Professional Documents

Culture Documents

Fitter - Semester II - CITS - Module 1: Limits and Fits

Uploaded by

vivek dongareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fitter - Semester II - CITS - Module 1: Limits and Fits

Uploaded by

vivek dongareCopyright:

Available Formats

Fitter - Semester II - CITS - Module 1: Limits and Fits

Questions: Level 1 6 What is the smaller of two limits of size?

A Actual size

1 What is the name of the fit? B Maximum limit of size

C Minimum limit of size

D Limit of size

7 How many number of fundamental deviation

in the BIS system?

A 25

B 20

C 15

A Transition fit D 26

B Clearance fit 8 Which term is used to indicate maximum

C Shrinkage fit permissible overall variation of form or

D Interference fit position of a feature?

2 What is the term of the algebraic difference A Tolerance

between a size, to its corresponding basic B Deviation

size? C Geometrical tolerance

A Deviation D Fundamental tolerance

B Upper deviation 9 Which symbol is used to indicate datum face

C Lower deviation to represent geometrical tolerance?

D Actual deviation A Circle

3 What is the name of system if the size of the B Square

hole is kept constant, shaft is varied? C Triangle

A Bilateralsystem D Parallelogram

B Unilateral system 10 Which one of the following is belongs to form

C Hole basis system group of geometrical tolerance?

D Shaft basis system A Angularity

4 Which is grade of tolerance? B Parallelism

A Bilateral tolerance C Cylindricity

B Unilateral tolerance D Concentricity

C Fundamental tolerance 11 Which one of the following belongs to

D Fundamental deviation ‘attitude’ group in geometrical tolerance?

5 What is the name of fit? A Position

B Flatness

C Parallelism

D Straightness

12 What is the first step of lesson plan?

A Presentation

B Application

C Preparation

A Transition fit D Evaluation

B Shrinkage fit

C Clearance fit

D Interference fit

- NIMI Question Bank - Page1/ 6

13 Which step while teaching, the instructor

should include safety equipments?

A Preparation

B Presentation

C Application

D Test/Assignment

14 Which is the third step of skill teaching

cycle?

A Practice

B Imitation

C Demonstration

D Application

- NIMI Question Bank - Page2/ 6

Questions: Level 2 8 What is the tolerance if dimension is stated

as 25 ± 0.02 mm in a drawing?

1 What is the upper limit of the component size A +0.02 mm

+.008

ø 20 −.005 ? B -0.02 mm

A 0.005 C 0.04 mm

B 0.008 D 25.00 mm

C 19.995 9 What is the fit if the limits of hole are 25.000

D 20.008 to 25.021 mm and the limits of shaft are

2 What is the term used for the relationship 25.022 to 25.03 mm?

exists between two mating parts? A Clearance fit

A Fit B Interference fit

B Limit C Transition fit

C Tolerance D Maximum clearance fit

D Allowance 10 What is the group and characteristic of

3 What is the lower limit of size, if dimension is geometric tolerance?

stated as ø 25 +0.021 ?

−0.000

A 24.85 mm

B 24.75 mm

C 25.00 mm

D 25.021 mm A Attitude, Position

4 What is the algebraic difference between the B Location, Position

actual size and its corresponding basic size? C Attitude, Concentricity

A Deviation D Location, Concentricity

B Tolerance 11 What is the group and characteristic of the

C Actual deviation geometrical tolerance symbol shown?

D Upper deviation

5 What is the maximum limit of size if the basic

size of the hole is 25 mm and the deviation is

± 0.2mm?

A 25.2 mm

B 24.8 mm

C 25.02 mm

D 24.08 mm A Attitude, Squarness

6 What is the minimum limit of size if size on B Attitude, Parallelism

+ 0.008

drawing is 20 − 0.005 ? C Location, Squarness

A 19.995 D Location, Parallelism

B 19.979 12 What is the advantage of adopting

C 20.012 geometrical tolerance symbols on production

D 20.021 drawing?

7 Which term indicates the difference between A It indicates surface finish level

the maximum limit of size and minimum limit B It makes dimensional accuracy

of size? C It indicates method of operation

A Deviation D It over come usual language barrier

B Tolerance

C Actual size

D Upper deviation

- NIMI Question Bank - Page3/ 6

13 What is the characteristic of a geometrical 19 Which elements in the lesson plan the

tolerance? instructor make the learner to be ready to

receive the new lesson?

A Title

B Objectives

A Position C Review

B Symmetry D Teaching aids

C Angularity 20 What is the purpose of questioning a learner

D Cylindricity in a class room?

14 What is the group and characteristics of A Helps learner to score more marks

geometrical tolerance symbol? B Makes the learner to get distracted

C Provide opportunity to think and answer

D To select the most intelligent learner

21 What type of question is used at preparation

step?

A Drill questions

B Assignment questions

C Introductory questions

D Comprehension questions

A Location, position 22 Which characteristics makes a question free

B Location, symmetry from ambiguity?

C Location, cylindricity A Clarity

D Location, concentricity B Simplicity

15 What is the practical application of ‘Circular C Specificity

division method’ in production industry? D Challenging

A For holding jobs 23 Which method is best suitable for skill

B For holding tools teaching?

C For measure surface roughness A Lesson method

D For measuring and setting out angle B Lecture method

16 Which method is used to measure or set C Project method

angles in rotary table? D Demonstration method

A Linear division method

B Circular division method

C Concentric circle method

D Continuous fraction method

17 Which is used to conduct classes and teach

subject in sequential manner by instructor in

class room?

A Demo plan

B Lesson plan

C Action plan

D Response plan

18 Which step of lesson plan the instructor

should direct to utilize in actual practice?

A Preparation

B Presentation

C Test

D Application

- NIMI Question Bank - Page4/ 6

Questions: Level 3 5 What is the interpretation of geometrical

tolerance?

1 What is the name of the system, if the size of

the shaft is kept constant and the size of the

hole is varied to get the different class of fit?

A Tolerance

B Allowance

C Shaft basic system

D Hole basic system

2 What is the least count of vernier height A Hole must lies 0.08 a part

gauge? B Two holes are lies concentrically

A 0.1 mm C Axis of upper hole lies between two lines

B 0.01 mm 0.08 apart the lower hole

C 0.02 mm D Axis of upper hole lies within a cylindrical

D 0.2 mm zone 0.08 dia with axis of hole A

3 What is the meaning of symbol marked as 6 What is the interpretation of geometric

‘x’? tolerance?

A Flatness

B Squarness A Two planes 0.05 mm apart

C Parallelism B Two planes parallel with each other

D Straightness C Two planes 0.05 mm apart parall about the

4 What is the interpretation of symbol? datum

D Two planes 0.05 mm apart symmetrically

disposed about datum

7 When do the instructor given remedial

instruction for skill learning difficulties?

A During terms

B Introduction Shop talk

C Final shop talk

A Flatness for a component D Related shop talk

B Parallelism of a component

8 Why the instructor must rehearse the

C Straightness for entire axis of component

demonstration?

D Straightness for axis over length of

A Time saving

dimensioned feature only

B Quick learning

C Develop own style

D Smooth sequency of steps

9 Which step the instructor has to evaluate the

performance of learner?

A Presentation

B Imitation

C Application

D Practice

- NIMI Question Bank - Page5/ 6

Module 1 : Limits and Fits - Key paper

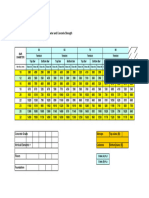

Questions: Level 1 Questions: Level 2 Questions: Level 3

SL.No Key SL.No Key SL.No Key

1 B 1 D 1 C

2 A 2 A 2 C

3 C 3 C 3 C

4 C 4 C 4 B

5 D 5 A 5 B

6 C 6 A 6 C

7 A 7 B 7 C

8 C 8 B 8 D

9 C 9 C 9 A

10 A 10 A

11 C 11 B

12 C 12 B

13 A 13 C

14 B 14 D

15 C

16 B

17 B

18 D

19 C

20 C

21 C

22 C

23 D

- NIMI Question Bank - Page6/ 6

Fitter - Semester II - CITS - Module 2 : Gauges

Questions: Level 1 5 Which device is used to check the workpiece

to confirm the shape?

1 What is the name of limit gauge? A Profile gauge

B Snap gauge

C Caliper gauge

D Progressive gauge

6 What is the name of gauge?

A Plain ring gauge

B Taper plug gauge

C Progressive plug gauge

D Double ended plug gauge

2 What is the name of gauge?

A Drill gauge

B Centre gauge

C Profile gauge

D Standard wire gauge

7 Which gauge is used to check the outside

diameter?

