Professional Documents

Culture Documents

Water Softening Processes

Uploaded by

Tushar SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Softening Processes

Uploaded by

Tushar SharmaCopyright:

Available Formats

Unit-1b Water and its treatment

Water Softening

Processes involved in removal of temporary and permanent hardness is called as “softening of

water”. It is very essential process since hard water is unsuitable for domestic and industrial use.

Use of hard water for generating steam in boilers so as to generate electricity results in problems

like sludge formation, priming, foaming, boiler corrosion and caustic embrittlement.

Boiler Hard water can be removed by two ways:

1. External Treatment: Treatment of hard water is done before its entry into the boiler.

This involves lime-soda, zeolite and ion exchange process. All are preventive methods.

2. Internal treatment: Treatment of raw water is done inside the boiler by two processes.

a. Appropriate chemicals are added to the boiler water to precipitate the scale forming

impurities in the form of sludges which can be later removed.

b. Cations causing hardness are converted into compounds which will stay in dissolved

form in water and thus do not cause any harm.

The processes involved are Colloidal conditioning, carbonate conditioning, phosphate

conditioning and calgon conditioning.

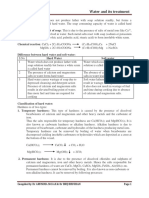

Difference b/w Internal and External treatment

S.No Internal Treatment External Treatment

1. These are corrective methods These are preventive methods

2. It is carried out inside the boiler It is carried out outside the boiler, before

the entry of water into the boiler.

3. Includes Colloidal conditioning, Includes lime-soda, zeolite and ion

carbonate conditioning, exchange process

phosphate conditioning and

calgon conditioning

Lime soda process:

The basic principle of this process is to chemically convert all the soluble hardness

causing salts of calcium and magnesium into insoluble precipitates which can then be

removed by settling and filtration.

Lime [Ca(OH)2] and soda ash (Na2CO3) is added to facilitate precipitation. The

precipitates thus formed are CaCO3, Mg(OH)2, Fe(OH)3, and Al(OH)3. These are then

filtered off.

But the precipitates formed at room temperature are not coarse and hence do not settle

down and thereby cause difficulty in filtration.

To facilitate precipitation, addition of lime is done at high temperature. This is

followed by addition of Coagulants like Alum [K2SO4.Al2 (SO4)3.24H2O], Aluminum

sulphate [Al2(SO4)3] or Sodium aluminate [NaAlO2]. By this process coarse

precipitate are formed which can then be filtered off.

Thus there are two methods of Lime soda: Cold Lime process and Hot Lime process.

Both operate under the same principle but their difference is as follows:

Compiled by Dr ARUNIMA NAYAK & Dr BRIJ BHUSHAN Page 1

Unit-1b Water and its treatment

Following are the reactions that takes place in this process when the following

substituent is present in hard water:

Constituent Reactions Lime/Soda

required

Ca(HCO3)2 Ca(OH)2 + Ca(HCO3)2 → 2CaCO3 ↓ + 2H2O 1Lime

Mg(HCO3)2 2Ca(OH)2 + Mg(HCO3)2 → Mg(OH)2 ↓ + 2CaCO3 ↓ + 2Lime

2H2O

Mg2+ Ca(OH)2 + Mg2+ → Mg(OH)2 ↓ + Ca2+ L

Ca2+ +Na2CO3 → CaCO3 ↓ +2Na+ S

MgCl2 MgCl2 + Ca(OH)2 → Mg(OH)2 ↓ + CaCl2

CaCl2 +Na2CO3 → CaCO3 ↓ +2NaCl

MgSO4 MgSO4+ Ca(OH)2 + → Mg(OH)2 ↓ + CaSO4 1lime+1Soda

CaSO4 + Na2CO3→ CaCO3↓ + Na2SO4

Ca2+ CaSO4 + Na2CO3. → CaCO3↓ + Na2SO4 1Soda

CaSO4

CaCl2 CaCl2 + Na2CO3. → CaCO3↓ + NaCl 1Soda

HCO3- NaHCO3 + Ca(OH)2 CaCO3↓ + H2O +Na2CO3 L-S

[NaHCO3]

Advantage of L-S Process:

i. It is very economical

ii. Treated water is alkaline and has less corrosion tendencies

iii. It removes not only hardness causing salts but also minerals.

iv. Iron and magnesium are also removed from water to some extent

Disadvantage of L-S Process:

i. The process results in sludge formation

ii. The process cannot be used for high pressure boilers

Compiled by Dr ARUNIMA NAYAK & Dr BRIJ BHUSHAN Page 2

Unit-1b Water and its treatment

Calculation for Lime/ Soda Requirement:

