Professional Documents

Culture Documents

Meoh Dehydratation Reactor For Dme Production R-201

Uploaded by

ingegnere1234Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meoh Dehydratation Reactor For Dme Production R-201

Uploaded by

ingegnere1234Copyright:

Available Formats

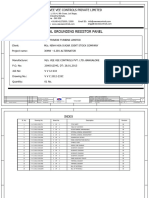

PROJ DESC: 124,2 KTPY DME PRODUCTION

PLANT

DATA SHEET

RIF. PROJECT: 00200-DME-0001

REVISION: 0 1 2

MEOH DEHYDRATATION REACTOR DATE: 24/01/2021 26/03/2021 11/04/2021

R-201 SHEET

DOC. N°: 00200-PDS-0001

1 of 3

CONFIDENTIAL DOCUMENT

MEOH DEHYDRATATION REACTOR

FOR DME PRODUCTION

R-201

0020-PDS-001_REV_2 11-04-2021 ISSUE FOR CONCEPTUAL DESIGN L. BARBAGALLO C.E.S.

0020-PDS-001_REV_1 26-03-2021 REISSUE FOR INFORMATIONS AND COMMENTS L. BARBAGALLO C.E.S.

0020-PDS-001_REV_0 24-01-2021 ISSUE FOR INFORMATIONS AND COMMENTS L. BARBAGALLO C.E.S.

DOCUMENT NUMBER DATE DESCRIPTION DOCUMENT COMPILED / CHECKED APPROVED

PROJ DESC: 124,2 KTPY DME PRODUCTION

PLANT

DATA SHEET

RIF. PROJECT: 00200-DME-0001

REVISION: 0 1 2

MEOH DEHYDRATATION REACTOR DATE: 24/01/2021 26/03/2021 11/04/2021

R-201 SHEET

DOC. N°: 00200-PDS-0001

2 of 3

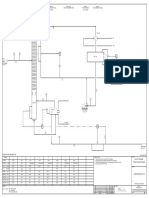

Service: MEOH Dehydratation for DME Item: R-201 Flow direction: Countercurrent

Type: Packed Bed Multitubular Cooled (PBCR) Unit operation: Vertical DME production: 124,2 KTPY

N°of Unit: 1 Duty: 2048 KW Environmental Cond.: min. T (°C): 1,5 , max.T (°C): 35

OPERATING DATA TUBE SIDE SHELL SIDE

Fluid Process (mixture) Boiling Feed Water

Flow Rate Kg/h 24170 23405

Sides INLET OUTLET INLET OUTLET

Phase Gas Gas Liquid Liquid

Operating Temperature °C 250 290 18 93

Operating Pressure Barg 14,7 14,6 4 3,95

Pressure Drop (Allowable) Bar 0,10 (1) 0,05 (1)

Density Kg/m3 12,51 11,21 997,8

Viscosity cP 0,012 0,013

Volumetric Flow Rate @ operating T, P m3/h 1932 2156 23,45

COMPOSITION INLET OUTLET INLET OUTLET

MEOH mol% 96,50 12,88

WATER mol% 0,91 42,72 100 100

ETOH mol% 2,59 2,59

DME mol% - 41,81

DESIGN DATA TUBE SIDE SHELL SIDE

CONFIDENTIAL DOCUMENT

Design Temperature °C 400 400

Design Pressure Barg FV / 16,20 FV / 16,20

MAWP Barg 20 20

PRESSURE VESSEL DATA TUBE SIDE SHELL SIDE

Material of Construction SS AISI 316L SS DUPLEX 2205

Inner Diameter mm 102,26 (2) 4500

Inner Height mm 11080 (3)

Thickness mm AS SCHEDULE STD - 4" AS PER STD CODES ASME/ANSI DIV 1

N°of Packed Tubes 905 N/A

Corrosion Allowance mm 3 1,6

CATALYST BED DATA

Catalyst Type γ-Al2O3, 99-DME ECO Pellets (4)

Catalyst Bed Height mm 11080

Catalyst Bulk Density Kg/m3 940

Catalyst Density Kg/m3 1880

Catalyst Size mm 33

Catalyst Volume m3 170

Catalyst Weight Kg 319600

NOTES:

1 - MFR will be indicate real pressure drop both shell and tube sides effective one.

