Professional Documents

Culture Documents

General Rules of Sample Preparation of Coal Sample

Uploaded by

akloio0 ratings0% found this document useful (0 votes)

29 views1 pageOriginal Title

General rules of sample preparation of Coal Sample

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views1 pageGeneral Rules of Sample Preparation of Coal Sample

Uploaded by

akloioCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

General rules of sample preparation of Coal

Sample.

Any errors resulted from the sample preparation practice will remain in the

final sample. Therefore, the standard procedure to be used for sample

preparation should be carefully selected. Whenever possible, mechanical

methods are preferable to manual methods to minimize human error.

Sample preparation operations should be carried out by trained and

experienced personnel. Before preparing the sample, the number and nature

of the analysis and tests should be considered. A reserve sample is desirable in

case a check analysis or test is required.

The following precautions should be taken during sample preparation

• in collecting, handling and preparing the sample, all operations should be

done rapidly and in as few operations as possible to minimize possible coal

oxidation and changes in coal moisture content;

• the sample should be protected from moisture change due to exposure

to rain/snow, wind, sun, extreme temperatures, and from

contamination on contact with other material;

• Most coals oxidize on exposure to air and hence, the air-drying procedure

should not be prolonged past the time necessary for air-drying (follow the

procedure specified by the Standards). When the sample is air dried at

above ambient temperatures, the sample should be allowed to attain

ambient temperature before weighing and further reduction and division;

• Whenever the sample is stored or transported, the sample bag/container

should be weighed. The sample should be allowed to attain equilibrium to

the new atmosphere by air-drying and the weight Loss or gain should be

used in the calculation of moisture content;

• The sample bag/container should be strong and large enough for the largest

sample expected. After a Sample is stored; the sample bag/container should

be sealed properly;

• Loss of material during sample preparation should be avoided.

Prepared By: Ahmed Ismail

You might also like

- Sampling of Air: Pranay Krishnan MSC Evs Part Ii Roll No: 14Document44 pagesSampling of Air: Pranay Krishnan MSC Evs Part Ii Roll No: 14Pranay Krishnan100% (1)

- Water Sampling and Preservation Techniques: A.Gnanavelu CPCB, BangaloreDocument32 pagesWater Sampling and Preservation Techniques: A.Gnanavelu CPCB, BangaloreKashif Md 3NA16CV413100% (1)

- 4.3.2 Field Quality Assurance: Prevention of Sample Contamination and LossesDocument1 page4.3.2 Field Quality Assurance: Prevention of Sample Contamination and LossesthisiscookingNo ratings yet

- Collection of SamplesDocument20 pagesCollection of SamplesMuhammadUsmanNo ratings yet

- Practical Note Soils 509Document13 pagesPractical Note Soils 509Omprakash MeenaNo ratings yet

- Astm D3302-D3302M-12Document8 pagesAstm D3302-D3302M-12Sendy Arfian SaputraNo ratings yet

- Hygienic DesignDocument18 pagesHygienic DesignJosé Luis García PérezNo ratings yet

- Good Manufacturing Practicce: Pharmacy 5Document23 pagesGood Manufacturing Practicce: Pharmacy 5Fabulously ShooktNo ratings yet

- Total Moisture in Coal: Standard Test Method ForDocument7 pagesTotal Moisture in Coal: Standard Test Method ForroylesterlaraNo ratings yet

- 2017 - Water Sampling Protocols and HandlingDocument61 pages2017 - Water Sampling Protocols and HandlingaseascanNo ratings yet

- Basic Knowledge of CoalDocument86 pagesBasic Knowledge of CoalDwi Wahyu RamadhanNo ratings yet

- Adigrat UniversityDocument41 pagesAdigrat Universityaregawi selemonNo ratings yet

- Lec 4 MoistureDocument27 pagesLec 4 Moisturemamoonfareed20No ratings yet

- Lab Safety 1Document77 pagesLab Safety 1biomedlabsciNo ratings yet

- Topic 1.2 - Analytical ProcessDocument44 pagesTopic 1.2 - Analytical ProcessHaiqal Aziz100% (1)

- Collection and Preservation of Water SamplesDocument24 pagesCollection and Preservation of Water SamplesSyed Talha AhmedNo ratings yet

- D1348Document6 pagesD1348Ненад КнежевићNo ratings yet

- Lab Report PST Ex3Document6 pagesLab Report PST Ex3Nurin FalihahNo ratings yet

- USAID RISE - SOP On Medical Oxygen Sample Collection Using Tedlar BagDocument8 pagesUSAID RISE - SOP On Medical Oxygen Sample Collection Using Tedlar BagAhmed Abo FornNo ratings yet

- Environmental Engineering: Dr. Ramakrishna Bag Dept of Civil Engineering NIT RourkelaDocument25 pagesEnvironmental Engineering: Dr. Ramakrishna Bag Dept of Civil Engineering NIT Rourkelafaithconnors9100% (1)

- GPA Sampling Method (Scope, Definition, Principles, Safety)Document27 pagesGPA Sampling Method (Scope, Definition, Principles, Safety)Candra Aditya Wiguna100% (2)