A Ring gauge A Plug gauge

B Plug gauge B Plain ring gauge

C Taper ring gauge

C Taper ring gauge

D Progressive plug gauge

D Taper plug gauge

8 What is the name of gauge?

3 What is the name of gauge?

A Ring gauge

B Snap gauge

C Taper ring gauge

A Plain snap gauge D Internal thread gauge

B Thread snap gauge 9 What is the name of gauge?

C Thread pitch gauge

D Adjustable snap gauge

4 What is the name of gauge?

A Pitch gauge A Thread plug gauge

B Angle gauge B Thread ring gauge

C Feeler gauge C Caliper gauge

D Radius gauge D Ring gauge

- NIMI Question Bank - Page1/ 6

10 What is the name of gauge? 16 Which is the method of locking number of

bolts with the help of soft steel wire inserted

and twisted?

A Self locking

B Wire locking

C With locknut

A Taper gauge D Locking nut with one over other

B Snap gauge 17 How self locking is achieved in simmonds

C Progressive plug gauge nut?

D Double end plug gauge A By inserting soft steel wire and twisted

11 Which material is used to clean the slip B By fixing split pin in the slot

gauge? C By using nylon inserts

A Wax D By a slot cut across the nut screw fitted on

B Kerosene the top

C Soluble oil 18 What is the name of nut?

D Carbon tetra chloride

12 What is the instrument used for measuring

external diameter?

A Castle nuts

B Cap nuts

C Hexagonal nut with collar

A Vernier caliper D Square nut

B Outside caliper

C Parallel leg caliper

D Pair of special jaws using with slip gauges

13 How many sets of feeler gauges are

available?

A 2 sets

B 4 sets

C 5 sets

D 6 sets

14 Which protective coat is applied on the

surface of slip gauge against rust?

A C.T.C

B Grease

C Lubricant oil

D Petroleum jelly

15 Which material is used to make slip gauge

blocks?

A Tool steel

B Low grade steel

C High carbon steel

D High grade steel

- NIMI Question Bank - Page2/ 6

Questions: Level 2 9 What is the purpose of nylon insert provided

in the self locking nut?

1 Which gauge is used to check the gap A To give positive grip

between the mating parts? B To give leak proof joint

A Slip gauge C To permit minimum clearance

B Plug gauge D To give cusion effect

C Feeler gauge 10 Which type of nut is used where frequent

D Radius gauge adjustment is required?

2 Which gauge is used to check the accuracy A T-nuts

of an external thread? B Knurled nuts

A Snap gauge C Cap nuts

B Thread ring gauge D Square nuts

C Thread plug gauge 11 What type of nuts are used in coach building

D Screw pitch gauge work?

3 What is the purpose of feeler gauge? A Square nut

A Check the depth of drilled hole B T-nuts

B Check the pitch of screw thread C Wing nuts

C Check the radius of workpiece D Cap nuts

D Check the gap between the mating parts 12 What is the purpose of T-nuts used on

4 What is the act of joining the slip gauges machine tools?

together for building up sizes? A For structural and machine tool building

A Glazing B Suitable for frequent adjustment

B Pinning C For fixing work holding devices

C Loading D To protect bolt and thread from damage

D Wringing 13 Which nut provides additional bearing

5 Which grade slip gauge is used for precision surface in the assembly?

tool room applications? A Hexagonal nut with collar

A Grade 00 B Knurled nuts

B Grade 0 C Cap nuts

C Grade I D Castle nuts

D Grade II 14 What is the purpose of three projections

6 What is the purpose of taper plug gauge? provided on the hexagonal weld nut?

A Check the hole with perfect fit A To provide uniform contact on the surface

B Check the inside threaded dia B To provide correct seating on the surface

C Check tapered hole with perfect fit C To raise the surface to be welded

D Check the tapered accuracy of outside dia D To permit clearance between surface and

7 What is the thickness range of BIS set of nut

feeler gauge? 15 Where the wing nuts are used?

A 0.01 mm to 1 mm A Frequent adjustment and removal

B 0.02 mm to 1 mm B Heavy duty assembly work

C 0.03 mm to 1 mm C In coach building work

D 0.04 mm to 1 mm D Provide decorative appearance

8 What is the calibration grade of slip gauges? 16 Which locking device is used along with bolts

A Grade 0 in assembly?

B Grade 00 A Screws

C Grade I B Nuts

D Grade II C Rivets

D Dowel pins

- NIMI Question Bank - Page3/ 6

17 Which nut both the faces are machined and 24 Which device is used for providing an

placed below a nut in the assembly? increased bearing surface for bolt heads and

A Sawn nut nuts?

B Self locking nut A Screws

C Lock - nut B Dowel pins

D Slotted and castle nuts C Keys

18 Which nut provides positive locking while D Washers

tightening? 25 Which washer is used with flat or oval type

A Slotted and castle nuts head screws?

B Self locking nut A External type

C Lock nut B Internal and external type

D Sawn nut C Counter sunk type

19 Which lock nut nylon or fibre ring insert is D Internal type

placed in the upper part of the nut?

A Sawn nut

B Self locking nut

C Slotted and castle nuts

D Lock nut

20 Which locking device is used for preventing

the hexagonal nut from loosening?

A Screws

B Dowel pins

C Locking plate

D Keys

21 Which washer is used for locking the nuts

that are located near an edge or corner?

A Lock-washers with lug

B Locking plate

C Spring washer

D Tab washer

22 Which washer offers stiff resistance against

the surface of the nuts from loosening?

A Locking plate

B Tab washers

C Lock washers with lug

D Spring washer

23 Which device is used for distributing the

clamping pressure over a larger area and

prevents the surface from damaging?

A Screws

B Washers

C Bolts

D Nuts

- NIMI Question Bank - Page4/ 6

Questions: Level 3 7 How the nominal length of split pin

calculated?

1 Find out the height of slip gauge ‘a’? (sin 25° A Under side of the eye to the end of short leg

= 0.4226) B Under side of the eye to the end of long leg

C Centre point of eye to the end of short leg

D Centre point of eye to the end of long leg

8 Why 'GO' and 'NO GO' ends are provided in

one end of the progressive plug gauge?

A To check the components of holes quickly

B Easy for handling

A 84.50 mm C Easy for machining

B 84.52 mm D For good appearance

C 84.51 mm

D 85.20 mm

2 What is the material of screw pitch gauge

blades?

A Mild steel

B Cast iron

C Spring steel

D Medium carbon steel

3 Which of the following is used to measure

the size of a wire and thickness of sheet?

A Screw pitch gauge

B Feeler gauge

C Radius gauge

D Standard Wire Gauge (SWG)

4 What is the height of slip gauge, whose

angle is 30° and the sine bar length is 200

mm?

A 84.52 mm

B 100 mm

C 114.72 mm

D 128.56 mm

5 Why the nylon ring or fibre inserted in the

internal groove cut on self locking nut?

A To provide leak proof joint

B To make good appearance

C To serve as locking device

D To allow easy fitment and removal

6 Why slots are provided in the slotted and

castle nuts?

A For easy removal and fitment

B To fix split pins

C For good appearance

D Reduce the weight of nut

- NIMI Question Bank - Page5/ 6

Module 2 : Gauges - Key paper

Questions: Level 1 Questions: Level 2 Questions: Level 3

SL.No Key SL.No Key SL.No Key

1 C 1 C 1 B

2 A 2 B 2 C

3 D 3 D 3 D

4 D 4 D 4 B

5 A 5 C 5 C

6 D 6 C 6 B

7 B 7 C 7 A

8 C 8 B 8 A

9 B 9 A

10 B 10 B

11 D 11 A

12 D 12 C

13 B 13 A

14 D 14 A

15 D 15 A

16 B 16 B

17 C 17 C

18 C 18 D

19 B

20 C

21 D

22 D

23 B

24 D

25 C

- NIMI Question Bank - Page6/ 6

Fitter - Semester II - CITS - Module 3 : Rivets and Riveting

Questions: Level 1 5 What is the name of gear?

1 What is the velocity ratio of gear train

formula?

A N1T1=N2T2

N1 N 2

B =

T1 T2

C NIT2 = N2T1

A Mitre gear

N2 T

D = 2 B Bevel gear

N1 T1

C Spur gear

2 What is the type of belt fastener? D Herring bone gear

6 What is the type of belt fastner?

A Wire type

B Crescent plate A Wire type belt fastner

C Alligator type B Cresent plate belt fastner

D Lagrelle type C Jackson type belt fastner

3 What is the type of clutch? D Alligator type belt fastner

7 What is the name of part marked as 'x'?

A Dog clutch

B Cone clutch A Driver pulley

C Air clutch B Driven pulley

D Centrifugal clutch C Jockey pulley

D Step pulley

4 What is the type of belt?

8 Where the jockey pulley to be fitted?

A Near driver pulley

B Near driven pulley

C Between driver and driven pulley

D On the driven pulley

A Flat belt

B Toothed belt

C Ribbed belt

D Multiple ’v’ belt

- NIMI Question Bank - Page1/ 10

9 What is the type of belt drive? 13 What is the formula to calculate the length

of round head rivet?

