Professional Documents

Culture Documents

L-Js1 - Features L-Ol - Features

Uploaded by

EdderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L-Js1 - Features L-Ol - Features

Uploaded by

EdderCopyright:

Available Formats

L-OL

L-JS

L-OL- -FEATURES

L-JS1 FEATURES

RETURN AIR GRILLE

L-OL-OB

L-JS

L-OL-OB - FEATURES

L-JS1 - FEATURES

RETURN AIR GRILLE

L-OL

L-JS

L-OL -4FEATURES

L-JS1 LOUVER GRILL

FEATURES HOW TO SELECT

RETURN AIR GRILLE

They are designed for to exhaust or 1. Determinate CFM and preassure

intake air, normally mounted in W.G. according with desing data.

exterior areas , produced with

extruded aluminum profiles 2. Select wich FPM value in

designed for eliminate the dew VELOCITY/PREASSURE chart.

precipitation and avoid water

inside the occupated space. 3. Effective pressure area is

determitated by diving the CFM by

Frame and blades are produced the velocity.

with extruded aluminum profiles

AA6063 T5 and their thickness 4. The free pressure area (SQ. FT)

provide strengh and high chart shows the sizes to be suitable

fabrication elements up to 84" high

with 4" increases.

Finished with white powder coating

or natural annodized finish.

Those L-OL are available with

metalic meh or mosquito net.

L-JS

L-OL

L-OL LOUVER

L-JS1 - FEATURES

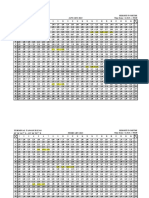

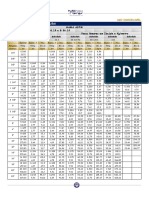

L-OL-4 EXTRUDED ALUMINUM OUTSIDE LOUVERS

FREE PRESSURE AREA IN SQ. FT.

HEIGHT WIDTH (INCHES)

RETURN AIR GRILLE

12 14 16 18 42 48 54 60 72

(INCHES) 20 24 30 36

12 ,23 ,30 ,35 ,40 ,45 ,55 ,69 ,84 ,98 1,13 1,28 1,42 1,71

16 ,39 ,46 ,54 ,62 ,69 ,84 1,06 1,29 1,51 1,74 1,96 2,29 2,63

20 ,50 ,62 ,73 ,83 ,93 1,13 1,43 1,74 2,04 2,34 2,64 2,94 3,55

24 ,65 ,79 ,91 1,05 1,17 1,43 1,81 2,19 2,57 2,95 3,33 3,71 4,47

28 ,79 ,96 1,11 1,26 1,41 1,72 2,18 2,63 3,09 3,55 4,01 4,45 5,39

32 ,93 1,12 1,3 1,47 1,65 2,01 2,35 3,08 3,62 4,16 4,69 5,23 6,30

36 1,07 1,28 1,48 1,69 1,89 2,30 2,92 3,53 4,15 4,76 5,38 5,99 7,22

40 1,21 1,44 1,67 1,90 2,14 2,59 3,29 3,98 4,67 5,37 6,06 6,75 8,14

44 1,35 1,60 1,86 2,12 2,38 2,89 3,66 4,43 5,20 5,97 6,74 7,52 9,06

48 1,48 1,77 2,05 2,33 2,62 3,18 4,03 4,88 5,73 6,58 7,43 8,28 9,97

52 1,64 1,93 2,24 2,55 2,86 3,48 4,40 5,33 6,26 7,18 8,11 9,04 10,89

56 1,77 2,11 2,43 2,76 3,09 3,77 4,77 5,78 6,78 7,79 8,80 9,80 11,81

60 1,90 2,27 2,62 2,98 3,34 4,06 5,14 6,23 7,31 8,40 9,48 10,56 12,73

64 2,04 2,43 2,61 3,19 3,58 4,36 5,52 6,68 7,84 9,32 10,16 11,32 13,65

68 2,19 2,59 2,99 3,41 3,82 4,65 5,89 7,13 8,37 9,61 10,85 12,09 14,56

72 2,31 2,76 3,18 3,62 4,06 4,98 6,26 7,58 8,89 10,21 11,53 12,85 15,48

VELOCITY / PRESSURE

Vel, FPM 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

Exhaust ,005 ,012 ,019 ,033 ,046 ,059 ,083 ,100 ,125 ,156 ,181 ,215 ,250 ,285

Intake -,007 -,016 -,031 -,046 -,066 -,097 -,125 -,150 -,185 -,225 -,275 -,315 -,370 -,425

CFM = Velocity x Free Pressure Area

NOTE:

For sizes not shown, the approximate free area in square feet can be calculated by using the

formula below:

6 1

1

Free Pressure Area 2 2

144

SELECTION PROCEDURE

EXAMPLE:

Exhaust requirement for 3000 CFM with pressure of ,083 W.G.