- Sterilisation Practices: by Dr. Iyer Ranganathan N Global Hospitals HyderabadDocument44 pagesSterilisation Practices: by Dr. Iyer Ranganathan N Global Hospitals HyderabadRanganathan IyerNo ratings yet

- Ash Determination LectureDocument28 pagesAsh Determination LectureNasir AhmedNo ratings yet

- Microwave-Assisted Sample Digestion - Sample Preperation - 4Document19 pagesMicrowave-Assisted Sample Digestion - Sample Preperation - 4kasemelk1990No ratings yet

- D3302-Standard Test Method For Total Moisture in CoalDocument7 pagesD3302-Standard Test Method For Total Moisture in CoalPradjnaParamitaMichele100% (2)

- Methods of Determining Moisture ContentDocument4 pagesMethods of Determining Moisture ContentwycliffkamajowaNo ratings yet

- Lecture 2 J TanyanyiwaDocument20 pagesLecture 2 J TanyanyiwaRumbidzai MunguniNo ratings yet

- Presentation 8Document99 pagesPresentation 8Marry Jane Lustre CanabalNo ratings yet

- Celda Flash Site Skim Air Test Procedure With PhotosDocument9 pagesCelda Flash Site Skim Air Test Procedure With Photosealfaro6580No ratings yet

- Astm OvenDocument8 pagesAstm Ovennurul nabilah bt khairul anuarNo ratings yet

- General Guidelines To Assist With Microwave Digestion Method DevelopmentDocument20 pagesGeneral Guidelines To Assist With Microwave Digestion Method DevelopmentMichael Leyva100% (1)

- Sample Preparation and Assaying: G E. G, E V. P, W E. H, JDocument11 pagesSample Preparation and Assaying: G E. G, E V. P, W E. H, JAg Badia PatoNo ratings yet

- Chapter 4 - Basic Requirements For AnalysisDocument80 pagesChapter 4 - Basic Requirements For AnalysisSPMUSER9A100% (1)

- Standard Test Method For Moisture in The Analysis Sample of Coal and CokeDocument7 pagesStandard Test Method For Moisture in The Analysis Sample of Coal and CokemuchtarNo ratings yet

- Proximate AnalysisDocument29 pagesProximate AnalysisAhmad ArifNo ratings yet

- Method 1:0: Preparation of The Sample For AnalysisDocument4 pagesMethod 1:0: Preparation of The Sample For AnalysisgabisoNo ratings yet

- Environmental Analytical ChemistryDocument6 pagesEnvironmental Analytical ChemistrykatlegoNo ratings yet

- School of Chemistry SOP For Operation of Vacuum Pumps and Evacuated Apparatus V18.04Document3 pagesSchool of Chemistry SOP For Operation of Vacuum Pumps and Evacuated Apparatus V18.04Anand HSNo ratings yet

- Astm 4Document3 pagesAstm 4Generation Z -IbamNo ratings yet

- Total Suspended SolidsDocument3 pagesTotal Suspended SolidsOpata OpataNo ratings yet

- Guidelines For Soil and Groundwater Sampling - Brownfields/Voluntary Cleanup ProgramDocument3 pagesGuidelines For Soil and Groundwater Sampling - Brownfields/Voluntary Cleanup ProgramStiharu100% (1)

- Confined Space RescueDocument27 pagesConfined Space RescuePRITAM KUMARNo ratings yet

- Analysis of ASH and MINERALSDocument15 pagesAnalysis of ASH and MINERALSMuhammad Taha Jilani100% (1)

- Study The Effect of Material/temperature On Rate of DryingDocument23 pagesStudy The Effect of Material/temperature On Rate of DryingNayyerShahNo ratings yet

- Moisture Analysis 3 2 2Document22 pagesMoisture Analysis 3 2 2CArlosNo ratings yet

- SMWW 1060Document9 pagesSMWW 1060Helio C. SouzaNo ratings yet

- Unit 2 - Lect 3 Facilities and Environmental ConditionsDocument28 pagesUnit 2 - Lect 3 Facilities and Environmental ConditionsGarshel KellyNo ratings yet

- SamplingDocument47 pagesSamplingsatrio wekaNo ratings yet

- Kidd - Glencore - PPT - Welding Present. Rev4Document21 pagesKidd - Glencore - PPT - Welding Present. Rev4caterineflorezNo ratings yet

- Sop AirDocument28 pagesSop Airvarun awasthiNo ratings yet

- 0220 - Sop AutoclaveDocument6 pages0220 - Sop Autoclaveankit7588No ratings yet

- Assignment of Control TechniquesDocument15 pagesAssignment of Control TechniquesAnanda NairNo ratings yet

- Mapua University: Experiment No. 1Document11 pagesMapua University: Experiment No. 1Geojanni PangibitanNo ratings yet

