Professional Documents

Culture Documents

Prolift SCL/Prolift HD: Owner'S Manual

Uploaded by

Mohammed Qaid AlathwaryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prolift SCL/Prolift HD: Owner'S Manual

Uploaded by

Mohammed Qaid AlathwaryCopyright:

Available Formats

Prolift SCL/Prolift HD

Accessibility Lifts

OWNER’S MANUAL

(To Be Retained by Owner After Installation

by Authorized Savaria Dealer)

Part No. 000782

29-m08-2018

2

IMPORTANT

Ensure that only an Authorized Savaria Dealer installs and services the Savaria™

Prolift SCL/Prolift HD. Under no circumstances is anyone other than a dealer

with Savaria training and authorization to install, adjust, service or modify any

mechanical or electrical device on this equipment. Failure to follow this

warning can result in safety system compromises or defeat; this can result in

serious injury or death. Savaria accepts no liability for property damage,

warranty claims or personal injury, including death, in this circumstance.

Passenger safety is the result of countless details in the equipment’s design,

manufacture, and installation. After installation, reliable operation and

continual safe operation requires regular service and inspection at least twice

per year, or more frequently where usage, environment, or local jurisdiction

requires. As the Owner, you are responsible for ensuring that regular service

and inspections occur in a timely manner.

Refer to this manual for specifications, operating instructions and maintenance

of the Savaria™ Prolift SCL/Prolift HD Accessibility Lifts.

Upon completion of installation, the dealer must provide you with the

following information and ensure it is recorded in this manual. In addition,

either the dealer or you must keep any service and/or maintenance records in

the Maintenance Record section of this manual.

WARRANTY

Ensure your Authorized Savaria Dealer provides you with a copy of the

manufacturer’s limited parts warranty and documentation relating to any

Dealer labour warranty.

-------------------------------------------------------------------------------------------------

FOR OWNER’S RECORDS

Customer Name: _________________________________________

Installing Dealer: _________________________________________

Dealer’s Telephone Number: _______________________________

Date Installed: ___________________________________________

Serial/Job Number: _______________________________________

Prolift SCL/Prolift HD Owner’s Manual Part No. 000782, 29-m08-2018

3

Table of Contents

TO ENSURE SAFE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operating from the Landing Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operating from the Cab Operating Panel (COP) Controls . . . . . . . . . .11

5. POWER FAILURE AND EMERGENCY LOWERING . . . . . . . . . . . . . . . . . . . . . . . . . .11

6. EMERGENCY LIGHTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

7. MANUAL LOWERING DEVICE (MACHINE ROOM) . . . . . . . . . . . . . . . . . . . . . . . . .12

8. EMERGENCY HANDS-FREE PHONE (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . .13

9. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Part No. 000782, 29-m08-2018 Prolift SCL/Prolift HD Owner’s Manual

4

TO ENSURE SAFE OPERATION

To ensure safe operation of this equipment, pay careful attention to the

important notes below.

• Read this manual carefully before using the equipment.

• To prevent accidents, adhere strictly to the instructions and keep clear

of moving parts at all times.

• Follow instructions on all equipment labels at all times. Replace any

damaged labels immediately.

• Ensure that only qualified personnel perform maintenance and service

on the unit.

• When replacing parts, be sure that only genuine Savaria parts are used.

• This unit is intended for use by a mature person who understands its

proper operation as set out in this manual.

• Prior to operation, make sure that:

• All doors and gates are locked and secure.

• All areas in and around the lift are clear of any obstructions.

• All lights are functioning properly.

• Test your keys and emergency stop button every month.

Prolift SCL/Prolift HD Owner’s Manual Part No. 000782, 29-m08-2018

5

1. SPECIFICATIONS

Prolift SCL/HD Specifications

SCL: 550 lb (250 kg), 750 lb (341 kg), 1000 lb (454 kg)

Load capacity

HD: 1400 lb (635 kg)

Rated speed 30 ft/min (0.15 m/s) (nominal)

CDN: 23 ft (7 m) or per local code

Maximum travel

US: 14 ft (4.3 m) or per local code

Maximum # of stops 4 stops

Normal: 30

Heavy: 75

Daily cycle

Excessive: 100

Maximum starts in 1 hour on standard installation: 15

Power supply

NOTE: Amperage may vary 208 volt, three phase, 30 amps or

depending on individual units.