𝐌𝐖 𝐨𝐟 𝐥𝐢𝐦𝐞

Lime requirement = [Hardness in ppm] x Volume of water (L)

𝐌𝐖 𝐨𝐟 𝐂𝐚𝐂𝐎𝟑

𝐌𝐖 𝐨𝐟 𝐬𝐨𝐝𝐚

Soda requirement = [Hardness in ppm] x Volume of water (L)

𝐌𝐖 𝐨𝐟 𝐂𝐚𝐂𝐎𝟑

MW of lime= 74, MW of soda= 106

NUMERICALS on L-S Process:

Q1. Calculate the amount of lime required for softening of 5000L of hard water

containing 72ppm of MgSO4.

Ans: 72 ppm of MgSO4 = 72x100/120 = 60ppm of CaCO3 equivalent.

Lime requirement = 74/100x60x5000 mg = 222g.

Q2. Calculate the amount of lime required for softening 50,000L of hard water

containing Mg(HCO3)2 = 144ppm, Ca(HCO3)2 = 25ppm, MgCl2 = 95 ppm, CaCl2

= 111ppm, Fe2O3 = 25 ppm, Na2SO4 = 15 ppm

Ans:

Constituent Reactions Lime/Soda

required

Ca(HCO3)2 Ca(OH)2 + Ca(HCO3)2 → 2CaCO3 ↓ + 2H2O 1Lime

Mg(HCO3)2 2Ca(OH)2 + Mg(HCO3)2 → Mg(OH)2 + 2CaCO3 ↓ + 2H2O 2Lime

CaCl2 CaCl2 + Na2CO3→ CaCO3 + NaCl 1Soda

MgCl2 MgCl2 + Ca(OH)2 → Mg(OH)2 + CaCl2 1Lime

Fe2O3 and Na2SO4 do not cause hardness and hence do not require L or S

Hardness causing Amount (ppm) Multiplication CaCO3

salt factor equivalent

Mg(HCO3)2 144 100/146 144x100/146 =

98.6ppm

Ca(HCO3)2 25 100/162 25x100/162 =

15.4 ppm

MgCl2 95 100/95 95x100/95 = 100

ppm

Lime requirement = 74/100 (2x98.6 +15.4 +100) mg/L x50, 0000L = 1156200mg =

11.57kg

Compiled by Dr ARUNIMA NAYAK & Dr BRIJ BHUSHAN Page 3

Unit-1b Water and its treatment

Q3. A water sample on analysis gave the following results:

Ca2+ = 30mg/L; Mg2+ = 18mg/L, K+ = 19.5mg/L, HCO3- = 122mg/L, Cl- = 35.5

mg/L, SO42- = 48 mg/L

Calculate the total hardness and alkalinity present in water sample.

Also, calculate the lime soda required for softening 1L sample of the hard water.

Ans: Total hardness = [Ca2+ +Mg2+ + HCO3-] = 30x100/40 +18x100/24 + 122x100/122 =

250 ppm

Alkalinity = [HCO3-] = 122x100/122 = 100ppm

Lime required = 74/100[Mg2+ + HCO3- in CaCO3 equiv.] mg/L x V (L) =

74/100[18x100/24 + 122x100/122] x 1 L= 129.5mg

Soda required = 106/100[[Ca2+ +Mg2+ - HCO3- in CaCO3 equiv.] mg/L x V (L)

= 106/100[30x100/40 +18x100/24 - 122x100/122] x 1L = 53mg

Q4. Calculate the amount of lime and soda needed for softening a water sample containing

36ppm Mg2+, 20ppm Ca2+ and 183ppm HCO3-

Ans:

Lime required = 74/100[Mg2+ + HCO3- in CaCO3 equiv.] mg/L =

74/100[36x100/24 + 183x100/122] mg/L = 222ppm

Soda required = 106/100[[Ca2+ +Mg2+ - HCO3- in CaCO3 equiv.] mg/L =

106/100[36x100/40 +20x100/24 - 183x100/122] mg/L= 53ppm

Q5. A water sample contains the following impurities:

Ca2+ = 20ppm, Mg2+ = 18ppm, HCO3- = 183ppm, SO42- = 24ppm

Calculate the lime and soda required for softening

Ans:

Lime required = 74/100[Mg2+ + HCO3- in CaCO3 equiv.] mg/L =

74/100[18x100/24 + 183x100/122] mg/L = 166.5ppm

Soda required = 106/100[[Ca2+ +Mg2+ - HCO3- in CaCO3 equiv.] mg/L =

106/100[20x100/40 +18x100/24 - 183x100/122] = - 26.5ppm

Soda is hence not required

Compiled by Dr ARUNIMA NAYAK & Dr BRIJ BHUSHAN Page 4

You might also like

- Unit 4-Water TreatmentDocument11 pagesUnit 4-Water Treatmentgopi nath sahuNo ratings yet

