Professional Documents

Culture Documents

User Guide Recommended Torque: HDG Anti Vibration

Uploaded by

Erick KhosasiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User Guide Recommended Torque: HDG Anti Vibration

Uploaded by

Erick KhosasiCopyright:

Available Formats

USER GUIDE REC OMMENDED T ORQ UE

Fasteners

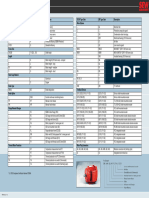

HDG ANTI VIBRATION Type Description Finish

Spanner Recommended Maximum

Comment

size (mm) torque (Nm) torque (Nm)

ØS HDG Anti

M6 Flange Nuts S-M NU-FL-M6 A4 10 8 10 A4 is used for M6

Vibration flange nuts M10 Flange Nuts S-M NU-FL-M10 HDG 15 55 55

M12 Flange Nuts S-M NU-FL-M12 HDG 18 95 95

SS ANTI VIBRATION Type Description Finish

Spanner Recommended Maximum

Comment

size (mm) torque (Nm) torque (Nm)

ØS SS (A4) Anti M6 Flange Nuts S-M NU-FL-M6 A4 10 8 10

Vibration flange nuts M8 Flange Nuts S-M NU-FL-M8 A4 13 20 23

M10 Flange Nuts S-M NU-FL-M10 A4 15 40 45

M12 Flange Nuts S-M NU-FL-M12 A4 18 80 85

STANDARD Spanner Recommended Maximum

Type Description Finish Comment

size (mm) torque (Nm) torque (Nm)

DIN 934 Standard nuts

M6 S-M NU-M6 A4/HDG 10 6-7 7

ØS UNO Channel nuts M8 S-M NU-M8 A4/HDG 13 15-17 17

M10 S-M NU-M10 A4/HDG 17 30-33 33

M12 S-M NU-M12 A4/HDG 19 60-62 62

WITH NYLON INSULATION Type Description Material

Spanner Recommended Maximum

Comment

size (mm) torque (Nm) torque (Nm)

Nylon insulation for M6 Insulation sleeve and washers Nylon - 6 7 Recommended torque

galvanic barrier solutions M8 Insulation sleeve and washers Nylon - 15 17 for Nylon types in direct

M10 Insulation sleeve and washers Nylon - 30 33 contact with A4 nut.

M12 Insulation sleeve and washers Nylon - 60 62 See ØI-RD-PB-EN-0113

NOTES FOR USE

Grade Anti Vibration

The data shown is for Øglænd System bolt & nut fasteners only in A4-70 and Class 8.8 Øglænd System anti-vibration flange nuts prevent loosening from vibration when the clamping force is retained.

for SS/HDG respectively with corresponding material fastener parts where not specified. Inspection and maintenance programs must be considered where other sources of loosening may be present,

particularly when clamping non-metallic elements.

Application & conditions

Our recommendation is based only on fastening Øglænd System products in correspon- Fastening non-metallic materials

ding material, without additional washers or additional lubricants. When fastening non-metallic materials such as composites or polymers with steel bolts, the hardness of the material

being fastened may limit the pre-tension which can be achieved by tightening the bolt. Material creep and relaxation

Pre-tension over time may also reduce the pre-tension further.

Bolted connections rely on the pre-tension or ”stretch” of the bolt to maintain the

clamping force between the parts when tightened. There are several factors which can Depending on the material specification, it may be necessary to reduce the tightening torque from that shown

reduce this pre-tension including but not limited to; embeddment, thermal expansion in the table above to prevent damage to the base material. An additional level of protection to prevent loosening

and contraction, shock and vibration. must also therefore be considered depending on the application together with consideration of a maintenance and

inspection program.

