Professional Documents

Culture Documents

Componete Electronico

Uploaded by

StuxnetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Componete Electronico

Uploaded by

StuxnetCopyright:

Available Formats

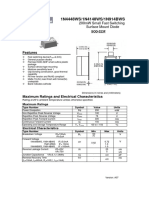

Technical Data Sheet

1.9mm Round Subminiature“ Z-Bend” Lead Photodiode

PD95-21B/TR10

Features

․Fast response time

․High photo sensitivity

․Small junction capacitance

․Compatible with infrared and vapor phase reflow solder process.

․Pb free

․The product itself will remain within RoHS compliant version.

Descriptions

․PD95-21B/TR10 is a high speed and high sensitive PIN

photodiode in miniature top view lens SMD package

and it is molded in a black plastic .The device is

spectrally matched with the infrared emitting diode.

Applications

․Infrared applied system

․Copier

․Sensor in automotive project

Device Selection Guide

Chip

LED Part No. Lens Color

Material

PD Silicon Black

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 1 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

Package Dimensions

Notes: 1.All dimensions are in millimeters

2.Tolerances unless dimensions ±0.1mm

Absolute Maximum Ratings (Ta=25℃)

Parameter Symbol Rating Units

Reverse Voltage VR 32 V

Operating Temperature Topr -25 ~ +85 ℃

Storage Temperature Tstg -40 ~ +85 ℃

Soldering Temperature Tsol 260 ℃

Power Dissipation at(or below) Pc 150 mW

25℃Free Air Temperature

Notes: *1:Soldering time≦5 seconds.

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 2 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

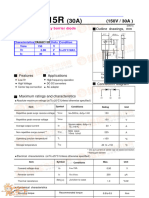

Electro-Optical Characteristics (Ta=25℃)

Parameter Symbol Condition Min Typ Max Unit

Rang Of Spectral Bandwidth λ0.5 --- 730 --- 1100 nm

Wavelength Of Peak Sensitivity λP --- --- 940 --- nm

Ee=5mW/cm2

Open-Circuit Voltage VOC --- 0.42 --- V

λp=940nm

Ee=1mW/cm2

Short- Circuit Current ISC --- 4 --- μA

λp=870nm

Ee=1mW/cm2

Reverse Light Current IL λp=870nm --- 4 --- μA

VR=5V

Ee=0mW/cm2

Reverse Dark Current ID --- --- 10 nA

VR=10V

Ee=0mW/cm2

Reverse Breakdown Voltage BVR 32 170 --- V

IR=100μA

Ee=0mW/cm2

Total Capacitance Ct VR=5V --- 5 --- pF

f=1MHz

Rise Time tr --- 6 ---

VR=10V

nS

RL=1000Ω

Fall Time tf --- 6 ---

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 3 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

Typical Electro-Optical Characteristics Curves

Fig.1 Power Dissipation vs. Fig.2 Spectral Sensitivity

Ambient Temperature

1.0

O

200 1.0 Ta=25 C

0.8 O

Ta=25 C

150 0.8

0.6

0.6

100 0.4

0.4

0.2

50

0.2

0

0 600 700 800 900 1000 1100 1200

-25 25 50 75 85 100 0

0 600 700 800 900 1000 1100 1200

Fig.3 Dark Current vs. Fig. 4 Reverse Light Current vs.

Ambient Temperature Ee

1000 20

15

100

10

10

5

VR=5V

VR=10V

1 0

20 40 60 80 100 0.5 1.0 1.5 3.0

2

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 4 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

Typical Electro-Optical Characteristics Curves

Fig.5 Terminal Capacitance vs. Fig.6 Response Time vs.

Reverse Voltage Load Resistance

1

10 10 VR=10V

f=1MHZ O

VR=5V Ta=25 C

2

0

8 10

t

-1

6 10

-2

4 10

-3

2 10

0.1 1 10 100 1 2 3 4 5

10 10 10 10 10

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 5 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

Precautions For Use

1. Over-current-proof

Customer must apply resistors for protection , otherwise slight voltage shift will cause big

current change ( Burn out will happen ).

