Professional Documents

Culture Documents

Umatic Ux1000 Underground Core Drilling Rig: Partner of Advanced Drilling Solutions

Uploaded by

Sugeng Ciko Darminto0 ratings0% found this document useful (0 votes)

41 views4 pagesOriginal Title

AMMECO UM1000

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views4 pagesUmatic Ux1000 Underground Core Drilling Rig: Partner of Advanced Drilling Solutions

Uploaded by

Sugeng Ciko DarmintoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

UMATIC UX1000

Underground Core Drilling Rig

Partner of advanced drilling solutions

www.ammeco.com

Power unit

The standard power unit is electric, which is fit for typical

underground applications. Diesel version power pack is

also available according to specific application need.

OVERVIEW:

Power rating ...................................... 75KW/1450RPM

The UX1000 is an underground type of coring drill rig for Main pump max flow .......................... 160 l/m

drilling medium to deep holes, capable of drilling for both Main pump max pressure .................. 300 Bar

surface and underground applications. Service pump max flow ..................... 40.5 l/m

Service pump max pressure .............. 300 Bar

The drill is compact and modular design with flexible Weight ............................................... 980Kg

maneuverability for convenience to meet specific needs of LxWxH ............................................... 1845x790x1380 mm

operating conditions.

With the use of a hydraulic-operated positioner and a fast

calibrating turntable, the drill is easy for set up and capable

of drilling holes in all angles. The unique positioning Feed length ........................ 1800mm, hydraulic cylinder.

mechanism requires no moving of the wireline hoist, from Feed length.......................... 1800 (mm)

vertically up to vertically down. Feed frame length ............... 2900 (mm)

Extension mast length…...... 2000 (mm)

Equipped with a robust cylinder-driven feed frame and a Feed force ........................... 89 (kN)

75KW (optional for 90KW) power pack, this drill provides Pull force ............................. 89 (kN)

high pullback force, fast drilling penetration and quick rod- Feed speed.......................... 0.9 (m/s)

handling rate. The drill uses an electric motor (optional for

diesel) to power the hydraulics on the machine.

The rod holder is hydraulically opened and gas-pressure

closed. In case of loss of hydraulic pressure the rod holder

FEATURES: closes instantly. The gas pressure can be conveniently

monitored.

The classic Canadian-origin 12HH chuck and rotation

unit provides expectation for outstanding reliability and

performance in the industry. The integrated gearbox is

two-speed and fully variable-control with an Max rod size ........................ 89mm

independent lubrication system offering increased Bore(without jaws) .......... 102mm

controllability and longer service intervals. Bore(without covers)…... 170mm

Axial holding force ............... 45kN

The rod holder, which is fully synchronized with the Axial holding force (TC)…… 90kN

chuck, is operated by a hydraulic cylinder (opening)

and a long life Nitrogen spring (closing) ensuring high

clamping force and quick closing action as well as

improved control and decreased service needs.

The rigid but lightweight feed frame guard prevents

risks of accidents. It is easy for manual positioning at

any of the several retaining points.

The control panel is pilot-hydraulic-control design

equipped with user-friendly interface and monitoring

gauges. The buttons and knobs are well crafted for

hand comfort and operation accuracy providing

excellent ergonomic control of the rig, as well as

improved safety and productivity.

E-stop buttons on the control panel and the drill rig

ensure urgent system shutoff against accidental

situations.

The rotation unit is capable of handling B-H rods with

optional alternative for P rods. The rotation unit consists

of a hydraulic motor, a two-speed gearbox, and a 12 HH

hydraulic chuck. The chuck closes to hold the rod by

hydraulic pressure, and opens to release by spring force.

Capacity ...................................... 1000m,4.75mm

Pull min ....................................... 3600 N (full drum) B

Pull max ...................................... 9700 N (empty drum)

Line speed min ............................ 1.8 m/s (empty drum)

Line speed max ........................... 4.8 m/s (full drum)

Type ............................................ FMC/AW 1122BCD

Maximum flow ............................. 140 l/m

Maximum pressure ...................... 70 Bar

The control panel is pilot-hydraulic-control design,

which is compact and lightweight. The PHC control

panel is equipped with user-friendly interface and

monitoring gauges. The buttons and knobs are well

crafted for hand comfort and operation accuracy D

providing excellent ergonomic control of the rig, as well

as improved safety and productivity.

A

E-stop button is set for easy access to ensure operation

safety.