230 volt, single phase, 40 amps

Verify requirements prior to

installation of power supply.

Drive system 1:2 cable hydraulic

SCL Type 1L/1R, Type 2, Type 5:

• 36” x 48” (914 mm x 1219 mm)

• 36” x 54” (914 mm x 1372 mm)

• 36” x 60” (914 mm x 1524 mm)

• 42” x 48” (1067 mm x 1219 mm)

SCL Type 3/4, Type 3/4 with 42” B wall opening:

Cab sizes

• 42” x 48” (1067 mm x 1219 mm)

HD all cab types (Type 1L/1R, Type 2, Type 3/4, Type 3/4 with

42” B wall opening, Type 5:

• 42” x 54” (1067 mm x 1372 mm)

• 42” x 60” (1067 mm x 1524 mm)

• 48” x 60” (1219 mm x 1524 mm)

SCL: 8” (203 mm) minimum

Pit depth required

HD: 12” (305 mm) minimum

Minimum overhead clearance 92” (2337 mm)

Control system Constant pressure

Floor selection Magnetic selector

Flooring material Plywood

Control panel finish Stainless steel

Hall station finish Stainless steel

SCL: 3 HP (2.24 kW)

Motor

HD: 5 HP (3.73 kW)

Cab panel finish Standard solid melamine panels

Lighting supply 115 volt, 60 cycle, 15 amps

Part No. 000782, 29-m08-2018 Prolift SCL/Prolift HD Owner’s Manual

6

Prolift SCL/HD Specifications (continued)

Emergency alarm and stop buttons with emergency battery

back-up for cab lighting and lowering

Four recessed incandescent down lights

Standard features

Metal push buttons with illuminated haloes

Stainless steel handrail

White egg crate ceiling

Prolift SCL/Prolift HD Owner’s Manual Part No. 000782, 29-m08-2018

7

2. FEATURES

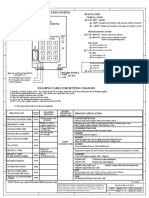

1 Cab Key Switch (Optional) (Figure 1-A)

The optional key switch turns the cab controls ON Figure 1: 4 Stop COP

and OFF. It is provided to limit the use of the elevator

to authorized persons only.

2 Cab Operating Panel Buttons (Figure 1-B)

Constant pressure cab control buttons facilitate the

UP/DOWN movement of the cab between landings.

The selected landing button must be pressed and

held until the cab moves to the landing. The cab will

stop when the button is released or when the

selected landing is reached.

3 Door Open Button (Figure 1-C)

The elevator door will close automatically after a

pre-set adjustable time of 8 seconds. This button can

be pressed to open the door when the cab is at a

landing.

A

4 Alarm Button (Figure 1-D)

This button can be pressed at any time to sound the B

alarm in case of an emergency. If equipped with the

Hands-Free Telephone, hold down the button for

approximately 3 to 10 seconds to activate the

telephone line. Refer to section 8 for more details.

5 Emergency Stop Button (Figure 1-E) C

This button can be pressed at any time to stop the D

cab and activate the alarm buzzer. E

6 Handrail

A single handrail is mounted on the Cab Operating

Panel side of the cab.

7 Emergency Light

The COP emergency light remains ON in the event of a main power failure. The

emergency light uses a Battery Back-Up system with an automatic recharger.

Part No. 000782, 29-m08-2018 Prolift SCL/Prolift HD Owner’s Manual

8

8 Landing Hall Call Station Controls (Figure 2)

Figure 2: Hall Call

Constant pressure Hall Call buttons are installed at all

landings to move the cab to the landing from which it

is being called. An optional key switch limits the use of

the elevator to authorized persons only.

9 Landing Door Interlock

The Landing Door lock prevents the movement of the

cab unless the door is in the closed and locked position.

If the door is not completely closed, the cab will not

move.

10 Emergency Battery Operation

In the event of a building power failure, the door system is provided with a

temporary power back-up system to continue the opening operation for a

number of times. On resuming normal building power, the back-up system will

turn OFF and begin automatic recharging.