Bottom chart shows 800 FPM velocity achieved at ,083 W.G.

Effective pressure area is determitated by diving the CFM by the velocity 3000/800=3,75 required

square feet of free pressure area

The chart thus shows the following sizes to be suitable, 18 x 72, 20 x 68, 27 x 56, etc.

You might also like

- Industry 4.0: Reshaping the Manufacturing LandscapeDocument20 pagesIndustry 4.0: Reshaping the Manufacturing Landscapeambika1969inNo ratings yet

- Tubo ScheduleDocument1 pageTubo ScheduleMarcos AntonioNo ratings yet

- EN-UHS-CatalogDocument27 pagesEN-UHS-Catalogkien.trantrungkienNo ratings yet

- Single-Span Support: Trapez Load Tables Positive PositionDocument1 pageSingle-Span Support: Trapez Load Tables Positive PositionmikeshiiNo ratings yet

- Distribution Tabel Nilai F0,05 PDFDocument1 pageDistribution Tabel Nilai F0,05 PDFMilanNo ratings yet

- F-table Distribution for Degrees of FreedomDocument1 pageF-table Distribution for Degrees of FreedomRIDWAN TORONo ratings yet

- Tubos SCH MedidasDocument1 pageTubos SCH Medidashm2531No ratings yet

- Distribusi Nilai F Tabel Sig. 5%Document1 pageDistribusi Nilai F Tabel Sig. 5%DelinaNo ratings yet

- Tabela A-26: UNESP (Bauru/SP) - Lajes de ConcretoDocument1 pageTabela A-26: UNESP (Bauru/SP) - Lajes de ConcretoFernando BragaNo ratings yet

- ERGA04-08DVA Capheat 3D112789D ENDocument1 pageERGA04-08DVA Capheat 3D112789D ENPeter TitoNo ratings yet

- TrocaDocument1 pageTrocaLAERCIO ENGEVALENo ratings yet

- Insulation performance comparisonDocument1 pageInsulation performance comparisonDaniel StanNo ratings yet

- Tabla FisherDocument8 pagesTabla FisherYeison Lizarve CahuanaNo ratings yet

- Profile Structurale Si Prelucrari Mecanice: Divisione Acciaio Al CarbonioDocument17 pagesProfile Structurale Si Prelucrari Mecanice: Divisione Acciaio Al CarbonioStefanRazvanStanNo ratings yet

- Table 1 Construction PipesDocument3 pagesTable 1 Construction PipesbayzuraNo ratings yet

- Soal 1: Metode MomentDocument9 pagesSoal 1: Metode MomentMuh FaisalNo ratings yet

- Lampiran 1 Spesifikasi Alat Muat Backhoe Komatsu PC - 200Document15 pagesLampiran 1 Spesifikasi Alat Muat Backhoe Komatsu PC - 200abdul hakimNo ratings yet

- Starlift MetricDocument2 pagesStarlift MetricCralesNo ratings yet

- TABLA Distribución F Áreas A Derecha: GL Nume / GL DenoDocument3 pagesTABLA Distribución F Áreas A Derecha: GL Nume / GL DenoJuan Camilo Rojas BarrientosNo ratings yet

- Cold Formed SQUAREDocument2 pagesCold Formed SQUAREmikarceNo ratings yet

- Aa Perfiles Correas AppDocument7 pagesAa Perfiles Correas AppMADELAINE BETHSABE TAYUPANDA MAZANo ratings yet

- Sieves: Rekord / Ondula Tria / Serpenti Harp ScreensDocument12 pagesSieves: Rekord / Ondula Tria / Serpenti Harp ScreensArnab MannaNo ratings yet

- Distribution Table F0,05 Degrees of FreedomDocument1 pageDistribution Table F0,05 Degrees of FreedomNiiWuuNo ratings yet

- HTTP WWW - Ped-Co - pdf3 StandardDocument1 pageHTTP WWW - Ped-Co - pdf3 StandardMostafa HashemiNo ratings yet

- Pipe schedule overzicht websiteDocument1 pagePipe schedule overzicht websiteteguh.setionoNo ratings yet

- Standard 2697 defines hardness to tensile strength conversionsDocument19 pagesStandard 2697 defines hardness to tensile strength conversionsanhthoNo ratings yet

- EN 10208-1 Pipe dimensions-EXTRASDocument1 pageEN 10208-1 Pipe dimensions-EXTRASPaulNo ratings yet

- Terminal Tangguh LNG Height DataDocument12 pagesTerminal Tangguh LNG Height DataMuzwar RusadiNo ratings yet