A L = T + d (1.3 ~ 1.6)

B L = T + d (1.6 ~ 1.2)

C L = T + d (0.8 ~ 1.2)

D L = T + d (1.4 ~ 1.6)

14 What is the formula to calculate the length

of flat head rivets?

A L = T + d (0.8 ~ 1.2)

B L = T + d (1.6 ~ 1.2)

A Open belt drive C L = T – d (0.8 ~ 1.2)

B Cross belt drive D L = T – d (1.6 ~ 1.2)

C Stepped belt drive 15 What is the distance of the rivet from the

D Right angle belt drive edge of the metal?

10 What is the nominal included angel of the V A 2D

belt? B 1.5D

A 52° C 1D

B 65° D 2.5D

C 40° 16 What is the formula to calculate the pitch

D 38° distance between rivets?

11 What is the type of pulley? A 3 x dia of rivet

B 2 x dia of rivet

C 2.5 x dia of rivet

D 3.5 x dia of rivet

17 How diameter of rivet is determined?

A D = 2.5 x Thickness

B D = 1.5 x Thickness

C D = 1.8 x Thickness

A V groove pulley D D = 1.2 x Thickness

B Flat pulley 18 What is the name of the special rivets?

C Fast and loose pulley

D Step pulley

12 What is the type of pulley?

A Speed nut

B Tublar rivet

C Explosive rivet

D Hank rivet bushes

A Fast and loose pulley

B Flat pulley

C Rope pulley

D “V” groove pulley

- NIMI Question Bank - Page2/ 10

19 What is the type of rivets? 24 What is the name of tooth element of broach

marked as ‘x’?

A Tublar rivet

B Speed nut A Land

C Hank rivet bush B Pitch

D Explosive rivet C Face

20 Which tool is used to bring the plates closely D Tooth depth

together after inserting the rivet in the hole? 25 What is the name of tool?

A Drift

B Dolly

C Rivetset

D Caulking tool

21 What is the materials used to manufacture

rivets?

A Rubber

B Synthetic

C Hardened steel

A Pull broach

D Mild steel, copper, brass

B Push broach

22 What is the name of part marked as ‘x’ in

C Surface broach

rivet?

D Continuous broach

26 What is the type of broaching?

A Tail

B Body

C Head A Pull broaching

D Diameter B Push broaching

23 Which type of rivet does not require skill C Surface broaching

while riveting? D Continuous broaching

A Solid rivet 27 What is the range of rake angle provided in

B Tublar rivet a broach teeth?

C Hank rivet bush A 6 - 8°

D Counter sink head rivet B 8 - 12°

C 12 - 15°

D 15 - 20°

- NIMI Question Bank - Page3/ 10

Questions: Level 2 8 Which pulley can transmit the power to shaft

at different heights and at varying distance?

1 Which gear changes rotary movement into A V groove pulleys

linear movement? B Flat pulleys

A Rack and pinion gears C Rope pulleys

B Hypoid gears D Fast and loose pulleys

C Herring barn gears 9 Which coupling will have self-disengaging

D Worm shaft and worm gears provision?

2 Which type of belt fastner used on heavy A Clamp coupling

duty machines? B Slip type coupling

A Cresent plate belt fastner C Universal coupling

B Lagrelle type belt fastner D Plate coupling

C Wire type belt fastner 10 Where the clamp coupling in used?

D Jackson type belt fastner A Used in boiler industry

3 Which type of knot secures rope to pipe or B Used in flywheels and rolling mills

post? C Used in automobile vehicles

A Slip knot D Used on line shaft in textiles mills

B Bowline knot 11 Where the universal coupling used?

C Square knot A Used in automobile vehincles

D Clove-hitch knot B Used on line shaft in textile mile

4 Which belt is used, if the distance between C Used in steel rolling mill

the shafts is too short? D Used in oil refineries pipe lines

A Flat belt 12 Where the wire type belt fastner is used?

B Link belt A Used on heavy machines

C ‘V’ belt B Used on medium duty machines

D Ribbed belt C Used on light duty machines

5 How the tension of the belt between two D Used for industrial purpose only

fixed pullys adjusted? 13 Where ropes drives are employed?

A Idler pulley A Mining and textile industries

B Adjustment screw B Boiler industries

C Adjusting the length of the belt C Lifting and moving equipment

D Sliding the pulley D Fabrication industries

6 What is the purpose of fitting jockey pulley 14 Which Chain drive will provide noiseless

in power transmission? and uniform drive?

A To decreases tesion of belt A Simplex chain

B To decrease the arc of contact B Triple roller type chain

C To increase tesion and arc of contact C Toothed chain

D To increase wrapping angle of belt D Duplex chain

7 Which type of pulley drive is easy for 15 Which clutch provides positive drive and can

starting and stopping? only be engaged if two elements of the

A Fast and loose pulley clutch are stationery?

B V groove pulley A Cone clutch

C Flat pulley B Air clutch

D Step pulley C Dog clutch

D Over riding clutch

- NIMI Question Bank - Page4/ 10

16 Which clutch can be engaged while one or 23 What is the name of tool to form final shape

both of the elements rotating and can riveting head?

transmit low power? A Dolly

A Air clutch B Rivet set

B Centrifugal clutch C Rivet snap

C Over riding clutch D Caulking tool

D Cone clutch 24 Which tool is closing down the edges of the

17 Which type of clutch is compact, smooth in plates and heads of rivets to form metal to

operation and very powerful? metal join?

A Cone clutch A Dolly

B Centrifugal clutch B Rivet set

C Over riding clutch C Rivet snap

D Multiplate clutch D Caulking tool

18 Which clutch joins the shaft and the gear 25 Which tool is used to make fluid - tight joint

and can be operated through a cable from by pressing the riveted edge plate?

distance? A Dolly

A Electromagnetic multiplate disc clutch B Drift

B Multiplate disc clutch C Caulking tool

C Centrifugal clutch D Fullering tool

D Single plate clutch 26 Which of the following broaching operation

19 What is the advantage of using speed nut in is more suitable for mass production?

rivets? A Pull broaching

A Self locking B Push broaching

B Minimum cost C Surface broaching

C Take more load D Continuous broaching

D Wear resistance 27 How many passes are required to complete

20 Which rivets are used in heavy structural a broaching operation?

work? A One pass

A Pan head rivet B Two pass

B Snap head rivet C Four pass

C Counter sunk rivet D Three pass

D Conical head rivet 28 What is the only disadvantage of broaching?

21 What is the name of tool used to support the A Poor finish

snap head rivet B Slow process

A Dolly C Unsuitable for heavy stock removal

B Drift D Causes distortion in work piecess

C Rivet set 29 What is the function of front pilot of a

D Rivet snap broaching tool?

22 What is the name of tool marked as ‘x’ in A Finish the final shape

riveting? B Centres the broach in hole

C Remove excess stock in hole

D Help to engage with broaching machine

30 What is the function of ‘back off angle’ in a

broaching teeth?

A To enter rear pilot

B Relive the tooth flank

A Dolly C Provide clearance of tooth face

B Rivet set D Provide clearance of tooth flank

C Fullering tool

D Caulking the tool

- NIMI Question Bank - Page5/ 10

31 Why the push broaching is not using to 37 How the broaching operation is performing?

heavy works? A With a form tool

A Increase in load damages work B “With an abrasive wheel

B Increase in load reduces finishing C With a multi point cutting tool

C Increase in load buckle the broach D With a single point cutting tool

D Very costly for big jobs 38 Which teeths of broach are removing most

32 What is the main purpose of surface of the stock in a hole?

broaching? A Finishing teeths

A Irregular shapes can be broached B Roughing teeths only

B Spline broaching C Semi finishing teeths only

C For broaching serrations D Roughing and semifinishing teeths

D Key way broaching 39 Which portion of the broaching tool supports

33 Which broaching method is using in the broach after the last teeth leaves the

horizontal broaching machine? hole?

A Pull broaching A Pull end

B Push broaching B Front pilot

C Surface broaching C Finishing teeth

D Continuous broaching D Rear pilot and follower rest

34 Which of the following statement is correct 40 Which portion of the broaching tool teeth

relating to continuous broaching? construction is designed to maintain the size

A Either work or broach moves and shape required in the finished hole?