2. Storage

2.1 Do not open moisture proof bag before the products are ready to use.

2.2 Before opening the package, the LEDs should be kept at 30℃ or less and 90%RH or less.

2.3 The LEDs should be used within a year.

2.4 After opening the package, the LEDs should be kept at 30℃ or less and 70%RH or less.

2.5 The LEDs should be used within 168 hours (7 days) after opening the package.

2.6 If the moisture absorbent material (silica gel) has faded away or the LEDs have exceeded the

storage time, baking treatment should be performed using the following conditions.

Baking treatment : 60±5℃ for 24 hours.

3. Soldering Condition

3.1 Pb-free solder temperature profile

3.2 Reflow soldering should not be done more than two times.

3.3 When soldering, do not put stress on the LEDs during heating.

3.4 After soldering, do not warp the circuit board.

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 6 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

4.Soldering Iron

Each terminal is to go to the tip of soldering iron temperature less than 280℃ for 3

seconds within once in less than the soldering iron capacity 25W. Leave two seconds and more

intervals, and do soldering of each terminal. Be careful because the damage of the product is often

started at the time of the hand solder.

5.Repairing

Repair should not be done after the LEDs have been soldered. When repairing is

unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed

beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 7 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

Reliability Test Item And Condition

The reliability of products shall be satisfied with items listed below.

Confidence level:90%

LTPD:10%

NO. Item Test Conditions Test Hours/ Sample Failure Ac/Re

Cycles Sizes Judgement

Criteria

1 REFLOW TEMP.:260℃±5℃ 6Mins 22pcs 0/1

5secs

2 Temperature Cycle H : 100℃ 15mins 50Cycles 22pcs IL≦L×0.8 0/1

5mins

L : -40℃ 15mins L:Lower

3 Thermal Shock H :+100℃ 5mins 50Cycles 22pcs Specification 0/1

10secs Limit

L :-10℃ 5mins

4 High Temperature TEMP.:+100℃ 1000hrs 22pcs 0/1

Storage

5 Low Temperature TEMP.:-40℃ 1000hrs 22pcs 0/1

Storage

6 DC Operating Life VR=5V 1000hrs 22pcs 0/1

7 High Temperature/ 85℃ / 85% R.H 1000hrs 22pcs 0/1

High Humidity

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 8 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

Package Dimensions

Loaded Quantity Per Reel 1000PCS/Reel

Unit :mm

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 9 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

PD95-21B/TR10

Packing Quantity Specification

1.1000Pcs/1Volume,1Volume/1Bag

2.10Boxes/1Carton

Label Form Specification

CPN: Customer’s Production Number

P/N : Production Number

QTY: Packing Quantity

RoHS

CAT: Ranks

PD95-21B/TR10 HUE: Peak Wavelength

REF: Reference

LOT No: Lot Number

MADE IN TAIWAN: Production Place

Notes

1. Above specification may be changed without notice. EVERLIGHT will reserve authority on

material change for above specification.

2. When using this product, please observe the absolute maximum ratings and the instructions

for using outlined in these specification sheets. EVERLIGHT assumes no responsibility for

any damage resulting from use of the product which does not comply with the absolute

maximum ratings and the instructions included in these specification sheets.

3. These specification sheets include materials protected under copyright of EVERLIGHT

corporation. Please don’t reproduce or cause anyone to reproduce them without EVERLIGHT’s

consent.

EVERLIGHT ELECTRONICS CO., LTD. Tel: 886-2-2267-2000, 2267-9936

Office: No 25, Lane 76, Sec 3, Chung Yang Rd, Fax: 886-2267-6244, 2267-6189, 2267-6306

Tucheng, Taipei 236, Taiwan, R.O.C http:\\www.everlight.com

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 2 Page: 10 of 10

Device No:DTD-095-001 Prepared date:10-11-2005 Prepared by:Jaine Tsai

You might also like

- Foto Diodo Infrarrojo Receptor 5mmDocument7 pagesFoto Diodo Infrarrojo Receptor 5mmkevin arreaga miñoNo ratings yet

- Technical Data Sheet 1206 Package Phototransistor With Inner LensDocument10 pagesTechnical Data Sheet 1206 Package Phototransistor With Inner LenschauNo ratings yet

- Everlight - Evers06924 1 1734927Document8 pagesEverlight - Evers06924 1 1734927conef150No ratings yet