2 - According to 4" pipe size inner diameter, schedule STD;

3 - Inner height of the vessel shall be designing in accordance with effective sizes of dome roof and dome bottom;

4 - Catalyst is supplied by MFR.

NOTICE FOR ENGINEERING DESIGN:

- No steam out operations will be led for this equipment.

- Catalyst and shell side will be maintaned out of normal cycle of operational period.

PROJ DESC: 124,2 KTPY DME PRODUCTION

PLANT

DATA SHEET

RIF. PROJECT: 00200-DME-0001

REVISION: 0 1 2

MEOH DEHYDRATATION REACTOR DATE: 24/01/2021 26/03/2021 11/04/2021

R-201 SHEET

DOC. N°: 00200-PDS-0001

3 of 3

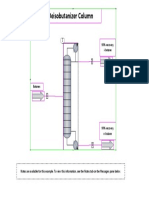

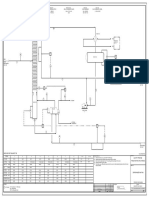

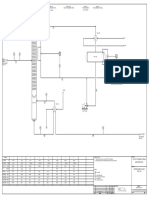

LAYOUT OF THE REACTOR

N°. Of Nozzle Description Size Rating

1 Inlet nozzle HOLD HOLD

1 2 Outlet nozzle HOLD HOLD

1A Manway HOLD HOLD

WELDED HEAD - TUBE SHEET

1B Manway HOLD HOLD

3 Inlet BFW HOLD HOLD

1A

4 4 Outlet BFW HOLD HOLD

5 Instr. connection HOLD HOLD

5

6 Instr. connection HOLD HOLD

7 Instr. connection HOLD HOLD

CATALYST TUBE BUNDLE

Total Lenght T.L.: 11400 mm

6 Intenal Diameter I.D.: 4450 mm

Outer Diameter O.D.: mm

Catalyst Tube I.D: 4" (Inches)

VESSEL REQUIREMENT AND TREATMENTS

PWHT □ yes □ no

X - RAYS INPECTIONS □ yes □ no

CONFIDENTIAL DOCUMENT

PENETRANT LIQUIDS □ yes □ no

7

WITH U - STAMP □ yes □ no

Supports and others related to overall vessel will be required by MFR (2)

STANDARD & CODES

3 ASME/ANSI VIII - DIV. 1/2

1B PED - PRESSURE VESSEL / EN ISO

ATEX

FLOATING HEAD - TUBE SHEET

NO NACE (1)

MFR STD AND CODES

2

OTHER REGULATIONS AND LAWS IF ALLOWED

NOTES:

1 - No nace applicable, fluids are not present with other corrosive as H2S, H2Sx, VOC, CO2 and NH3.

2 - Supports, gaskets, Foundations are to be into account by MFR STD.

You might also like

- Design Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201Document26 pagesDesign Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201ingegnere1234No ratings yet

- Design Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201Document10 pagesDesign Technical Specification: Conceptual Design of Meoh Dehydratation Reactor For 124,2 Ktpy Dme Production R-201ingegnere1234No ratings yet

- 02 0186 06 PB 005 A Control Philosophy Rev 0 FaridhDocument40 pages02 0186 06 PB 005 A Control Philosophy Rev 0 FaridhVijay Rajaindran100% (1)

- Us-Pc-02-0360 - Technical Specification of LV Power, Control & Instrument Cable PDFDocument14 pagesUs-Pc-02-0360 - Technical Specification of LV Power, Control & Instrument Cable PDFankit trivediNo ratings yet

- Boiler VMIDocument42 pagesBoiler VMIKỳ PhamNo ratings yet

- R13-I05b01-Tjs-Mts-El-0023 (02) Method Statement For PV Electrical Equipment InstallationDocument31 pagesR13-I05b01-Tjs-Mts-El-0023 (02) Method Statement For PV Electrical Equipment InstallationJegan SureshNo ratings yet

