Professional Documents

Culture Documents

Din 9427 - Metric Socket Button Head Cap Screws

Uploaded by

Alexis BarolinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din 9427 - Metric Socket Button Head Cap Screws

Uploaded by

Alexis BarolinCopyright:

Available Formats

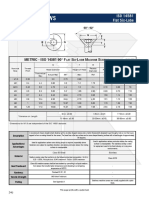

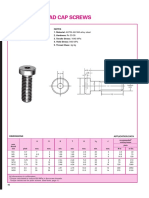

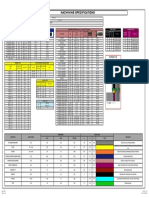

METRIC SOCKET BUTTON HEAD CAP SCREWS

Dimensions

Threads: ANSI B1.13M, ISO 262(coarse series only) NOTES

Similar Specifications: DIN 9427, ISO 7380 1. Material: ASTM F835M

General Note: Flat, countersunk head cap screws and 2. Dimensions: ANSI B18.3.4M

button head cap screws are designed and recommend- 3. Property Class: 12.9

ed for moderate fastening applications: machine guards,

hinges, covers, etc. They are not suggested for use in 4. Hardness: Rc 38-43

critical high strength applications where socket head cap 5. Tensile Stress: 1040 MPa

screws should be used.

6. Shear Stress: 630 MPa

7. Yield Stress: 945 MPa

8. Bearing surface of head square with body within 2°.

9. Thread Class: 4g 6g

H L

J

T

APPROX 45°

S

THREAD

A SIZE

LENGTH TOLERANCE

nominal screw diameter

M3 thru M16

nominal

screw length tolerance on lgth., mm

Up to 16 mm, incl. ±0.3

Over 16 to 60 mm, incl. ±0.5

Over 60 mm ±0.8

DIMENSIONS APPLICATION DATA

recommended

A H T R S J seating torque**

nom. plain

thread

size pitch max. max. min. ref. ref. nom. N-m in-lbs.

M3 0.5 5.70 1.65 1.05 2.95 .35 2.0 1.2 11

M4 0.7 7.60 2.20 1.35 4.10 .35 2.5 2.8 25

M5 0.8 9.50 2.75 1.92 5.20 .45 3.0 5.5 50

M6 1.0 10.50 3.30 2.08 5.60 .45 4.0 9.5 85

M8 1.285 14.00 4.40 2.75 7.50 .45 5.0 24.0 210

M10 1.50 18.00 5.50 3.35 10.00 .60 6.0 47.0 415

M12 1.75 21.00 6.60 4.16 11.00 .60 8.0 82.0 725

*M16 2.0 28.00 8.60 5.20 15.00 .60 10.0 205.0 1800

All dimensions in millimeters.

*Non-stock Diameter

**Torque calculated to induce 420 MPa in the screw threads.

Torque values are for plain screws. (See Note, page 1.)

41

You might also like

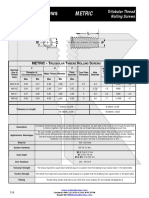

- DIN 7500 - Trilobular Thread Rolling ScrewsDocument3 pagesDIN 7500 - Trilobular Thread Rolling ScrewsDerek100% (1)

- Iso 14581 CSK ScrewDocument1 pageIso 14581 CSK ScrewMitesh MakvanaNo ratings yet

- MAPEH ARTS 8 First To Fourth Quarter ExaminationDocument8 pagesMAPEH ARTS 8 First To Fourth Quarter ExaminationArgel Quilab Larongco78% (18)

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

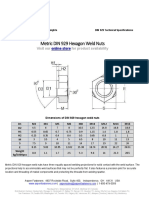

- Metric DIN 934 Hexagon Nuts: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 934 Hexagon Nuts: Visit Our For Product AvailabilityThiago CurvoNo ratings yet

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDocument24 pagesGalvanized and Black Malleable Iron Pipe Fittings Specificationshse vje100% (1)

- El Poder de Los HábitosDocument190 pagesEl Poder de Los HábitosAlexis BarolinNo ratings yet

- TKR-304P/305P/335P/345P/355P NEW SONG OCT 2018 1Document1 pageTKR-304P/305P/335P/345P/355P NEW SONG OCT 2018 1Benmar CoronadoNo ratings yet

- Button Head Socket Screws Metric Technical SpecificationDocument1 pageButton Head Socket Screws Metric Technical SpecificationXto PeregrinNo ratings yet

- Metric Socket Head Cap Screws1 PDFDocument2 pagesMetric Socket Head Cap Screws1 PDFRavi BabaladiNo ratings yet

- Metric Socket Head Cap Screws: DimensionsDocument2 pagesMetric Socket Head Cap Screws: DimensionsCarlos Bracho100% (1)