BQ .................................................. 960 m

NQ ................................................. 760 m

HQ ................................................. 520 m

........................... 2100Kg

Depth capacity is subject to drilling application and site

conditions.

Ammeco Exploration Equipment Technology

A-1311 Jinhai Fortune Business Center, No.21 Guangqu Rd,

Beijing, China

Tel: 86-10-59574810

Fax: 86-10-59574989

www.ammeco.com Partner of advanced drilling solutions

You might also like

- Volvo EC210BDocument12 pagesVolvo EC210BStroia Constantin Marius78% (27)

- Product Catalog For CrossoverDocument52 pagesProduct Catalog For CrossoverSerkan Cenberlitas100% (4)

- Piloteadora PDFDocument514 pagesPiloteadora PDFoscar el carevergaNo ratings yet

- V Ew160 215 1147 0105Document10 pagesV Ew160 215 1147 0105Jozef75% (4)

- Net Flywheel Power 118 KW - 158 HP Max Operating Weight 23 310 KG Bucket Capacity 0.52 - 1.31 MDocument10 pagesNet Flywheel Power 118 KW - 158 HP Max Operating Weight 23 310 KG Bucket Capacity 0.52 - 1.31 MOliver MoraNo ratings yet

- Lightweight portable diamond drill rigDocument2 pagesLightweight portable diamond drill rigSugeng Ciko DarmintoNo ratings yet

- Lightweight portable diamond drill rigDocument2 pagesLightweight portable diamond drill rigSugeng Ciko DarmintoNo ratings yet

- Lightweight portable diamond drill rigDocument2 pagesLightweight portable diamond drill rigSugeng Ciko DarmintoNo ratings yet

- Hussain Rabia - Drill Bits (Chapter 9)Document44 pagesHussain Rabia - Drill Bits (Chapter 9)Andreas Ansen VitalisNo ratings yet

- V Ec290 213 1619 0008 PDFDocument12 pagesV Ec290 213 1619 0008 PDFSunil Kathat50% (2)

- Data Sheet EC290 PDFDocument12 pagesData Sheet EC290 PDFnay thureinNo ratings yet

- RoofBolter - Technical Specification-FinalDocument5 pagesRoofBolter - Technical Specification-FinalSushantNo ratings yet

- Komatsu 930E - 4SEDocument4 pagesKomatsu 930E - 4SECarlos ChavezNo ratings yet

- KG 850,650 LB: Maximum GVWDocument4 pagesKG 850,650 LB: Maximum GVWVasquez EjvbNo ratings yet

- VOLVO EXCAVATOR EC460 LONG CRAWLERDocument10 pagesVOLVO EXCAVATOR EC460 LONG CRAWLERMaria Da Graça RomãoNo ratings yet

- 30 Metric Tonne 33 Short Ton Payload - 13.5 M 17.6 Yd CapacityDocument2 pages30 Metric Tonne 33 Short Ton Payload - 13.5 M 17.6 Yd CapacityRasoolKhadibiNo ratings yet

- Powerful Mini ExcavatorDocument8 pagesPowerful Mini ExcavatorShailesh Khodke100% (1)

- Komatsu 730 eDocument4 pagesKomatsu 730 eFranco Rojas BozaNo ratings yet

- 50 Metric Tonne 55 Short Ton Payload - 28 M 36.6 Yd CapacityDocument2 pages50 Metric Tonne 55 Short Ton Payload - 28 M 36.6 Yd CapacitynambiiasNo ratings yet

- Dux Scaler Spec Sheet - Fix Cab PDFDocument2 pagesDux Scaler Spec Sheet - Fix Cab PDFvivalpsNo ratings yet

- Catalogo PC4000 PDFDocument8 pagesCatalogo PC4000 PDFErick Parra100% (1)

- V Ec360 212 1620 0009 PDFDocument12 pagesV Ec360 212 1620 0009 PDFJessica NoriegaNo ratings yet

- Atlas Copco Off Highway Dump Trucks Spec 11ece7Document4 pagesAtlas Copco Off Highway Dump Trucks Spec 11ece7Fazal AhmedNo ratings yet

- PC5500-6 Mining Shovel: 531-549 Ton 1,170,000-1,210,000 LBDocument8 pagesPC5500-6 Mining Shovel: 531-549 Ton 1,170,000-1,210,000 LBcristiannnnnnnnnnNo ratings yet

- Komatsu Pala Pc4000Document8 pagesKomatsu Pala Pc4000Franco Rojas BozaNo ratings yet