- Pipe Dimensions and Weights Data Sheet enDocument6 pagesPipe Dimensions and Weights Data Sheet enhaidderNo ratings yet

- Naldo 5-230 Pa10-1Document4 pagesNaldo 5-230 Pa10-1Angel NaldoNo ratings yet

- Technical Data Sheet - TR 153Document5 pagesTechnical Data Sheet - TR 153gherman_cld7549No ratings yet

- Tugas Rekayasa Lalu-Lintas 1Document6 pagesTugas Rekayasa Lalu-Lintas 1Efti WeaslyNo ratings yet

- Tevi Pentru Apa Si Gaz SR en 10255Document3 pagesTevi Pentru Apa Si Gaz SR en 10255cloantafNo ratings yet

- Tablas F de FisherDocument18 pagesTablas F de FisherFayzulit AlvarezNo ratings yet

- Slip On FlangesDocument11 pagesSlip On FlangesMANo ratings yet

- Tabelle Di Misura Six Team 5060Hz 2012Document2 pagesTabelle Di Misura Six Team 5060Hz 2012Cataloghi TecniciNo ratings yet

- PT. Jaya Makmur Eka Lestari Carbon Steel Pipes & Fittings SupplierDocument7 pagesPT. Jaya Makmur Eka Lestari Carbon Steel Pipes & Fittings SupplierAgeng CahayaNo ratings yet

- Mazzei Injectors Performance SpecificationsDocument1 pageMazzei Injectors Performance SpecificationstopoginoNo ratings yet

- Stainless Steel Tube Dimensions and WeightsDocument1 pageStainless Steel Tube Dimensions and WeightshelderfsnNo ratings yet

- Valvitalia-Cat. Ltg1 Special TrimsDocument7 pagesValvitalia-Cat. Ltg1 Special Trimslydia.wasprimaNo ratings yet

- EWYA-D (W1 V3) P (-H-) Capheat 4D130967A ITDocument1 pageEWYA-D (W1 V3) P (-H-) Capheat 4D130967A ITStefano NatalizioNo ratings yet

- Lampiran A Sampai oDocument26 pagesLampiran A Sampai onur annisaNo ratings yet

- Al Conductor Stranded 6Document4 pagesAl Conductor Stranded 6Ankit AgarwalNo ratings yet

- ScheduleDocument1 pageScheduleannosek4843No ratings yet

- Kalkulator HDD 1Document2 pagesKalkulator HDD 1Yosua BanjarnahorNo ratings yet

- Blind Flanges and Socket Welding Flanges Technical SpecificationsDocument11 pagesBlind Flanges and Socket Welding Flanges Technical SpecificationsMANo ratings yet

- Calculating Traffic Performance on a Road SectionDocument22 pagesCalculating Traffic Performance on a Road SectionEfti WeaslyNo ratings yet

- Fisher 2Document10 pagesFisher 2Diomedes DiazNo ratings yet

- Welded structural hollow sections - pipe dimensions and weightsDocument1 pageWelded structural hollow sections - pipe dimensions and weightshhhrocker3093No ratings yet

- Types and weights of metal sheetsDocument1 pageTypes and weights of metal sheetsZé MirtoNo ratings yet

- 300 LB WELDING NECK FLANGE DIMENSIONSDocument2 pages300 LB WELDING NECK FLANGE DIMENSIONSemre ozdemirNo ratings yet

- ULMA Flange #150 #300 CatalogDocument3 pagesULMA Flange #150 #300 CatalogEPC Patuha BMJNo ratings yet

- Autofilettanti - Self TappingDocument2 pagesAutofilettanti - Self TappingFranco FranchiNo ratings yet

- PP165 ISO Metric Size and DimensionDocument2 pagesPP165 ISO Metric Size and DimensionDar FallNo ratings yet

- Tubos Padrão Schedule de Aço Inox Nas Normas Astm A312, A409, A778 CONFORME ANSI B36.10 E B36.19Document2 pagesTubos Padrão Schedule de Aço Inox Nas Normas Astm A312, A409, A778 CONFORME ANSI B36.10 E B36.19Markin33No ratings yet

- Book 1Document4 pagesBook 1irfanNo ratings yet

- Figure 1. (Left) Geometry For Vertical Arrangement (Right) Geometry For Horizontal ArrangementDocument13 pagesFigure 1. (Left) Geometry For Vertical Arrangement (Right) Geometry For Horizontal ArrangementLuis PerdomoNo ratings yet

- Kay Blower Performance Chart Modified Ke SeriesDocument1 pageKay Blower Performance Chart Modified Ke SeriessanketNo ratings yet

- Girders - DetailsDocument5 pagesGirders - DetailsPaul Gabriel BălteanuNo ratings yet

