Professional Documents

Culture Documents

Clapet SCG

Clapet SCG

Uploaded by

ioan cristian cotorobaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clapet SCG

Clapet SCG

Uploaded by

ioan cristian cotorobaiCopyright:

Available Formats

Swing Check Valve - Grooved

SCG

Check Valves

Technical Features

• Sizes available (Nominal): 2”/DN50, 2-1/2”/DN65,

3”/DN80, 4”/DN100, 6”/DN150, 8”/DN200, 10”/DN250

& 12”/DN300

• Pressure data:

Working Pressure: 21 bar (300 psi).

• Working Temperature: 0°C to 80°C

• Seat: Bronze

• Clapper: EPDM coated ductile iron

• Finish: Fusion bonded epoxy coated internal and

external or painting according to request.

• Connections: Grooved joint dimensions are made

in accordance with metric or AWWA C806.

Note: Check valves may be damaged by excessively turbulent water

flow. Model SCG check valves should be installed a reasonable distance

from pumps, elbows, expanders, reducers, or similar devices. Typical

piping practices suggest a minimum distance of five times the pipe

diameter for general use.

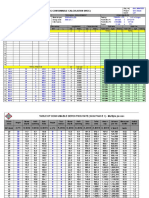

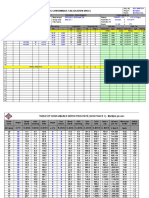

Swing Check Valve - Grooved - SCG Physical Data

Nominal pipe size Dimensions (mm) Weight

Part number

Updates datasheet of 17-10-2017 (added note at end of Technical Features and removed footnot from Physical Data table)

Metric inch L D1 D2 b c (kg)

SCG-0200 DN50 2” 172 57.2 60.3 7.9 3.3

SCG-0250-073 69.1 73.0

DN65 2-1/2” 184 7.9 3.6

SCG-0250-076 72.3 76.1

SCG-0300 DN80 3” 197 84.9 88.9 7.9 15.9 4.6

SCG-0400 DN100 4” 206 110.1 114.3 9.5 7.44

SCG-0600-165 160.9 165.1

DN150 6” 325 9.5 16.2

SCG-0600-168 164.0 168.3

SCG-0800 DN200 8” 372 214.4 219.1 11.1 26.9

SCG-1000 DN250 10” 457 268.3 273 19.1 51.9

12.7

SCG-1200 DN300 12” 535 318.3 323.9 75.6

Swing Check Valve - Grooved - SCG Materials List

Item Part Name Material ASTM Specification

1 Valve body Ductile iron ASTM A 536 Gr. 65-45-12

2 Hinge pin Stainless steel AISI 420

3 Spring Stainless steel AISI 304

4 Spring washer Stainless steel AISI 304

DN50-DN100 Stainless steel AISI 304

5 Disc

DN150-DN300 Ductile iron ASTM A 536 Gr. 65-45-12

6 Disc sealing ring EPDM Commercial

7 Seat ring Bronze ASTM B62 C83600

8 Plug Malleable iron - Galvanised

9 Bushing Bronze ASTM B62 C83600

30-10-2017

www.viking-emea.com

FireKing™ is a trademark of The Viking Corporation. Specifications subject to change without notice.. Pressure ratings require the use of couplings with equivalent pressure ratings. Rigid couplings are recommended for all valve end connections.

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Surs PDFDocument27 pagesSurs PDFsaeed65No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- AN6204Document4 pagesAN6204CTN2010No ratings yet

- Specification Chart For Conventional Duo-Cone Seal Groups (0599, 7561)Document8 pagesSpecification Chart For Conventional Duo-Cone Seal Groups (0599, 7561)Andrey GyrychNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Oilfield UnionsDocument5 pagesOilfield Unionslalberto96No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Octane Boosters - Which Is BestDocument3 pagesOctane Boosters - Which Is Besttaufany99No ratings yet

- Case Study CreepDocument9 pagesCase Study CreepKevinSatriaNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Feasibility Study and Detailed Design of Budhi Gandaki HPPDocument49 pagesFeasibility Study and Detailed Design of Budhi Gandaki HPPstormxeronNo ratings yet

- Parallel Pump OperationDocument5 pagesParallel Pump Operationarunima04100% (1)

- Lift & EscalatorsDocument19 pagesLift & EscalatorsINCREDIBLEInteriors& FURNITURES DECOR100% (1)

- Extras de Cont / Account: 2. Valuta / Currency 3. Data Extras / Statement DateDocument1 pageExtras de Cont / Account: 2. Valuta / Currency 3. Data Extras / Statement DateIrina Luciana DumitriuNo ratings yet

- OSS Managed Services - A New Business Model For Service ProvidersDocument12 pagesOSS Managed Services - A New Business Model For Service ProviderstranceforgeNo ratings yet