- Allen Parker Metric BoltsDocument2 pagesAllen Parker Metric BoltssebastianNo ratings yet

- METRIC FASTENERS: HEX CAP SCREWS AND BOLTSDocument1 pageMETRIC FASTENERS: HEX CAP SCREWS AND BOLTSSean YangNo ratings yet

- Metric Socket Set ScrewsDocument2 pagesMetric Socket Set ScrewsvvvvvvNo ratings yet

- METRIC LOW HEAD CAP SCREWS SPECIFICATIONSDocument1 pageMETRIC LOW HEAD CAP SCREWS SPECIFICATIONSBala Lakshman0% (1)

- Metric Fastener Specifications for ISO 14583 Pan Six-Lobe Machine ScrewsDocument1 pageMetric Fastener Specifications for ISO 14583 Pan Six-Lobe Machine ScrewsDerekNo ratings yet

- Screw, IsO 14583, PAN, Metric, TorxDocument1 pageScrew, IsO 14583, PAN, Metric, TorxDerekNo ratings yet

- Countersunk Socket Head Screws MetricDocument2 pagesCountersunk Socket Head Screws MetricSATHISHKUMAR MNo ratings yet

- Metric Fasteners: K-Lock Nut W/ Free Spinning External Tooth LWDocument1 pageMetric Fasteners: K-Lock Nut W/ Free Spinning External Tooth LWYossiNo ratings yet

- Screw, ISO 7380, Six Lobe, Metic, TorxDocument1 pageScrew, ISO 7380, Six Lobe, Metic, TorxDerekNo ratings yet

- Metric Hex Bolt DimensionsDocument7 pagesMetric Hex Bolt DimensionsVishal MistryNo ratings yet

- MetmachthreadDocument3 pagesMetmachthreadPatrick - Assist. Técnica - CetemNo ratings yet

- Self-Tapping Screw SpecificationsDocument3 pagesSelf-Tapping Screw Specificationsalfred2000No ratings yet

- Din 933Document2 pagesDin 933Sugumar0% (1)

- DIN 934 Metric Hex Nuts SpecificationDocument1 pageDIN 934 Metric Hex Nuts SpecificationfastenersworldNo ratings yet

- Tensió nucli cargol i cisallament dels filetsDocument3 pagesTensió nucli cargol i cisallament dels filetsmacitusNo ratings yet

- Bolt A325 A490 PDFDocument2 pagesBolt A325 A490 PDFmostapha soubraNo ratings yet

- Maintenance Manual General Informations: Original InstructionsDocument8 pagesMaintenance Manual General Informations: Original InstructionsFer NuñezNo ratings yet

- Metric Fastener Dimensions and SpecificationsDocument1 pageMetric Fastener Dimensions and SpecificationsDerekNo ratings yet

- DIN 929 Hexagon Weld Nut Technical Specifications and DimensionsDocument4 pagesDIN 929 Hexagon Weld Nut Technical Specifications and DimensionsDobrica PetrovicNo ratings yet

- Fastening technology hexagon head boltsDocument2 pagesFastening technology hexagon head boltsLavanyanNo ratings yet

- STPE600 - Dadi A ProiezioneDocument17 pagesSTPE600 - Dadi A ProiezioneLucaNo ratings yet

- M48D965Document1 pageM48D965Gulfstream Data, IncNo ratings yet

- UNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherDocument1 pageUNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherrimshadtpNo ratings yet

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

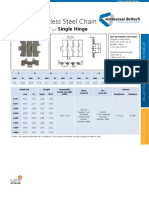

- Slat Top Stainless Steel Chain: Uni 512 Single HingeDocument2 pagesSlat Top Stainless Steel Chain: Uni 512 Single HingeRIGOBERTONo ratings yet

- Main Component For Two2Document3 pagesMain Component For Two2اسعد الماوريNo ratings yet

- Metric Dowel PinsDocument1 pageMetric Dowel PinsAbhijeet MitraNo ratings yet

- AS3600 Punching - PS1Document1 pageAS3600 Punching - PS1Yugatheeran ThavaratnasingamNo ratings yet

- Rothoblaas - HBS ScrewsDocument6 pagesRothoblaas - HBS ScrewsGuillaumeHNONo ratings yet

- Timber Screws CapacitiesDocument6 pagesTimber Screws CapacitiesΘανάσης ΓεωργακόπουλοςNo ratings yet

- SocketspipedryDocument1 pageSocketspipedryLuís Felipe GuimaraesNo ratings yet

- Id 075 - 09 04 2008Document2 pagesId 075 - 09 04 2008bouzahri boumedieneNo ratings yet

- ISO - 7380 - Button Head Hexagon Socket Cap Screw PDFDocument5 pagesISO - 7380 - Button Head Hexagon Socket Cap Screw PDFKevinNo ratings yet