- 6.4 Metric Tonne 7.0 Short Ton Payload - 3.8 M 5.0 Yd CapacityDocument2 pages6.4 Metric Tonne 7.0 Short Ton Payload - 3.8 M 5.0 Yd CapacitynambiiasNo ratings yet

- PC8000 6 HandbookDocument8 pagesPC8000 6 Handbookmmaidana2001100% (2)

- KG 650,000 LB 172 T 190 U.S. Ton 1491 KW 2,000 HP: Maximum GVW Payload Gross HorsepowerDocument4 pagesKG 650,000 LB 172 T 190 U.S. Ton 1491 KW 2,000 HP: Maximum GVW Payload Gross HorsepowerJavierPariNo ratings yet

- EC460B LC: Volvo ExcavatorDocument16 pagesEC460B LC: Volvo ExcavatorAvaa AmgaaNo ratings yet

- PC5500 PDFDocument8 pagesPC5500 PDFFelipe Quezada CastañedaNo ratings yet

- PC4000 6Document8 pagesPC4000 6Sergio Velarde RomayNo ratings yet

- V Ec160blc NLC 21d1000548 2005 12Document16 pagesV Ec160blc NLC 21d1000548 2005 12waqsa.ahmadjNo ratings yet

- PC2000 11Document6 pagesPC2000 11arun_anuNo ratings yet

- Spec EC460B INT EN 30E4351646Document16 pagesSpec EC460B INT EN 30E4351646Stroia Constantin MariusNo ratings yet

- PC3000 6 PDFDocument8 pagesPC3000 6 PDFRocioSanchezCalderonNo ratings yet

- Compact underground dump truck specsDocument2 pagesCompact underground dump truck specsnambiiasNo ratings yet

- 26 Metric Tonne 28.6 Short Ton Payload - 12.0 M 15.7 Yd CapacityDocument2 pages26 Metric Tonne 28.6 Short Ton Payload - 12.0 M 15.7 Yd CapacitynambiiasNo ratings yet

- VOLVO EXCAVATOR EC210B GUIDEDocument16 pagesVOLVO EXCAVATOR EC210B GUIDEAna100% (1)

- Especificaciones Zaxis 210LCDocument4 pagesEspecificaciones Zaxis 210LCGustavo AlemanNo ratings yet

- VOLVO EC290B EXCAVATOR SPECSDocument12 pagesVOLVO EC290B EXCAVATOR SPECSfilipericardodi124780% (5)

- Spec EC210B INT EN 30E4351641Document12 pagesSpec EC210B INT EN 30E4351641Min Min SoeNo ratings yet

- Komatsu Pc5500 6Document8 pagesKomatsu Pc5500 6matt_alc100% (1)

- PC8000 (English)Document8 pagesPC8000 (English)CarlosBacaTorres100% (1)

- Komatsu Demag PC4000-6 Shovel - ACF4666Document8 pagesKomatsu Demag PC4000-6 Shovel - ACF4666Miomir Mikić100% (1)

- Fiat Kobelco Excavators SpecDocument12 pagesFiat Kobelco Excavators SpecMorad ZeroualNo ratings yet

- Volvo Excavator: BE Backhoe EquipmentDocument6 pagesVolvo Excavator: BE Backhoe EquipmentAbduNo ratings yet

- PC240LC NLC-7SLF UESS010100 10-2004 EnglishDocument8 pagesPC240LC NLC-7SLF UESS010100 10-2004 EnglishFadi JaberNo ratings yet

- 11 Metric Tonne 12 Short Ton Payload - 6.0 M 7.8 Yd CapacityDocument2 pages11 Metric Tonne 12 Short Ton Payload - 6.0 M 7.8 Yd CapacityGian RR.FF.No ratings yet

- Ec 360 SpecDocument12 pagesEc 360 SpecYahdi AzzuhryNo ratings yet

- EC290B LC Ec290B NLC: Monoblock/2-Piece BoomDocument12 pagesEC290B LC Ec290B NLC: Monoblock/2-Piece BoomClaret CastroNo ratings yet

- Foreløpig Brosjyre Komatsu PC88MR 10Document4 pagesForeløpig Brosjyre Komatsu PC88MR 10LU YONo ratings yet

- 33 Metric Tonne 36.4 Short Ton Payload - 19.6 M 25.7 Yd CapacityDocument2 pages33 Metric Tonne 36.4 Short Ton Payload - 19.6 M 25.7 Yd CapacitynambiiasNo ratings yet