Ø I - R D- UG - E N- 0160 R e v. 3

You might also like

- Torrent: Frame Assembly & Service Parts ReferenceDocument3 pagesTorrent: Frame Assembly & Service Parts ReferencebenssjNo ratings yet

- Plastic Rivets and ScrewsDocument23 pagesPlastic Rivets and ScrewsMV Research & Development TRSNo ratings yet

- Data Expansion Joint (Bellows)Document3 pagesData Expansion Joint (Bellows)Sreesanth SaruvilNo ratings yet

- TR Fastenings How ToDocument20 pagesTR Fastenings How ToSantosh KatkarNo ratings yet

- Dilatoflex KP High PressureDocument1 pageDilatoflex KP High PressureJo KingsNo ratings yet

- 4bornier Sur Rail 120MM Abb (Item 14)Document2 pages4bornier Sur Rail 120MM Abb (Item 14)sarl matilec lightingNo ratings yet

- 81 1 Catalogo Cilindri ENGDocument14 pages81 1 Catalogo Cilindri ENGsundyaNo ratings yet

- BICYCLEDocument31 pagesBICYCLEAlejo Mateo SfercoNo ratings yet

- Series 450 - JOUCOMATIC Tie Rod Cylinders Type PESDocument2 pagesSeries 450 - JOUCOMATIC Tie Rod Cylinders Type PESIrham Lazuardi100% (1)

- Split Plummer Block Housings, SNL and SE Series For Bearings On An Adapter Sleeve, With Standard Seals - SNL 517 + 1217 K + H 217Document3 pagesSplit Plummer Block Housings, SNL and SE Series For Bearings On An Adapter Sleeve, With Standard Seals - SNL 517 + 1217 K + H 217Sadok KzadriNo ratings yet

- Id 075 - 09 04 2008Document2 pagesId 075 - 09 04 2008bouzahri boumedieneNo ratings yet

- Bellows Suction Cup (Round) With Optimal Adaptation To Uneven SurfacesDocument3 pagesBellows Suction Cup (Round) With Optimal Adaptation To Uneven Surfacesnguyen HungNo ratings yet

- DEORE SIDE SWING Front Derailleur: (3x10-Speed)Document1 pageDEORE SIDE SWING Front Derailleur: (3x10-Speed)Marcos ZanelliNo ratings yet

- CounterboreDocument3 pagesCounterborejonNo ratings yet

- FD-M611 FD-M611: DEORE Front Derailleur For TripleDocument1 pageFD-M611 FD-M611: DEORE Front Derailleur For TriplePepe GarciaNo ratings yet

- Insensitive Propulsion Systems For Large Caliber Ammunition: Beat Vogelsanger, Alexander Huber, and Heinz JaskolkaDocument21 pagesInsensitive Propulsion Systems For Large Caliber Ammunition: Beat Vogelsanger, Alexander Huber, and Heinz JaskolkaTenshiJibrilNo ratings yet

- Counterbores & CountersinksDocument6 pagesCounterbores & Countersinkscaeiro60No ratings yet

- Quick Reference Parts CatalogueDocument17 pagesQuick Reference Parts CataloguePatrice GuilhaumonNo ratings yet

- Datasheet 2600-ODocument2 pagesDatasheet 2600-Opavel10082020No ratings yet

- Datasheet 2600 CDocument2 pagesDatasheet 2600 Chendra prayogaNo ratings yet

- En SNR SNC206Document4 pagesEn SNR SNC206Jessica Issa JuliaNo ratings yet

- 16 MMDocument1 page16 MMThomas RisingNo ratings yet

- Atlas Copco - Hydraulic Nut SplitterDocument3 pagesAtlas Copco - Hydraulic Nut Splitterlildevil277No ratings yet

- 175 CacDocument5 pages175 CacshjefkeNo ratings yet

- XTR Front Derailleur (3x11-Speed)Document1 pageXTR Front Derailleur (3x11-Speed)Marcos ZanelliNo ratings yet

- TAS - 3071 Shrink DiscDocument3 pagesTAS - 3071 Shrink DiscCarlyleNo ratings yet

- 2016-09 MSZ Alu Prospekt en PDFDocument12 pages2016-09 MSZ Alu Prospekt en PDFRasid AsepNo ratings yet

- CDocument1 pageCocnogueiraNo ratings yet

- NZ17DH5N3KW03800 ZR00Document3 pagesNZ17DH5N3KW03800 ZR00DanielEscobarMontecinosNo ratings yet

- M81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationDocument1 pageM81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationFlavio Abreu100% (1)

- How To Cut Metal EffectivelyDocument2 pagesHow To Cut Metal EffectivelyManuel PQNo ratings yet

