Professional Documents

Culture Documents

Classificação de Motores - Ex

Uploaded by

Anderson MarcosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classificação de Motores - Ex

Uploaded by

Anderson MarcosCopyright:

Available Formats

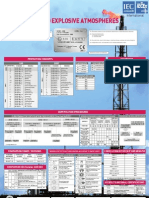

Marking of ATEX/IECEx electrical explosion protected equipment

Potentially explosive areas Subdivisions and classification of gases and vapours

Conditions and Zone classification Required marking on the equipment Gases and vapours Assignment Temperature Maximum Permitted

of gases and vapours class surface Temperature

Flammable Temporary behaviour Classi- Group Equipment Equipment Equipment

accordance to the temperature classes

materials of explosive atmosphere fication as defined in category group protection level

ignition temperature (equipment) (equipment)

of directive as defined in as defined in (EPL)

hazardous 2014/34/EU directive EN IEC 60079-0 as defined in Ammonia, Town gas, Hydrogen > 450 °C T1 450 °C T1 to T6

areas 2014/34/EU EN IEC 60079-0 methane, ethane, acrylnitril

Gases is present continuously or Zone 0 II 1G II Ga propane

Vapours for long periods or frequently

Ethyl alcohol, Ethylene, Ethine > 300 °C ... < 450 °C T2 300 °C T2 to T6

arises in normal Zone 1 II 2G or 1G II Gb or Ga cyclohexane, ethylene oxide (Acetylene)

operation occasionally n-butane

is not likely to arise in normal Zone 2 II 3G or II Gc or Gasoline, Ethylene glycol, > 200 °C ... < 300 °C T3 200 °C T3 to T6

operation, or if it does, will 2G or 1G Gb or Ga n-hexane hydrogen sul-

persist for a short time only phide

Dusts is present in the form of a Zone 20 II 1D III Da

cloud continuously, or for Acetaldehyde Ethyl ether > 135 °C ... < 200 °C T4 135 °C T4 to T6

long periods or frequently > 100 °C ... < 135 °C T5 100 °C T5 to T6

occasionally develops Zone 21 II 2D or 1D III Db or Da Sulphide of

into a cloud during normal > 085 °C ... < 100 °C T6 85 °C T6

carbon

operation

is not likely to develop into Zone 22 II 3D or III Dc or

a cloud during normal 2D or 1D Db or Da

operation, or if it does,

Gas groups

for a short time only

Methane operation where there is - I M1 I Ma IIA IIB IIC

Carbon dust a risk of explosion

Permitted Equipment groups

disconnection where there - I M2 or M1 I Mb or Ma

is a risk of explosion IIA, IIB, IIC IIB, IIC IIC

AT E X

Gases/Vapours NB1) II 2G Ex db eb IIC T6 Gb NB2) 18 ATEX 1234 X

Dusts NB1) II 2D Ex tb IIIC T120 °C Db NB2) 18 ATEX 1234 X

IECEx

Gases/Vapours Ex db eb IIB T4 Gb IECEx ExCB3) 11.1234 X

Dusts Ex tc IIIB T120 °C Dc IECEx ExCB3) 11.1234 X

Protection principle/types of protection Use of the operating equipment

Applications Flammable materials Protection principle Type of protection Marking in accordance with the equipment protection level Standards Marking Conditions

very high high enhanced

level of protection level of protection level of protection without Equipment can be operated without

All applications Gases, vapours (G) and – General requirements X or U restrictions

dusts (D) + + + EN IEC 60079-0

Specific conditions of use of the

with X

equipment

Control stations, motors, fuses, Gases and vapours (G) Propagation of an explosion Flameproof enclosure Ex da* Ex db Ex dc EN IEC 60079-1

with U Component certificate (uncomple-

switchgear, power electronics, inside to the outside is excluded

ted), conformity is certified when

*catalytic gas detectors only

used in an overall equipment

Junction and connection boxes, Gases and vapours (G) Avoidance of arcs, sparks and Increased safety – Ex eb Ex ec EN IEC 60079-7