- Bolt Torquing and Tensioning Procedure KHLDocument26 pagesBolt Torquing and Tensioning Procedure KHLHazieqah KahilNo ratings yet

- 03b.sch B Ded Ugcrp1 01Document181 pages03b.sch B Ded Ugcrp1 01RANA. ADNANNo ratings yet

- Gearless Mill Drive Refill Station: 144-CK-1022-6: ManualDocument56 pagesGearless Mill Drive Refill Station: 144-CK-1022-6: ManualRomel Fuentes GutiérrezNo ratings yet

- 25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisDocument15 pages25509-100-V1B-EKL0-00966 - Substation Building Structural Design BasisAnonymous FHkX0ANo ratings yet

- Technical Report: (7620) 350-0024 ADD: Consumer Products Services DivisionDocument4 pagesTechnical Report: (7620) 350-0024 ADD: Consumer Products Services Divisioneded_ls_caNo ratings yet

- 1416 PS PDS V 101 - Rev.2Document4 pages1416 PS PDS V 101 - Rev.2KrunalNo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- Process design basis for interphase processing facilityDocument7 pagesProcess design basis for interphase processing facilitySanju ChauhanNo ratings yet

- RPT-1000483-PL-000-00-00-010_Rev 1Document65 pagesRPT-1000483-PL-000-00-00-010_Rev 1process1plecoNo ratings yet

- Datasheets for Pressure Regulating ValvesDocument11 pagesDatasheets for Pressure Regulating ValvesDiana Paula Echartea MolinaNo ratings yet

- Data Sheet for Ball ValvesDocument19 pagesData Sheet for Ball ValvesAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverDocument5 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. A CoverAgus SupriadiNo ratings yet

- BMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. ADocument6 pagesBMR-PIP-DTS-ST-0001 DATA SHEET FOR VALVE Rev. AAgus SupriadiNo ratings yet

- FCM Kao DCS - Rev1Document34 pagesFCM Kao DCS - Rev1Izarulhaq AwangNo ratings yet

- (4001005) 2654 16-NM-0022-001 1Document2 pages(4001005) 2654 16-NM-0022-001 1nuno.diasNo ratings yet

- Transformers Technical SpecificationDocument35 pagesTransformers Technical SpecificationRonald MadriagaNo ratings yet

- Certificate of Calibration: CustomerDocument1 pageCertificate of Calibration: Customergaconvt92No ratings yet

- Fdocuments - in DBR For Water TreatmentDocument28 pagesFdocuments - in DBR For Water TreatmentRavi ChandranNo ratings yet

- Revision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsDocument2 pagesRevision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsAdilson MirandaNo ratings yet

- Review Method Statement of Domestic Clean Water & Irrigation Water InstallationDocument23 pagesReview Method Statement of Domestic Clean Water & Irrigation Water InstallationDenni SaputraNo ratings yet

- Project Title: Neom Water Transmission System Project Document TransmittalDocument12 pagesProject Title: Neom Water Transmission System Project Document TransmittalMohammad NowfalNo ratings yet

- Manual 0583-PP-7130 A 7132Document261 pagesManual 0583-PP-7130 A 7132gabrielgonzaloverga2No ratings yet

- R13 I07b01 Alf MTS TC 0005Document37 pagesR13 I07b01 Alf MTS TC 0005SulimanNo ratings yet

- 5) Method Statement For HVAC Electrical WorkDocument11 pages5) Method Statement For HVAC Electrical WorkIzaaz Ahamed100% (2)

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- Appendix A - DATASHEET - BilectricDocument11 pagesAppendix A - DATASHEET - BilectricChakravarthy BharathNo ratings yet

- Installation of Electrical Earthing SystemDocument10 pagesInstallation of Electrical Earthing SystemMohammad Fazal KhanNo ratings yet

- Wt2201 RWD CW MST XXXX XXXX XX - Mos For Deep Excavation - RemovedDocument6 pagesWt2201 RWD CW MST XXXX XXXX XX - Mos For Deep Excavation - RemovedJuber JamshedNo ratings yet

