Linear Programming Problem:

1. Four products are processed sequentially on three machines. The following table gives

the pertinent data of the problem.

Manufacturer time (hr) per unit

achine per hr(Rs.) Product I oduct II duct III oduct IV apacity(hr)

1 10 2 3 4 2 500

2 5 3 2 1 2 380

3 4 7 3 2 1 450

Unit selling price 75 70 55 45

Formulate the problem as an LP model and find the optimum solution by using Excel.

2. A company produces two products, A and B. The unit revenues are $2 and $3,

respectively. Two raw materials, M1 and M2, used in the manufacturer of the two

products have respective daily availabilities of 8 and 18 units. One unit of A uses 2 units

of M1 and 2 units of M2, and 1 unit of B uses 3 units of M1 and 6 units of M2.

(a) Determine the dual or shadow prices of M1 and M2 and their feasibility

ranges.

(b) Suppose that 4 additional units of M1 can be acquired at the cost of 30 cents

per unit. Would you recommend the additional purchase?

(c) If M2 availability is increased by 5 units, determine the associated optimum

revenue.

Demand Forecasting:

3. Your manager is trying to determine what forecasting method to use. Based upon the

following historical data calculate the following forecast and specify what procedure you

will apply?

Month Actual Demand

1 62

2 65

3 67

� 4 68

5 71

6 73

7 76

8 78

9 78

10 80

11 84

12 85

(a) Calculate the simple 3 month moving average forecast for periods 4-12

(b) Calculate the single exponential smoothing forecast for periods 2-12 using an initial

forecast (F1) of 61 and α=0.30

(c) Calculate the mean absolute deviation (MAD) for the forecasts made by each

technique in periods 4-12. Which forecasting method do you prefer?

4. A sportswear manufacturer wishes to use data from a five year period to develop seasonal

indexes for 12 months. Seasonal indexes (S.I.) for most months are calculated and

already shown in Table 1. April and May actual sales and corresponding centered moving

averages (CMA) for five years are shown in Table 2. Compute the seasonal indexes for

April and May.

Table 1

Table 2

Actual

l

5. Here are quarterly data for the past two years. From these data, prepare a forecast demand

for the upcoming year using decomposition.

� riod al Demand

1 300

2 540

3 885

4 580

5 416

6 760

7 1191

8 760

6. The following equation summarizes the trend portion of quarterly sales of wardrobes over

a long cycle. Sales also exhibit seasonal variations.

Ft = 40 – 6 .5t + 2t2

Where Ft =Unit Sales, t=0 at the 1st quarter of 2004, The seasonal indexes for each quarter are

given below

Quarter Index

1 1.1

2 1.0

3 0.6

4 1.3

Using the information given, select the forecast of sales (rounded to the next integer) for the first

quarter of 2008 from the choices given.

Process Analysis:

7. Consider a process consisting of five resources that are operated eight hours per day. The

process works on three different products A, B, and C:

essing Time essing Time

sing Time for A

source of workers for B for C

(Min/Unit)

(Min/Unit) (Min/Unit)

1 2 5 5 5

2 2 3 4 5

3 1 15 0 0

4 1 0 3 3

5 2 6 6 6

�Demand for the three products is as follows: Product A. 40 units per day; Product B. 50 units

per day; Product C. 60 units per day. Find the bottleneck of the process?

8. Consider a company which manufactures two products. Demand for each of the product

is independent and may take values of 50,100 and 150 with equal chances of occurrence.

Say, you have two systems; system 1 is flexible in the sense both the products can be

produced in the same line with a total capacity of 200 units. System 2 is not flexible and

constitutes two distinct/dedicated lines with capacity of producing 100 units each of the

two products. Find out the capacity of the two system?

9. Consider an operator engaged in Xeroxing. The activities involved are loading (L),

Xeroxing, unloading (UL) and inspection. L and UL are done by operator; total time for

L and UL being 1 sec. The machine cannot be used for any other purpose during L and

UL. On loading, the machine starts automatically, and Xeroxing takes 3 secs. The

unloaded paper has to be inspected by the operator. Each inspection takes 1sec. Consider

continuous operation as above with 1operator & 1machine. Find out the capacity of the

system?

Aggregate Production Planning:

10. Centipade Equipment has asked you to develop a stable workforce plan for the next four

quarters. Below is the relevant information. How much money is spent on wages

(Regular time and overtime) over the time of the plan?

er 1 er 2 er 3 er 4

nv.

nd

Productivity: 40 units per worker per quarter

Regular time wages: $ 16 per hour

Over time wage premium: 50%

1 Quarter = 450 labor-hours

Workers are guaranteed 450 hours of work per qtr.

There are 46 workers at centipede.

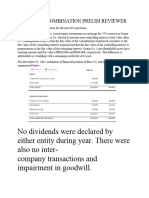

11. The Table below summarizes the cost of four aggregate production plans. Describe each

type of plan.

� Cost

f Cost

ory Cost

rders

ntracting

me

ar time 0 0 0 0

0 8 0 1

12. For the following information, what is the level production rate that will achieve an

ending inventory of 1500 at the end of month 4?

h

ning Inv.

nd

ction

g Inv.