enclosures, motors, luminaires, excessive temperature

terminals

Max. permissible surface temperature

Junction and connection boxes, Dusts (D) Explosive dust atmosphere keep at Protection by enclosure Ex ta Ex tb Ex tc EN IEC 60079-31

enclosures, motors, luminaires, a distance from the ignition source of the equipment

switch and control cabinets, plugs Temperature limitation Tmax. < T5 mm - 75°C

because of dust layer

Measurement and control Gases, vapours (G) and Limitation of energy as well as arcs Intrinsic safety Ex ia Ex ib Ex ic EN IEC 60079-11

technology, automation dusts (D) and temperature EN IEC 60079-25 T5 mm: Minimum ignition

technology, sensors, actuators temperature of 5 mm layer

of dust

Switch and control stations, Gases, vapours (G) and Explosive atmosphere keep at a Pressurization – Ex pxb, Ex pyb Ex pzc EN IEC 60079-2

motors, analyzers, computers dusts (D) distance from the ignition source Temperature limitation Tmax. < 2/3 TCL

because of dust cloud

Coils of motors or relays, Gases, vapours (G) and Explosive atmosphere keep at a Encapsulation Ex ma Ex mb Ex mc EN IEC 60079-18

TCL: Minimum ignition

solenoid valves, dusts (D) distance from the ignition source

temperature of the cloud of

connection systems

dust

Transformers, relays, Gases and vapours (G) Explosive atmosphere keep at a Liquid immersion – Ex ob Ex oc EN IEC 60079-6 Max. permissible lowest outcome of

control stations, distance from the ignition source surface temperature the Tmax. - values

magnetic contactors of the equipment:

Capacitors, transformers, relays Gases and vapours (G) A propagation of an explosion Powder filling – Ex q – EN IEC 60079-5

inside to the outside is excluded

Subdivision of dusts

Applications for zone 2 Gases and vapours (G) Protection principles adapted Enclosed construction – – Ex nC EN IEC 60079-15

for zone 2 Permitted Dust groups Dusts

Restricted breathing Ex nR

Equipment

Optical devices, laser scanners, Gases, vapours (G) and Limitation of optical energy Inherent safe optical Ex op is – – EN IEC 60079-28 groups

light barriers, fibre-optic systems dusts (D) radiating in the explosive radiation combustible

atmosphere IIIA, IIIB, IIIC IIIA

flyings

Fibre-optic systems Gases, vapours (G) and Ex atmosphere is kept distant from Protected optical – Ex op pr – EN IEC 60079-28

D-D-WEG250608-01/2019-Marketing & Communications-286323

IIIB, IIIC IIIB non-conductive

dusts (D) the ignition source radiation

Fibre-optic systems Gases, vapours (G) and Ex atmosphere is kept distant from Optical system with – Ex op sh – EN IEC 60079-28 IIIC IIIC conductive

dusts (D) the ignition source interlocking

1) Identification number of the Notified Body responsible for the surveillance of the manufacturer‘s

quality system (Cat. 1 and 2).

Application area (equipment)

2) Notified Body (NB) that has tested and certified the product (Cat. 1 and 2).

Zone 0/20 Zone 1/21 Zone 2/22

3) Certification Body (CB) that has tested and certified the product (EPL a, b and c). Zone 1/21 Zone 2/22

Zone 2/22

ATEX is in the European Union a mandatory and IECEx a voluntary certification procedure.

For the correct application of the certification procedures, please follow the corresponding regulations

guidelines and standards.

