Professional Documents

Culture Documents

Pump Start Up Checklist

Uploaded by

Sharif Mohammad Adwan0 ratings0% found this document useful (0 votes)

31 views1 pageOriginal Title

Pump Start Up Checklist Copy

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views1 pagePump Start Up Checklist

Uploaded by

Sharif Mohammad AdwanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

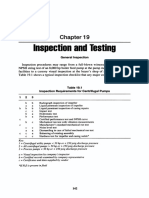

Maintenance & Start-up Checklist: Boosting Pump

Use this checklist as a general guide for recommended inspection of boosting pumps.

General Information

Inspection Date: Inspector:

Building Address:

Pump Location: Floor:

Pump & Motor Nameplate Information

Pump Model:

Pump Type:

Pump Serial Number:

Recommended Boosting Pump Maintenance Steps:

Check the pump and associated plumbing for leaks and corrosion

Verify operation of the isolation valves

Verify function of check valves or PRV’s (if equipped)

Ensure all critical fasteners are tightened

Grease the pump and motor bearings

Change the lubricant in the bearing house (if equipped)

Review pump performance gauge, flowmeter and transducer readings

Check the integrity of the electric motor using voltage or amp readings and insulation breakdown test

Review drive coupling wear

Inspect the condition of the operating setpoints of the VFD’s (if equipped)

Verify system meets operating setpoints and stops, and can keep required setpoint

Test and check dry run protection (if equipped); stop function; limits function operation — both low and

high limits and make sure each pump has individually been re-primed

Inspect the diaphragm tank conditions and pressure settings (if equipped)

Test/verify that the pumps alternate and that each pump does not have an excessive run time

Inspect the conditions of the electrical panel, overload settings, alarm history, etc.*

Perform vibration analysis on the pump and motor to evaluate bearing wear if unusual noise is detected

Identify any anomalies on the suction pressure conditions

Align pump (if necessary)

* If in a live panel technician must have NFPA70E certification and use all required PPE for the task.

Live panel work should never be done alone.

You might also like

- SAT - Centrifugal Pump For TDUDocument4 pagesSAT - Centrifugal Pump For TDUNIKHIL JOHRI100% (4)

- Method Statement of Sump PumpDocument3 pagesMethod Statement of Sump Pumpjames jatt Bond100% (2)

- Testing & Commissioning of Chilled Water PumpsDocument3 pagesTesting & Commissioning of Chilled Water Pumpsamg00733% (3)

- Methodology of Testing & Commissioning SystemsDocument38 pagesMethodology of Testing & Commissioning SystemsDung Nguyen50% (2)

- Test Procedure:: Functional Testing Guidance Pump PerformanceDocument10 pagesTest Procedure:: Functional Testing Guidance Pump PerformanceSagar Naduvinamani100% (1)

- Testing & Commissioning Method Statement For Fire Fighting PumpsDocument2 pagesTesting & Commissioning Method Statement For Fire Fighting PumpsHumaid Shaikh100% (1)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhNo ratings yet

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocument3 pagesTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- P8217 Checklist Fire Pump PDFDocument7 pagesP8217 Checklist Fire Pump PDFQuynh NguyenNo ratings yet

- ITP For Centrifugal Pump4Document1 pageITP For Centrifugal Pump4Adades Safede EfdNo ratings yet

- Pump Performance Test Procedure Sheet 2Document2 pagesPump Performance Test Procedure Sheet 2renjithv_4No ratings yet

- Pump inspection and testing proceduresDocument4 pagesPump inspection and testing proceduresAmal KaNo ratings yet

- General Overhaul - DEGDocument5 pagesGeneral Overhaul - DEGMuhammad RosihanNo ratings yet

- Maintain Elevators and Electrical Systems SafelyDocument3 pagesMaintain Elevators and Electrical Systems SafelydjukalNo ratings yet

- Factory Performance Testing of Vertical Turbine PumpsDocument3 pagesFactory Performance Testing of Vertical Turbine PumpsSrećko BlaževićNo ratings yet

- Boiler Feed Water PumpDocument28 pagesBoiler Feed Water Pumpfelix asadeNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Schedule Large Vertical TurbineDocument1 pageSchedule Large Vertical TurbineGodwin ChagotaNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Technical Supplement: With Tier 3 Engine With Rear SteerDocument71 pagesTechnical Supplement: With Tier 3 Engine With Rear SteerAngel Alberto Franco KukNo ratings yet

- Centrifugal pump maintenance scheduleDocument3 pagesCentrifugal pump maintenance schedulemhnmndrkNo ratings yet

- Oil Filled Transformers Standard Testing ProcedureDocument17 pagesOil Filled Transformers Standard Testing ProcedureNajeeb AbbasiNo ratings yet

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- 8 Alvarez - Submersible Pump Maintenance and RepairDocument29 pages8 Alvarez - Submersible Pump Maintenance and RepairIqa SuhailiNo ratings yet

- Fire Water Pump ChecklistDocument4 pagesFire Water Pump Checklistmuki10No ratings yet

- Injection Molding MaintainanceDocument28 pagesInjection Molding MaintainanceShubham Chaudhary0% (1)

- Fire Pump Testing E211 0Document9 pagesFire Pump Testing E211 0mfhaleem@pgesco.comNo ratings yet

- Preventive Maintenance Introduction: For Centrifugal Pump SystemsDocument13 pagesPreventive Maintenance Introduction: For Centrifugal Pump SystemsZaenal AripinNo ratings yet

- SpringchecklistDocument1 pageSpringchecklistmcjuddyNo ratings yet

- Blending Units MaintenanceDocument18 pagesBlending Units MaintenanceGeorgina SuleNo ratings yet