- 26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)Document20 pages26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)bangunNo ratings yet

- Service Water System DescriptionDocument22 pagesService Water System Descriptionکالرو تحریک اتحادNo ratings yet

- 26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)Document20 pages26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)bangunNo ratings yet

- Mechanical Datasheet for DM Water Feed TankDocument4 pagesMechanical Datasheet for DM Water Feed Tanksanjay wakchoureNo ratings yet

- B224 Cdu TPL 000 MP Ga PR0013 0001 0 - 2Document4 pagesB224 Cdu TPL 000 MP Ga PR0013 0001 0 - 2PRASHANTNo ratings yet

- Painting Specification Plan For Combustion Air PreheaterDocument4 pagesPainting Specification Plan For Combustion Air PreheaterNamta GeorgeNo ratings yet

- Instrument Process Datasheet Control Valves Section 100: Technologies TechnologiesDocument13 pagesInstrument Process Datasheet Control Valves Section 100: Technologies TechnologiesMohamedNo ratings yet

- Demi Water Storage and Distribution System description 除盐水储存和分配Document26 pagesDemi Water Storage and Distribution System description 除盐水储存和分配کالرو تحریک اتحادNo ratings yet

- Ras Laffan Olefin Project Ras Laffan Olefin Company: Process DatasheetDocument6 pagesRas Laffan Olefin Project Ras Laffan Olefin Company: Process DatasheetShaaban NoamanNo ratings yet

- TAP0000271-revision1_240316_222031Document16 pagesTAP0000271-revision1_240316_222031ewgenykuzinNo ratings yet

- Technical Report: (7620) 350-0024: Consumer Products Services DivisionDocument4 pagesTechnical Report: (7620) 350-0024: Consumer Products Services Divisioneded_ls_caNo ratings yet

- Liebherr India PVT Ltd. Ledger For FY 21-22Document1 pageLiebherr India PVT Ltd. Ledger For FY 21-22mvssrinivasNo ratings yet

- MP/LP Let Down and Desuperheating Station (DS-721-02 A/B) : Process Data SheetDocument4 pagesMP/LP Let Down and Desuperheating Station (DS-721-02 A/B) : Process Data SheetZeynab HazratiNo ratings yet

- Plumbing System - Jetty Control Building - Calculation ReportDocument8 pagesPlumbing System - Jetty Control Building - Calculation ReportDaniel NjokuNo ratings yet

- Platso WatDocument37 pagesPlatso WatAshoka NarayananNo ratings yet

- NDE Procedure - Flare KOD - Structure Rev ADocument90 pagesNDE Procedure - Flare KOD - Structure Rev ARajesh K PillaiNo ratings yet

- RTU Panel For Typical SS REV1Document11 pagesRTU Panel For Typical SS REV1Ahmed RyiadNo ratings yet

- 00027639-B DCPR1 Wiring DiagramDocument67 pages00027639-B DCPR1 Wiring DiagramKarikalan JayNo ratings yet

- Australia Pacific LNG Building Dimension ControlDocument7 pagesAustralia Pacific LNG Building Dimension ControlAnonymous FHkX0ANo ratings yet

- M12 - Data Sheet - Non Return Dampers: Index of Revisions Rev. Description And/Or Revised SheetsDocument2 pagesM12 - Data Sheet - Non Return Dampers: Index of Revisions Rev. Description And/Or Revised SheetsReno MeatShopNo ratings yet

- HVAC Cause & Effect DiagramDocument6 pagesHVAC Cause & Effect DiagramAdrian IrawanNo ratings yet

- Welding Consumable Control Procedure - Flare KOD Rev ADocument8 pagesWelding Consumable Control Procedure - Flare KOD Rev ARajesh K PillaiNo ratings yet

- 977 (1606) LaVida BID BoQ MPF - 15oct2021Document109 pages977 (1606) LaVida BID BoQ MPF - 15oct2021Bernard PanchoNo ratings yet

- NGR - Ninh Hoa - R#0Document18 pagesNGR - Ninh Hoa - R#0trungtruc nguyenNo ratings yet