BARTEC GmbH Max-Eyth-Str. 16 97980 Bad Mergentheim Germany Phone: +49 7931 597 0 info@bartec.de www.bartec.com

You might also like

- ATEX Marking Electrical Equipment Ex PDFDocument1 pageATEX Marking Electrical Equipment Ex PDFBinhvvNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFMMNo ratings yet

- Atex ClassificationDocument1 pageAtex ClassificationDANE80No ratings yet

- Hazardous Area Classification EN PDFDocument6 pagesHazardous Area Classification EN PDFUsama IqbalNo ratings yet

- Equipment For Explosive AtmospheresDocument33 pagesEquipment For Explosive AtmospheresGreggBaeten0% (1)

- BS EN 60079-5-2007, Explosive AtmospheresDocument26 pagesBS EN 60079-5-2007, Explosive AtmospheresyahiabiaNo ratings yet

- Po Ex en 170413 WebDocument1 pagePo Ex en 170413 Webswordleee swordNo ratings yet

- Scba & FMS PDFDocument74 pagesScba & FMS PDFHamid MasoodNo ratings yet

- DS59 IEC 60079 0 2011 The Differences and The ConsequencesDocument3 pagesDS59 IEC 60079 0 2011 The Differences and The ConsequencesGlen AshwellNo ratings yet

- IEC 60079-18 - 2009 - Encapsulated Protection - Ex M PDFDocument35 pagesIEC 60079-18 - 2009 - Encapsulated Protection - Ex M PDFRadu Babau100% (1)

- Iecex TCD 02 Scheme Ed 7.0Document103 pagesIecex TCD 02 Scheme Ed 7.0Bhavik PrajapatiNo ratings yet

- En 61000-4!7!2002 - CEI IEC - EMC-Part 4-7-Testing and Measurement Techniques - 2Document2 pagesEn 61000-4!7!2002 - CEI IEC - EMC-Part 4-7-Testing and Measurement Techniques - 2Mahmoud ShaheenNo ratings yet

- Installation Instructions For CMP Cable Gland Types T3Cds & T3CdspbDocument2 pagesInstallation Instructions For CMP Cable Gland Types T3Cds & T3CdspbLailyMLNo ratings yet

- Is 636Document11 pagesIs 636suseelaparvathimspNo ratings yet

- Iec 61869-9-2016Document61 pagesIec 61869-9-2016moham akhNo ratings yet

- Hazardous Area Chart - E&H PDFDocument2 pagesHazardous Area Chart - E&H PDFBuddy EkoNo ratings yet

- BS EN 13463-1, No Elec EquipmentDocument47 pagesBS EN 13463-1, No Elec EquipmentErol BurnsNo ratings yet

- ATEX Non ElectricalDocument10 pagesATEX Non ElectricalmigelNo ratings yet

- ATEX 2014-34-EU Guidelines - 2nd Edition December 2017Document238 pagesATEX 2014-34-EU Guidelines - 2nd Edition December 2017ARTURONo ratings yet

- IEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Document104 pagesIEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Mohd Lutfi MahaliNo ratings yet

- Iec 60079-6 - 2007Document19 pagesIec 60079-6 - 2007Victor Almeida BressianiNo ratings yet

- BS Iec 60079-19-1993 (1999)Document30 pagesBS Iec 60079-19-1993 (1999)Bilal QasimNo ratings yet

- Iec61869-2 (Ed1 0) B PDFDocument11 pagesIec61869-2 (Ed1 0) B PDFfrarains0% (2)

- Handbook For Use and Maintenance and Directive ATEX: Elvem S.R.LDocument18 pagesHandbook For Use and Maintenance and Directive ATEX: Elvem S.R.LE.ANANDANNo ratings yet

- CompEx Course SyllabusDocument14 pagesCompEx Course SyllabusJoshuaNo ratings yet

- N176 Iso CD 5149 4 2006 PDFDocument25 pagesN176 Iso CD 5149 4 2006 PDFniceday9_4100% (1)

- Certifications d2p Ewp Circuit Breaker Panelboards Ul E84577 Appleton en 7120036Document1 pageCertifications d2p Ewp Circuit Breaker Panelboards Ul E84577 Appleton en 7120036Diego Betancourt MejiaNo ratings yet

- Aemt Ex Labels GuidelinesDocument52 pagesAemt Ex Labels GuidelinesEfari BahchevanNo ratings yet

