo EN PDFkunkzNo ratings yet

- DC 6 Digital Gov Data Sheet PDFDocument4 pagesDC 6 Digital Gov Data Sheet PDFCarlos MajanoNo ratings yet

- DPG-2201-00X Digital Controllers: User ManualDocument50 pagesDPG-2201-00X Digital Controllers: User ManualPatrick CreighNo ratings yet

- Load Demand Scheme ExplainedDocument2 pagesLoad Demand Scheme Explainedahamed jabirNo ratings yet

- DG SPEC C110D5 With 6BT5.9G2Document4 pagesDG SPEC C110D5 With 6BT5.9G2Anonymous tXzjQAJttH100% (1)

- Doosan Electronic Engine DP222 C - Series: For GeneratorDocument2 pagesDoosan Electronic Engine DP222 C - Series: For GeneratorSergio Raul Baez100% (1)

- 3012Tag3A 3000 Series: Diesel Engine - ElectropakDocument2 pages3012Tag3A 3000 Series: Diesel Engine - ElectropakMounir Yousfi100% (1)

- Eaam0199 enDocument36 pagesEaam0199 enRaymund SanoneNo ratings yet

- Operation and Maintenance Manual for 2806D-E18TA Industrial EngineDocument3 pagesOperation and Maintenance Manual for 2806D-E18TA Industrial EngineMostafa ShannaNo ratings yet

- Catalog Mecc AlteDocument18 pagesCatalog Mecc Alteeduardoguerra155_604No ratings yet

- 320Document61 pages320Rashid Mahmood JaatNo ratings yet

- COMAP IL-MRS11-16 Thong So Ky Thuat PDFDocument2 pagesCOMAP IL-MRS11-16 Thong So Ky Thuat PDFthanhhai31No ratings yet

- SAMSUN, TURKEY 2x GPE-1900 EWS TRAININGDocument33 pagesSAMSUN, TURKEY 2x GPE-1900 EWS TRAININGTuncay Özgür TaşdemirNo ratings yet

- Cummins DFHA DFHB DFHC DFHD Generator Set Parts Manual Powercommand 3100 ControllerDocument114 pagesCummins DFHA DFHB DFHC DFHD Generator Set Parts Manual Powercommand 3100 ControllerVictor Gustavo de Carvalho100% (1)

- Powercommand 2.3 Control System: Specification SheetDocument7 pagesPowercommand 2.3 Control System: Specification SheetJoseLunaNo ratings yet

- Perkins 2806a E18tag1 2806a E18tag2 Briz MotorDocument20 pagesPerkins 2806a E18tag1 2806a E18tag2 Briz MotorAdry MendeNo ratings yet

- Zenith ZTG SeriesDocument8 pagesZenith ZTG SeriesFlo MircaNo ratings yet

- SG2D Governador de VelocidadeDocument4 pagesSG2D Governador de VelocidadealbertooliveiraNo ratings yet

- IGS NT 2.6 Installation GuideDocument115 pagesIGS NT 2.6 Installation Guidesdiaman100% (1)

- Dse 704-4120Document3 pagesDse 704-4120Jose Daniel Garcia RodriguezNo ratings yet

- AUTO MAINS FAILURE MODULEDocument2 pagesAUTO MAINS FAILURE MODULESOSNo ratings yet

- B2-Lehe4748-01 - Emcp3.3Document8 pagesB2-Lehe4748-01 - Emcp3.3Ali H. Al-ZowayedNo ratings yet

- Woodward E6 Lean & Rich Burn Gas Engine ControlDocument22 pagesWoodward E6 Lean & Rich Burn Gas Engine ControlclaudioNo ratings yet

- Inteligen NTCDocument141 pagesInteligen NTCMohamed AbdelmalekNo ratings yet

- InteliVision 5 Reference GuideDocument45 pagesInteliVision 5 Reference Guidexuyen tranNo ratings yet

- Micrologic 2.0A PDFDocument154 pagesMicrologic 2.0A PDFGabriel ZorattiNo ratings yet

- General: Technical Data TAD721GEDocument8 pagesGeneral: Technical Data TAD721GEbaljeetjatNo ratings yet

- Deep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualDocument92 pagesDeep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualMostafa ShannaNo ratings yet

- GEP62SP-3 (Single Phase)Document5 pagesGEP62SP-3 (Single Phase)Jose PirulliNo ratings yet

- Gep110 1104C Tag2 LL3014BDocument6 pagesGep110 1104C Tag2 LL3014BDaniel EvansNo ratings yet

- Volvo TWD1643GE - 613 KW PDFDocument2 pagesVolvo TWD1643GE - 613 KW PDFvictoros27No ratings yet