- Bomba Hidráulica (Ppal) Serie 16.55 - 17.55 y 21.55 Sauer 90 PumpDocument63 pagesBomba Hidráulica (Ppal) Serie 16.55 - 17.55 y 21.55 Sauer 90 PumpIngenieriaNo ratings yet

- 1 Pump-90 Technical 10029 eDocument64 pages1 Pump-90 Technical 10029 eKadir Koray BozyelNo ratings yet

- Specsheet pc4000 EnglishDocument8 pagesSpecsheet pc4000 EnglishAhmad HisyamNo ratings yet

- PC3000-6 A4 9seiten InternetDocument9 pagesPC3000-6 A4 9seiten InternetAkhmad SebehNo ratings yet

- Carte Tehnica Excavator VolvoDocument12 pagesCarte Tehnica Excavator VolvoCiufudean AdrianNo ratings yet

- Komatsu PC8000 EnglishDocument11 pagesKomatsu PC8000 EnglishluisNo ratings yet

- SR15-PC210-8-SLF Long ArmDocument8 pagesSR15-PC210-8-SLF Long ArmReymond RoyNo ratings yet

- PC 3000 PDFDocument8 pagesPC 3000 PDFDashzeveg BayrsaikhanNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- 10 Frame Piston Pump: SpecificationsDocument4 pages10 Frame Piston Pump: SpecificationsSugeng Ciko DarmintoNo ratings yet

- Tap Drill SizesDocument2 pagesTap Drill SizeszeenewsNo ratings yet

- Hand TapsDocument17 pagesHand TapsIndra WibawaNo ratings yet

- Engine Cylinder LinersDocument23 pagesEngine Cylinder LinersSugeng Ciko DarmintoNo ratings yet

- Final Drive Part NoDocument1 pageFinal Drive Part NoSugeng Ciko DarmintoNo ratings yet

- LY 38 Drill Rig SpecDocument3 pagesLY 38 Drill Rig SpecSugeng Ciko DarmintoNo ratings yet

- Changsha Exploration Machinery Factory: Proforma InvoiceDocument1 pageChangsha Exploration Machinery Factory: Proforma InvoiceSugeng Ciko DarmintoNo ratings yet

- Final Drive1Document1 pageFinal Drive1Sugeng Ciko DarmintoNo ratings yet

- Piston Pump Service Manual: Installation and Start-Up InformationDocument8 pagesPiston Pump Service Manual: Installation and Start-Up InformationErik RodriguezNo ratings yet

- Drill Rod Size AfkosDocument2 pagesDrill Rod Size AfkosSugeng Ciko DarmintoNo ratings yet

- LY 38 Drill Rig SpecDocument3 pagesLY 38 Drill Rig SpecSugeng Ciko DarmintoNo ratings yet

- Detailed Product Description: Csd1800 SpecificationsDocument2 pagesDetailed Product Description: Csd1800 SpecificationsSugeng Ciko DarmintoNo ratings yet

- CoreBoss F14 RigDocument2 pagesCoreBoss F14 RigSugeng Ciko DarmintoNo ratings yet

- Atlas Copco Exploration Drilling Christensen CS14 Core DrillDocument2 pagesAtlas Copco Exploration Drilling Christensen CS14 Core DrillSugeng Ciko DarmintoNo ratings yet

- Drill Chuck Arbors and Adapters GuideDocument8 pagesDrill Chuck Arbors and Adapters GuideSugeng Ciko DarmintoNo ratings yet

- Tap Drill SizesDocument2 pagesTap Drill SizeszeenewsNo ratings yet

- Drill Rod Size AfkosDocument2 pagesDrill Rod Size AfkosSugeng Ciko DarmintoNo ratings yet

- Sprag Clutch MDocument56 pagesSprag Clutch MwasayNo ratings yet

- Piston Pump Service Manual: Installation and Start-Up InformationDocument8 pagesPiston Pump Service Manual: Installation and Start-Up InformationErik RodriguezNo ratings yet

- CAT Pump CatalogDocument20 pagesCAT Pump CatalogJayakrishnan RadhakrishnanNo ratings yet

- Thread Data Chart: British Thread (British Standard Fine) - Fine PitchDocument2 pagesThread Data Chart: British Thread (British Standard Fine) - Fine PitchSugeng Ciko DarmintoNo ratings yet

- Chain Couplings CR - EN PDFDocument16 pagesChain Couplings CR - EN PDFTriyo SusantoNo ratings yet