- lc1230 How To View PDFDocument2 pageslc1230 How To View PDFManuel PQNo ratings yet

- Castable - Tancbor 2Document1 pageCastable - Tancbor 2chenghongwei2008No ratings yet

- HiltiDocument5 pagesHilticipsiccNo ratings yet

- RHINO Insert PDFDocument168 pagesRHINO Insert PDFtran namNo ratings yet

- Metric Socket Head Cap Screws1 PDFDocument2 pagesMetric Socket Head Cap Screws1 PDFRavi BabaladiNo ratings yet

- Allen Parker Metric BoltsDocument2 pagesAllen Parker Metric BoltssebastianNo ratings yet

- Metric Socket Head Cap Screws: DimensionsDocument2 pagesMetric Socket Head Cap Screws: DimensionsCarlos Bracho100% (1)

- Nut TapDocument2 pagesNut TapjonNo ratings yet

- Saxm 40 Ed 85 G1 4 Ig 10 01 19 00019Document3 pagesSaxm 40 Ed 85 G1 4 Ig 10 01 19 00019Dong HungNo ratings yet

- Esp 141028Document2 pagesEsp 141028Mai Thế ToanNo ratings yet

- CouplingDocument1 pageCouplingdavih007No ratings yet

- Hilti Pipe Rings: System ML Channel InstallationDocument26 pagesHilti Pipe Rings: System ML Channel InstallationEssam Nabih YacoubNo ratings yet

- Metal Plug TorqueDocument2 pagesMetal Plug TorqueArun JaisonNo ratings yet

- Extension Pipe: Overall Length (MM) AØ MM BØ MMDocument1 pageExtension Pipe: Overall Length (MM) AØ MM BØ MMyagefi3262No ratings yet

- Pramet 2016.2 - en PDFDocument26 pagesPramet 2016.2 - en PDFManish MoghaNo ratings yet

- Toolin'Fix: Sertisseurs OléopneumatiquesDocument1 pageToolin'Fix: Sertisseurs OléopneumatiquesYigit YedidağNo ratings yet

- Food Sms1145 Pathel-Europe En-De PDFDocument4 pagesFood Sms1145 Pathel-Europe En-De PDFkrisNo ratings yet

- Bellows Suction Cup NBR (Round) : SAB 30 NBR-60 G1/4-IGDocument2 pagesBellows Suction Cup NBR (Round) : SAB 30 NBR-60 G1/4-IGAndor TorokNo ratings yet

- 13.-En NT Bolts UtilcellDocument3 pages13.-En NT Bolts Utilcellnu.arabiaNo ratings yet

- BC-LP-001 2021-22Document2 pagesBC-LP-001 2021-22Ravikant YadavNo ratings yet

- Y-Bearing Plummer Block Units - SYJ 20 KFHDocument2 pagesY-Bearing Plummer Block Units - SYJ 20 KFHVisitOn.T.witte.rNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- Wear Sleeves, SKF Speedi-Sleeve: DimensionsDocument2 pagesWear Sleeves, SKF Speedi-Sleeve: DimensionsP S VenkateshNo ratings yet

- Din 9427 - Metric Socket Button Head Cap ScrewsDocument1 pageDin 9427 - Metric Socket Button Head Cap ScrewsAlexis BarolinNo ratings yet

- 1SNC160001C0207-CH-G Distribution TerminalsDocument11 pages1SNC160001C0207-CH-G Distribution TerminalsHUGO ANDRÉS CRUZ GONZÁLEZNo ratings yet

- DR Nomenclature Poster 9TRP0700Document1 pageDR Nomenclature Poster 9TRP0700hatem.ahmedNo ratings yet

- Datasheet - Uni RTB M2Document2 pagesDatasheet - Uni RTB M2Macedo S OliveiraNo ratings yet

- Datasheet uniRTBM2 1640174129Document2 pagesDatasheet uniRTBM2 1640174129Nguyễn Văn ĐộNo ratings yet

- Operating Manual and Spare Parts List: Pressure Accumulators On Hydraulic Hammers Design and MaintenanceDocument24 pagesOperating Manual and Spare Parts List: Pressure Accumulators On Hydraulic Hammers Design and MaintenanceJean MoralesNo ratings yet