- Astm D 2974 - 2020Document5 pagesAstm D 2974 - 2020Mohammed AliNo ratings yet

- MA1Document49 pagesMA1aregawi selemonNo ratings yet

- Sampling For Oil and Gas AnalysisDocument7 pagesSampling For Oil and Gas AnalysisBenito CameñaNo ratings yet

- Exp 6Document5 pagesExp 6sju65No ratings yet

- Sustainable Utilization of Carbon Dioxide in Waste Management: Moving Toward Reducing Environmental ImpactFrom EverandSustainable Utilization of Carbon Dioxide in Waste Management: Moving Toward Reducing Environmental ImpactNo ratings yet

- Air Content of Hydraulic Cement Mortar: Standard Test Method ForDocument4 pagesAir Content of Hydraulic Cement Mortar: Standard Test Method ForakloioNo ratings yet

- Determination of HGI in CoalDocument6 pagesDetermination of HGI in CoalakloioNo ratings yet

- Sampling and The Amount of Testing of Hydraulic Cement: Standard Practice ForDocument7 pagesSampling and The Amount of Testing of Hydraulic Cement: Standard Practice ForakloioNo ratings yet

- Heat of Hydration of Hydraulic Cement: Standard Test Method ForDocument7 pagesHeat of Hydration of Hydraulic Cement: Standard Test Method ForakloioNo ratings yet

- (TOTL-WI-13) Determination of Chloride in FertilizerDocument7 pages(TOTL-WI-13) Determination of Chloride in FertilizerakloioNo ratings yet

- Tankoil: Independent Inspection and Testing CompanyDocument20 pagesTankoil: Independent Inspection and Testing CompanyakloioNo ratings yet

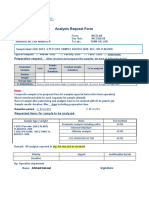

- Wednesday, August 12, 2020 200434 Yellow Corn 1: Date: Lab Ref. No.: Material: No. of Sample(s)Document1 pageWednesday, August 12, 2020 200434 Yellow Corn 1: Date: Lab Ref. No.: Material: No. of Sample(s)akloioNo ratings yet

- ISO - 589 - 2008 (En) - Total MoistureDocument16 pagesISO - 589 - 2008 (En) - Total Moistureakloio100% (2)

- Preparation of Test Samples and Typical Analysis of Solid FuelsDocument9 pagesPreparation of Test Samples and Typical Analysis of Solid FuelsakloioNo ratings yet

- 2226-Suez - 2 Petcoke Sample August On 31.08Document1 page2226-Suez - 2 Petcoke Sample August On 31.08akloioNo ratings yet

- Petcoke Raw Data SheetDocument6 pagesPetcoke Raw Data SheetakloioNo ratings yet

- 2249-Suez - 2 Petcoke Sample Sept 2020 - Rec. On 05.10.2020Document1 page2249-Suez - 2 Petcoke Sample Sept 2020 - Rec. On 05.10.2020akloioNo ratings yet

- AOAC 962.02 P2O5preparation of PhosphrousDocument1 pageAOAC 962.02 P2O5preparation of PhosphrousakloioNo ratings yet

- Aoac 962.02 P2o5Document1 pageAoac 962.02 P2o5akloioNo ratings yet

- (TOTL-WI-03) Determination of Total Moisture in CoalDocument7 pages(TOTL-WI-03) Determination of Total Moisture in CoalakloioNo ratings yet

- TOTL-WI-F12 Verification by Benzoic AcidDocument1 pageTOTL-WI-F12 Verification by Benzoic AcidakloioNo ratings yet

- (TOTL-WI-05) Determination of Gross Calorific Value by The Bomb Calorimetric Method and Calculation of Net Calorific ValueDocument14 pages(TOTL-WI-05) Determination of Gross Calorific Value by The Bomb Calorimetric Method and Calculation of Net Calorific ValueakloioNo ratings yet

- (TOTL-WI-18) Determination of Carbon, Hydrogen and Nitrogen in CoalDocument8 pages(TOTL-WI-18) Determination of Carbon, Hydrogen and Nitrogen in CoalakloioNo ratings yet

- CHNS Verification by Petroleum Coke CRM: ISO/IEC 17025 Form Working Instruction FormsDocument1 pageCHNS Verification by Petroleum Coke CRM: ISO/IEC 17025 Form Working Instruction FormsakloioNo ratings yet

- TOTL-WI-09 Experimental Investigation of Regeneration For Silica-GelDocument1 pageTOTL-WI-09 Experimental Investigation of Regeneration For Silica-GelakloioNo ratings yet

- Iso 1171 - 2010Document12 pagesIso 1171 - 2010akloioNo ratings yet

- (TOTL-WI-02) Determination of Ash in CoalDocument6 pages(TOTL-WI-02) Determination of Ash in CoalakloioNo ratings yet

- ASTM D5373-16 Standard Test Methods For Determination of Carbon, Hydroge...Document11 pagesASTM D5373-16 Standard Test Methods For Determination of Carbon, Hydroge...akloioNo ratings yet

- Astm D5373-Red16 ChnoDocument14 pagesAstm D5373-Red16 ChnoakloioNo ratings yet