- Technical Data Sheet 5mm Phototransistor T-1: FeaturesDocument7 pagesTechnical Data Sheet 5mm Phototransistor T-1: Features9cf634095aNo ratings yet

- Infrared Datasheet PDFDocument7 pagesInfrared Datasheet PDFMizael AlonsoNo ratings yet

- Led5r05 600 LL503VC2Z V1 4if 3547Document7 pagesLed5r05 600 LL503VC2Z V1 4if 3547Tomi OzzyNo ratings yet

- Diode RR2LAM6STFDocument8 pagesDiode RR2LAM6STF강이석No ratings yet

- Silicon Switching Diode Array DatasheetDocument4 pagesSilicon Switching Diode Array DatasheetEibar016No ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 1.0" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 1.0" Single Digit DisplaysStuxnetNo ratings yet

- Bav 99W: Type Marking Ordering Code Pin Configuration PackageDocument4 pagesBav 99W: Type Marking Ordering Code Pin Configuration PackageGhulam MurtazaNo ratings yet

- 3mm Photodiode, T-1 PD204-6C/L3: FeaturesDocument10 pages3mm Photodiode, T-1 PD204-6C/L3: FeaturesMuhammad RiduwanNo ratings yet

- 2N5849 (SILICON) : NPN Silicon RF Power Transistor RF Power Transistor NPN SiliconDocument4 pages2N5849 (SILICON) : NPN Silicon RF Power Transistor RF Power Transistor NPN SiliconSir Héctor FiordalisoNo ratings yet

- Technical Data Sheet Opto Interrupter: FeaturesDocument7 pagesTechnical Data Sheet Opto Interrupter: FeatureswhocaresdudeNo ratings yet

- Everlight Electronics Co., LTD.: 5mm PhototransistorDocument7 pagesEverlight Electronics Co., LTD.: 5mm PhototransistorFrancisco Javier González HernándezNo ratings yet

- Super Fast Recovery Diode: Rfn1Lam7StfDocument8 pagesSuper Fast Recovery Diode: Rfn1Lam7StfCastro G. LombanaNo ratings yet

- IR Emitter and Detector: Product Data SheetDocument5 pagesIR Emitter and Detector: Product Data SheetSyaiful RahmanNo ratings yet

- Bav70 (A4w32)Document5 pagesBav70 (A4w32)Emilio QuijanoNo ratings yet

- BN44 00852a L48MSF FdyDocument53 pagesBN44 00852a L48MSF FdyRaimundo SantanaNo ratings yet

- Phototransistor: Part Number: L-93DP3CDocument5 pagesPhototransistor: Part Number: L-93DP3Cqwerty100% (1)

- Technical Data Sheet Power LED @150ma Current: 34-03UYC/S599Document8 pagesTechnical Data Sheet Power LED @150ma Current: 34-03UYC/S599Jeannot MpianaNo ratings yet

- Technical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2Document8 pagesTechnical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2StuxnetNo ratings yet

- 1N4148WS (T4)Document4 pages1N4148WS (T4)DuanReisNo ratings yet

- BYV255V: High Efficiency Fast Recovery Rectifier DiodesDocument5 pagesBYV255V: High Efficiency Fast Recovery Rectifier DiodesaleksNo ratings yet

- Galaxy Electrical 1N4148W: Silicon Epitaxial Planar Diode FeaturesDocument4 pagesGalaxy Electrical 1N4148W: Silicon Epitaxial Planar Diode Featurescecep encepNo ratings yet

- Datasheet Pdfview171323EVERLIGHTITR9608+05Q445VwTESLKIlZfObaphCK+Datasheet PDFDocument6 pagesDatasheet Pdfview171323EVERLIGHTITR9608+05Q445VwTESLKIlZfObaphCK+Datasheet PDFpipoNo ratings yet

- Rohs Rohs: 1N4448WS/1N4148WS/1N914BWSDocument3 pagesRohs Rohs: 1N4448WS/1N4148WS/1N914BWSRich ManNo ratings yet

- ff6050af9cf9080f0ac2ebc0e4d4b378Document3 pagesff6050af9cf9080f0ac2ebc0e4d4b378Day SadNo ratings yet

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290StuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysStuxnetNo ratings yet