- 13.-En_NT_Bolts_UtilcellDocument3 pages13.-En_NT_Bolts_Utilcellnu.arabiaNo ratings yet

- UID-21.1 Machining SpecsDocument1 pageUID-21.1 Machining SpecsNestor SerranoNo ratings yet

- Metric DIN 6885 SpecDocument4 pagesMetric DIN 6885 SpecDobrica PetrovicNo ratings yet

- Acople 5R10Document1 pageAcople 5R10Jose Emilio Carrero AngaritaNo ratings yet

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDocument24 pagesGalvanized and Black Malleable Iron Pipe Fittings SpecificationsdeniNo ratings yet

- Katalog TSP PTDocument24 pagesKatalog TSP PTendroNo ratings yet

- 20 Torque Calculation DIN946Document2 pages20 Torque Calculation DIN946Riyan EsapermanaNo ratings yet

- SD II PDF - OCRDocument18 pagesSD II PDF - OCRSuraj KumarNo ratings yet

- Saddle-Design-Operating - FinalDocument17 pagesSaddle-Design-Operating - FinalSiva baalan75% (4)

- Metric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionsDocument1 pageMetric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionssnorklingmonkeyNo ratings yet

- Katalog TSP NPTDocument28 pagesKatalog TSP NPThabib TaofikNo ratings yet

- Tpping Screws - Chapter 4Document13 pagesTpping Screws - Chapter 4Miguel QueirosNo ratings yet

- Bolt Torque-Tension Calculator MS3 2501Document9 pagesBolt Torque-Tension Calculator MS3 2501rafeekmekgceNo ratings yet

- Socket Head Cap Screws Dimensions and Torque SpecsDocument4 pagesSocket Head Cap Screws Dimensions and Torque SpecssarbiniNo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- Countersunk Socket Head Screws Inch Sizes and SpecsDocument2 pagesCountersunk Socket Head Screws Inch Sizes and SpecsMob PhoNo ratings yet

- Diesel Parts Catalog for STEYR EnginesDocument175 pagesDiesel Parts Catalog for STEYR EnginesАндрей СилаевNo ratings yet

- RITZ Screw Specification PDFDocument12 pagesRITZ Screw Specification PDFThawatchai DanwangkhawNo ratings yet

- Technical data sheet for #10 Master Gripper mini drill pointDocument4 pagesTechnical data sheet for #10 Master Gripper mini drill pointAlexis BarolinNo ratings yet

- Aztec Washer Arandela Vulcanizada MS-GALVANIZED-STEEL-SPECIFICATION-12-7-17Document1 pageAztec Washer Arandela Vulcanizada MS-GALVANIZED-STEEL-SPECIFICATION-12-7-17Alexis BarolinNo ratings yet

- Roll Turn DirectionDocument2 pagesRoll Turn DirectionAlexis BarolinNo ratings yet

- HT 100 InductoScan Rev3Document2 pagesHT 100 InductoScan Rev3Alexis BarolinNo ratings yet

- Acidity Removal - HDU2x27 108 108 - PSST1003UKDocument2 pagesAcidity Removal - HDU2x27 108 108 - PSST1003UKAlexis BarolinNo ratings yet

- Tycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Document1 pageTycoons - Specs of Carbon Steel Wire - 10B21, 10B38, 1010, 4140Alexis BarolinNo ratings yet

- Spheroidized Annealing in Process (SAIP)Document1 pageSpheroidized Annealing in Process (SAIP)Alexis BarolinNo ratings yet

- Alambres HPRDocument1 pageAlambres HPRAlexis BarolinNo ratings yet

- WTG Catalog 2017Document124 pagesWTG Catalog 2017Alexis BarolinNo ratings yet

- Universal Punch Hexagon Punches 2012Document32 pagesUniversal Punch Hexagon Punches 2012Alexis BarolinNo ratings yet

- Honeywell dc1000 dc1010 dc1030 dc1040 Manual PDFDocument29 pagesHoneywell dc1000 dc1010 dc1030 dc1040 Manual PDFDani Setia Ramdani100% (1)

- WTP CatalogDocument130 pagesWTP CatalogAlexis BarolinNo ratings yet

- d1040 HoneywellDocument32 pagesd1040 Honeywellduybac-spkhcmNo ratings yet

- UDC3200 Universal Digital Controller Operator Manual: 51-52-25-143 April 2008Document90 pagesUDC3200 Universal Digital Controller Operator Manual: 51-52-25-143 April 2008Alexis BarolinNo ratings yet

- d1040 HoneywellDocument32 pagesd1040 Honeywellduybac-spkhcmNo ratings yet

- Universal Punch Hexagon Punches 2012Document32 pagesUniversal Punch Hexagon Punches 2012Alexis BarolinNo ratings yet