Prolift SCL/Prolift HD Owner’s Manual Part No. 000782, 29-m08-2018

9

3. OPTIONS

Automatic Door Opener

1 Press and hold the Landing Hall Call button to call the elevator. The entrance

door will open automatically once the elevator stops at the landing.

2 Press the Remote Control (if equipped) to open the entrance door once the

elevator stops at the landing.

3 Push ’n’ Go allows the entrance door to open automatically with a slight

push to the door itself. The door timer is inoperative when this feature is

activated.

NOTE

An “entry” and “exit” timer allows approximately 9 seconds

before the Hall Call buttons become operational. This delay

allows time for a person to enter/exit the cab.

Part No. 000782, 29-m08-2018 Prolift SCL/Prolift HD Owner’s Manual

10

4. OPERATION

Operating from the Landing Controls

1 If equipped with a key switch, insert the key into the key switch on the Hall

Call station and turn the key to the ON position.

2 Press and hold the Hall Call button until the cab stops at your landing. To

stop the cab at any point simply release the Hall Call button.

3 Turn the key (if equipped) to the OFF position and remove the key.

4 If required, turn the door handle and pull the door open.

5 Once inside the cab, insert the key (if equipped) into the key switch, and

turn the key to the ON position.

If the elevator is equipped with our Automatic Pro-Door follow this procedure:

• Stay clear of the swing of the landing door as the door will swing open

automatically. The door is timed to stay open for a few seconds. Enter

the cab. Once inside the cab, lock the wheelchair wheels.

If the elevator is equipped with our Manual Pro-Door follow this procedure:

• Pull on the door handle and open the landing door. Enter the cab.

Once inside the cab, close the landing door. Lock the wheelchair

wheels.

NOTE

When using the landing controls, the cab can only be moved

(called) to the level from which you are calling. When using the

control buttons in the cab, the cab can be moved to any level.

WARNING

Wheelchair wheels must be locked at all times when the

elevator is moving.

Prolift SCL/Prolift HD Owner’s Manual Part No. 000782, 29-m08-2018

11

Operating from the Cab Operating Panel (COP) Controls

1 If equipped with a key switch, insert the key into the key switch on the Cab

Operating Panel and turn the key to the ON position.

2 Press and hold the selected Landing button to move the elevator. Maintain

constant pressure until the elevator automatically stops at the desired

landing. To stop the elevator at any point, simply release the Landing

button.

3 Release the Landing button when the elevator arrives at the landing.

4 Turn the key (if equipped) to the OFF position and remove the key.

5 Unlock the wheelchair wheels and exit the cab (if applicable).

If the elevator is equipped with our Automatic Pro-Door follow this procedure:

• The door will “chime” and then swing open automatically. The door is

timed to stay open for a few seconds. Exit the cab. The door will close.

If the elevator is equipped with our Manual Pro-Door follow this procedure:

• Open the manual swing landing door. Exit the cab. Close the landing

door.

5. POWER FAILURE AND EMERGENCY LOWERING

In the event of a power failure, the elevator is equipped with a Battery Back-Up

system that allows the user to lower the elevator from the inside of the cab. This

device operates on batteries and is only activated if a main power supply failure

occurs. The operation is as follows:

1 For elevators with automatic operation, press any Landing button below

the floor where the elevator is located.

2 For elevators with constant pressure operation, press any Landing button

below the floor where the elevator is located and maintain constant

pressure until the cab is level with the lower landing.

3 On arrival at the selected floor, the landing door will automatically unlock.

4 Release the Landing button, remove the key, and exit the cab.

6. EMERGENCY LIGHTING

In the event of a main power failure, the emergency cab light will turn on

automatically.

Part No. 000782, 29-m08-2018 Prolift SCL/Prolift HD Owner’s Manual

12

7. MANUAL LOWERING DEVICE (MACHINE ROOM)

In the event of a power failure, the cab can be moved to a lower level manually

by using the following procedure:

1 Obtain the key to unlock the door to the machine room where the elevator

pump unit is located (if applicable).

2 Instruct the passenger s) in the elevator to remain calm and stay well back

from the door of the elevator. Ease their concern by telling them your

intentions.