- Swing Check Valve - Grooved: Technical FeaturesDocument1 pageSwing Check Valve - Grooved: Technical Featuresprvns0074377No ratings yet

- FIREKING Valves & Accessories (Jun 2022) V1.4Document2 pagesFIREKING Valves & Accessories (Jun 2022) V1.4Ahlan kpNo ratings yet

- BCV Fireking VikingsDocument2 pagesBCV Fireking VikingsPepeng GantengNo ratings yet

- Sanitary FittingsDocument113 pagesSanitary FittingsAmeer AliNo ratings yet

- Cim 3739 Series en - Rev 0Document20 pagesCim 3739 Series en - Rev 0BellatchaNo ratings yet

- Grinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataDocument4 pagesGrinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataСергей КолесниковNo ratings yet

- Butterfly-Valve Grooved Type-163-C-En-Ds-Fig 216Document3 pagesButterfly-Valve Grooved Type-163-C-En-Ds-Fig 216NOMANNo ratings yet

- 612 D Fig702 Flanged y Type Strainer UlDocument2 pages612 D Fig702 Flanged y Type Strainer UlkskadryNo ratings yet

- VP e 011 06 0004 - Catalog PDFDocument6 pagesVP e 011 06 0004 - Catalog PDFRajesh KannaNo ratings yet

- Gunnebo Master Link MDocument1 pageGunnebo Master Link MKyi HanNo ratings yet

- WW C70 Product-PageDocument1 pageWW C70 Product-PageElvis RosarioNo ratings yet

- 5900 FlexBalance Plus Series Separators Submittal 401-082 102319Document1 page5900 FlexBalance Plus Series Separators Submittal 401-082 102319Rafael SalazarNo ratings yet

- Data Sheet: Valid From: 5/19/20Document1 pageData Sheet: Valid From: 5/19/20Angel Francisco NavarroNo ratings yet

- Parts Service Operation: Introduction of Kit of O-Ring Which Komatsu Logo & Parts Number Is Printed For Hose ExchangeDocument2 pagesParts Service Operation: Introduction of Kit of O-Ring Which Komatsu Logo & Parts Number Is Printed For Hose ExchangeNaughty VongNo ratings yet

- Teslin TableDocument1 pageTeslin TableEzequiel FernandezNo ratings yet

- Neway Check ValvesDocument3 pagesNeway Check ValvesismaeljcoorpNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Shock Absorber Specification CardDocument1 pageShock Absorber Specification Cardanna mannaNo ratings yet

- Liquidtight Strain Relief Cord and Cable Connectors: StraightDocument3 pagesLiquidtight Strain Relief Cord and Cable Connectors: Straighttajamul husainNo ratings yet

- Check of Camshaft Coupling: Service Letter SL2012-567/AABDocument5 pagesCheck of Camshaft Coupling: Service Letter SL2012-567/AABAKINMOLADUN OMOLADENo ratings yet

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Document14 pagesWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimNo ratings yet

- 24 DP Spur Gear: Quality Transmission ComponentsDocument8 pages24 DP Spur Gear: Quality Transmission ComponentsDidik HariantoNo ratings yet

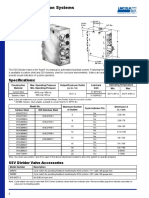

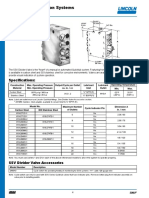

- Divider Valves: Quicklub Lubrication SystemsDocument4 pagesDivider Valves: Quicklub Lubrication SystemsBehi BshNo ratings yet

- SITESTAR Partes PDFDocument140 pagesSITESTAR Partes PDFNicolas Leon LunaNo ratings yet

- Q9 006 E - Knife Gate Valves DN 50-400 PDFDocument7 pagesQ9 006 E - Knife Gate Valves DN 50-400 PDFJORGE HUARAYA LABRANo ratings yet

- ANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesDocument2 pagesANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesEdisonCorderoNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Gate Valves: Pressure Control Sandbuster Slab Gate ValveDocument2 pagesGate Valves: Pressure Control Sandbuster Slab Gate ValveNico PanNo ratings yet

- Gemue 655 GBDocument4 pagesGemue 655 GBLucio J. Rojas R.No ratings yet

- FlowBiz 3 Piece Design Metal Seated Ball Valve 150Document2 pagesFlowBiz 3 Piece Design Metal Seated Ball Valve 150Shakir AnsariNo ratings yet

- Avk Universal Under-Pressure Tee 257/31: With DN80 - 300 Flanged Branch 001Document3 pagesAvk Universal Under-Pressure Tee 257/31: With DN80 - 300 Flanged Branch 001Arshad IqbalNo ratings yet