- Revised Module 2Document57 pagesRevised Module 2GnanashekaranNo ratings yet

- CHY1701 M2 - Dr. Krishnendu BiswasDocument70 pagesCHY1701 M2 - Dr. Krishnendu Biswaslalithkumaran LNo ratings yet

- Water ChemistryDocument19 pagesWater ChemistryNupur ChoudharyNo ratings yet

- Unit-2 Water ChemistryDocument15 pagesUnit-2 Water ChemistryKunjal singhNo ratings yet

- Softening Methods: The Process Removing Hardness Causing Salts From Water Is Known As Water Softening ProcessDocument12 pagesSoftening Methods: The Process Removing Hardness Causing Salts From Water Is Known As Water Softening ProcessBELIEVERNo ratings yet

- Final (Water Fuel Polymer)Document18 pagesFinal (Water Fuel Polymer)amanNo ratings yet

- Hardness Removal MethodsDocument5 pagesHardness Removal MethodsShekh Muhsen Uddin AhmedNo ratings yet

- 3Document66 pages3Nikhil AroraNo ratings yet

- Module 1B,,Water Treatment, Hardnessdoc.2Document8 pagesModule 1B,,Water Treatment, Hardnessdoc.2Kashish shrivastwaNo ratings yet

- Softening hard water externallyDocument15 pagesSoftening hard water externallyvishalNo ratings yet

- SofteningDocument8 pagesSofteningKhodarahm FarjoodiNo ratings yet

- Softening FinalDocument23 pagesSoftening FinalSonali Jahagirdar100% (1)

- 2 ADocument45 pages2 AShyam SundarNo ratings yet

- Softening MethodsDocument7 pagesSoftening MethodsPranay ChandrikapureNo ratings yet

- Chapter 8 Miscellaneous Treatment Processes: 8.1. SofteningDocument4 pagesChapter 8 Miscellaneous Treatment Processes: 8.1. SofteningShita AlemieNo ratings yet

- PPTDocument13 pagesPPTLakshmi ShivaNo ratings yet

- Chapter 5 SofteningDocument11 pagesChapter 5 SofteningMuluken MelesseNo ratings yet

- Book Files I Hate You GiveDocument39 pagesBook Files I Hate You Givesabeethabegam1984No ratings yet

- WaterDocument20 pagesWaterPhyu Mar Thein KyawNo ratings yet

- WaterDocument40 pagesWaterhimanshuchawla654No ratings yet

- Water Its Treatment Part2Document43 pagesWater Its Treatment Part2netsanet mesfinNo ratings yet

- Unit 1Document11 pagesUnit 1softsen10No ratings yet

- Removal of Hardness 1Document35 pagesRemoval of Hardness 1KISHAN PATELNo ratings yet

- Reject PretreatmentDocument2 pagesReject PretreatmentVisheasNo ratings yet

- Softening: CEL212 Dr. Divya Gupta 9 Feb, 2021Document26 pagesSoftening: CEL212 Dr. Divya Gupta 9 Feb, 2021Prashant Kumar SagarNo ratings yet

- 202003241126075319ranvijay Engg Water TechnologyDocument13 pages202003241126075319ranvijay Engg Water Technologyvel muruganNo ratings yet

- CoagulationDocument70 pagesCoagulationMoazzamNo ratings yet

- Water Softening: Removal of Hardness Hardness Is?..Document38 pagesWater Softening: Removal of Hardness Hardness Is?..Pradhumna AdhikariNo ratings yet

- 16 Lime SofteningDocument10 pages16 Lime SofteningMohammad Al-TamimiNo ratings yet

- Water TreatmentDocument37 pagesWater TreatmentAMAL MATHEWNo ratings yet

- Technology of Water - Unit IDocument61 pagesTechnology of Water - Unit I21MEB358 Kunal AryaNo ratings yet

- Anthony M. Wachinski - Environmental Ion Exchange - Principles and Design-Taylor & Francis, Chapman and Hall - CRC (2016) (1) (032-042)Document11 pagesAnthony M. Wachinski - Environmental Ion Exchange - Principles and Design-Taylor & Francis, Chapman and Hall - CRC (2016) (1) (032-042)HARDY EDDISONNo ratings yet