3 Switch the main disconnect switch for the main power supply to the

elevator pump unit to the “OFF” position.

4 If equipped, use the owner’s key to

Figure 3: EPV Valve

unlock the Controller Tank cover. The

EPV Valve is located inside.

5 Locate the RED manual release knob

on the EPV Valve and pull the knob to

lower the cab (refer to Figure 3).

Maintain a constant pull on the knob

until the elevator reaches the lowest

landing and stops automatically.

(Although you may not be able to see

the elevator, this is readily detected,

as there will be no further noise as

the oil flows to the reservoir).

6 To exit the cab, open the lower

landing door (using the special key) Manual release knob

and assist the passenger(s). (pull to lower cab)

7 After the passenger has exited the

cab, remove the cab key. Make sure the landing door is closed, reconnect

the disconnect switch in the machine room, and lock the door.

NOTE

After use of any emergency function (access key or manual lowering

device), ensure that all doors/gates are secure and locked. While the

emergency function is in use, DO NOT leave the area unattended.

Prolift SCL/Prolift HD Owner’s Manual Part No. 000782, 29-m08-2018

13

8. EMERGENCY HANDS-FREE PHONE (OPTIONAL)

1 If your lift is equipped with an Emergency Hands-Free Telephone, press and

hold down the Alarm button to activate the phone line. A short time delay

(adjustable by the installing technician) will occur.

2 Release the Alarm button once the call is picked up by the telephone line.

The system will automatically dial out to a pre-programmed telephone number

as set up by the installing technician.

9. MAINTENANCE

Regular maintenance (performed by your Authorized Savaria Dealer) will keep

your elevator in proper operating condition. As the owner of this elevator, you

are responsible for making sure that maintenance and upkeep are done on a

regularly scheduled basis. To ensure proper operating condition of your unit,

the items listed below must be inspected and, if necessary, serviced at least

twice per year. Additional inspections may be required depending on usage.

NOTE

Units installed in adverse environments will require additional

maintenance on a monthly basis.

IMPORTANT: Please test the phone in your elevator during every maintenance.

If the phone is inactive, please shut down the elevator until the phone line is

active.

1 Tighten all rail and cab fastening bolts.

2 Lubricate the door hinges and adjust the door closure if required.

3 Lubricate the rails with light grease, such as white lithium.

4 Inspect the travelling cable for wear. Replace the cable if any cuts or damage

to the jacket are evident.

5 Inspect the elevator cables for wear or damage and replace if necessary.

Always replace the safety washers at the swaged end of the cable when

replacing cables. The washers are provided with replacement cables.

6 Inspect the safety washers at the swaged end of the elevator cables. Put the

elevator on slack rope high enough so you can safely get under the elevator.

Pull the manual lowering device so there is enough slack in the rope to pull

the rope with the swag fitting down to view the washer. Replace the washer

if there is any visible damage.

Part No. 000782, 29-m08-2018 Prolift SCL/Prolift HD Owner’s Manual

14

7 Check for any hose/pipe leaks. Replace and/or tighten the fittings to correct

any hydraulic leaks found.

8 Check the fluid level of the pump reservoir (with the elevator at its lowest

landing), and fill as required. (Use Grade 32 Hydraulic Oil). There must be at

least 1” inch of oil on the dipstick.

9 Tighten any hose connections or bleeder valves found loose. Check the

hydraulic cylinder (jack) for any leaks. If necessary, the packing seals may

have to be replaced.

10 Replace the batteries inside the control panel as indicated on the battery

label.

11 To perform the required maintenance to the door locks, contact your

Authorized Savaria Dealer.

12 Activate and test the safety mechanism.

13 Check that the phone is functioning properly.

WARNING

Never adjust the pump controls or valve settings. This

must be done by an Authorized Savaria Dealer.

Prolift SCL/Prolift HD Owner’s Manual Part No. 000782, 29-m08-2018

15

Maintenance Record

Date Time Reason for Call Comments Dealer

Part No. 000782, 29-m08-2018 Prolift SCL/Prolift HD Owner’s Manual

Prolift SCL/Prolift HD

Accessibility Lifts

OWNER’S MANUAL

Part No. 000782

Copyright 2018

Savaria Concord Lifts, Inc.