B Work is stationary broach moves A Front pilot

C Work is stationary and broach is also B Finishing teeth

stationary C Roughing teeth

D Broach held stationary work moves D Semifinishing teeth

continuously 41 Which instrument is used to check the

35 Which operation is best suitable to produce proper depth or key seat?

following shapes in a hole? A Steel rule

B Micrometer

C Slide caliper

D Vernier caliper

42 Which rivets is used for fastening light parts

A Filing thin plates, leather, plastic etc?

B Milling A Conical head rivet

C Slotting B Counter sink head rivet

D Broaching C Snap head rivet

36 What is the type of operation can be done D Bifurcated head rivet

by the machine? 43 What is the criteria to calculate the diameter

of rivet?

A Depends upon the thickness of the

compenents

B Depends upon the required strength

C To intended use of workpiece to be rivetted

D Depends upon the type of materials

A Slotting

B Shaping

C Honing

D Broaching

- NIMI Question Bank - Page6/ 10

44 What is the criteria to select the shape of

the rivet?

A To intended use of workpiece to be rivetted

B Depends upon the required strength

C Depends upon the thickness of the material

D Depends of the material

45 What is the criteria to calculate the length of

the rivet?

A Depends upon intended to use of workpiece

to be rivetted

B Depends upon the required strength

C Depends upon the thickness of the

components to be rivetted

D Depends upon the type of materials

46 Calculate the length of the flat head rivet if

diameter is 8mm metal thickness are 8mm

and rivet propertion is ~ 0.8?

A 22mm

B 24mm

C 23mm

D 22.4mm

- NIMI Question Bank - Page7/ 10

Questions : Level 3 5 How to improve the gripping property of the

belt?

1 What is the name of the part in fast and A Apply tallow or powered resin on inner face

loose pulley assembly marked as 'x'? of belt

B Increases the tesion by jockey pulley

C Reduce the distance between the pulleys

D Increase the distance between the pulleys

6 What is a defect caused by excessive belt

tension in the power transmission?

A Reduce the life of pulleys

B Reduce the life of belt and bearings

C Increase belt slip and creap

D Reduce the surface speed of pulleys

7 Why vertical drives should be avoided in

power transmission?

A crown pulley A Because of excessive arc of contact

B fast pulley B Because of gravitational pull and slipage

C loose pulley C Because of increase in Surface speed of

D flat drive pulley pulleys

2 What is the elements of gear marked as 'x'? D Because of small wrapping of belt

8 How to rectify the defect of "Belt wrapping

Excessively" in power transmission?

A Reduce the tension of belt

B Align the pulleys

C Increase the tension of belt

D Provide and idle pulley

9 What is the reason of frequent belt slipage

in power transmission?

A Flank A Less tension, oilness in the groove

B Addendum B More pulsating load between pulleys

C Face width C High starting load between pulleys

D Root circle D Excessive heat, misalignment, foreign

3 What will be the effect, if the wrapping angle particles

is big in belt drive? 10 What is the distance from the edge to centre

A High torque of the rivet to prevent splitting of the edge?

B Low torque A 3 x dia of rive

C Low load B 2 x dia of rivet

D Low speeds C 2.5 x dia of rivet

4 What is the ultimate result of belt slip and D 3.5 x dia of rivet

creep in power transmission?

A RPM drop

B Power loss

C Increases of surface speed of belt

D Increases the life of belt

- NIMI Question Bank - Page8/ 10

11 What is the defect cause in the rivet? 15 Which is the fault in riveting?

A Burrs between plates

A Rivet not perpendicular to plate

B Rivet head not centered

B Too little allowance given

C Too much allowance given

C Too much allowance given

D Holes on the plate are not in line

D Burns between plates

16 What is the name of fault in riveting?

12 What is the fault in riveted joint?

A Too little allowance

B Burrs between the plates

A Burrs between plates C Holes on the plate not in line

B Improper joining of plates D Rivet body not perpendicular

C Rivet head not centered with the shank 17 What is the reason for faulty rivetting?

D Body of the rivet not perpendicuar to the

plate

13 What is the defect in riveted joint?

A Burrs between plates

B Too much allowance given

C Improper joining of plates

A Burrs between the plates

D Too little allowance given

B Holes on the plate not in line

C Rivet head not centered with body

D Too much allowance has been given

14 What is the reason for faulty rivetting?

A More allowance

B Rivet head is not centred

C The holes on the plate are not in line

D Burrs between the plates and in drilled holes

- NIMI Question Bank - Page9/ 10

Module 3 - Rivets and Riveting - Key paper

Questions: Level 1 Questions: Level 2 Question: Level 3

SL.No Key SL.No Key SL.No Key SL.No Key

1 A 1 A 37 C 1 A

2 C 2 B 38 B 2 B

3 A 3 D 39 A 3 A

4 B 4 C 40 B 4 B

5 D 5 A 41 C 5 A

6 B 6 C 42 D 6 B

7 C 7 A 43 B 7 B

8 A 8 C 44 A 8 D

9 B 9 B 45 C 9 D

10 C 10 D 46 D 10 B

11 B 11 A 11 A

12 D 12 C 12 C

13 A 13 A 13 A

14 A 14 C 14 A

15 A 15 C 15 D

16 A 16 D 16 A

17 A 17 D 17 C

18 A 18 A

19 C 19 A

20 C 20 A

21 D 21 A

22 B 22 C

23 B 23 C

24 A 24 D

25 A 25 D

26 B 26 D

27 C 27 A

28 C

29 B

30 B

31 B

32 A

33 A

34 D

35 A

36 C

- NIMI Question Bank - Page10/ 10

Fitter - Semester II - CITS - Module 4 : Jigs and Fixture

Questions: Level 1 5 What is the name of jig?

1 What is the name of jig?

A Post jig

B Solid jig

A Leaf jig C Channel jig

B Solid jig D Trunnion jig

C Table jig 6 What is the name of clamp used in jig?

D Angle plate jig

2 What is the name of jig?

A Tooth clamp

B Latch clamp

A Box jig C Toggle clamp

B Post jig D Wedge clamp

C Turn over jig 7 What is the name of jig?

D Sandwich jig

3 What is the name of clamp?

A Box jig

B Drill jig

C Post jig

A Strap clamp

D Leaf jig

B Cam clamp

8 What is the type of jig?

C Latch clamp

D Screw clamp

4 Which type of fixture used for machining on

evenly spaced surfaces?

A Plate fixture

B Vice jaw fixture

C Indexing fixtures A Post jig

D Angle plate fixture B Plate jig

C Indexing jig

D Angle plate jig

- NIMI Question Bank - Page1/ 10

9 What is the name of part marked as 'x' in 13 What is the name of part marked as 'x' in fly

power press? press?

A Handle

B Guide

A Ram C Punch

B Bolster plate D Die

C Bed 14 What is the name of part marked 'x' in fly

D Fly wheel press?

10 What is the name of part marked as 'x' in

power press?

A Arrestor

B Handle

C Nut

D Guide

15 What is the name of press tool?

A Ram

B Bolster plate

C Bed

D Fly wheel

11 What is the name of power press?

A Piercing tool

B Blanking tool

C Progressive tool

A Horn bar press D Compound tool

B Adjustable bed press 16 What is the name of press tool?

C Pillar press

D Gap press

12 What is the name of power press?

A Piercing tool

B Cut off tool

A Horn bar press

C Parting off tool

B Adjustable bed press

D Progressive tool

C Pillar press

D Gap press

- NIMI Question Bank - Page2/ 10

17 What is the name of press tool? 22 What is the name of part marked as 'x'?

A Piece part

B Punch

A Blanking tool

C Strip

B Piercing tool

D land

C Compound tool

D Progressive tool 23 What is the name of part marked as 'x'?

18 What is the name of press tool?

A Die

B Die size

C Land

D Ejector

A Blanking tool 24 What is the name of part marked as 'x'?

B Piercing tool

C Compound tool

D Progressive tool

19 What is the name of the portion of materials

remaining between two adjacent openings

after blanking? A Die size

A Strip layout B Die straight

B Strip C Die opening

C Scrap bridge D Land

D Unit stock

25 What is the minimum economy factor

20 Which material is required greater angular percentage for strip layout?

clearance in die? A 40%

A Very hard materials B 60%

B Soft materials C 50%

C Hard materials D 70%

D Normal materials

26 Which stage of punch movement the

21 What is the normal value of angular material breaks while punching?

clearance in die? A One and half stage

A 2 degrees per side B Second stage

B 1 degree per side C Third stage

C 2.5 degrees per side D First stage

D 1.5 degrees per side

27 How the amount of cutting clearance is

expressed?

A Clearance per side

B Clearance in two side

C Clearance in all side

D Clearance three side

- NIMI Question Bank - Page3/ 10

28 How many factors are to be considered for

visual examination of punched component?