- Wärtsilä Hamworthy Centrifugal Pumps Model C2G: Sectional DrawingDocument2 pagesWärtsilä Hamworthy Centrifugal Pumps Model C2G: Sectional DrawingLakshmi KishoreNo ratings yet

- DHARMAJI TEXTILES - Sheet1Document2 pagesDHARMAJI TEXTILES - Sheet1Vrushank ShahNo ratings yet

- Quicklub Lubrication Systems: SSV Divider ValvesDocument4 pagesQuicklub Lubrication Systems: SSV Divider ValvesVelina MilevaNo ratings yet

- Access SightGlasses SLW OLGDocument1 pageAccess SightGlasses SLW OLGCamilo Taborda SalazarNo ratings yet

- Specification Sheet ANSI B16.5 RTJ Weld Neck - Class 1500 or 2500 Precision Tube Series ModelDocument1 pageSpecification Sheet ANSI B16.5 RTJ Weld Neck - Class 1500 or 2500 Precision Tube Series ModelDhong888No ratings yet

- Stag en MainDocument8 pagesStag en MainFederico AlarconNo ratings yet

- Cateye Enduro 2 (Bike Computer)Document4 pagesCateye Enduro 2 (Bike Computer)Eddy WadeNo ratings yet

- Swing Check Valve Series 712: 1.0 Product DescriptionDocument5 pagesSwing Check Valve Series 712: 1.0 Product DescriptionKrausserRudolfNo ratings yet

- 88 - 02 Exhaust Manifold Gasket Service BulletinDocument3 pages88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerNo ratings yet

- Acoples Lovejoy CS-LS (Jaw)Document1 pageAcoples Lovejoy CS-LS (Jaw)marcelo castilloNo ratings yet

- XXAAXXDocument8 pagesXXAAXXMuhammad Emirzan FirdausNo ratings yet

- QueryDocument2 pagesQueryTu PhamNo ratings yet

- 10-24 A.K. INSERT (Spaenaur)Document1 page10-24 A.K. INSERT (Spaenaur)Jennifer FrenchNo ratings yet

- NM1 Product ManualDocument11 pagesNM1 Product ManualJorge Antonio Cossio RamirezNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Metallic Sealing - Short Face-To-Face Length - Stainless Steel - With HandwheelDocument3 pagesMetallic Sealing - Short Face-To-Face Length - Stainless Steel - With HandwheelJawad ChamsouNo ratings yet

- The Alumiguard Sheet Piling Is Used ForDocument2 pagesThe Alumiguard Sheet Piling Is Used ForVitor José RodriguesNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01cmpuckNo ratings yet

- R/F - 600Lb Rating Medium Duty 'Y'-Type Strainer: Sizes: " To 12" Nominal Bore Pressure: FeaturesDocument1 pageR/F - 600Lb Rating Medium Duty 'Y'-Type Strainer: Sizes: " To 12" Nominal Bore Pressure: FeaturesNagLakshmananNo ratings yet

- Pipe Couplings and Fittings: End CapsDocument4 pagesPipe Couplings and Fittings: End Capsioan cristian cotorobaiNo ratings yet

- GEPRO - Fire Protection ProductsDocument5 pagesGEPRO - Fire Protection Productsioan cristian cotorobaiNo ratings yet

- Katalog International en Jan2020 200319Document184 pagesKatalog International en Jan2020 200319ioan cristian cotorobaiNo ratings yet

- Complete Fire Protection Systems From A Single Source: Safe For CertainDocument36 pagesComplete Fire Protection Systems From A Single Source: Safe For Certainioan cristian cotorobaiNo ratings yet

- DATA SHEET FireDos FD8000 StationaryDocument4 pagesDATA SHEET FireDos FD8000 Stationaryioan cristian cotorobaiNo ratings yet

- Danfoss HPWM HydrantDocument1 pageDanfoss HPWM Hydrantioan cristian cotorobaiNo ratings yet

- Swing Check Valve - Grooved: Technical FeaturesDocument1 pageSwing Check Valve - Grooved: Technical Featuresioan cristian cotorobaiNo ratings yet

- TYCO FS&BP Metal Framing CatalogueDocument293 pagesTYCO FS&BP Metal Framing Catalogueioan cristian cotorobaiNo ratings yet

- Changes Catalogue 2020Document14 pagesChanges Catalogue 2020ioan cristian cotorobaiNo ratings yet

- Fire Sprinkler Application Chart: Standard CoverageDocument1 pageFire Sprinkler Application Chart: Standard Coverageioan cristian cotorobaiNo ratings yet

- WFDEN Series Waterfl Ow DetectorDocument4 pagesWFDEN Series Waterfl Ow Detectorioan cristian cotorobaiNo ratings yet