- 141itr9608 F PDFDocument9 pages141itr9608 F PDFjboronatsNo ratings yet

- MPSA13Document4 pagesMPSA13Momcilo DakovicNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.8" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.8" Single Digit DisplaysStuxnetNo ratings yet

- Susgar Csube RselayDocument2 pagesSusgar Csube RselayMarudhasalamMarudhaNo ratings yet

- Zowie Technology Corporation: High Voltage TransistorDocument4 pagesZowie Technology Corporation: High Voltage TransistorVinhNo ratings yet

- Esd0p2rf-02lrh E6327 Esd0p2rf-02ls E6327Document10 pagesEsd0p2rf-02lrh E6327 Esd0p2rf-02ls E6327Michael BamfordNo ratings yet

- Nfsa123dt e (4114C)Document18 pagesNfsa123dt e (4114C)ShrikantNo ratings yet

- ITR8307-S17-TR8Document10 pagesITR8307-S17-TR8cointoinNo ratings yet

- YA868C15R: High Voltage Schottky Barrier DiodeDocument3 pagesYA868C15R: High Voltage Schottky Barrier DiodeleventtozkoparanNo ratings yet

- SFH 229 - en PDFDocument15 pagesSFH 229 - en PDFbarisNo ratings yet

- FR201 Thru FR207: 2.0 A Fast Recovery Silicon RectifierDocument2 pagesFR201 Thru FR207: 2.0 A Fast Recovery Silicon RectifierMega GhostNo ratings yet

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetNo ratings yet

- 0805 Package Phototransistor PT17-21C/L41/TR8: FeaturesDocument8 pages0805 Package Phototransistor PT17-21C/L41/TR8: FeatureschauNo ratings yet

- AlinkhDocument8 pagesAlinkhhassan safi nezhadNo ratings yet

- Display - ELD-511SURWB-S530-A3Document5 pagesDisplay - ELD-511SURWB-S530-A3guibsgvNo ratings yet

- DF10M PDFDocument2 pagesDF10M PDFAnonymous IeIEHSANo ratings yet

- Bas 28 R 2Document3 pagesBas 28 R 2sergio ribeiroNo ratings yet

- DL3 2532RB 6Document6 pagesDL3 2532RB 6athinabebaNo ratings yet

- Sbd10c 100f (Power Supply TV Led)Document6 pagesSbd10c 100f (Power Supply TV Led)Saharuddin SangkalaNo ratings yet

- Technical Data Sheet: Everlight Electronics Co., LTDDocument12 pagesTechnical Data Sheet: Everlight Electronics Co., LTDNhân Hồ ChíNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysStuxnetNo ratings yet

- Luckylight: 0.45mm Height 0402 Package White Chip LED Technical Data SheetDocument11 pagesLuckylight: 0.45mm Height 0402 Package White Chip LED Technical Data SheetVictorburgen Siebenburgen Burgenburg SiebenburgenburgNo ratings yet

- Data Sheet: para Light Electronics Co., LTDDocument14 pagesData Sheet: para Light Electronics Co., LTDmuaadhNo ratings yet

- DS PDB C134 1Document4 pagesDS PDB C134 1عبدالله عليNo ratings yet

- STTA2512P STTA5012TV1/2: Turboswitch Ultra-Fast High Voltage DiodeDocument9 pagesSTTA2512P STTA5012TV1/2: Turboswitch Ultra-Fast High Voltage DiodeDavid ReyesNo ratings yet

- Silicon PNP Power Darlington TransistorDocument4 pagesSilicon PNP Power Darlington TransistorRomário CaribéNo ratings yet

- Everlight Elec ITR8307 L24 TR8 - C181894Document11 pagesEverlight Elec ITR8307 L24 TR8 - C181894Влад ГорNo ratings yet

- ESDH12VD1Document5 pagesESDH12VD1EduardoPassosNo ratings yet

- Fast Recovery Rectifier Diode: ApplicationsDocument3 pagesFast Recovery Rectifier Diode: ApplicationsMiloud ChouguiNo ratings yet

- Foto Diodo Infrarrojo Receptor 5mmDocument1 pageFoto Diodo Infrarrojo Receptor 5mmcreative_26No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- High Efficiency, Three-Digit Numeric Displays: LB-303AK SeriesDocument4 pagesHigh Efficiency, Three-Digit Numeric Displays: LB-303AK SeriesStuxnetNo ratings yet

- DatasheetDocument7 pagesDatasheetStuxnetNo ratings yet

- 37mm (1.4 INCH) 5x8 SINGLE COLOR DOT Matrix Displays: Mechanically RuggedDocument5 pages37mm (1.4 INCH) 5x8 SINGLE COLOR DOT Matrix Displays: Mechanically RuggedStuxnetNo ratings yet

- DatasheetDocument11 pagesDatasheetStuxnetNo ratings yet

- High Efficiency, Three-Digit Numeric Displays: LB-203BL SeriesDocument2 pagesHigh Efficiency, Three-Digit Numeric Displays: LB-203BL SeriesStuxnetNo ratings yet

- Technical Data Sheet 0.39" Quadruple Digit SMD Displays: ELSF-405SYGWA/S530-E2Document8 pagesTechnical Data Sheet 0.39" Quadruple Digit SMD Displays: ELSF-405SYGWA/S530-E2StuxnetNo ratings yet

- DatasheetDocument2 pagesDatasheetStuxnetNo ratings yet

- High Efficiency, Single-Digit Numeric Displays: LA-101AK SeriesDocument2 pagesHigh Efficiency, Single-Digit Numeric Displays: LA-101AK SeriesStuxnetNo ratings yet

- Technical Data Sheet 0.51" Triple Digit SMD Displays: ELST-506SYGWA/S530-E2Document8 pagesTechnical Data Sheet 0.51" Triple Digit SMD Displays: ELST-506SYGWA/S530-E2StuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 1.0" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 1.0" Single Digit DisplaysStuxnetNo ratings yet

- Data Sheet: ReceivedDocument7 pagesData Sheet: ReceivedStuxnetNo ratings yet

- STTH10LCD06: Turbo2 Ultrafast - High Voltage Rectifier For Flat Panel DisplaysDocument10 pagesSTTH10LCD06: Turbo2 Ultrafast - High Voltage Rectifier For Flat Panel DisplaysStuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysStuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Model No: ELS-512EWADocument5 pagesEverlight Electronics Co.,Ltd.: Model No: ELS-512EWAStuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 2.24" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 2.24" Single Digit DisplaysLuis Angel PNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.36" Triple Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.36" Triple Digit DisplaysStuxnetNo ratings yet

- DatasheetDocument9 pagesDatasheetStuxnetNo ratings yet

- Agilent HDSP-B58x Series 53.3 MM (2.1 Inch) General Purpose 5 X 8 Dot Matrix Bi-Color Alphanumeric DisplaysDocument8 pagesAgilent HDSP-B58x Series 53.3 MM (2.1 Inch) General Purpose 5 X 8 Dot Matrix Bi-Color Alphanumeric DisplaysStuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.36" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.36" Single Digit DisplaysStuxnetNo ratings yet

- Black Surface Seven Segment Displays: Technical DataDocument14 pagesBlack Surface Seven Segment Displays: Technical DataStuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysStuxnetNo ratings yet

- 0.510-INCH (13MM) Seven Segment Displays: Package DimensionsDocument10 pages0.510-INCH (13MM) Seven Segment Displays: Package DimensionsStuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysStuxnetNo ratings yet

- Hexadecimal and Numeric Displays For Industrial ApplicationsDocument8 pagesHexadecimal and Numeric Displays For Industrial ApplicationsStuxnetNo ratings yet

- 10 MM (0.40 Inch) Seven Segment Displays: Technical DataDocument11 pages10 MM (0.40 Inch) Seven Segment Displays: Technical DataStuxnetNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 2.24" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 2.24" Single Digit DisplaysLuis Angel PNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysStuxnetNo ratings yet

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetNo ratings yet

- 7 Segmentos Anodo ComunDocument5 pages7 Segmentos Anodo ComunJunior Calzadilla JackmanNo ratings yet

- Data Sheet: ReceivedDocument7 pagesData Sheet: ReceivedStuxnetNo ratings yet

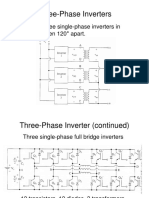

- Three-Phase Inverter 180° ConductionDocument27 pagesThree-Phase Inverter 180° ConductionWana BilaNo ratings yet