2 Walker Drive

Brampton, Ontario, L6T 5E1, Canada

www.savaria.com

For service or questions about this product, please contact your installing dealer.

DEALER NAME: _________________________________________________

DEALER PHONE: _________________________________________________

You might also like

- Orion Owners Manual 000586Document16 pagesOrion Owners Manual 000586mohammedalathwaryNo ratings yet

- Infinity Elevator Owner's ManualDocument20 pagesInfinity Elevator Owner's Manualolivier.bigouretNo ratings yet

- Eclipse Owner's ManualDocument16 pagesEclipse Owner's ManualTek tek hapNo ratings yet

- Owner'S Manual: Inclined Platform LiftDocument16 pagesOwner'S Manual: Inclined Platform LiftElla MariaNo ratings yet

- Orion LULA Elevator Owner's ManualDocument16 pagesOrion LULA Elevator Owner's Manualolivier.bigouretNo ratings yet

- Zenith Elevator Owner's ManualDocument20 pagesZenith Elevator Owner's Manualolivier.bigouretNo ratings yet

- Ecoquest Air PurifierDocument9 pagesEcoquest Air Purifierjuanita norealnameaNo ratings yet

- DMX Operator Pro: User ManualDocument40 pagesDMX Operator Pro: User Manualrp1858009462No ratings yet

- EIKILC-XT4U LCD Projector Service ManualDocument160 pagesEIKILC-XT4U LCD Projector Service Manualcoldfusion161No ratings yet

- D1252C RIP Roller Idler Press - Complete Manual PDFDocument29 pagesD1252C RIP Roller Idler Press - Complete Manual PDFmarlon diazNo ratings yet

- Color Monitor: Service ManualDocument24 pagesColor Monitor: Service ManualStefano PartexanoNo ratings yet

- Satellite Controller: MODEL 3187Document36 pagesSatellite Controller: MODEL 3187Jan ZmudaNo ratings yet

- Philips PM3380 Users ManualDocument297 pagesPhilips PM3380 Users ManualDRF2540% (1)

- LUDP8997SNDocument107 pagesLUDP8997SNUtilisateurNo ratings yet

- Manual Colisionador Umf1Document78 pagesManual Colisionador Umf1wolf125No ratings yet

- Color Monitor: Service ManualDocument35 pagesColor Monitor: Service ManualReparatii Calculatoare TimisoaraNo ratings yet

- ADL200G Series Frequency Converter Operation ManualDocument180 pagesADL200G Series Frequency Converter Operation ManualAbenetherNo ratings yet

- CQ6280 For BJ-32120 Manual TornoDocument81 pagesCQ6280 For BJ-32120 Manual TornoJuan Daniel Frias Sosa100% (1)

- Aseptico DTC Motor l6cfm45 en 1402Document20 pagesAseptico DTC Motor l6cfm45 en 1402ilietisbitulNo ratings yet

- Alarma Crime Guard 830i6 (Instalacion)Document22 pagesAlarma Crime Guard 830i6 (Instalacion)stecamheNo ratings yet

- PALLET STRETCH WRAPPING MACHINE OPERATION GUIDEDocument39 pagesPALLET STRETCH WRAPPING MACHINE OPERATION GUIDEtrutleptNo ratings yet

- Jt100 - Operators ManualDocument268 pagesJt100 - Operators ManualMarcelo MalagoNo ratings yet

- SN 74 LVC 1 G 32Document34 pagesSN 74 LVC 1 G 32Sebastian QuaroneNo ratings yet

- Monitor Ab 6186-M15altrDocument64 pagesMonitor Ab 6186-M15altrJulianJucazaNo ratings yet

- 2160a Manual CompletoDocument64 pages2160a Manual CompletoJohny Joel GallardoNo ratings yet

- Recloser S280771Document52 pagesRecloser S280771Gamal YonesNo ratings yet

- Nuova Simonelli Auralia - Instruction ManualDocument36 pagesNuova Simonelli Auralia - Instruction ManualSteve Sullivan-LanphierNo ratings yet

- Bromma TukanDocument430 pagesBromma TukanNgà NguyễnNo ratings yet

- Cursus Hinowa GL17.75 S3Document129 pagesCursus Hinowa GL17.75 S3Folkwin LapNo ratings yet