- Pts 0800 - A (Process Description)Document6 pagesPts 0800 - A (Process Description)ingegnere1234No ratings yet

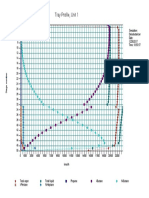

- Deisobutanizer Column: 99% Recovery I-ButaneDocument1 pageDeisobutanizer Column: 99% Recovery I-Butaneingegnere1234No ratings yet

- Guide Note On Thermal Design of S&T Heat Exchanger Rev 0Document105 pagesGuide Note On Thermal Design of S&T Heat Exchanger Rev 0ingegnere1234No ratings yet

- Pts 0800 - A (Process Description)Document6 pagesPts 0800 - A (Process Description)ingegnere1234No ratings yet

- Components ProfilesDocument1 pageComponents Profilesingegnere1234No ratings yet

- Column SummaryDocument2 pagesColumn Summaryingegnere1234No ratings yet

- Column ProfileDocument2 pagesColumn Profileingegnere1234No ratings yet

- C.E.S. - PresentationDocument4 pagesC.E.S. - Presentationingegnere1234No ratings yet

- Dme Simulation With DwsimDocument4 pagesDme Simulation With Dwsimingegnere1234No ratings yet

- Logo Ces ModelloDocument1 pageLogo Ces Modelloingegnere1234No ratings yet

- Dme Prodution CoverDocument1 pageDme Prodution Coveringegnere1234No ratings yet

- Modeling of Sulphonation of Tridecylbenzene in A Falling Film ReactorDocument13 pagesModeling of Sulphonation of Tridecylbenzene in A Falling Film Reactoringegnere1234No ratings yet

- Hydrogen Attack in Ammonia Plants - LinkedInDocument8 pagesHydrogen Attack in Ammonia Plants - LinkedIningegnere1234No ratings yet

- 2432 Wang YuanDocument103 pages2432 Wang Yuaningegnere1234No ratings yet

- Meoh Dehydratation Reactor For Dme Production R-201Document3 pagesMeoh Dehydratation Reactor For Dme Production R-201ingegnere1234No ratings yet

- Presentation Book: C.E.S. - Chemical Engineering SimulationsDocument3 pagesPresentation Book: C.E.S. - Chemical Engineering Simulationsingegnere1234No ratings yet

- Meoh Dehydratation Reactor For Dme Production R-201Document3 pagesMeoh Dehydratation Reactor For Dme Production R-201ingegnere1234No ratings yet

- Process Flow Diagram and Material BalanceDocument1 pageProcess Flow Diagram and Material Balanceingegnere1234No ratings yet

- Meoh Dehydratation Reactor For Dme Production R-201Document3 pagesMeoh Dehydratation Reactor For Dme Production R-201ingegnere1234No ratings yet

- Mass and Heat Balance Tab: From Water Distribution UNIT-120Document1 pageMass and Heat Balance Tab: From Water Distribution UNIT-120ingegnere1234No ratings yet

- 32,8 Ktpy Propane Storage and ProductionDocument1 page32,8 Ktpy Propane Storage and Productioningegnere1234No ratings yet

- Mass and Heat Balance Tab: No ConfidentialDocument1 pageMass and Heat Balance Tab: No Confidentialingegnere1234No ratings yet

- 32,8 Ktpy Propane Storage and ProductionDocument1 page32,8 Ktpy Propane Storage and Productioningegnere1234No ratings yet

- Stainless Steel Grade 2205 Duplex (UNS S32205)Document7 pagesStainless Steel Grade 2205 Duplex (UNS S32205)ingegnere1234No ratings yet

- Aalco Metals LTD - Stainless Steel ASTM A815 S31803 - 261Document2 pagesAalco Metals LTD - Stainless Steel ASTM A815 S31803 - 261HalenaBuanNo ratings yet

- David Exaudi Sianipar'Curriculum VitaeDocument1 pageDavid Exaudi Sianipar'Curriculum VitaeJoelNo ratings yet