- 530B Trimanual PDFDocument56 pages530B Trimanual PDFJuan Pablo CruzNo ratings yet

- LM317Document25 pagesLM317Meris MavricNo ratings yet

- TES - Rec15 - 25 - Guide - UG - Al1 - 5p - EN - 2 TAVRIDADocument136 pagesTES - Rec15 - 25 - Guide - UG - Al1 - 5p - EN - 2 TAVRIDALinkisNo ratings yet

- MID 15-25KTL3-X DatasheetDocument2 pagesMID 15-25KTL3-X DatasheetestebandNo ratings yet

- Insulated Gate Bipolar TransistorDocument4 pagesInsulated Gate Bipolar Transistor1balamanianNo ratings yet

- 315B Forest Swing Machine Electrical System: 7RZ284-UPDocument2 pages315B Forest Swing Machine Electrical System: 7RZ284-UPGilvan JuniorNo ratings yet

- Wiring Diagram For Base Module (GM) 1Document8 pagesWiring Diagram For Base Module (GM) 1Roy Ferdy MassoloNo ratings yet

- Install Manual - Provolt KeypadsDocument2 pagesInstall Manual - Provolt Keypadsiran1412690No ratings yet

- LV Power Quality Products - Pricelist Mid Year 2021Document28 pagesLV Power Quality Products - Pricelist Mid Year 2021Sanjay-kunal TeleNo ratings yet

- Fabrication of Resistors PDFDocument2 pagesFabrication of Resistors PDFAnish0% (1)

- Repair SMPS PC (For Example, JNC SY-300ATX) - Repair and Renovation - Blogs ElectronicsDocument7 pagesRepair SMPS PC (For Example, JNC SY-300ATX) - Repair and Renovation - Blogs ElectronicsaladinthewizardNo ratings yet

- Cable Gland Selection ChartDocument4 pagesCable Gland Selection Chartajeez86100% (2)

- BQ 24297Document57 pagesBQ 24297Chaitu KumarNo ratings yet

- Bin 4X: Universal Interface With 4 Configurable Binary Inputs / LED Outputs Zio-Bin4X Technical Documentation FeaturesDocument2 pagesBin 4X: Universal Interface With 4 Configurable Binary Inputs / LED Outputs Zio-Bin4X Technical Documentation FeaturesДимитър МирчевNo ratings yet

- Substation LightingDocument13 pagesSubstation LightingHikmat AyerNo ratings yet

- Basic Characteristics of Digital IcsDocument17 pagesBasic Characteristics of Digital IcsfgkloNo ratings yet

- VC (HD160&170) 07MY General PDFDocument165 pagesVC (HD160&170) 07MY General PDFVăn HòaNo ratings yet

- Fuse Voltage Drop Chart - Maxi FuseDocument2 pagesFuse Voltage Drop Chart - Maxi FuseJose Cespedes88% (8)

- Operation of The Classical CMOS SchmittDocument5 pagesOperation of The Classical CMOS SchmittAakash ChandraNo ratings yet

- Automatic Headlight Dim BrightDocument15 pagesAutomatic Headlight Dim BrightPraveen Krishna0% (2)

- Silicon N-Channel Junction FETDocument4 pagesSilicon N-Channel Junction FETLê Thiên ThanhNo ratings yet

- IS11.6 SiC Device ReliabilityDocument64 pagesIS11.6 SiC Device Reliabilityshriram1082883No ratings yet

- Form 4 Test Results SummaryDocument1 pageForm 4 Test Results SummaryKarim AmerNo ratings yet

- Electronics Keralam - CIRCUITSDocument69 pagesElectronics Keralam - CIRCUITSMnichandraNo ratings yet

- Row Part of Designation Reference Material Description ManufacturerDocument1 pageRow Part of Designation Reference Material Description ManufacturerEdwinGomezNo ratings yet

- S00 Standardization Parts ListDocument48 pagesS00 Standardization Parts ListRaphael Ruiz RamosNo ratings yet

- SynchronisedDocument28 pagesSynchronisedsanjay sharmaNo ratings yet

- Mpa 4150Document149 pagesMpa 4150GrahamNo ratings yet

- Work Methodology (LBS)Document2 pagesWork Methodology (LBS)Callista CollectionsNo ratings yet