100% found this document useful (1 vote)

491 views23 pagesCase Study Structures

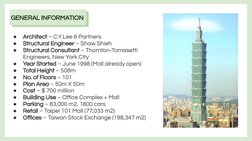

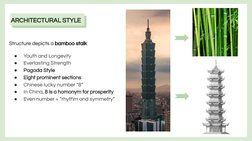

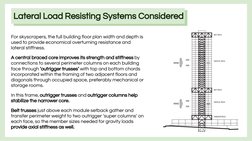

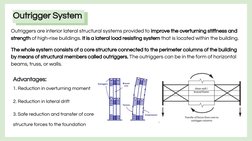

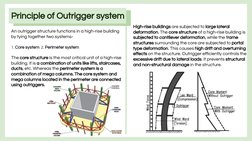

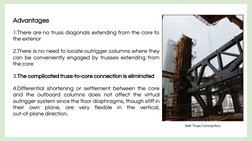

Taipei 101 Tower in Taiwan is the world's tallest green building. It has 101 floors and stands 508 meters tall. To withstand earthquakes and typhoons, its structural system incorporates a central reinforced concrete core with outrigger trusses and belt trusses that connect the core to perimeter columns. It also uses special moment frames, shear walls, tuned mass dampers, and a sloped glass facade to resist lateral forces and minimize sway.

Uploaded by

Aayushi DCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

491 views23 pagesCase Study Structures

Taipei 101 Tower in Taiwan is the world's tallest green building. It has 101 floors and stands 508 meters tall. To withstand earthquakes and typhoons, its structural system incorporates a central reinforced concrete core with outrigger trusses and belt trusses that connect the core to perimeter columns. It also uses special moment frames, shear walls, tuned mass dampers, and a sloped glass facade to resist lateral forces and minimize sway.

Uploaded by

Aayushi DCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd