Professional Documents

Culture Documents

Final

Final

Uploaded by

Jignasa Shah0 ratings0% found this document useful (0 votes)

10 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesFinal

Final

Uploaded by

Jignasa ShahCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

Our Company

io 7 = Welding and Joining

!) e

Waking. andFabisnion J Wenge Jsinng {Wel Jont Donn

Hore / Aloe

Weld Joint Design

riveston sg cusroven ENGLISH © ¢ sooaetone

Reon B powa O resase aon

The Home ot HASTELLOYE Search

and HAYNES® Alloys Q

Markets Alloys

Contact p

Weld Joint Design

‘Selection ofa corect weld joint design is ical tothe successful fabrication of HASTELLOY® and

HAYNES® alloys. Poor joint design can negate even the most optimum welding conditions. The main

consideration in weld joint design of Ne-iCo-base alloys is to provide sufficient accesshilly and space for

‘movement ofthe welding electrode oiler metal. Slightly diferent weld joint geometies are required

‘comparedto those for carbon or stainless steal: in particular, a larger included weld angle, wider root

‘opening (gap), and reduced land (rot face) thickness are typcaly required

“The most important characteristic that must be understood when considering weld joint design Is that N-

‘and Co-base mote weld metals relatively “skiggish’, meaning that it does not flow or spread out as

‘eadly to "wer the sidewalls ofthe weld joint. Therefore, care must be taken ta ensure that the jolt

‘opening is wide enough to alow proper electrode manipulation and placement ofthe weld bead to

achieve proper weld bead tie-in and fusion. The welding are and filer metal must be manipulated in order

to place the molten metal where itis needed. The joint design shoul allow forthe fst wold bead to be

deposited witha convex surface. An included weld angle or root opening tat i to narrow promotes the

formation of @ concave weld bead that places the weld surface in tension and promotes sliifeation

‘racking inthe weld metal

‘Additonal, wold ponetraton is signiteantly less than tat of atypical carbon or stainless stel. This

charactrstie requires tho use of reduced lan thickness atthe root af the joint compared to carbon and

lainioss stool. Since this isan inrent property of N-ICo-base alloy, increasing weld current will not

‘signiicanly improve thei shallow weld penetration characteris.

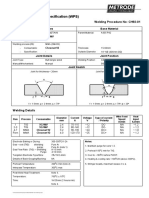

‘Typical but joint dosign that ao used withthe gas tungsten arc welding (GTAW), gas metal ae welding

(GMAW), and shielded metal arc welding (SMAW) processes are: () Square-Groove, (i) Single-V-Groove,

‘and (il) Double-V-Groove, as ehown in Figure 1. Gas tungsten are welding is often the preferred method

{or depositing the root pass for square-groove or single-V-groove joints, whe ther is access to only one

‘ido of th joint. The remainder ofthe jint can then be filed using other welding processes as

‘appropiate. Fo! gtoove welds on heavy section plates grater than 2/4 inch (19 mm) thick, Jegroove Ie

permissible. Such a joint reduces the amount o llr metal and Lime required ta complete the weld. Other

weld joint designs for spect stations are shown in Figure 2

Various welding document

provide detailed guidance are:

available toa

3 nthe dasign of waded joints. Two documents that

Wielding Handbook, Ninth Eaton, Volume 1, Welding Science and Technology, Chapter 5, Design for

Welding, p9. 157-238, American Welding Society, 2001

‘ASM Handbook, Volume 6, Welding, Brazing and Soldering, Wolding of Nckol Alloys, pg. 740-751, ASM

Intemational, 1993.

In addon, fabrication codes such as the ASME Pressure Vessel and Piping Code may impose design

requirements

19

Lecatone and Dvechone

“The actual numberof passes required to filhe weld joint depends upon a numberof factors that include

the fier metal size (electrode or wre diameter, the amperage, andthe travel speed. The estimated

\woight of weld metal required per unt length of welding is provided in Figure 1.

Figure 1: Typical Butt Joints for Manual Welding

i ar a

;

we ixty

— :

1 Tr 8

waa retaee seins gFSt | 4 pce | Apo gto al

ctr] been age | moaneaoee

cof agn | P| THe s

in| mm - in |mm in] mm degrees Ibsift ‘kgim

18) 32 1 Jo1s|032) NA ‘None 00s =| (009

ae aaa aa

2) 127 W 60-75 09) tat

12 | 127 Mw wszaise 60-75 060 (O88

wasn | 228)

woes

34) 194 f 60-75 190) 283

Figure 2: Other Weld Joint Designs for Specific Situations

64,0806

456.6012

Power Generation

28

Corporate Governance

Heath, Safty, Eneermora, and uatty

ur Hertage

News

auoys

‘Aioy Potato

ary Data Shoots

fecha Larary

Sales

“Technical Support

Investor Relations

‘General information

Emerging Technaogios

SSALES AND SERVICE

Sales ad Service

Processing Capabiis

© 2021 HAYNES INTERNATIONAL. ‘sITEMAP

PRIVACY POLICY TERMS OF WEBSITE USAGE- CONTACT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Brochure - SRSVGD - Iil - Hdpe - Water - Pipe - Compressed ManningDocument31 pagesBrochure - SRSVGD - Iil - Hdpe - Water - Pipe - Compressed ManningJignasa ShahNo ratings yet

- Pestse 2014 6805302Document5 pagesPestse 2014 6805302Jignasa ShahNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Consolidation 555Document12 pagesConsolidation 555Jignasa ShahNo ratings yet

- LHP - Newsletter - Volume VIDocument7 pagesLHP - Newsletter - Volume VIJignasa ShahNo ratings yet

- 2419 Part A DCHB VadodaraDocument890 pages2419 Part A DCHB VadodaraJignasa ShahNo ratings yet

- Click Here: Graphic DesignerDocument1 pageClick Here: Graphic DesignerJignasa Shah100% (1)

- CFP Africa Business ConferenceDocument3 pagesCFP Africa Business ConferenceJignasa ShahNo ratings yet

- HSRC BrochureDocument10 pagesHSRC BrochureJignasa ShahNo ratings yet

- Tentative Schedule GandhinagarDocument2 pagesTentative Schedule GandhinagarJignasa ShahNo ratings yet

- Irjet V3i9193Document4 pagesIrjet V3i9193Jignasa ShahNo ratings yet

- Electron ConfigurationDocument6 pagesElectron ConfigurationJignasa ShahNo ratings yet

- Micro-Irrigation SystemsDocument48 pagesMicro-Irrigation SystemsJignasa ShahNo ratings yet

- Bhavnagar Municiple CorporationDocument5 pagesBhavnagar Municiple CorporationJignasa ShahNo ratings yet

- Electrotherm DI PipeDocument24 pagesElectrotherm DI PipeJignasa ShahNo ratings yet

- BaDocument73 pagesBaJignasa ShahNo ratings yet