- Hypervsn Operating ManualDocument39 pagesHypervsn Operating ManualAvinash TiwariNo ratings yet

- Acom 1010Document20 pagesAcom 1010Carlos Henrique MonteiroNo ratings yet

- Conventional Fire AlarmDocument24 pagesConventional Fire Alarmlouie starNo ratings yet

- Spreader GottwaldDocument448 pagesSpreader Gottwaldkron32100% (1)

- HyundaiWia - SKT100 200 CNC Installation MaintenanceDocument283 pagesHyundaiWia - SKT100 200 CNC Installation Maintenanceaoaby100% (1)

- Avr 1612 1622Document146 pagesAvr 1612 1622Ronald100% (1)

- E E E - Flo® Flo® Flo® DC DC DC 2000, 2000, 2000, 3000, 3000, 3000, and and and 4000 4000 4000 Circulation Circulation Circulation Pumps Pumps PumpsDocument80 pagesE E E - Flo® Flo® Flo® DC DC DC 2000, 2000, 2000, 3000, 3000, 3000, and and and 4000 4000 4000 Circulation Circulation Circulation Pumps Pumps Pumpspavel josé olivo rangelNo ratings yet

- HTC 1200Document14 pagesHTC 1200Dina LydaNo ratings yet

- Actuator CatalogDocument71 pagesActuator CatalogaquinorickyNo ratings yet

- Volvo EC210BDocument12 pagesVolvo EC210BStroia Constantin Marius78% (27)

- Steiner 525 OpDocument34 pagesSteiner 525 OpMuhamad Nur Firdaus100% (1)

- Berkeley Nucleonics 745Document33 pagesBerkeley Nucleonics 745enticoNo ratings yet

- User Manual Stairlift EssentialDocument16 pagesUser Manual Stairlift EssentialMirko Mejias SotoNo ratings yet

- CAT MD6240 - 6290 - Manual InglésDocument228 pagesCAT MD6240 - 6290 - Manual InglésJORGE C. CHAO R.100% (3)

- Screenland 26M911 PDFDocument63 pagesScreenland 26M911 PDFJacques51No ratings yet

- E74h IbmDocument37 pagesE74h IbmJose BerrospiNo ratings yet

- HoHsingHVP 70manual PDFDocument32 pagesHoHsingHVP 70manual PDFAmbar PrihatmantoNo ratings yet

- TC Electronic M-One XL Manual EnglishDocument46 pagesTC Electronic M-One XL Manual EnglishmarkocioNo ratings yet

- KET-3000W4 S-Mini AC Drive ManualDocument127 pagesKET-3000W4 S-Mini AC Drive ManualShashikant PatilNo ratings yet

- PIM Master Anritsu MW82119BDocument20 pagesPIM Master Anritsu MW82119Bwilliamr5070No ratings yet

- Phobos BT: Electromechanical Low-Voltage Automation For Swing GatesDocument9 pagesPhobos BT: Electromechanical Low-Voltage Automation For Swing GatesIoan PascuNo ratings yet

- Magnetic Particle Equipment Selection GuideDocument16 pagesMagnetic Particle Equipment Selection GuideWellington S. FrançaNo ratings yet

- Stryker X7000 ManualDocument38 pagesStryker X7000 Manualbuspers100% (2)

- VOLVO EC290B EXCAVATOR SPECSDocument12 pagesVOLVO EC290B EXCAVATOR SPECSfilipericardodi124780% (5)

- EH5U Liebherr Eng 00 PDFDocument418 pagesEH5U Liebherr Eng 00 PDFDucthien VoNo ratings yet

- Cutter User's Manual: Setup, Operation & Maintenance GuideDocument38 pagesCutter User's Manual: Setup, Operation & Maintenance GuideNagaKBNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Start Up Routine OVF10 PDFDocument12 pagesStart Up Routine OVF10 PDFEng M ElseaidyNo ratings yet

- MFR Connection DiagramDocument1 pageMFR Connection DiagramCharefNo ratings yet

- User Manual: Door Detector G5 Series With Power SupplyDocument4 pagesUser Manual: Door Detector G5 Series With Power SupplyRoselle SantiagoNo ratings yet

