Professional Documents

Culture Documents

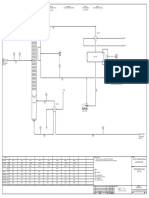

Process Flow Diagram and Material Balance

Uploaded by

ingegnere12340 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

DME PFD

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageProcess Flow Diagram and Material Balance

Uploaded by

ingegnere1234Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Methanol Dehydration for Dimethyl Ether

Production for Transportation

Thomas Higgins, Adam McCoy, Brandon Musitano

Department of Chemical Engineering, University of New Hampshire

Introduction Process Flow Diagram and Material Balance

• 250,000 gal/day DME production rate

• MeOH DME + Water

• No side reactions or byproducts

• Quality: 99.92 wt% DME

• Low T acid catalyst (Amberlyst 35)

Market Analysis

Jie, L., et.al., “Regulated and non-regulated Emissions from a DME Powered Compression Ignition Engine”

Safety Considerations Economic Analysis Conclusions and Recommendations

• DME Sell Price: $0.93/kg or $2.33/gal

• Minimize

• Unit size & storage • 20 year • Recommend motivating transportation users to switch from low

inventory operation sulfur diesel to DME fuel

• Substitute

• Water as coolant • Total capital • There are enough engineered protections to build a safe plant

• Mechanical seals & investment • Recommended to move on for further design analysis

welded pipes

of $10M .

• Moderate

• T & P drops • DCFRR:

Acknowledgements

• Simplify

• Use of same equipment 198% • We would like to thank Dr. McLarnon as well as the entire

Chemical Engineering department for guidance and assistance

You might also like

- Pts 0800 - A (Process Description)Document6 pagesPts 0800 - A (Process Description)ingegnere1234No ratings yet

- Guide Note On Thermal Design of S&T Heat Exchanger Rev 0Document105 pagesGuide Note On Thermal Design of S&T Heat Exchanger Rev 0ingegnere1234No ratings yet

- Pts 0800 - A (Process Description)Document6 pagesPts 0800 - A (Process Description)ingegnere1234No ratings yet

- Modeling of Sulphonation of Tridecylbenzene in A Falling Film ReactorDocument13 pagesModeling of Sulphonation of Tridecylbenzene in A Falling Film Reactoringegnere1234No ratings yet

- Dme Simulation With DwsimDocument4 pagesDme Simulation With Dwsimingegnere1234No ratings yet

- Design Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201Document26 pagesDesign Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201ingegnere1234No ratings yet

- Design Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201Document10 pagesDesign Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201ingegnere1234No ratings yet

- Appunti Fisica Tecnica-SLIDEDocument219 pagesAppunti Fisica Tecnica-SLIDEingegnere1234No ratings yet

- Meoh Dehydratation Reactor For Dme Production R-201Document3 pagesMeoh Dehydratation Reactor For Dme Production R-201ingegnere1234No ratings yet

- Stainless Steel Grade 2205 Duplex (UNS S32205)Document7 pagesStainless Steel Grade 2205 Duplex (UNS S32205)ingegnere1234No ratings yet

- General Information: Stainless Steel, Austenitic, AISI 316L, AnnealedDocument8 pagesGeneral Information: Stainless Steel, Austenitic, AISI 316L, Annealedingegnere1234No ratings yet

- 32,8 Ktpy Propane Storage and ProductionDocument1 page32,8 Ktpy Propane Storage and Productioningegnere1234No ratings yet

- Azu Etd HR 2018 0229 Sip1 MDocument89 pagesAzu Etd HR 2018 0229 Sip1 Mingegnere1234No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Coal Stockpile WordDocument6 pagesCoal Stockpile Wordsathish kumarNo ratings yet

- Blending GasolineDocument32 pagesBlending GasolineDanu Bratakusuma100% (1)

- Fusion ProcDocument26 pagesFusion Procdip_maanNo ratings yet

- Elements of Group 161718 Class 12th Chemistry Term PaperDocument5 pagesElements of Group 161718 Class 12th Chemistry Term PaperNived DohaleNo ratings yet

- CNG & LPG EnginesDocument38 pagesCNG & LPG EnginesVinod Kumar PatelNo ratings yet

- Compressed Natural Gas (CNG)Document4 pagesCompressed Natural Gas (CNG)hortalemosNo ratings yet

- What's More: Activity 1.1 Understanding Enzyme ActivityDocument2 pagesWhat's More: Activity 1.1 Understanding Enzyme ActivityJewel EspirituNo ratings yet

- Pipeline TransportationDocument7 pagesPipeline TransportationZHENGUO LIUNo ratings yet

- Jacket Area CalculationDocument12 pagesJacket Area CalculationPraveen Prajapati100% (2)

- Thermal Design Analysis of A Liquid Hydrogen VesselDocument9 pagesThermal Design Analysis of A Liquid Hydrogen Vessel이경률No ratings yet

- Teg ContactorDocument4 pagesTeg ContactorrepentinezNo ratings yet

- BooksDocument2 pagesBooksAnimesh ChoudharyNo ratings yet

- Polythionic Acid CorrosionDocument4 pagesPolythionic Acid Corrosion최승원No ratings yet

- Petroleum Refining & PetrochemicalsDocument32 pagesPetroleum Refining & PetrochemicalsprasoonNo ratings yet

- Green Hydrogen: Mohammad Bassam Al-AyyatDocument7 pagesGreen Hydrogen: Mohammad Bassam Al-AyyatMostafa Shawky El ShenawyNo ratings yet

- Mann Automotive Filter Stock List19052021Document3 pagesMann Automotive Filter Stock List19052021B Sathish BabuNo ratings yet

- Debutaniser OptimisationDocument5 pagesDebutaniser OptimisationAntonNo ratings yet

- Diptico Diesel WmoDocument2 pagesDiptico Diesel WmoSanchez Martinez Hugo De Dios100% (1)

- Pet Coke Cargo Data From Jan 2020Document78 pagesPet Coke Cargo Data From Jan 2020Tushar GangolyNo ratings yet

- CdtechebDocument2 pagesCdtechebLuisColmonero0% (2)

- Catalyst To EthanolDocument26 pagesCatalyst To EthanolFatih FıratNo ratings yet

- Integrate Process Simulation and Process SynthesisDocument6 pagesIntegrate Process Simulation and Process Synthesisjanota24No ratings yet

- Thermochemistry Worksheet 1Document7 pagesThermochemistry Worksheet 1Bennett BongNo ratings yet

- FPSO PresentationDocument30 pagesFPSO PresentationJogi100% (1)

- Colligative Property and Solution ObjectiveDocument6 pagesColligative Property and Solution ObjectivenoelNo ratings yet

- New Methods For Hydrogen Purity AnalysisDocument2 pagesNew Methods For Hydrogen Purity AnalysisSteve OoiNo ratings yet

- Energetics QuestionsDocument20 pagesEnergetics Questionslianchen251110No ratings yet

- Distillation ExperimentDocument6 pagesDistillation ExperimentJureen Flores BelicarioNo ratings yet

- Adhea Ppktugasweek5 PDocument1 pageAdhea Ppktugasweek5 PAdhea SeftiNo ratings yet

- BT6604Document6 pagesBT6604SangeethaNo ratings yet