A 1

B 2

C 3

D 4

- NIMI Question Bank - Page4/ 10

Questions: Level 2 9 Which device is used to hold, locate and not

guide the cutting tool during machining

1 Which type of bush is used in jig to perform operation?

more than one operation in same location? A Jig

A Slip bush B Fixtures

B Plain bush C ‘C’ clamp

C Fixed bush D Machine vice

D Liner bush 10 Which type of fixture is provided an easy

2 Why the balancing weight is provided in the method of holding parts for machining?

turning fixture? A Turning fixture

A To guide tool B Vice fixture

B To balance the tool C Nailling fixture

C To balance worktable D Grinding fixture

D To balance irregular workpiece 11 Why the tenons provided at the bottom of

3 What is the purpose of setting blocks used in base plate of milling fixture?

the fixture? A For guiding the tool

A Position the balancing weight B For clamping purpose

B Position the clamp and locators C For balancing workpiece

C Position the fixture on machine table D For proper location of fixture

D Position the fixture and work related to cutter 12 Which type of press is commonly used in

4 Why two or four hold down slots are provided industry?

in the base plate of milling fixture? A Gap press

A For rigid clamping B Inclinable press

B For guiding the tool C Adjustable bed press

C For locating workpiece D Horn bar press

D For adjusting the job setting 13 Which type of power press have the

5 Which bush is used to provide a hardened mechanical arrangement for raising or

hole for renewable bushes? lowering the bolster press?

A Slip bush A Gap press

B Plain bush B Inclinable press

C Fixed bush C Adjustable bed press

D Liner bush D Horn bar press

6 Which part restrict the movement of the 14 Which type of power press is suitable for

component in jig? heavy work?

A Clamp A Gap press

B Guide plate B Inclinable press

C Locating pin C Adjustable bed press

D Press fit bush

D Straight slide press

7 What is the purpose of drill bushes provided

15 Which type of power press is used for

in the drill jig?

forming and deep drawing?

A To support base plate

A Horn bar press

B To support drill plate

B Pillar press

C To locate and guide cutting tool

C Inclinable press

D To restrict the movement of job

D Straight slide press

8 Which type of jig is used for drilling holes at

16 Which press tool is used to make holes in

different directions?

the stamping?

A Post jig

A Blanking tool

B Solid jig

B Piercing tool

C Trunnion jig

C Progressive tool

D Indexing jig

D Compound tool

- NIMI Question Bank - Page5/ 10

17 Which press tool is used to separates the 24 Which is the special process to manufacture

work material along a straight line in a single collapsible tubes and shells?

cut? A Extrusion

A Cut off tool B Bending

B Perforating tool C Embossing

C Trimming tool D Planishing

D Notching tool 25 Which press tool operation a flat blank is

18 Which press tool perform two or more transformed into a cup or shell?

operation at different stages every stroke? A Embossing

A Blanking tool B Drawing

B Piercing too C Coining

C Compound tool D Forming

D Progressive tool 26 Which press tool operation is used to

19 Which press tool is performing two or more strengthen and provide a protective edge?

cutting operation in same stage in single A Curling

stroke? B Drawing

A Blanking tool C Bending

B Compound tool D Embossing

C Progressive tool 27 Which tool is used to clear the blanks will

D Piercing tool have straight walls without angular

20 What is the name of press tool operation of clearance?

removing the excess metal that remains after A Thrust plate

a deep drawing operation? B Stripper

A Notching C Ejector

B Trimming D Stopper

C Shaving 28 Calculate the cutting force for the

D Piercing component?

21 Which press tool operation is a continuous

bending and cutting along a line in the work

material?

A Notching

B Shaving

C Lancing

D Trimming A 54.12 KN

22 Which press tool operation removes a small B 54.21 KN

amount of material from the edges of the C 45.21 KN

strip? D 45.12 KN

A Trimming 29 Which tool is used to produce flat

B Notching components?

C Shaving A Contour tool

D Lancing B Blanking tool

23 Which press tool operation is used to press C Gang die / tool

letters and numbers into a sheet metal? D Piercing tool

A Broaching 30 Which operation is carried out if the blanks

B Planishing has two parallel side in strip?

C Coining A Forming operations

D Embossing B Cut off operation

C Blanking operations

D piercing operations

- NIMI Question Bank - Page6/ 10

31 How the cutting force is reduced while using

lower capacity press?

A By stamping punches

B By reducing the sheet thickness

C By increasing the punch length

D By decreasing the punch length

32 What is the formula for calculating ideal

clearance between punch and die?

Tmax

A C XS X

12

Tmax

B C XS X

10

Tmax

C C XS X

20

S

D C X Tmax

10

33 Calculate the cutting clearance of piercing

punch & pierced hole of the component?

A 12 micron / side

B 0.12mm / side

C 0.012mm / side

D 0.0012mm / side

- NIMI Question Bank - Page7/ 10

Questions: Level 3 8 What will be the result, if misalignment

between punch and die?

1 Which of the following fixture is used for A Clearance on one side increases

machining the part at right angles other than B Clearance on all side increases

90°? C If cutting edges are sharp

A Plate fixture D Initial pressure will be more

B Vice jaw fixture 9 What will be result, if excessive clearance is

C Modified angle plate fixture given between punch and die?

D Indexing fixture A Heavy burrs are formed

2 What is the remedy of using lower capacity B Light burrs are formed

press for higher cutting force? C No burrs are formed

A Reduce the clearance D Medium burrs are formed

B Increase the clearance 10 What will be result, if the gap between the

C Reduce the cutting force punch and die is comparatively more?

D Increase the cutting force A A barnished cut bend is produced

3 What is reason for the die wall below the B Small edge radius is formed

land are relived at an angle? C The edge radius becomes larger

A Easy to cutting of punch D Width of cut band will be more

B Blanks to fall off the die easily 11 What will be result, if the cutting clearance is

C Easy location of strip optimum?

D Morking strip easily A The stock materials reacts to the initial

4 What will be the result, if the inner walls of pressure

the die opening are straight? B Small edge radius is formed

A Heavy burrs are formed C The edge radius becomes larger

B Piece part will pass through the die opening D Width of cut band will be more

freely 12 What is the reason for wide run is preferred

C Blank get jammed in strip layout?

D No burrs in blanks A Easy feeding of strip

5 What is the reason for two or more cut bands B Difficult in feeding

will be formed? C Feed can be by automatic

A Misalignment D Depends upon productions layout

B Optimum cutting clearance 13 What will be the result, if bending the strip

C Excessive cutting clearance along the grains directions?

D Insufficient cutting clearance A May develop cracks

6 What is the reason for the cut band becomes B It is very easy bend the same direction of

smaller? grain

A Misalignment C It may be difficult to bend

B Insufficient cutting clearance D It may be not develop crack

C Excessive cutting clearance 14 What is the method of reducing cutting

D Optimum cutting clearance force?

7 What is the reason for punched components

are having heavy burrs?

A Optimum cutting clearance

B Excessive cutting clearance

C Insufficient cutting clearance

D Mis aligment

A Reducing clearance angle

B By stepping punches

C By providing angular clearance

D By providing shear angle

- NIMI Question Bank - Page8/ 10

15 What will be the result, if cutting clearance is

less?

A Small edge radius is formed

B Width of cut band will be more

C Width of cut band will be less

D Edge radius becomes larger

- NIMI Question Bank - Page9/ 10

Module 4 : Jigs and Fixture - Key paper

Questions: Level 1 Questions: Level 2 Questions: Level 3

SL.No Key SL.No Key SL.No Key

1 D 1 A 1 C

2 C 2 D 2 C

3 B 3 D 3 B

4 C 4 A 4 B

5 C 5 D 5 D

6 C 6 C 6 C

7 A 7 C 7 B

8 C 8 C 8 A

9 A 9 B 9 A

10 B 10 B 10 C

11 A 11 D 11 B

12 C 12 B 12 A

13 C 13 C 13 A

14 A 14 D 14 D

15 B 15 B 15 B

16 A 16 B

17 D 17 A

18 C 18 D

19 C 19 B

20 B 20 B

21 D 21 C

22 C 22 B

23 D 23 D

24 D 24 A

25 B 25 B

26 C 26 A

27 A 27 C

28 D 28 C

29 B

30 B

31 A

32 B

33 B

- NIMI Question Bank - Page10/ 10

Fitter - Semester II - CITS - Module 5 - Lapping and Honing

Questions: Level 1 5 What type of abrasives are used in honing

the cast iron and hardened steel?

1 Which is used to clean the lapping plate A Diamond

after charging? B Boron carbide

A Oil C Silicon carbide

B Kerosene D Aluminium oxide

C Coolant oil 6 Which material is used to make small

D Petroleum jelly diameter laps?