- Gba 26800 H II Startup PDFDocument15 pagesGba 26800 H II Startup PDFJms QuinteroNo ratings yet

- Control Systems Comparison TableDocument2 pagesControl Systems Comparison TableMohammed Qaid AlathwaryNo ratings yet

- Monarch-Nice 1000 Electric Drawing PDFDocument9 pagesMonarch-Nice 1000 Electric Drawing PDFGalang AntoNo ratings yet

- Heytech Hsi User ManuelDocument24 pagesHeytech Hsi User ManuelMohammed Qaid AlathwaryNo ratings yet

- OTIS Elevator Fault CodeDocument2 pagesOTIS Elevator Fault CodeMohammed Qaid Alathwary100% (1)

- Otis NCE506A Maintenance GeneralDocument8 pagesOtis NCE506A Maintenance GeneralMohammed Qaid AlathwaryNo ratings yet

- Otis+Elevator+Fault+Code+Lcb 2+Tcbc+Gecb+BoardDocument3 pagesOtis+Elevator+Fault+Code+Lcb 2+Tcbc+Gecb+BoardMohammed Qaid AlathwaryNo ratings yet

- Sigma Error CodesDocument8 pagesSigma Error Codesyuriska wahyu17No ratings yet

- Control electronic door operator C4T in 40 charactersDocument2 pagesControl electronic door operator C4T in 40 charactersAnonymous 0QeJ6DxMaKNo ratings yet

- LC1F630 Schneider Electric Datasheet 140218681Document3 pagesLC1F630 Schneider Electric Datasheet 140218681Mohammed Qaid AlathwaryNo ratings yet

- Otis Ovfr2b 403 Aaa21310adDocument7 pagesOtis Ovfr2b 403 Aaa21310adMohammed Qaid AlathwaryNo ratings yet

- Planar Loothru td3200 User ManualDocument16 pagesPlanar Loothru td3200 User ManualMohammed Qaid AlathwaryNo ratings yet

- OTIS AT120 System Adjusting Manual in English VersionDocument1 pageOTIS AT120 System Adjusting Manual in English VersionMohammed Qaid AlathwaryNo ratings yet

- Monarch Service Tool MDKE6 Guide ManualDocument2 pagesMonarch Service Tool MDKE6 Guide ManualMohammed Qaid Alathwary0% (1)

- Igbt ToshibaDocument11 pagesIgbt ToshibaMohammed Qaid AlathwaryNo ratings yet

- MACH3 - Basic SettingDocument5 pagesMACH3 - Basic SettingMohammed Qaid AlathwaryNo ratings yet

- Off-Grid InverterDocument1 pageOff-Grid InverterMohammed Qaid AlathwaryNo ratings yet

- One-Dooraccesscont R Ol L Er: 2.I NST Al L at I Onsgui deDocument2 pagesOne-Dooraccesscont R Ol L Er: 2.I NST Al L at I Onsgui deMohammed Qaid AlathwaryNo ratings yet

- Variador Otis Regen en InglésDocument138 pagesVariador Otis Regen en InglésAnonymous Mike88% (8)

- Orona 3g 6014 Assemply InstructionDocument3 pagesOrona 3g 6014 Assemply Instructionlotf hamood50% (2)

- Heat Exchanger: Application Manual NX Liquid-Cooled Frequency ConvertersDocument54 pagesHeat Exchanger: Application Manual NX Liquid-Cooled Frequency ConvertersMohammed Qaid AlathwaryNo ratings yet

- Technical IssueDocument1 pageTechnical IssueMohammed Qaid AlathwaryNo ratings yet

- Vacon Lift: User'S ManualDocument53 pagesVacon Lift: User'S ManualMohammed Qaid AlathwaryNo ratings yet

- 15886-kjch Sgmldiag PDFDocument50 pages15886-kjch Sgmldiag PDFAnonymous F5vymvFINo ratings yet

- ARD Enquiry Form For TractionDocument1 pageARD Enquiry Form For TractionFazilNo ratings yet

- Variador Otis Regen en InglésDocument138 pagesVariador Otis Regen en InglésAnonymous Mike88% (8)