- Volvo Twd1643ge Technical Data PDFDocument2 pagesVolvo Twd1643ge Technical Data PDFMuhammad rizkiNo ratings yet

- TAD1642GE: Volvo Penta Genset EngineDocument2 pagesTAD1642GE: Volvo Penta Genset EngineMahdi DehghankarNo ratings yet

- Tad1241ge PDFDocument14 pagesTad1241ge PDFMasum uddin mondolNo ratings yet

- WDG 12 - Technical Data Sheet LV 804 TDocument8 pagesWDG 12 - Technical Data Sheet LV 804 T3efooNo ratings yet

- Cummins - Guide Line For ATS SelectionDocument6 pagesCummins - Guide Line For ATS Selectionchock channel 19No ratings yet

- Generator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power SystemsDocument6 pagesGenerator Set Noise Solutions:: Controlling Unwanted Noise From On-Site Power Systemstonybutcher90No ratings yet

- CPG December 2023Document68 pagesCPG December 2023mohsen_cumminsNo ratings yet

- Manual de Partes Electricas Qsk23 PDFDocument39 pagesManual de Partes Electricas Qsk23 PDFalexander900616100% (6)

- QSK60G8 Data SheetDocument3 pagesQSK60G8 Data SheetDhineshbabu Govindan100% (1)

- DSE2548 Installation InstructionsDocument2 pagesDSE2548 Installation InstructionsArc HieNo ratings yet

- Tableau de Commande PCC1.2Document6 pagesTableau de Commande PCC1.2thainarimeNo ratings yet

- DSE2152 Installation InstructionsDocument2 pagesDSE2152 Installation Instructionsmohsen_cumminsNo ratings yet

- Perkins - 4008 Series-En-ItDocument58 pagesPerkins - 4008 Series-En-Itkarimakki100% (4)

- QSK23-G3 Partial Datasheet PDFDocument2 pagesQSK23-G3 Partial Datasheet PDFBidonsBidons100% (1)

- X Series x25 g4 29jun09Document4 pagesX Series x25 g4 29jun09acere18No ratings yet

- QSK23-G3 Partial Datasheet PDFDocument2 pagesQSK23-G3 Partial Datasheet PDFBidonsBidons100% (1)

- Fault CurrentDocument9 pagesFault CurrentP.p. Arul IlancheeranNo ratings yet

- 0908-0110 - I8 - 201505 Health and SafetyDocument54 pages0908-0110 - I8 - 201505 Health and Safetythainarime100% (1)

- Cummins35kvaX33 G1 PDFDocument2 pagesCummins35kvaX33 G1 PDFWallyNo ratings yet

- G-Drive Engines: Unregulated EmissionsDocument7 pagesG-Drive Engines: Unregulated EmissionsPraveen BraggsNo ratings yet

- Technical Data HVSI804X WDG 61 V9 TDSDocument6 pagesTechnical Data HVSI804X WDG 61 V9 TDSmohsen_cumminsNo ratings yet

- VTA28G6Document3 pagesVTA28G6chanchan100% (1)

- PDFDocument5 pagesPDFTaylorNo ratings yet

- Design Change Notice (DCN) Technical Specification SummaryDocument17 pagesDesign Change Notice (DCN) Technical Specification Summarymohsen_cumminsNo ratings yet

- QSK60-G13: Fuel OptimizedDocument3 pagesQSK60-G13: Fuel Optimizedmohsen_cumminsNo ratings yet

- Power Factor Controller ManualDocument56 pagesPower Factor Controller Manualmohsen_cumminsNo ratings yet

- QSK23G3Document3 pagesQSK23G3mohsen_cumminsNo ratings yet

- Instruction Manual DM110 - V1.0-EnDocument72 pagesInstruction Manual DM110 - V1.0-Enmohsen_cumminsNo ratings yet

- Diode Failure Detector: Technical Specification Supply VoltageDocument2 pagesDiode Failure Detector: Technical Specification Supply Voltagemohsen_cumminsNo ratings yet

- DWG General Arrangement G.A. A047V941Document2 pagesDWG General Arrangement G.A. A047V941mohsen_cumminsNo ratings yet

- Vta28 - g5 ExhaustDocument2 pagesVta28 - g5 Exhaustmohsen_cumminsNo ratings yet

- AD1120CF Series: Cro Ngineering NcorporationDocument3 pagesAD1120CF Series: Cro Ngineering Ncorporationmohsen_cumminsNo ratings yet

- PI734C - Winding 13: Technical Data SheetDocument7 pagesPI734C - Winding 13: Technical Data Sheetmohsen_cummins100% (1)

- Air Motors: P1V-M Robust Type 0.2, 0.4, 0.6, 0.9 & 1.2 KWDocument32 pagesAir Motors: P1V-M Robust Type 0.2, 0.4, 0.6, 0.9 & 1.2 KWBrunnoNo ratings yet