- Lime Soda ProcessDocument1 pageLime Soda Processrikiw17874No ratings yet

- Lime-Soda Process ExplainedDocument10 pagesLime-Soda Process Explainedgaurav toppoNo ratings yet

- Thermal Power Plant Water ChemistryDocument33 pagesThermal Power Plant Water ChemistryNAITIK100% (4)

- Watertreatmentandanalysis 2Document19 pagesWatertreatmentandanalysis 2O MNo ratings yet

- 17BEM0049DA1Document12 pages17BEM0049DA1Vedant KarnatakNo ratings yet

- Water TreatmentDocument42 pagesWater Treatmentpooja.amanchiNo ratings yet

- Soda Ash PresDocument32 pagesSoda Ash PresGaurav GuptaNo ratings yet

- Lecture-8 & 9CHDocument25 pagesLecture-8 & 9CHanantlakhotiya.11No ratings yet

- Engineering Chemistry Unit 1 Notes RGPVDocument7 pagesEngineering Chemistry Unit 1 Notes RGPVMufaddal HamidNo ratings yet

- Silica Removal During Lime Softening in Water Treatment PlantDocument10 pagesSilica Removal During Lime Softening in Water Treatment PlantLouay MansourNo ratings yet

- Chapter 7Document21 pagesChapter 7Solomon DesalegnNo ratings yet

- Dr. M. Akhila Maheswari: CHY 1701 Engineering ChemistryDocument51 pagesDr. M. Akhila Maheswari: CHY 1701 Engineering ChemistryShaunak bagadeNo ratings yet

- Module 2 - ECDocument76 pagesModule 2 - ECXavier HunterNo ratings yet

- Water Treatment Processes and Chemical CalculationsDocument6 pagesWater Treatment Processes and Chemical CalculationsAhmed AliNo ratings yet

- Water: HardnessDocument60 pagesWater: HardnessDinesh VermaNo ratings yet

- Water Treatment & Contaminants ExplainedDocument47 pagesWater Treatment & Contaminants ExplaineddarshanNo ratings yet

- Water: Sodium Stearate (Soap)Document4 pagesWater: Sodium Stearate (Soap)Rajeshwar Rao AervaNo ratings yet

- WINSEM2020-21 CHY1701 ETH VL2020210507113 Reference Material I 15-Mar-2021 Module-2-2021Document66 pagesWINSEM2020-21 CHY1701 ETH VL2020210507113 Reference Material I 15-Mar-2021 Module-2-2021Puneeth PuneethNo ratings yet

- Softening Method: - "The Process of Removing ofDocument5 pagesSoftening Method: - "The Process of Removing ofslchemNo ratings yet

- Cold Lime Soda Softening ProcessDocument10 pagesCold Lime Soda Softening ProcessSaurabh JadhavNo ratings yet

- Water Softening: 150 MG/L As CacoDocument5 pagesWater Softening: 150 MG/L As CacoKFJDONo ratings yet

- Chemistry Module 5 (2019 Scheme)Document28 pagesChemistry Module 5 (2019 Scheme)Rubiks WorldNo ratings yet

- Softening water processesDocument20 pagesSoftening water processesHassan AliNo ratings yet

- Chemistry Da 1Document14 pagesChemistry Da 1Aditya GhoshNo ratings yet

- Class Notes - BT101 - 1679890571Document133 pagesClass Notes - BT101 - 1679890571Aayush GehlotNo ratings yet

- Module I and II ChemistryDocument28 pagesModule I and II ChemistryMohd Naif FirozNo ratings yet

- Lecture 12 - Thevenins Theorem and Nortons TheoremDocument15 pagesLecture 12 - Thevenins Theorem and Nortons TheoremTushar SharmaNo ratings yet

- Lecture 11 (B) - Superposition TheoremDocument11 pagesLecture 11 (B) - Superposition TheoremTushar SharmaNo ratings yet

- Lecture 0 - Introduction To The CourseDocument4 pagesLecture 0 - Introduction To The CourseTushar SharmaNo ratings yet

- Lecture 4 - Analysis of Voltage, Current Sources and Resistances in Series and ParallelDocument11 pagesLecture 4 - Analysis of Voltage, Current Sources and Resistances in Series and ParallelTushar SharmaNo ratings yet

- Water Treatment: Hardness & TypesDocument2 pagesWater Treatment: Hardness & TypesTushar SharmaNo ratings yet

- Water and Its Treatment-7,8Document4 pagesWater and Its Treatment-7,8Tushar SharmaNo ratings yet

- Water and Its Treatment-5,6Document3 pagesWater and Its Treatment-5,6Tushar SharmaNo ratings yet