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- Appendix F Sample Graving Dock Maintenance Tasks: Pumpwell Biennial PMDocument4 pagesAppendix F Sample Graving Dock Maintenance Tasks: Pumpwell Biennial PMwaleedyehiaNo ratings yet

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssNo ratings yet

- Weekly Fire Pump InspectionDocument6 pagesWeekly Fire Pump InspectionShabaaz Mohammed AbdulNo ratings yet

- Major Works To Be DoneDocument6 pagesMajor Works To Be DoneAustin UdofiaNo ratings yet

- 1009 HotWaterSystemPumpTestDocument9 pages1009 HotWaterSystemPumpTestnt_long76No ratings yet

- Commission Fire Pump SystemsDocument3 pagesCommission Fire Pump Systemsizhar100% (2)

- Milton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceDocument2 pagesMilton Cat Preventive Maintenance PM 1 and PM 2 Marketing PieceEdwin AlexNo ratings yet

- Hydro PlantDocument11 pagesHydro PlantSagar PatilNo ratings yet

- FM Fire Pump Inspection Checklist and FormDocument4 pagesFM Fire Pump Inspection Checklist and Formkrunalb@inNo ratings yet

- Plugin DTC Fault Codes PDFDocument106 pagesPlugin DTC Fault Codes PDFRafael HubnerNo ratings yet

- Generators Expected ServicesDocument3 pagesGenerators Expected Servicesmoaz zahidNo ratings yet

- Technical Seminar Agenda and Generator System OverviewDocument86 pagesTechnical Seminar Agenda and Generator System OverviewKenneth100% (1)

- Fire Pump PropertiesDocument62 pagesFire Pump Propertiesyamaha100% (2)

- Testing & Commissioning Method Statement For Fire Fighting PumpsDocument4 pagesTesting & Commissioning Method Statement For Fire Fighting Pumpsvin ssNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- D.P. Test For All PartsDocument1 pageD.P. Test For All PartsS DasNo ratings yet

- E&M Health CheckupDocument3 pagesE&M Health CheckupAlliedNo ratings yet

- Maintenance of Plastics Processing & Testing Machinery Unit 1Document41 pagesMaintenance of Plastics Processing & Testing Machinery Unit 1Mohsin Alam100% (5)

- Skt-Maintenance of Electro-Mechanicl Equipment of SHPDocument51 pagesSkt-Maintenance of Electro-Mechanicl Equipment of SHPsktyagi_iitr6102No ratings yet

- Pump Performance Test Procedure Sheet 3Document4 pagesPump Performance Test Procedure Sheet 3renjithv_4No ratings yet

- Boatsmart Pre Season Maint ChecklistDocument1 pageBoatsmart Pre Season Maint ChecklistZdravko PodolskiNo ratings yet

- Centrifugal PumpsDocument4 pagesCentrifugal PumpsTengku Mohd ImranNo ratings yet

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationDark CenobiteNo ratings yet

- Centrifugal Pump Commissioning ReportDocument3 pagesCentrifugal Pump Commissioning ReportOctavio PerezNo ratings yet

- Fire Pumps SopDocument7 pagesFire Pumps SopPankaj PandeyNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Pump Start Up ChecklistDocument14 pagesPump Start Up ChecklistSharif Mohammad AdwanNo ratings yet

- Packings Brochure 2018Document19 pagesPackings Brochure 2018Sharif Mohammad AdwanNo ratings yet

- Packings Brochure 2018Document19 pagesPackings Brochure 2018Sharif Mohammad AdwanNo ratings yet

- Packings Brochure 2018Document19 pagesPackings Brochure 2018Sharif Mohammad AdwanNo ratings yet

- CR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsDocument18 pagesCR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsXuan Man NguyenNo ratings yet

- English (GB) Installation and Operating Instructions, Correction SheetDocument1 pageEnglish (GB) Installation and Operating Instructions, Correction SheetSharif Mohammad AdwanNo ratings yet

- 62 85 Booster Startup ChecklistDocument2 pages62 85 Booster Startup ChecklistIsabel CarolinaNo ratings yet

- English (GB) Installation and Operating Instructions, Correction SheetDocument1 pageEnglish (GB) Installation and Operating Instructions, Correction SheetSharif Mohammad AdwanNo ratings yet

- CR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsDocument18 pagesCR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsXuan Man NguyenNo ratings yet

- 62 85 Booster Startup ChecklistDocument2 pages62 85 Booster Startup ChecklistIsabel CarolinaNo ratings yet

- CR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsDocument18 pagesCR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsXuan Man NguyenNo ratings yet

- CR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsDocument18 pagesCR, Cri, CRN, CRT ATEX-approved Pumps: Installation and Operating InstructionsXuan Man NguyenNo ratings yet

- Synchronous Generator 7Document5 pagesSynchronous Generator 7Sharif Mohammad AdwanNo ratings yet

- English (GB) Installation and Operating Instructions, Correction SheetDocument1 pageEnglish (GB) Installation and Operating Instructions, Correction SheetSharif Mohammad AdwanNo ratings yet

- English (GB) Installation and Operating Instructions, Correction SheetDocument1 pageEnglish (GB) Installation and Operating Instructions, Correction SheetSharif Mohammad AdwanNo ratings yet

- RelationsDocument9 pagesRelationsSharif Mohammad AdwanNo ratings yet

- Electric GeneratorDocument8 pagesElectric GeneratorSharif Mohammad AdwanNo ratings yet

- List of Projects 091109Document2 pagesList of Projects 091109Sharif Mohammad AdwanNo ratings yet

- Control Valves: Dr. Ashraf SaleemDocument24 pagesControl Valves: Dr. Ashraf SaleemSharif Mohammad AdwanNo ratings yet