- QRG Ghid Aleger - RoDocument16 pagesQRG Ghid Aleger - Roioan cristian cotorobaiNo ratings yet

- G-FIRE EMEA Catalog 2013 FINALDocument100 pagesG-FIRE EMEA Catalog 2013 FINALioan cristian cotorobaiNo ratings yet

- Instructiuni de Montaj - RoDocument48 pagesInstructiuni de Montaj - Roioan cristian cotorobaiNo ratings yet

- Pipe Couplings and Fittings: Elbows 90°Document6 pagesPipe Couplings and Fittings: Elbows 90°ioan cristian cotorobaiNo ratings yet

- Grinnell Emea Catalog 2013Document284 pagesGrinnell Emea Catalog 2013ioan cristian cotorobaiNo ratings yet

- Cuplaje Rigide - RoDocument2 pagesCuplaje Rigide - Roioan cristian cotorobaiNo ratings yet

- Cuplaje Flexibile - RoDocument2 pagesCuplaje Flexibile - Roioan cristian cotorobaiNo ratings yet

- Cruci Si Reductii - RoDocument4 pagesCruci Si Reductii - Roioan cristian cotorobaiNo ratings yet

- KSB - Etanorm FXV - TSB Pompe KSBDocument44 pagesKSB - Etanorm FXV - TSB Pompe KSBioan cristian cotorobai100% (1)

- Cuplaje Reduse - RoDocument2 pagesCuplaje Reduse - Roioan cristian cotorobaiNo ratings yet

- ISO 45001 and The Evolution of OHSMSDocument7 pagesISO 45001 and The Evolution of OHSMSAndrei SavuNo ratings yet

- Reactive Power and Voltage RegulationDocument19 pagesReactive Power and Voltage RegulationDiaz AnggaNo ratings yet

- Robot C2 - Using Pseudo Code and Flowcharts For RobotC Programming For LEGODocument6 pagesRobot C2 - Using Pseudo Code and Flowcharts For RobotC Programming For LEGODominicNo ratings yet

- CG TestDocument2 pagesCG TestSanket PujariNo ratings yet

- 2N5484Document8 pages2N5484camilo sanchezNo ratings yet

- Ultrasonic Pulse Velocity in Concrete Using Direct and Indirect TDocument8 pagesUltrasonic Pulse Velocity in Concrete Using Direct and Indirect TBaehakiNo ratings yet

- Digital MOC: Files Included in dMOCDocument5 pagesDigital MOC: Files Included in dMOCSAGALOGNo ratings yet

- Serpiente - Juego CMDDocument8 pagesSerpiente - Juego CMDDavid Fabian AraujoNo ratings yet

- Internship Report of PELDocument53 pagesInternship Report of PELRehan Aqeel100% (3)

- Learning Activity SheetDocument4 pagesLearning Activity SheetUnard Jv CasimeroNo ratings yet

- 795H GTT OptiCom Emitter Installation ManualDocument25 pages795H GTT OptiCom Emitter Installation ManualFrank Docimo Jr.No ratings yet

- Silicon Avalanche Photodiodes On The Base of Metal Resistor Semiconductor Structures PDFDocument7 pagesSilicon Avalanche Photodiodes On The Base of Metal Resistor Semiconductor Structures PDFlaboratorNo ratings yet

- Advanced Digital Design: HW Datapath ComponentsDocument20 pagesAdvanced Digital Design: HW Datapath ComponentsAli AhmadNo ratings yet

- Catalogue Thiet Bi Dien Dong ADocument20 pagesCatalogue Thiet Bi Dien Dong Aprimmt13No ratings yet

- Bayloc Style Dry Disconnect - 2016Document8 pagesBayloc Style Dry Disconnect - 2016Eduardo Luna MaggiNo ratings yet

- Evolution of The TelevisionDocument10 pagesEvolution of The TelevisionMikin KaushikNo ratings yet

- Yaskawa 1000Document269 pagesYaskawa 1000mahh1234No ratings yet

- SME Development in Sri Lanka 2003Document18 pagesSME Development in Sri Lanka 2003mahinda_desilva9157No ratings yet

- (Fiberglass Insulation) Glasswool: Contact UsDocument5 pages(Fiberglass Insulation) Glasswool: Contact Usjacok22No ratings yet

- Auto Ship ManualDocument172 pagesAuto Ship ManualAngelNo ratings yet

- Eaton WhitePaper Distributed Vs Centralized BypassDocument9 pagesEaton WhitePaper Distributed Vs Centralized BypassParveshi PusunNo ratings yet

- The World Today Is Quite Different Than It Was 20 Years BackDocument5 pagesThe World Today Is Quite Different Than It Was 20 Years BackAnonymous OP6R1ZSNo ratings yet