- Akari Solenoid Valve CatalogueDocument110 pagesAkari Solenoid Valve CatalogueAsad Ahmed67% (3)

- Diagramas Eléctricos Chevrolet Captiva Sport FWD 2.4l 4 Cil 2015Document102 pagesDiagramas Eléctricos Chevrolet Captiva Sport FWD 2.4l 4 Cil 2015Sebiche1No ratings yet

- Cooling System Parts List S530Document3 pagesCooling System Parts List S530Pepe AlNo ratings yet

- Bepco Air Brake Troubleshooting ChartDocument5 pagesBepco Air Brake Troubleshooting ChartМирослав ВујицаNo ratings yet

- QCM Landing GearDocument6 pagesQCM Landing GearAdil KhNo ratings yet

- 1NZ-FE Engine: Toyota's 1497cc 4-Cylinder PowerplantDocument17 pages1NZ-FE Engine: Toyota's 1497cc 4-Cylinder PowerplantRaul Aris100% (2)

- Motorized Gyroscope Apparatus 1Document7 pagesMotorized Gyroscope Apparatus 1Rickson Viahul Rayan CNo ratings yet

- Haojue Ka150 Pedido Octubre 27 10 2023Document5 pagesHaojue Ka150 Pedido Octubre 27 10 2023Fpkservicios ZonaNo ratings yet

- Jockey Pumps: Peerless Pump Company MTH Tool Co. Series T41, T51, 150, 160 Regenerative Turbine Vane TypeDocument2 pagesJockey Pumps: Peerless Pump Company MTH Tool Co. Series T41, T51, 150, 160 Regenerative Turbine Vane TypeAndri AjaNo ratings yet

- Keiper Specification Festo Components 2.4Document41 pagesKeiper Specification Festo Components 2.4castro2160No ratings yet

- Basics of HVAC SystemDocument82 pagesBasics of HVAC SystemMDRNo ratings yet

- Hyundai Fork Loaders Diesel 7 Series 20/25/30 / 33D-7 Hydraulic System Page 3080 Hydraulic Oil TankDocument2 pagesHyundai Fork Loaders Diesel 7 Series 20/25/30 / 33D-7 Hydraulic System Page 3080 Hydraulic Oil TankhamedNo ratings yet

- Parts Manual Di450Document58 pagesParts Manual Di450Hugo Luis EscalanteNo ratings yet

- Screw Pump 40 - 80 Bar - Olaer - de PDFDocument12 pagesScrew Pump 40 - 80 Bar - Olaer - de PDFAbdoEmanuelMalverdiNo ratings yet

- Af115fx+x-Ride Parts CatalogDocument45 pagesAf115fx+x-Ride Parts CatalogMalausma NetNo ratings yet

- Model 701 / 702 Installation and Operating InstructionsDocument2 pagesModel 701 / 702 Installation and Operating Instructionsabuzer1981No ratings yet

- PTC MenuDocument23 pagesPTC MenuYanethNo ratings yet

- BHT - Technical Publications - LUBDocument4 pagesBHT - Technical Publications - LUBmarcelo juniorNo ratings yet

- Valve-RefacingDocument5 pagesValve-RefacingKaranbir Singh0% (1)

- Adv - Micro. DC Motor Control With L293D Motor Driver IC and ArduinoDocument25 pagesAdv - Micro. DC Motor Control With L293D Motor Driver IC and Arduinowillingcoder.billionaireNo ratings yet

- "2004" Seminar Information: GM & FordDocument118 pages"2004" Seminar Information: GM & FordStephany castroNo ratings yet

- Automated Punching MachineDocument8 pagesAutomated Punching MachineMohamed IbrahemNo ratings yet

- 722.5 - Some Tests 3Document8 pages722.5 - Some Tests 3Bernhard JaniszewskiNo ratings yet

- DTS Syllabus12122011Document1 pageDTS Syllabus12122011ntsdharmaNo ratings yet

- Bosch Rexroth AZMFDocument48 pagesBosch Rexroth AZMFGarri BaldiNo ratings yet

- Brevini Evolution Winches Series CTF048000 20Document112 pagesBrevini Evolution Winches Series CTF048000 20Denis RembrantNo ratings yet

- 02 - Wet Riser SystemDocument2 pages02 - Wet Riser SystemJeghiNo ratings yet

- 00-PM Checklist For 415 Volts Motors - Rev 1Document1 page00-PM Checklist For 415 Volts Motors - Rev 1معين الظفاريNo ratings yet

- Dynamic Analysis of Valve Train Single Cylinder IC EngineDocument22 pagesDynamic Analysis of Valve Train Single Cylinder IC EngineHernan SeilikovichNo ratings yet