- IEC 60079-5 - Powder Filling 'Q' - 2015Document26 pagesIEC 60079-5 - Powder Filling 'Q' - 2015Institute of Marketing & Training ALGERIANo ratings yet

- BS en Iso 80079-36-2016Document96 pagesBS en Iso 80079-36-2016Annie De WildeNo ratings yet

- Atex and CE Declaration CertificateDocument7 pagesAtex and CE Declaration Certificaterudrakr100% (1)

- Risk Assessment of Mechanical Equipment EN1127-1Document11 pagesRisk Assessment of Mechanical Equipment EN1127-1Luis CarlosNo ratings yet

- ATEX Presentation To CustomersDocument28 pagesATEX Presentation To CustomersSameh EzzatNo ratings yet

- Atex PosterDocument1 pageAtex PosteratumrakisNo ratings yet

- Catalog - e - LorünserDocument99 pagesCatalog - e - Lorünserbrayan colorado tobonNo ratings yet

- New Atex Directive: Lars EkströmDocument23 pagesNew Atex Directive: Lars EkströmvalimironescuNo ratings yet

- Electrostatics - Code of Practice For The Avoidance of Hazards Due To Statict ElectricityDocument82 pagesElectrostatics - Code of Practice For The Avoidance of Hazards Due To Statict ElectricityAnonymous 1XHScfCINo ratings yet

- IEC 60079-26 - Group II Zone 0 Electrical Apparatus - 2014Document20 pagesIEC 60079-26 - Group II Zone 0 Electrical Apparatus - 2014Institute of Marketing & Training ALGERIANo ratings yet

- (BS en 60079-30-1) - Explosive Atmospheres. Part 30-1. Electrical Resistance Trace Heating. General, Type Testing and Design RequirementsDocument68 pages(BS en 60079-30-1) - Explosive Atmospheres. Part 30-1. Electrical Resistance Trace Heating. General, Type Testing and Design RequirementsKumar GadekarNo ratings yet

- En 60079-26 (2015)Document22 pagesEn 60079-26 (2015)Prissana RuangsareeNo ratings yet

- E71278 PowerPlus D2L Panels Compliance LetterDocument1 pageE71278 PowerPlus D2L Panels Compliance Letterandersson benito herrera100% (1)

- 10-1 2018 3Document9 pages10-1 2018 3Efari BahcevanNo ratings yet

- Iec 60034-29-2008Document62 pagesIec 60034-29-2008Luis R100% (1)

- BS en Iso 80079-36 - 2016 PDFDocument96 pagesBS en Iso 80079-36 - 2016 PDFchertanNo ratings yet

- Iso 13577-1-2016Document52 pagesIso 13577-1-2016Vanni Valeri100% (1)

- Multifunctional Controls For Gas Burning AppliancesDocument24 pagesMultifunctional Controls For Gas Burning AppliancessonerNo ratings yet

- Compex Training PDFDocument12 pagesCompex Training PDFFederico Maggi100% (1)

- NEK 606offshore Cables CatalogDocument214 pagesNEK 606offshore Cables CatalogJose Luius100% (1)

- Operating Manual of Smoke Density Test ApparatusDocument7 pagesOperating Manual of Smoke Density Test ApparatusRAKESHNo ratings yet

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- Marking Electrical Equipment ExDocument1 pageMarking Electrical Equipment ExFendy ShirahNo ratings yet

- Marking Non Electrical Equipment ExDocument1 pageMarking Non Electrical Equipment ExTurkish Medical CareNo ratings yet

- ATEX For Non-ElectricalDocument1 pageATEX For Non-ElectricalRajesh KumarNo ratings yet

- Marking Iecex Equipment Ex..Document1 pageMarking Iecex Equipment Ex..jerrinjNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFAgus RianNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFNicolae VisanNo ratings yet

- Marking Electrical Equipment Ex PDFDocument1 pageMarking Electrical Equipment Ex PDFrakacyuNo ratings yet

- Marking IECEx Equipment ExDocument1 pageMarking IECEx Equipment Exadirocks89No ratings yet

- WWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentDocument1 pageWWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentfrancisNo ratings yet

- Ex Motor PresentationDocument72 pagesEx Motor PresentationsanatikalaNo ratings yet

- Fiocchi USA Catalogue 2010Document60 pagesFiocchi USA Catalogue 2010Mario LopezNo ratings yet

- D-1967 (Clean) Quilting Machine ManualDocument33 pagesD-1967 (Clean) Quilting Machine Manualvalter craccoNo ratings yet

- Applies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)Document5 pagesApplies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)apletonprinceNo ratings yet

- Mercedes Benz RangeDocument37 pagesMercedes Benz RangeUZNAPMNo ratings yet

- HOF - To PrasannaDocument3 pagesHOF - To PrasannahishamndtNo ratings yet

- PhillipsDocument22 pagesPhillipsArthur RodriguezNo ratings yet

- Operation and Maintenance Manual: Mux-2200E Integrated Service MultiplexerDocument82 pagesOperation and Maintenance Manual: Mux-2200E Integrated Service Multiplexerlee.tetleie1675No ratings yet

- Ice Plant TrainerDocument1 pageIce Plant TrainerVirender RanaNo ratings yet

- Especificaciones Tecnicas Motor 4g54 2.6ltsDocument20 pagesEspecificaciones Tecnicas Motor 4g54 2.6ltsjr50% (2)

- Case Study FormatDocument2 pagesCase Study FormatMarianel Antiqueña EspinosaNo ratings yet

- C/C++ Programming Language NotesDocument68 pagesC/C++ Programming Language Notesctf challengeNo ratings yet

- Cardox-Blockage Removal SystemDocument5 pagesCardox-Blockage Removal SystemNaelNo ratings yet

- Diseño de Tuberías C-10 Y C-40Document1 pageDiseño de Tuberías C-10 Y C-40samuelcordova36No ratings yet

- Ms 95-2018 Solved AssignmentDocument15 pagesMs 95-2018 Solved AssignmentPramod ShawNo ratings yet

- En 10268Document4 pagesEn 10268Alex LacerdaNo ratings yet

- Sampling Procedure and Tables For InspectionDocument43 pagesSampling Procedure and Tables For InspectionAnonymous AoTZuNvxNo ratings yet

- Braemar ApplicationDocument2 pagesBraemar Applicationjoemedia0% (1)

- External Command in 10 Steps For Revit 2015Document2 pagesExternal Command in 10 Steps For Revit 2015JigneshNo ratings yet

- MclogitDocument19 pagesMclogitkyotopinheiroNo ratings yet

- Module 8: Numerical Relaying I: Fundamentals: Fourier AlgorithmsDocument15 pagesModule 8: Numerical Relaying I: Fundamentals: Fourier Algorithmsjijo123408No ratings yet

- 94-0518-4 Mini-RadaScan Engineers and Service GuideDocument15 pages94-0518-4 Mini-RadaScan Engineers and Service GuideAlex Sandoval100% (1)

- Eminence Deltalite II 2515Document1 pageEminence Deltalite II 2515Suto BandNo ratings yet

- Final Project Miguel Santana GallegoDocument44 pagesFinal Project Miguel Santana GallegoDaniel PereiraNo ratings yet

- TGS8100 Product InfomationDocument10 pagesTGS8100 Product Infomationbemxgm-1No ratings yet

- Serial Index CaterpillarDocument260 pagesSerial Index CaterpillarRamón Mangles90% (10)

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresNo ratings yet

- Yuli's PPT FloralDocument28 pagesYuli's PPT FloralYuli MyeshaNo ratings yet

- Emmeskay MIL-SIL TutorialDocument52 pagesEmmeskay MIL-SIL TutorialNeacsu EugenNo ratings yet

- New Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamDocument6 pagesNew Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamMatnSambuNo ratings yet

- Patrick C Hall@yahoo - com-TruthfinderReportDocument13 pagesPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithNo ratings yet