2 Which abrasive is used to lapping soft steel A Cast iron

and nonferrous metals? B Aluminium

A Diamond C Bronze or zinc

B Boron carbide D Copper or brass

C Silicon carbide 7 What is lapping?

D Aluminium oxide A Filing operation

3 What is the name of part marked ‘x’ in B Grinding operation

lapping tool? C Chiseling operation

D Precision finishing operation

8 What is the name of the lap tool?

A Slit

B Bush

C Sleeve

A Split bush lap

D Groove

B Adjustable ring lap

4 What is the name of operation?

C Adjustable solid lap

D Charging cylindrical lap

9 What is the name of term?

A Internal ring lapping

B External ring lapping

C Lapping internal cylinder

D Lapping large diameter

A Roughness

B Waviness

C Surface texture

D 'Ra' values

- NIMI Question Bank - Page1/ 7

10 What is the term marked as 'X'? 15 Which term in the surface finish is

expressed and assessed numerically?

A Waviness

B Roughness

C Surface texture

D Primary texture

16 Which surface texture is centre line

average?

A Primary texture

B Profile

A Waviness C 'Ra" value

B Tool feed marks D Lay

C Profile

17 Which representation of 'Ra' value?

D Lay

11 What is the term marked as 'X'?

A Geometrical

B Radial line

C Parallel line

A Profile D Graphical

B Waviness (Secondary textures) 18 What is the 'Ra' value expressed in terms of

C Roughness (Primary texture) micrometer?

D Waviness spacing A '0.00001 metre

12 Which device the surface texture is B '0.000001 metre

extremely fine and practically no waviness? C '0.0001 metre

A 'V' Block D '0.001 metre

B Angle plate 19 What is the roughness grade number

C Slip gauges range?

D Surface plate A N1 to N10

13 Which places the quality of the surface B N1 to N18

texture is very important? C N1 to N15

A Vibrations D N1 to N12

B Heat treatment 20 Which instrument is used for measuring the

C Chatter surface texture in mechaincal type?

D Sliding surfaces A Taly surf

14 Which surface texture is needed for the B Electronic surface indicator

movement of the piston with cylinder bore of C Surface finish standards

an engine? D Mechanical surface indicator

A Waviness

B Certain degree of roughness

C Profile

D Lay

- NIMI Question Bank - Page2/ 7

21 What is the name of the surface measuring

instrument?

A Electronic surface indicator

B Taly surf

C Mechanical surface indicator

D Surface finish standards

22 What is the name of the surface measuring

instrument?

A Dial test indicator

B Electronic surface indicator

C Mechanical surface indicator

D Lever type indicator

23 How many blocks consists in the surface

finish standard?

A 25 blocks

B 30 blocks

C 20 blocks

D 15 blocks

24 What is the name of finishing process

carried out by using abrasive sticks for the

removal of stock?

A Honing

B Lapping

C Grinding

D Filing

- NIMI Question Bank - Page3/ 7

Questions: Level 2 8 Which abrasive is used for lapping soft

steels and non-ferrous metals?

1 Which finishing process has a high degree A Silicon carbide

of dimensional accuracy? B Diamond

A Filing C Boron carbide

B Turning D Fused alumina

C Grinding 9 Which abrasive is used for lapping dies and

D Lapping gauges?

2 What is the purpose of slit provided in the A Boron carbide

lapping tool? B Silicon carbide

A For clearance C Diamond

B For expansion D Aluminium oxide

C To retain abrasive 10 Which is the hardest abrasive material used

D To adjust the sleeve for lapping tungsten carbide?

3 Why manual stroking is prefered for large A Silicon carbide

quantities in honing operation? B Boron carbide

A To reduce cost C Diamond

B To reduce time D Aluminium oxide

C To keep close tolerance 11 Which lap is used for lapping accurately

D To reduce maintenance cost finishing very small holes?

4 Which operation the fine abrasive particles A Close grained iron

are used? B Rotary diamond laps

A Filing C Copper

B Lapping D Brass

C Scraping 12 What is the purpose of lapping tool?

D Polishing

5 Which finishing process the tool rotate and

reciprocate simultaniously?

A Drilling

B Honing

C Lapping

D Grinding

6 What is the finishing process carried out

A Lapping tool for external surface

with abrasive sticks to correct the profile of

B Lapping tool for internal surface

cylindrical surfaces?

C Lapping tool for external cylindrical surface

A Lapping

D Lapping tool for flat surface

B Honing

13 Which term is the irregularities in the

C Grinding

surface texture result from the inherent

D Filing

action of the production process?

7 Which type of abrasive material used for

A Waviness

lapping hardened steel and heavy stock

B Roughness

removal?

C Surface texture

A Silicon carbide

D 'Ra' values

B Aluminium oxide

14 Which is the term of the surface texture

C Boron carbide

upon that roughness is super imposed?

D Diamond

A 'Ra' values

B Primary texture

C Roughness

D Waviness

- NIMI Question Bank - Page4/ 7

15 Which is the term may result from machine 23 What is the name of process that achieving

or work deflections and vibrations? a high degree of dimensional accuracy?

A Roughness A Honing

B Waviness B Filling

C Primary texture C Lapping

D 'Ra' values D Turning

16 Which method is used for expressing the 24 Which abrasive has excellent cutting

surface texture quality numerically? properties and expensive?

A Primary texture A Boron carbide

B 'Ra' value B Silicon carbide

C Waviness C Diamond

D Lay D Aluminium oxide

17 Which samples are used for comparing and 25 What is the process to improve the quality of

determining the quality of surfaces earlier? fit between the mating components?

A Components A Lapping

B Test pieces B Honing

C Slip gauges C Turning

D Surface finish standards D Filling

18 What denotes in the symbol 'ÑÑ' in surface 26 What will happen with excessive application

finish standard? of the abrasive compound in lapping

A Machining allowance operation?

B Roughness values A Develop good accuracy

C Roughness symbol B Develop fine finish

D Roughness grade number C Develop smooth finish

19 What is the roughness grade number for D Develop inaccuracies

roughness symbol ÑÑÑÑ? 27 Which process small amount of materials

A N7 to N9 are removed by rubbing the work?

B N4 to N6 A Honing process

C N1 to N3 B Lapping process

D N10 to N11 C Filling process

20 What is the equal roughness value for D Turning process

roughness grade number 'N6'? 28 How to true the lap plate surface before

A 1.6 Microns lapping?

B 0.2 Microns A By honing

C 0.8 Microns B By scraping

D 0.4 Microns C By grinding

21 What denotes the "Ra 63 µm" in surface D By filling

finish standard? 29 Which abrasive is used for lapping in cast

A Machining allowance iron?

B Roughness values A Diamond

C Other roughness values B Silicon carbide

D Sampling length C Aluminium oxide

22 What is the surface roughness value D Boron carbide

expected from filing process? 30 Which abrasive material is used for

A 6.3 to 100 Microns obtaining high quality finish?

B 0.32 to 25 Microns A Boron carbide

C 0.25 to 25 Microns B Diamond

D 1.6 to 25 Microns C Aluminium oxide

D Silicon carbide

- NIMI Question Bank - Page5/ 7

Questions : Level 3 8 Why manual stroking is preferred in honing

operation?

1 Why grooves are provided on the surface of A Flexibility in operation

the laping plate? B Easy in operation

A To allow expansion C Easy in mass production

B To provide clearance D Economy in operation

C To retain the abrasive paste 9 What is the process of corrects the profiles

D To permit minor adjustment of cylindrical surfaces?

2 What is the cause if the lap is harder than A Honing

the workpiece? B Lapping

A Workpiece will cut the lap C Scraping

B Accuracy can’t be obtained D Grinding

C Lap will cut the workpiece 10 What is the main advantage of power

D Lapping operation leaves high spots stroking in honing operation?

3 Why holes are provided in ring type lap? A Economical in mass production

A Lubrication B Economical in small parts

B Removal of heat C Flexibility in operation

C Hold lapping compound D Tolerances are extremely close

D Increase the efficiency 11 What is the precaution to be observed while

4 Which term used, if the movement of the lapping operation?

cutting tool leaves certain lines or patterns A Do not dwell in the same place

on the work surface while machining? B Should travel the full length of the core

A Roughness C Adjustable ring lap will have slots

B Surface texture D Produce high surface finish

C Wariness

D 'Ra' values

5 What is the abrasive grain sizes required for

lapping depending on the surface finish?

A 50 - 800

B 800 - 100

C 20 - 40

D 1000 - 1200

6 What is the advantages of dry lapping?

A Better finishing and appearance

B Rough finishing

C Reduce the cost

D Processing time is reduced

7 What is the advantage of silicon carbide

abrasive, while lapping the sharp cutting

edges?