- Law of Definite Proportions Lab ReportDocument3 pagesLaw of Definite Proportions Lab Reportrinkeanmark50% (2)

- Nalsize 7541: Emulsification AidDocument3 pagesNalsize 7541: Emulsification Aidalakazum28No ratings yet

- TESTS FOR INSULATING OILDocument2 pagesTESTS FOR INSULATING OILDINESHNo ratings yet

- Synthesis and Characterization of Kraft Lignin-Graft-Polylactide CopolymersDocument12 pagesSynthesis and Characterization of Kraft Lignin-Graft-Polylactide CopolymersRitaSantosNo ratings yet

- C A 1 M G: NsscoDocument7 pagesC A 1 M G: NsscoNamasiku MuyundaNo ratings yet

- Astm d1600 1999Document10 pagesAstm d1600 1999Greg YeeNo ratings yet

- DATA SHEET: Domex 700 MC steel specificationsDocument2 pagesDATA SHEET: Domex 700 MC steel specificationsflorin_iacob2001No ratings yet

- Steps and Tools in A Typical Quantitative AnalysisDocument5 pagesSteps and Tools in A Typical Quantitative Analysisjay cNo ratings yet

- Chemicals Used For Cleaning & Manual Cleaning Processes - FINAL 2Document45 pagesChemicals Used For Cleaning & Manual Cleaning Processes - FINAL 2jerimiah_manzonNo ratings yet

- 211 ArsenicDocument5 pages211 ArsenicsofianesedkaouiNo ratings yet

- Fajan's RuleDocument19 pagesFajan's RuleSaransh GoyalNo ratings yet

- Sample PaperDocument4 pagesSample Papermahima mishraNo ratings yet

- Mobilcut 102 Hoja TecnicaDocument2 pagesMobilcut 102 Hoja TecnicaCAGERIGONo ratings yet

- Chemistry - Qualitative AnalysisDocument2 pagesChemistry - Qualitative AnalysisAditya SenthilNo ratings yet

- Ref Manual - Additives For MA Spinel PDFDocument5 pagesRef Manual - Additives For MA Spinel PDFRITWIK SARKARNo ratings yet

- Protect and Decorate Concrete & Masonry with Acrylic CoatingDocument4 pagesProtect and Decorate Concrete & Masonry with Acrylic CoatingVedachalam ManiNo ratings yet

- Gladie Lesson PlanDocument6 pagesGladie Lesson PlanJustine MontemayorNo ratings yet

- Kalingastone Quartz Care and MaintenanceDocument4 pagesKalingastone Quartz Care and MaintenanceSabyasachi Bangal100% (1)

- Applied Energy: Nourredine Abdoulmoumine, Sushil Adhikari, Avanti Kulkarni, Shyamsundar ChattanathanDocument14 pagesApplied Energy: Nourredine Abdoulmoumine, Sushil Adhikari, Avanti Kulkarni, Shyamsundar ChattanathanGhulam MurtazaNo ratings yet

- Nitric AcidDocument37 pagesNitric AcidBryce DayapNo ratings yet

- Comparison Astm and JisDocument4 pagesComparison Astm and JisGokulAgNo ratings yet

- ISO9001:2000 Certified MSDS for Ammonium Buffer SolutionDocument6 pagesISO9001:2000 Certified MSDS for Ammonium Buffer SolutionMa'arij HarfadliNo ratings yet

- Biochem ExperiementsDocument2 pagesBiochem ExperiementsAlyssa PachecoNo ratings yet

- Textile Wet Processing UNIT-3Document7 pagesTextile Wet Processing UNIT-3Chaarvi SaranyaNo ratings yet

- Asme Ii B SB-677Document6 pagesAsme Ii B SB-677الGINIRAL FREE FIRENo ratings yet

- Humic Substances Increase Survival of Freshwater ShrimpDocument11 pagesHumic Substances Increase Survival of Freshwater ShrimpAlan ToribioNo ratings yet

- PPI Listing Of: TR-4/2018 HDB/HDS/PDB/ Sdb/Mrs/Crs Listed MaterialsDocument58 pagesPPI Listing Of: TR-4/2018 HDB/HDS/PDB/ Sdb/Mrs/Crs Listed MaterialsSaradhi Medapureddy100% (1)

- Din Handbook 402Document4 pagesDin Handbook 402fivehours5No ratings yet

- Pre-Medical: Chemistry: Exercise-IDocument6 pagesPre-Medical: Chemistry: Exercise-IAhkil NandaNo ratings yet

- Sri Chaitanya: IIT Academy., IndiaDocument11 pagesSri Chaitanya: IIT Academy., Indiadasari srinidhi100% (1)