- DistillationDocument4 pagesDistillationArvind SinghNo ratings yet

- 2-Conduction and Breakdown in Gases UpdatedDocument46 pages2-Conduction and Breakdown in Gases UpdatedsyakirmustapaNo ratings yet

- Fluid Dynamics EquationsDocument37 pagesFluid Dynamics EquationsTauseefNo ratings yet

- k17396 NRT DatasheetDocument2 pagesk17396 NRT DatasheetHasan KhanNo ratings yet

- Vapor/Liquid Equilibrium: Mata Kuliah: Termodinamika IIDocument70 pagesVapor/Liquid Equilibrium: Mata Kuliah: Termodinamika IIputri wahyuniNo ratings yet

- Magnesium and Hydrochloric Acid Lab ReportDocument12 pagesMagnesium and Hydrochloric Acid Lab ReportJack Murphy69% (13)

- Galaxy Surfactants Interview QuestionsDocument2 pagesGalaxy Surfactants Interview Questionsgouthamsai100% (2)

- Flow Diagram of Urea Production Process From Ammonia and CarbonDocument10 pagesFlow Diagram of Urea Production Process From Ammonia and CarbonGilang RamadhanNo ratings yet

- Causes and Prevention of Pump Cavitation DamageDocument2 pagesCauses and Prevention of Pump Cavitation DamageJJNo ratings yet

- Gases and vapour mixtures analysis composition propertiesDocument38 pagesGases and vapour mixtures analysis composition propertiesgergis emadNo ratings yet

- Analyzer Sample Systems Ver HappenDocument12 pagesAnalyzer Sample Systems Ver HappenIñaki Eseberri100% (1)

- Dryness Fraction of Steam ExpDocument5 pagesDryness Fraction of Steam ExpAthinaNo ratings yet

- Momentum Transfer: Engr. Eric R. HalabasoDocument32 pagesMomentum Transfer: Engr. Eric R. HalabasoClaire dela CruzNo ratings yet

- Venting CalculationsDocument3 pagesVenting CalculationsernestoNo ratings yet

- STATOIL-Slug ControlDocument28 pagesSTATOIL-Slug Controlviswalng100% (1)

- Bce 313 - Hydrology Complete SimDocument139 pagesBce 313 - Hydrology Complete SimItachi UchihaNo ratings yet

- International Cloud Atlas GlossaryDocument17 pagesInternational Cloud Atlas GlossaryacetopposNo ratings yet

- Flash English Edition 2009 1Document8 pagesFlash English Edition 2009 1dhananjaymoteNo ratings yet

- Fugitive Hydrogen Emissions Future Hydrogen EconomyDocument52 pagesFugitive Hydrogen Emissions Future Hydrogen EconomySofiaNo ratings yet

- Introduction To Plasma TechnologyDocument82 pagesIntroduction To Plasma TechnologyjawsmNo ratings yet

- Applied Sciences: Ionic Liquid Electrolytes For Safer and More Reliable Sodium Battery SystemsDocument6 pagesApplied Sciences: Ionic Liquid Electrolytes For Safer and More Reliable Sodium Battery SystemsYogesh KumarNo ratings yet

- Design BasisDocument11 pagesDesign BasisvasudhaNo ratings yet

- Advanced Fluid Mechanics Unsteady Pipe FlowDocument18 pagesAdvanced Fluid Mechanics Unsteady Pipe FlowHubert MoforNo ratings yet

- Hydraulic Report - 23th MarchDocument51 pagesHydraulic Report - 23th MarchGoutam GiriNo ratings yet

- An Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsDocument6 pagesAn Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsAdanenche Daniel EdohNo ratings yet

- Plate 2Document9 pagesPlate 2MichaelViloria0% (1)

- 4 Earth's Subsystem PDFDocument31 pages4 Earth's Subsystem PDFAyesha YusopNo ratings yet

- RefDocument5 pagesRefSana AkhtarNo ratings yet

- Drug Development and Industrial Pharmacy,: 1988 by Marcel Dekker, IncDocument43 pagesDrug Development and Industrial Pharmacy,: 1988 by Marcel Dekker, IncUntoro DewantoNo ratings yet