A Heavy stock removal

B High quality finish

C Specialised application

D Hardest of all material

- NIMI Question Bank - Page6/ 7

Module 5 : Lapping and Honing - Key paper

Questions: Level 1 Questions: Level 2 Question: Level 3

SL.No Key SL.No Key SL.No Key

1 B 1 D 1 C

2 D 2 B 2 A

3 A 3 C 3 C

4 D 4 B 4 B

5 C 5 B 5 A

6 D 6 B 6 A

7 D 7 A 7 A

8 A 8 D 8 A

9 C 9 A 9 A

10 B 10 C 10 B

11 B 11 B 11 A

12 C 12 C

13 D 13 B

14 B 14 D

15 C 15 B

16 C 16 B

17 D 17 D

18 B 18 C

19 D 19 C

20 D 20 C

21 C 21 B

22 B 22 C

23 C 23 C

24 A 24 A

25 A

26 D

27 B

28 B

29 B

30 C

- NIMI Question Bank - Page7/ 7

Fitter - Semester II - CITS - Module 6 : Sine Bar and Slip Gauge

Questions: Level 1 4 What is the name of measuring instrument?

1 What is the part marked as 'x' in sine bar?

A Slip gauges along with the special jaws

B Threaded clamp type divider

C Parallel jaw caliper

D Vernier caliper

A Length 5 What is the name of instrument?

B Depth surface

C Contact rollers

D Width

2 What is the part marked as 'x'?

A Height gauge with slip gauge holder

B Vernier height gauge

A Height of slip gauge

C Depth micrometer

B Length of sine bar

D Clamp type height gauge

C Datum surface

D Adjacent side 6 What is the name of part marked as 'x'?

3 What is the name of gauge?

A Sine bar

A Feeler gauge

B Slip gauges

B Slip gauge

C Dial gauge

C Radius gauge

D Datum surface

D Angle gauge

- NIMI Question Bank - Page1/ 12

7 What is the name of part marked as ‘x’ in 10 What is the name of the part marked as ‘X’

dial gauge? in lever type dial test indicator?

‘X’

X

A Pivot

A Anvil B Lever

B Stem C Stylus

C Pointer D Scroll

D Plunger 11 What is the name of the part marked as ‘X’

8 What is the name of part marked as ’X’? in dial test indicator?

‘X’

A Anvil

A Stem

B Stem

B Pointer

C Pointer

C Back lug

D Plunger

D Bezel clamp

12 Which instrument is used to magnify small

9 What is the name of instrument?

variation in sizes by means of pointer on a

graduated dial?

A Dial test indicator

B Inside micrometer

C Dial vernier caliper

D Vernier micrometer

13 Which precision instrument is used for

comparing and determining the variation in

A Dial vernier calliper the sizes of the component?

B Vernier micrometer A Micrometer

C Dial test indicator lever type B Comparators

D Dial test indicator plunger type C Dial test indicator

D Vernier bevel protector

14 What mechanism is used in the lever type

dial test indicator?

A Screw and nut

B Rack and pinion

C Lever and scroll

D Worm and worm wheel

- NIMI Question Bank - Page2/ 12

15 Which of the part in two point self-centering 22 What is shown in dovetail part?

bore dial gauge contains the mechanism for

transmitting the plunger motion to the dial?

A Centering shoes

B Fixed anvil insert

C Dial

D Stem

16 What is the name of act of joining the slip

gauges together while building up to sizes? A Parallel block and pins

A Setting B Work piece, round rods and slip gauges

B Joining C Packing blocks and round rods

C Butting D Slip gauges and precision rollers

D Wringing 23 How a sine bar is specified??

17 What is the material used to make protector A By the weight

type slip gauges? B By the length of sine bar

A Cast iron C By the width of sine bar

B Silicon carbide D By use thickness of sine bar

C Aluminium oxide 24 What is the name of hoist?

D Tungsten carbide

18 Which of the following is a desired property

of slip gauge material?

A Resilience

B Toughness

C Low thermal expansion

D High thermal expansion

19 What is the name of instrument?

A Differential hoist

B Screw geared hoist

C Spur geared hoist

D Come along chain hoist

25 What is the type of rope?

A Sine bar

B Slip gauge A Long lay rope

C Angle block B Regular lay rope

D Parallel block C Combined lay rope

20 Which one of the following is the principle D Flexible lay rope

of sine bar? 26 Which type knot will have non-Slipping eye

A Cubic function and easy to untie?

B Linear function A Clove Hitch knot

C Quadratic function B Square knot

D Trigonometrical functions C Slip knot

21 Which one of the following instrument is D Bowline knot

more accurate to measure angles?

A Sine bar

B Protractor

C Vernier bevel protractor

D Protractor head of combination set

- NIMI Question Bank - Page3/ 12

27 Which type of rope is used to join two 32 What is the type of lifting equipment?

pieces of rope of equal diameter?

A Bowline knot

B Square Knot

C Clove nitch knot

D Slip knot

28 Which moving equipment is used to move

the machine easy and fast?

A Crowbar A Gin pole derrick

B Lifting jack B Guy derrick

C Rollers C Stiff leg derrick

D Forklift D Breast derrick

29 What is the name of moving equipment? 33 What is the name of process forming

strands and untwisting of the strands in rope

binding?

A Laying and re-laying

B Crowning

C Whipping

D Round turn

34 What is the name of permanent method of

fastening of stands of a rope with slight

enlargement at the end?

A Rollers A Knot

B Tangs B Whipping

C Forklift C Loop

D Crow bars D Crowning

30 What is the name of lifting equipment? 35 What is the name of rope binding method?

A Crowning

B Whipping

A Tripod derrick C Knot

B Frame derrick D Round turn

C Gin pole derrick 36 What is the name of process in which

D Guy derrick fastening of one part of a rope to another

31 What is the name of lifting equipment? part of the rope?

A Knot

B Loop

C Crowning

D Whipping

37 What is meant by bight in rope binding

terminology?

A Frame derrick A Crossing the sides of rope

B Stiff leg derrick B Bending of a rope

C Breast derrick C Bending of one side of loop

D Guy derrick D Fastening of rope one part to other

- NIMI Question Bank - Page4/ 12

38 What is meant by “Loop” in rope binding 44 What is the type of rope?

terminology?

A Bending of rope

B Fastening of rope

C Turn made by crossing the sides of bight

D Binding of rope A Regular lay rope

39 What is the name of rope binding method? B Flxible lay rope

C Lang lay rope

D Combined lay rope

45 What is the type of chain hoist?

A Loop

B Bight

C Knot

D Round turn

40 What is the name of rope binding method?

A Differential hoist

B Screw geared hoist

C Spur geared hoist

D Come along chain hoist

46 Which type of chain hoist has two separate

A Loop chains and the sheave drives a worm and

B Round turn gear arrangement?

C Knot A Differential hoist

D Bight B Spur geared hoist

41 Which rope is manufactured from the fibre C Screw geared hoist

of wild plants? D Come along chain hoist

A Fibre and yarn ropes 47 Which chain hoist is fitted with gear

B Cotton and steel reduction unit?

C Manila and hemp ropes A Differential hoist

D Synthetic fibre and cotton B Spur geared hoist

42 Which wire rope strands are twisted in the C Screw geared hoist

same direction? D Come along chain hoist

A Regular lay rope 48 What is the type of chain hoist?

B Combined lay rope

C Lang lay rope

D Rigid lay rope

43 Which wire rope strands are twisted in the

opposite direction?

A Regular lay rope

B Combined lay rope

C Lang lay rope

D Rigid lay rope

A Screw geared hoist

B Spur geared hoist

C Differential hoist

D Come along chain hoist

- NIMI Question Bank - Page5/ 12

49 What is the other name of come along chain 53 What is the name of the crane?

hoist?

A Differential hoist

B Spur geared hoist

C Forklift

D Pull lift

50 What is the type of chain hoist?

A Pillar jib crane

B Travelling wall crane

C Bracket jib crane

D Gantry crane

54 What is the name of crane that can raise

loads and transport them to other locations?

A Gantry crane

B Travelling crane

C Truck mounted crane

A Differential hoist D Bracket jib crane

B Spur geared hoist

C Pull lift

D Screw geared hoist

51 What is the type of stationary crane?

A Tripod derrick

B Gin pole derrick

C Frame derrick

D Stiff leg derrick

52 What is the name of the crane?

A Travelling crane

B Bracket jib crane

C Gantry crane

D Pillar jib crane

- NIMI Question Bank - Page6/ 12

Questions: Level 2 6 What grade of slip gauge is used for

inspection purpose?