- Chapter 13 - Chain and SprocketsDocument78 pagesChapter 13 - Chain and SprocketsSugeng Ciko DarmintoNo ratings yet

- LM 75 Modular Core Drill: Technical Data SheetDocument4 pagesLM 75 Modular Core Drill: Technical Data SheetSugeng Ciko DarmintoNo ratings yet

- CoreBoss F14 RigDocument2 pagesCoreBoss F14 RigSugeng Ciko DarmintoNo ratings yet

- Bundox XT1000 SpecDocument2 pagesBundox XT1000 SpecSugeng Ciko DarmintoNo ratings yet

- 320XPC - Blasthole Drill - Spec SheetDocument4 pages320XPC - Blasthole Drill - Spec Sheetgoonzaalo_22No ratings yet

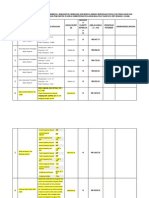

- Tender Specifications and Prices for Workshop Equipment ProcurementDocument12 pagesTender Specifications and Prices for Workshop Equipment ProcurementWak Tun0% (1)

- Tooling Modification of CNC - HBMDocument26 pagesTooling Modification of CNC - HBMpverma02No ratings yet

- Ruko Twist DrillsDocument80 pagesRuko Twist DrillsPeter NomikosNo ratings yet

- D36x50DRII SpecSheet 201604Document2 pagesD36x50DRII SpecSheet 201604IBS Soluciones CivilesNo ratings yet

- Plant Register TemplateDocument4 pagesPlant Register TemplateimamtaNo ratings yet

- Budget Racing Simulator CockpitDocument59 pagesBudget Racing Simulator CockpitCatalina FernandezNo ratings yet

- Feed DD321Document42 pagesFeed DD321Rene Ramos MenesesNo ratings yet

- Hilti Chemical Anchor SystemsDocument16 pagesHilti Chemical Anchor Systemsmiguelq_scribdNo ratings yet

- Atlas Copco CS4002 Core Drill Operator's ManualDocument146 pagesAtlas Copco CS4002 Core Drill Operator's ManualYuri SandersonNo ratings yet

- Bevin Skiff Building ManualDocument54 pagesBevin Skiff Building ManualKevin WilliamsNo ratings yet

- Terrier Rotary SpecificationDocument2 pagesTerrier Rotary Specificationliving goodNo ratings yet

- Catalogos Otto BockDocument31 pagesCatalogos Otto BockLuis Albano PobleteNo ratings yet

- MAY 2020 Surplus Record Machinery & Equipment DirectoryDocument716 pagesMAY 2020 Surplus Record Machinery & Equipment DirectorySurplus Record100% (1)

- TDS Nyxon Green LDocument2 pagesTDS Nyxon Green LBejinariu ValentinNo ratings yet

- 2016 RYOBI - POWERTOOLS - 2016 - Light PDFDocument44 pages2016 RYOBI - POWERTOOLS - 2016 - Light PDFProud BuddyNo ratings yet

- Owner's Manual: 1260 Holm Road, Suite C Petaluma, CA USA 94954 Phone 707-776-4500 FAX 707-776-4555Document32 pagesOwner's Manual: 1260 Holm Road, Suite C Petaluma, CA USA 94954 Phone 707-776-4500 FAX 707-776-4555cristian scharffNo ratings yet

- Mechanical Workshop Module - CompressedDocument78 pagesMechanical Workshop Module - CompressednanangasNo ratings yet

- Accessories Guide StandardDocument5 pagesAccessories Guide StandardRune ErikssonNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Saes Q 004Document24 pagesSaes Q 004AasimNo ratings yet

- Sandvik DP1500Document4 pagesSandvik DP1500soledad alvis arotaipeNo ratings yet

- Drilling&Connection PDFDocument199 pagesDrilling&Connection PDFRazvan RaduNo ratings yet

- Armature Specialist PDFDocument24 pagesArmature Specialist PDFsekhargm50% (2)

- Lokfix E75 TDS191018Document5 pagesLokfix E75 TDS191018msheshappaNo ratings yet

- Engineering Drill Press EssayDocument5 pagesEngineering Drill Press EssayChristopher Rayfus-WinstonNo ratings yet

- Find the Right Neobiotech Drill Kit Online in 40 CharactersDocument16 pagesFind the Right Neobiotech Drill Kit Online in 40 CharacterssalehalsadiNo ratings yet