- WTG Catalog 2017Document124 pagesWTG Catalog 2017Alexis BarolinNo ratings yet

- WTP CatalogDocument130 pagesWTP CatalogAlexis BarolinNo ratings yet

- UDC3200 Universal Digital Controller Operator Manual: 51-52-25-143 April 2008Document90 pagesUDC3200 Universal Digital Controller Operator Manual: 51-52-25-143 April 2008Alexis BarolinNo ratings yet

- Exploring urban design from philosophical and psychoanalytic perspectivesDocument27 pagesExploring urban design from philosophical and psychoanalytic perspectivesAlma Ukhtiani NurhasanNo ratings yet

- Assignment 1 - GE20Document5 pagesAssignment 1 - GE20Fegie GemarinoNo ratings yet

- Sewing Machine Troubleshooting GuideDocument4 pagesSewing Machine Troubleshooting GuideJuan Vicente100% (1)

- Crafts Beautiful 2017 02Document148 pagesCrafts Beautiful 2017 02Vladimir Baković100% (12)

- Medieval Towns, Traders and CraftsDocument10 pagesMedieval Towns, Traders and CraftsMurtaza YousufNo ratings yet

- Shakespeare Lesson Plan PDFDocument84 pagesShakespeare Lesson Plan PDFTrúc Hồ100% (1)

- Activity Sheet in Arts 7 Second GradingDocument2 pagesActivity Sheet in Arts 7 Second GradingBeverly Rivera RositaNo ratings yet

- Accessed From: Accessed On: Mon Feb 27 2023 17:41:45 Pacific Standard Time Access Provided By: British Columbia Institute of TechnologyDocument27 pagesAccessed From: Accessed On: Mon Feb 27 2023 17:41:45 Pacific Standard Time Access Provided By: British Columbia Institute of Technologysukhman kaurNo ratings yet

- ArtDocument4 pagesArtFatima JabeenNo ratings yet

- Kendor Catalog 2010 WebDocument53 pagesKendor Catalog 2010 WebRobert Gillespie50% (2)

- The Fruit Garden CAL: Getting Ready by Jane CrowfootDocument4 pagesThe Fruit Garden CAL: Getting Ready by Jane CrowfootMira100% (1)

- National Artist For Historical LiteratureDocument2 pagesNational Artist For Historical LiteraturejdmngNo ratings yet

- Guitar I - Course Outline and ContentsDocument22 pagesGuitar I - Course Outline and ContentsShantanu Kulkarni100% (1)

- Art21 Wkaip Guide DownloadDocument26 pagesArt21 Wkaip Guide DownloadJuan Hdez100% (1)

- LET Reviewer English Part 4Document4 pagesLET Reviewer English Part 41st Option Computer CenterNo ratings yet

- Hollenbeck DownBeatDocument4 pagesHollenbeck DownBeatHarry VetroNo ratings yet

- Terminated For Reasons of Taste by Chuck EddyDocument16 pagesTerminated For Reasons of Taste by Chuck EddyDuke University Press100% (1)

- The Improvised Shakespeare Company: Applause Series Curriculum GuideDocument16 pagesThe Improvised Shakespeare Company: Applause Series Curriculum GuideTodd CouchNo ratings yet

- Ielts Reading 2023 5Document10 pagesIelts Reading 2023 5Oluwadarasimi Akinola-OluwalanaNo ratings yet

- The Unaccompanied Solos For Saxophone: Scholarly Notes To Accompany A CD Recording ProjectDocument17 pagesThe Unaccompanied Solos For Saxophone: Scholarly Notes To Accompany A CD Recording ProjectDANA100% (1)

- 1.2 My Mother at Sixty-Six EXTRACTSDocument5 pages1.2 My Mother at Sixty-Six EXTRACTSSRISHTI bcomNo ratings yet

- Daftar Kebutuhan AtkDocument10 pagesDaftar Kebutuhan Atkhudori gantengNo ratings yet

- English Reading Practice: EgyptDocument3 pagesEnglish Reading Practice: EgyptSolen EichholtzerNo ratings yet

- Helen McNicoll: Life & Work by Samantha BurtonDocument115 pagesHelen McNicoll: Life & Work by Samantha BurtonArt Canada InstituteNo ratings yet

- Theatre props essentialDocument7 pagesTheatre props essentialMarcela MoscardiniNo ratings yet

- Soal Latihan Pas B.inggris Kelas 1Document7 pagesSoal Latihan Pas B.inggris Kelas 1ratih100% (6)

- Ar311 2026 Assignment-01Document3 pagesAr311 2026 Assignment-01Rachit AgarwalNo ratings yet

- Final Exam Review Questions For Architectural History Theory DesignDocument5 pagesFinal Exam Review Questions For Architectural History Theory DesignlucphinneyNo ratings yet