1 What is the name of instrument measuring A Grade ‘00’ accuracy

external diameter of work piece? B Grade ‘0’ accuracy

C Grade ‘I’ accuracy

D Grade II accuracy

7 What grade of slip gauge is used as

standard for reference to test all the other

grade?

A Grade ‘00’ accuracy

B Grade ‘0’ accuracy

A Parallel leg caliper C Grade I accuracy

B Outside caliper D Grade II accuracy

C Pair of special jaws with slip gauge

8 How do you protect slip gauges from rust?

D Vernier caliper

A Apply oil

2 Which grade slip gauge is used for general B Apply kerosene

workshop application? C Apply wax

A Grade I accuracy D Apply petroleum jelly

B Grade ‘0’ accuracy

9 What material is used to clean the slip gauge

C Grade ‘00’ accuracy

before use?

D Grade II accuracy

A Petroleum jelly

3 What is the measurement shown in the dial B Carbon tetrachoride

indicator its basic measurement is 40.00 C Lubricant oil

mm? D Acid free vaseline

10 What is the purpose of balls and rollers in

dovetail measurement?

A To provide taper contact

B To provide angular contact

C To protect finished surface

D To provide point or line contact

11 What kind of finishing processes is

A 40.05 to 40.06 employed for finishing the measuring faces

B 39.05 to 39.06 of slip gauges?

C 40.5 to 40.6 A Honing

D 39.5 to 39.6 B Lapping

4 What are the grades in slip gauges are C Scraping

recommended as per IS? D Surface grinding

A Grade 1,2,3 12 What is the use of grade ‘0’ accuracy slip

B Grade I,II,III gauge?

C Grade 0,I,II A Used in tool room applications

D Grade 00,0,I,II B Used in inspection purposes

5 What grade of slip gauge is used for precision C General workshop applications

tool room applications? D Calibration grade for standard referance

A Grade ‘0’ accuracy

B Grade II accuracy

C Grade I accuracy

D Grade ‘00’ accuracy

- NIMI Question Bank - Page7/ 12

13 What is the height of slip gauge pack, if 19 What measurement is taken in the shown

length of the sine bar is 200mm and angle is figure using slip gauges and precision

20°? (sin 20°=0.3420)? cylindrical pins?

A 63.4 mm

B 68.4 mm

C 72.5 mm

D 75.3 mm

14 What is the height of slip gauge pack, if

length of the sine bar is 100 mm and angle

is 15°? (sin15° = 0.2588)?

A 2.588 mm

A Width of the job

B 258.8 mm

B Length of the job

C 25.88 mm

C Thickness of the job

D 1.2588 mm

D Centre distance between the holes

15 What is the purpose of ‘wringing’ in the

20 What is the purpose of clove hitch knot in

usage of slip gauges?

rope?

A Joining of slip gauges to gether

A For lifting light loads

B Cleaning of slip gauges

B Secures rope to pipe or post

C Dismantling of slip gauges

C Secures rope to small pipe or ring

D Checking the quality of slip gauges

D Joins two pieces of ropes

16 What is the use of sine bar?

21 Which type of knot is used for shortening a

A To measure angle

rope without cutting?

B To measure length

A Bowline knot

C To measure weight

B Square Knot

D To measure diameter

C Slip knot

17 Which side of a right angle triangle is

D Sheep shank knot

formed by the sine bar in the angle

22 Which type of rope knot is used for lifting

measuring set up?

light loads?

A Hypotenuse

A Slip knot

B Adjacent side

B Bowline knot

C Opposite side

C Clove nitch knot

D Any side can be formed

D Sqaure Knot

18 What is the length of the sine bar?

23 What is the purpose of triangular with base

A Total length of the rectangle of sine bar

resting on the ground in the frame derrick

B Distance between the inner diameter of

lifting equipment?

rollers

A Prevent the vibartion

C Distance between the centres of the rollers

B Prevent imbalance of load

D Distance between the outer diameter of

C Prevent base from moving under load

rollers

D Avoid slipping of load

24 Which rope is used for heavy duty noisting?

A Wire ropes

B Cotton ropes

C Yarn ropes

D Manila ropes

- NIMI Question Bank - Page8/ 12

25 Which is the least efficient but most 33 What is the purpose of holes drilled across

common type of chain hoist? the sine bar?

A Screw geared hoist A To marking cut off jobs

B Spur geared hoist B Clamping of sinebar on angle plate

C Differential hoist C To better appearance

D To measure the angle is easy

D Come along chain hoist

34 Which of the following operation is carried

26 Which chain hoist is most efficient type

out in broaching machine?

among other chain hoist? A Threading

A Differential hoist B Grinding

B Screw geared hoist C Spline cutting

C Come along chain hoist D Enlarge the hole

D Spur geared hoist 35 What is the purpose of balls or rollers are

27 Which type of chain hoist is used to lift loads used to determine the dovetial angle by

to short distances only? using slip gauge?

A Spur geared hoist A It contacts less area

B Differential hoist B Calculate the size and taper accurately

C Point or line contact

C Come along chain hoist

D It has bright Appearance

D Screw geared hoist

36 Calculate the small end diameter of the

28 Which lifting equipment is used to lift the

tapered components if S=6.34mm, R=6mm,

load and shift them to different places?

Y=61.5mm?

A Pull lift

B Fork lift

C Differential hoist

D Spur geared hoist

29 Which type of stationary crane (Derrick)

used as a temporary hoist raise and lower

light loads with single pole?

A Tripod derrick

B Gin-pole derrick

C Stiff leg derrick A 30.68mm

D Breast derrick B 36.82mm

C 61.5mm

30 How jib cranes are generally operated?

D 24.68mm

A Mechanical power

B Electric power 37 What is the formula for determining small

C Hydraulic power end diameter of tapered component?

D Pneumatic power

31 How jib crane is used to move the load?

A Horizontally

B Vertically

C Inclind angle

D Radialy

32 What is the main advantage of toothed

chain drive? A 90−Q

Q=

A It increase the tension chain drive 2

B It provides high speed low torque r

B S=

(90 − Q)

transmission tan

2

C It provides noise less and uniform drive r

C S=

D It is effiecient between shafts in short Tan Q

2

distance D d = y -2 (s + r)

- NIMI Question Bank - Page9/ 12

Questions: Level 3 7 What is the size of slip gauge build up?

1 Calculate the angle of tapered components

the height of the slip gauge is 84.52 mm, the

length of the sine bar is 200 mm?

A 25°

B 28°

C 31°

D 22°

2 What is the procedure to built up the slip A 44.872 mm

gauge for particular dimension? B 44.8725 mm

A Start wringing with the small slip gauge C 44.8572 mm

B Use maximum number of blocks D 44.2875 mm

C Use minimum number of blocks 8 What could be the reason, if the pointer of

D Built with grade ‘0’ accuracy dial gauge moves clockwise direction, if the

3 Calculate the internal dovetail angle of a dial gauge moves towards the right

work piece as per data? direction?

A 40°

B 41°

C 39°

D 45°

A The sine bar is bend

4 What is the cause for damage of screws

B The height of slip gauge pack is less

frequently?

C The top roller of sine bar is worn out

A Screws are assembled in low level

D The height of slip gauge pack is more

applications

B Screws are manufactured in lower property 9 What could be the reason, if the dial test

classes indication left to right, but the needle rotate

C Cost of the screw is too high the angiclockwise direction?

D Screw are fastended proper fit

5 What will be effect if the clamping force is

too low in assembly?

A Fasteners may permanently stretch

B Fasteners may be get good assembly

C Components can be replaced easily

D Fasteners and work may lead to loose due

to vibrations

A The sine bar is bend

6 What is the reason of avoiding the handling

B The height of slip gauge pack is less

of slip gauges with bare hands?

C The height of slip gauge pack is more

A May lead to corrosion

B The sides are very sharp D The bottom rollor of sine bar is worn out

C Can cause wear and tear

D Affects the size due to heating

- NIMI Question Bank - Page10/ 12

10 What is to be checked by the use of a flat 15 Calculate the included angle of tapered

jaw along with a base and slip gauge holder? component, if X = 69.3, Y = 61.5, Height =

A For drawing circle 70mm?

B For measuring size

C For checking height

D For checking centre distance

11 Why the lifting pockets are provided in the

equipments?

A To place toe of the crowbar for lifting

B To position the roller for moving

C To place the steel wedge

D To give provision for bolt and nut A 5° 11'

12 Why the small steel wedge is tapped under B 3° 11'

the machine in lifting operation? C 6° 22'

A To increase the gap and place toe of the D 4° 22'

crow bar

B To decrease the gap to prevent slip

C To balance the machine

D To prevent vibration