Professional Documents

Culture Documents

Strake Calculation

Uploaded by

ABIDEEN BAMNEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strake Calculation

Uploaded by

ABIDEEN BAMNECopyright:

Available Formats

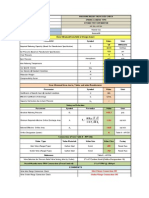

INPUT PARAMETERS:

* Linear Static Analysis

* Stress analysis based upon Allowable Stress Design

Total Stack Height = 40.052 m Top of Stack Elevation = 60.0 m

Grade Elevation = 0.0 m Bottom of Stack = 19.948 m

All elevations are entered based upon the bottom of the structure being at Elevation 19.948 m

Stack Geometry:

Elevation Inner Diameter | Elevation Thickness | Elevation Corrosion Allow

m mm m mm m mm

--------- -------------- - --------- --------- - --------- ---------------

60.0 1700.0 | 60.0 6.0 | 60.0 0.0

29.948 1700.0 | 44.0 8.0 |

19.948 2572.0 | 32.5 6.0 |

| 29.948 10.0 |

Materials:

Elev Material Temp Fyld Elas Mod Alpha Allow Strs Density Tensile

m Deg C MPa MPa mm/mm/C MPa Kg/m^3 MPa

---- -------- ------ ------ -------- -------- ---------- ------- -------

60.0 IS 2062 400.00 125.00 175954 1.37E-05 58.54 7849 204.98

30.00 250.00 202087 1.16E-05 117.14 7849 410.03

Helical Strakes: (3 Vanes 120 deg apart assumed)

ElTop = Top Strake Elevation = 59.009 m

ElBot = Bottom Strake Elevation = 46.009 m

Pitch = Strake Pitch (One complete wrap) = 8.9 m

Width = Strake Width = 180.0 mm

Thick = Strake Thickness = 6.0 mm

OD = Outer Diameter of Stack and Insulation (If Applicable) = 1700.0 mm

ShapeFac = Strake Shape Factor (Applied to bare stack shell) = 1.40

Tinss = External Insulation Thickness = 0.0 mm

SO = Stand-off from OD of shell to strake = 0.0 mm

Len = Pitch Length: [(PI*(OD+2*SO+2*Width))^2+(Pitch^2)]^0.5 = 11.004 m

Area = Total Painted Area (3 vanes): (2*Width*Len*3*Wraps) = 1205.51 sq cm

Wraps = Total Number of Wraps (Top elev - Bot elev)/ Pitch = 1.46

WtUni = Estimated Linear Weight of Strakes and Clips: Wt/(ElTop-ElBot) = 47.13 kg/m

Wt = Estimated total Wt of Strakes and Clips: 1.5*(Area/2)*Thick*Dens= 612.6 kg

Helical Strakes: (Wt = 612.6 kg, El COG = 52.51 m)

El Top El Bot El COG Lin Wt TOt Wt

m m m kg/m kg

------ ------ ------ ------ ------

59.01 46.01 52.51 47.13 612.6

Total 52.51 612.6

You might also like

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan Ramasamy100% (1)

- App 6 CalculationsDocument2 pagesApp 6 CalculationsNizarHamrouniNo ratings yet

- Jet Impingement CoolingDocument9 pagesJet Impingement CoolingDanish AbbasNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- Design Solution-4500wattDocument15 pagesDesign Solution-4500wattrofi azmanNo ratings yet

- PT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsDocument7 pagesPT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsAnshuman ChoudhuryNo ratings yet

- Ejector User GuideDocument2 pagesEjector User GuidehaseebNo ratings yet

- Callidus Production Flare Technology: Advanced Combustion Solutions For Production ApplicationsDocument4 pagesCallidus Production Flare Technology: Advanced Combustion Solutions For Production ApplicationsRay CNo ratings yet

- Section 7Document64 pagesSection 7WlopezaNo ratings yet

- Ows Piping Size2BLDocument3 pagesOws Piping Size2BLreach_arindomNo ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- Values Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesDocument7 pagesValues Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesaltruismNo ratings yet

- Darcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataDocument1 pageDarcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DatakamarularifinkamelNo ratings yet

- Manual Flare Sim ExproDocument69 pagesManual Flare Sim ExproJuan Pablo Alonso100% (1)

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 pagesPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideNo ratings yet

- Critical Property CorrelationsDocument16 pagesCritical Property Correlations李天No ratings yet