- Regen Drive UK PDFDocument2 pagesRegen Drive UK PDFAliRouyouNo ratings yet

- Final test grammar and vocabulary practiceDocument5 pagesFinal test grammar and vocabulary practicexico_euNo ratings yet

- CaffeineDocument2 pagesCaffeineSaini Malkeet100% (1)

- Administrator Guide: Document Version 3.6.1Document76 pagesAdministrator Guide: Document Version 3.6.1App PackNo ratings yet

- Refunds Maceda Law and PD957Document2 pagesRefunds Maceda Law and PD957QUINTO CRISTINA MAENo ratings yet

- Method of Statement For ELV SystemDocument7 pagesMethod of Statement For ELV SystemKo ZayNo ratings yet

- Underwater Cutting and Welding Equipment - 89250054 - AbDocument38 pagesUnderwater Cutting and Welding Equipment - 89250054 - AbAhmed Adel100% (1)

- Iccmrt HR Role Play CaseDocument2 pagesIccmrt HR Role Play CaseJoshua RichardsNo ratings yet

- Body PlanesDocument32 pagesBody PlanesStefanny Paramita EupenaNo ratings yet

- Partnership Dissolution QuizDocument8 pagesPartnership Dissolution QuizLee SuarezNo ratings yet

- PROGRAM DESIGN TOOLS LESSONDocument10 pagesPROGRAM DESIGN TOOLS LESSONDun kithekaNo ratings yet

- Modern tobacco marketing fundamentalsDocument6 pagesModern tobacco marketing fundamentalsAbdus SalamNo ratings yet

- Shahrzadgh InquiryassignmentDocument5 pagesShahrzadgh Inquiryassignmentapi-274076411No ratings yet

- Call For Applications To JASTIP-Net 2021 Guidelines For ApplicantsDocument6 pagesCall For Applications To JASTIP-Net 2021 Guidelines For ApplicantsNadya IrsalinaNo ratings yet

- Keerai BenefitsDocument3 pagesKeerai BenefitsjnaguNo ratings yet

- Soal Mid Ganjil 14Document4 pagesSoal Mid Ganjil 14Anonymous a2C6YgevfNo ratings yet

- Research Project On Capital PunishmentDocument6 pagesResearch Project On Capital PunishmentNitwit NoddyNo ratings yet

- 1.1.5.a Elisa-3Document3 pages1.1.5.a Elisa-3Zainab DioufNo ratings yet

- Quality Improvement Methodologies - PDCA Cycle RAD PDFDocument9 pagesQuality Improvement Methodologies - PDCA Cycle RAD PDFherita suasantaNo ratings yet

- CAE Proposal Expressions and SamplesDocument6 pagesCAE Proposal Expressions and SamplesKimLiênNguyễnNo ratings yet

- Theory of Machines Kinematics FundamentalsDocument31 pagesTheory of Machines Kinematics FundamentalsmungutiNo ratings yet

- Catalogue of Turkic Language BooksDocument26 pagesCatalogue of Turkic Language BooksBerhiv Şilan BiliciNo ratings yet

- The Structure of PoetryDocument3 pagesThe Structure of PoetryRose Razo100% (1)

- Syllabus Changes: March 2021 Version 1Document20 pagesSyllabus Changes: March 2021 Version 1Azul IrlaundeNo ratings yet

- Placement Test: VocabularyDocument6 pagesPlacement Test: VocabularyRachel*No ratings yet

- GJ ScriptDocument83 pagesGJ ScriptKim LawrenceNo ratings yet

- L-1 Preparation of Gases MCQDocument31 pagesL-1 Preparation of Gases MCQapi-233604231No ratings yet

- Pricelist PT SCB Maret 2023Document11 pagesPricelist PT SCB Maret 2023PT RUKUN CAHAYA ABADINo ratings yet

- Use of VariablesDocument5 pagesUse of VariablesJohn Clyde RanchezNo ratings yet

- Distribution and Production of Rice in IndiaDocument6 pagesDistribution and Production of Rice in IndiaZehan SheikhNo ratings yet

- Facilitating Learner Centered Teaching FinalsDocument3 pagesFacilitating Learner Centered Teaching FinalsPatricia Andrei De GuzmanNo ratings yet