- Academic Audit ReportDocument113 pagesAcademic Audit ReportAnonymous zwnFXURJNo ratings yet

- The Marine Survey ReportDocument27 pagesThe Marine Survey Reportsrjha100% (2)

- Yamaha MG06X/MG06 - Technical SpecificationsDocument2 pagesYamaha MG06X/MG06 - Technical SpecificationsrinconvegaNo ratings yet

- Safety Precautions and Safety Procedures For Maintenance of Circuit BreakersDocument10 pagesSafety Precautions and Safety Procedures For Maintenance of Circuit BreakersSayed NagyNo ratings yet

- Sierra MC Series 2014Document4 pagesSierra MC Series 2014MrJohnGaltshrugsNo ratings yet

- Desizing C LibreDocument17 pagesDesizing C Librekambledip1No ratings yet

- Pro Form - Plywood Formwork For Exposed Concrete AreaDocument2 pagesPro Form - Plywood Formwork For Exposed Concrete AreaĐức Anh NguyễnNo ratings yet

- LG N4B1 HDD Compatibility 20090623Document1 pageLG N4B1 HDD Compatibility 20090623pikkenNo ratings yet

- Load Test On Single Phase Induction Motor: EEE 308 Practical Experiment No. 2 Matric Number........................Document3 pagesLoad Test On Single Phase Induction Motor: EEE 308 Practical Experiment No. 2 Matric Number........................Oladeji Ifedayo RNo ratings yet

- CCNA 3 - Scaling NetworksDocument229 pagesCCNA 3 - Scaling NetworksalexNo ratings yet

- Physics Form 5: Electric Field & Charge FlowDocument32 pagesPhysics Form 5: Electric Field & Charge FlowMohdNizam Bin Musiran NizamNo ratings yet

- Fire Fighting Robot - Abstract-EDocument4 pagesFire Fighting Robot - Abstract-EMectrosoft Creative technologyNo ratings yet

- Digital CaliperDocument2 pagesDigital Caliperkesava rajNo ratings yet

- PROTEM Completo PDFDocument44 pagesPROTEM Completo PDFMarcelo AguileraNo ratings yet

- MDocument16 pagesMRathish RagooNo ratings yet

- Planner Work Management Planning User ManualDocument332 pagesPlanner Work Management Planning User ManualAndrés Rodríguez100% (2)

- Fundamental LC-MS Orbitrap Mass Analyzers PDFDocument30 pagesFundamental LC-MS Orbitrap Mass Analyzers PDFAlonso HurtadoNo ratings yet

- Experiment No. 14: Table 14.1 Truth Table of 1101Document27 pagesExperiment No. 14: Table 14.1 Truth Table of 1101NEAYZ AHMADNo ratings yet

- 3352 PDFDocument6 pages3352 PDFMSNo ratings yet

- Hydrogels in Sensing ApplicationsDocument42 pagesHydrogels in Sensing ApplicationsMasihullah J KhanNo ratings yet

- Ilco Brass Cylinder List Price Book 2014Document44 pagesIlco Brass Cylinder List Price Book 2014Security Lock DistributorsNo ratings yet

- Tensile Testing Standards and SpecificationsDocument3 pagesTensile Testing Standards and SpecificationsTestronix InstrumentsNo ratings yet

- SuperMongo PDFDocument245 pagesSuperMongo PDFgastromonoNo ratings yet

- 1 - System Administration For The Oracle Solaris 10 OS Part 1Document3 pages1 - System Administration For The Oracle Solaris 10 OS Part 1prakashpantpNo ratings yet

- Design of Shafts CouplingsDocument45 pagesDesign of Shafts CouplingsRavi Teja100% (3)

- Studio Apartment-List Revised)Document29 pagesStudio Apartment-List Revised)cubadesignstudNo ratings yet

- Gas Turbine Engine Construction: Intake and DuctsDocument49 pagesGas Turbine Engine Construction: Intake and DuctsIdrisNo ratings yet

- Gpcdoc Tds Darina R 2Document2 pagesGpcdoc Tds Darina R 2nutchai2538No ratings yet