- Liquid Pipe Sizing: Group Technology SolutionsDocument1 pageLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNo ratings yet

- Prediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent CorrelationDocument18 pagesPrediction of HETP For Randomly Packed Towers Operation:integration of Aqueous and Non-Aqueous Mass Transfercharacteristics Into One Consistent Correlationcamilo_ortiz_6No ratings yet

- PneumaticconveyingDocument4 pagesPneumaticconveyingfunloverjhaNo ratings yet

- Annex V External PressureDocument26 pagesAnnex V External PressureJohnny VillarroelNo ratings yet

- Limpet Coil CalculationDocument2 pagesLimpet Coil CalculationYusuf DabhiyaNo ratings yet

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- Routine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsDocument3 pagesRoutine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsMohamed Sayed AbdoNo ratings yet

- Catalyst Final CalculationsDocument47 pagesCatalyst Final CalculationsPrable SekhriNo ratings yet

- Pipe SizeDocument9 pagesPipe SizezniperxNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- Hoja de Datos Sistema Aire Comprimido ReferencialDocument18 pagesHoja de Datos Sistema Aire Comprimido ReferencialchepeluchounNo ratings yet

- Venting CalculationDocument14 pagesVenting CalculationValen MaselaNo ratings yet

- Foundation Option For LNG TanksDocument2 pagesFoundation Option For LNG TankssekarsanthanamNo ratings yet

- 16 - Gas Line SizingDocument11 pages16 - Gas Line SizingJunaid MateenNo ratings yet

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDocument5 pagesBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNo ratings yet

- Pipe Fitting Losses: Chemical Engineer's GuideDocument8 pagesPipe Fitting Losses: Chemical Engineer's GuideEdu CordonNo ratings yet

- Length Power Dynamic Viscosity Heat FluxDocument9 pagesLength Power Dynamic Viscosity Heat FluxAnubhav KhandelwalNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Reactor DesignDocument14 pagesReactor DesignAqib LatifNo ratings yet

- Ldo Storage Tank Calculation 170Document6 pagesLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Storage Tank Venting Calculations For Site Tank FarmDocument7 pagesStorage Tank Venting Calculations For Site Tank FarmGusfi CarsurinNo ratings yet

- Blank Diameter For Dished EndDocument1 pageBlank Diameter For Dished EndPrashant KhadtareNo ratings yet

- Dynamic Simulation of Centrifugal Compressor Startup With Inlet Guide VaneDocument8 pagesDynamic Simulation of Centrifugal Compressor Startup With Inlet Guide VaneKong LingweiNo ratings yet

- Flare Stack - FinalDocument7 pagesFlare Stack - FinalIoana Popescu0% (1)

- Dike WallDocument18 pagesDike WallManan MansoorNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Ipa-Water SeparationDocument8 pagesIpa-Water SeparationkashifwarsiNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Summary of Anchor / Nozzle Movements For Vertical VesselDocument17 pagesSummary of Anchor / Nozzle Movements For Vertical Vesselreach_arindomNo ratings yet

- StrainerDocument2 pagesStrainerRanjithNo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Api 2005Document2 pagesApi 2005Madeline DacianNo ratings yet

- 2 Inch OutputPCVDocument1 page2 Inch OutputPCVDuy Nguyễn VănNo ratings yet

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- Crane Vs Eqvlnt Length Method For FittingsDocument177 pagesCrane Vs Eqvlnt Length Method For FittingsSamuel OnyewuenyiNo ratings yet

- Basic Control Valve Sizing and SelectionDocument38 pagesBasic Control Valve Sizing and SelectionmohamedNo ratings yet

- Pressure Relief Valve Sizing and Selection CheckDocument2 pagesPressure Relief Valve Sizing and Selection CheckGiftObionochieNo ratings yet

- The Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemFrom EverandThe Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemNo ratings yet

- ChimneyDocument15 pagesChimneyLILISNo ratings yet

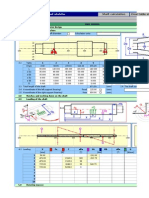

- Staad Analysis For StackDocument39 pagesStaad Analysis For StackABIDEEN BAMNENo ratings yet

- Tank Top Plate CalculationDocument1 pageTank Top Plate CalculationABIDEEN BAMNENo ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocument1 pageTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNENo ratings yet