- Arsalan - Research ProposelDocument9 pagesArsalan - Research ProposelArsalan AkhtarNo ratings yet

- SIP Summary & FormatDocument8 pagesSIP Summary & FormatSanith S NairNo ratings yet

- Chapter 3 2012Document76 pagesChapter 3 2012maedinNo ratings yet

- QC Inspector Functions Tests AnswersDocument8 pagesQC Inspector Functions Tests Answerszhangyili50% (2)

- The Role of Experiments in Scientific InquiryDocument41 pagesThe Role of Experiments in Scientific InquiryRika AmelliaNo ratings yet

- The Perfect Thread: - Walter Titex & Walter PrototypDocument53 pagesThe Perfect Thread: - Walter Titex & Walter PrototypTeenTeen GaMingNo ratings yet

- The Digital Self: Who Am I in The Cyberworld?Document16 pagesThe Digital Self: Who Am I in The Cyberworld?Marianne Jeuyce LuvidiceNo ratings yet

- MOS Integrated Circuits - Basics: BY:-Ajay Pratap SinghDocument42 pagesMOS Integrated Circuits - Basics: BY:-Ajay Pratap SinghFaizan NazirNo ratings yet

- DC - Batman Beyond JumpChainDocument27 pagesDC - Batman Beyond JumpChainAtinder SinghNo ratings yet

- Kra16480 Reductor Traslacion 2 Cx210d - Cx210bDocument3 pagesKra16480 Reductor Traslacion 2 Cx210d - Cx210bjavier muñozNo ratings yet

- Data Structure & Program Design: B.E. (Computer Science Engineering) Fourth Semester (C.B.S.)Document4 pagesData Structure & Program Design: B.E. (Computer Science Engineering) Fourth Semester (C.B.S.)sahil kambleNo ratings yet

- NTC Form ApplicationDocument2 pagesNTC Form ApplicationIvan c TanegaNo ratings yet

- Digital Photography Advantages for Police WorkDocument5 pagesDigital Photography Advantages for Police WorkGielhene MinearNo ratings yet

- SAE To Metric Conversion ChartDocument5 pagesSAE To Metric Conversion ChartLAliNo ratings yet

- Online Banking Authentication System Using QR-code and Mobile OTPDocument6 pagesOnline Banking Authentication System Using QR-code and Mobile OTPግሩም ሽ.No ratings yet

- Formulas Calculate Seal Chamber Pressure Pump Given Suction Discharge PressuresDocument2 pagesFormulas Calculate Seal Chamber Pressure Pump Given Suction Discharge PressuresSaadEddine AtifNo ratings yet

- D Ay Open Day Close by CSC Clerk and Collection Entries and Reports at CSCDocument29 pagesD Ay Open Day Close by CSC Clerk and Collection Entries and Reports at CSCAnandNo ratings yet

- Shreyasi Ghosh: Get in ContactDocument2 pagesShreyasi Ghosh: Get in ContactKunjan SomaiyaNo ratings yet

- Digital Marketing CompanyDocument4 pagesDigital Marketing CompanyArdanNo ratings yet

- Noman TariqDocument2 pagesNoman Tariqnomanattitude786No ratings yet

- FZS600 Owners ManualDocument105 pagesFZS600 Owners ManualjonboynzNo ratings yet

- Stacey Brougham: Professional SummaryDocument2 pagesStacey Brougham: Professional SummaryStacey BroughamNo ratings yet

- TACO - Free On Demand TrainingDocument18 pagesTACO - Free On Demand TrainingVinicius Paschoal NatalicioNo ratings yet

- Rollerdrive Ec5000 Ai/Bi: Operating ManualDocument56 pagesRollerdrive Ec5000 Ai/Bi: Operating ManualRapin SIEIMONo ratings yet

- Data Sheet For SIMOTICS S-1FK2: Article No.: 1FK2206-4AF10-1MA0Document1 pageData Sheet For SIMOTICS S-1FK2: Article No.: 1FK2206-4AF10-1MA0AbhishekNo ratings yet

- Capturing Marketing Insights: 1. Collecting Information and Forecasting DemandDocument64 pagesCapturing Marketing Insights: 1. Collecting Information and Forecasting DemandNandan Choudhary100% (1)

- Shell Air Tool S2 A 100 TDS PDFDocument2 pagesShell Air Tool S2 A 100 TDS PDFDonny HendrawanNo ratings yet

- Hydraulic OilDocument1 pageHydraulic OilNadeem AhmedNo ratings yet

- Pre-Assessment of 3Dprinting-Teacher VersionDocument3 pagesPre-Assessment of 3Dprinting-Teacher VersionDhirenNo ratings yet