- Verifying Coriolis Flow Meter CalibrationDocument8 pagesVerifying Coriolis Flow Meter Calibrationابوالحروف العربي ابوالحروفNo ratings yet

- Big SplitDocument12 pagesBig SplitMelanie JapayNo ratings yet

- Effect of Cooling Rate and Finish Rolling Temperature On Structure and Strength of API 5LX70 Linepipe Steel PlateDocument11 pagesEffect of Cooling Rate and Finish Rolling Temperature On Structure and Strength of API 5LX70 Linepipe Steel Platek4dr0nNo ratings yet

- B241B241M 16Document22 pagesB241B241M 16masoudNo ratings yet

- CDS VAM® 21 9.625in. 47lb-ft L80 Type 1 API Drift 8.525in. 87.5%Document1 pageCDS VAM® 21 9.625in. 47lb-ft L80 Type 1 API Drift 8.525in. 87.5%Budi INo ratings yet

- Calculo Flecha TerminadoDocument149 pagesCalculo Flecha TerminadoSebastián ValenciaNo ratings yet

- Moments Levers and Gears Answer SchemeDocument2 pagesMoments Levers and Gears Answer SchemeMr. SuitNo ratings yet

- Impact Testing of Concrete - The Measurement Device: August 2014Document6 pagesImpact Testing of Concrete - The Measurement Device: August 2014MakeshNo ratings yet

- Science10 Q1 W1Document38 pagesScience10 Q1 W1Rainier G. de Jesus100% (2)

- 14 SolutionsDocument60 pages14 SolutionsGlen MangaliNo ratings yet

- Solved Problems in Fluid MechanicsDocument19 pagesSolved Problems in Fluid MechanicsPrincess Janine CatralNo ratings yet

- 10 - Shaly SandDocument31 pages10 - Shaly SandLyn KenNo ratings yet

- MID Paper Manufacturing Processes (Fall 2020)Document2 pagesMID Paper Manufacturing Processes (Fall 2020)Muhammad Nouman khanNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- RSM SheetDocument2 pagesRSM SheetMohamed ShafeeNo ratings yet

- Colloidal SystemDocument13 pagesColloidal SystemCristinaNo ratings yet

- Parts and Function of The MicroscopeDocument3 pagesParts and Function of The MicroscopeStephen GutierrezNo ratings yet

- A9 Tech Book 1Document15 pagesA9 Tech Book 1DejanNo ratings yet

- Clearfil DC Core Plus Kit Brochure en PDFDocument4 pagesClearfil DC Core Plus Kit Brochure en PDFAsus AsusNo ratings yet

- Electroplating With Copper - ENDocument13 pagesElectroplating With Copper - ENLiu ZhuNo ratings yet

- HVAC Thermometer - Fluke 561 Infrared Thermometer - FlukeDocument3 pagesHVAC Thermometer - Fluke 561 Infrared Thermometer - FlukeUmmes AhmedNo ratings yet

- 23/04/2020 Lab Report Purpose: To Determine How Much More Soluble Salt Dissolves in Hot WaterDocument2 pages23/04/2020 Lab Report Purpose: To Determine How Much More Soluble Salt Dissolves in Hot WaterPedroDavid JoaquinFernandoNo ratings yet

- Liu2015Document57 pagesLiu2015Dewi KustatiNo ratings yet

- Magnetic HysteresisDocument232 pagesMagnetic HysteresisbjeserviceNo ratings yet

- Journal of Volcanology and Geothermal Research: Estu Kriswati Irwan Meilano, Masato Iguchi, H.Z. Abidin, SuronoDocument9 pagesJournal of Volcanology and Geothermal Research: Estu Kriswati Irwan Meilano, Masato Iguchi, H.Z. Abidin, Suronosap handayaniNo ratings yet

- SEPARACION MULTICOMPONENTES de Lecho de FluidizacionDocument86 pagesSEPARACION MULTICOMPONENTES de Lecho de FluidizacionBrando MendozaNo ratings yet

- SwepDocument2 pagesSweppiya_engineer2786No ratings yet

- Unclassified Ad Number Limitation Changes TODocument837 pagesUnclassified Ad Number Limitation Changes TOVo Dinh ThaoNo ratings yet

- List of Plastic DefectsDocument1 pageList of Plastic DefectsamploudNo ratings yet

- Ansys AnalysisDocument12 pagesAnsys AnalysisAmbaliyaSanjayNo ratings yet